-

养猪废水具有高

${\rm{NH}}_4^{\rm{ + }} $ -N、高COD、水质水量波动大等特点,较难实现低成本达标排放[1]。传统的生物脱氮途径为硝化-反硝化,即${\rm{NH}}_4^{\rm{ + }} $ -N先在好氧环境下被氨氧化菌(ammonia-oxidizing bacteria,AOB)氧化为${\rm{NO}}_2^ - $ -N,然后再由亚硝酸盐氧化菌(nitrite-oxidizing bacteria,NOB)氧化为${\rm{NO}}_3^ - $ -N,最后在缺氧环境下被反硝化菌还原为N2[2]。理论上,1 mg${\rm{NO}}_3^ - $ -N通过反硝化转化成N2需要消耗有机碳3.705 mg(以COD计)[3]。然而,大部分污水中的氮以${\rm{NH}}_4^{\rm{ + }} $ -N形式存在,在好氧去除${\rm{NH}}_4^{\rm{ + }} $ -N的同时,污水中的有机物被异养菌大量降解,导致反硝化由于缺少有机碳源被严重抑制[4]。例如,在进水COD与${\rm{NH}}_4^{\rm{ + }} $ -N 比值高达11.3时,同步硝化-反硝化系统才取得了较好的脱氮效果[5]。此外,我国规模化养猪场大多建有厌氧发酵装置(主要为沼气池)。厌氧处理后的沼液具有${\rm{NH}}_4^{\rm{ + }} $ -N浓度高、COD/TN低(甚至<1.0)等特点[6-7]。一些厌氧和好氧生物处理工艺可有效处理养猪废水,但存在能耗大、成本高、管理难度大等问题[8],难以在小型养猪企业推广应用。由于较低的运行成本和维护要求,表面流和水平潜流人工湿地在欧美发达国家畜禽养殖废水处理中应用案例较多[9-10],在我国也有一些示范和应用案例[11-12]。此外,垂直潜流人工湿地强化了氧在滤床中的扩散,在处理养猪废水时实现了较高的

${\rm{NH}}_4^{\rm{ + }} $ -N去除率(> 85%) [13-14]。但是,上述人工湿地较低的氧气传递速率导致系统处理效能较低[15]、占地面积过大。我国畜禽养殖企业的可用土地普遍低于欧美发达国家,这限制了传统人工湿地技术的推广应用。潮汐流人工湿地(tidal flow constructed wetland,TFCW)通过周期性的淹水-排水,有效提升了系统的供氧,从而具有通过强化好氧微生物分解和污染物与生物膜接触来提高处理效率的潜力[15]。理论上TFCW每排出1 L水可以吸入1 L空气,能为系统提供约280 mg氧气[3]。可见,TFCW的供氧量与水力负荷成正比,且基本能够满足处理生活污水时对氧气的需求。但是,这种供氧量远低于通过硝化去除1 L养猪沼液中的

${\rm{NH}}_4^{\rm{ + }} $ -N(> 200 mg)所需的氧气(> 900 mg),仍需要进一步优化。SUN等[15]采用五级串联的TFCW处理养猪废水的中试研究结果表明,系统对BOD5的总去除率高达82%,但对${\rm{NH}}_4^{\rm{ + }} $ -N的去除率和去除负荷仅为58%和14 g·(m2·d)−1。因此,采用多级潮汐流重复处理的方式对${\rm{NH}}_4^{\rm{ + }} $ -N的去除效能较低。HAN等[16]采用潮汐流-垂直潜流竖向组合的人工湿地处理养猪沼液,在水力负荷为16.7 cm·d−1的条件下,${\rm{NH}}_4^{\rm{ + }} $ -N的去除率和去除负荷分别为74%和56 g·(m2·d)−1,明显高于前人的研究结果,这与其在潮汐层采用了沸石有关。沸石具有多孔结构、大比表面积和对${\rm{NH}}_4^{\rm{ + }} $ -N良好的吸附性能,是理想的人工湿地填料之一[17],尤其适用于TFCW。间歇淹水曝气和落干通风换气是提升系统供氧的有效途径,在活性污泥系统[7]、人工湿地[18]及地下渗滤系统[19]中均有应用。然而,采用淹水曝气供氧方式,人工湿地的水力负荷和${\rm{NH}}_4^{\rm{ + }} $ -N去除负荷并未得到明显提升[20-21]。因此,有必要采用多种手段对TFCW进行优化,以期在处理养猪沼液时实现高${\rm{NH}}_4^{\rm{ + }} $ -N去除负荷。短程硝化-反硝化和短程硝化-厌氧氨氧化工艺大幅降低了对有机碳源的需求甚至几乎无需有机碳源,成为养猪废水等高氨氮废水处理研究的热点[22-23]。这类新型生物脱氮工艺成功的关键是如何稳定实现短程硝化,即通过对溶解氧(dissolved oxygen,DO)、温度、游离氨(free ammonia,FA)等关键参数的准确调控,选择性地抑制NOB而不抑制AOB[24]。有研究[25]表明,FA抑制是养猪废水等高氨氮废水实现短程硝化的主要途径。前人在这方面的研究主要集中在活性污泥系统或者曝气生物滤池[26-27],尚未见到在人工湿地中实现高效短程硝化的报道。

为此,本研究设计了一种基于沸石的间歇性曝气垂直-潮汐流人工湿地(vertical-tidal flow constructed wetland,V-TFCW)处理养猪沼液,并进行了250 d的现场小试运行,以期在高污染物负荷条件下实现稳定高效的短程硝化,为后续的厌氧氨氧化提供合适的底物。本文主要分析了水力负荷、FA和温度对V-TFCW系统短程硝化的影响,并对去除

${\rm{NH}}_4^{\rm{ + }} $ -N相关的功能基因进行了qPCR定量分析。本研究结果可为人工湿地优化及处理养猪废水等高氨氮废水提供参考。

全文HTML

-

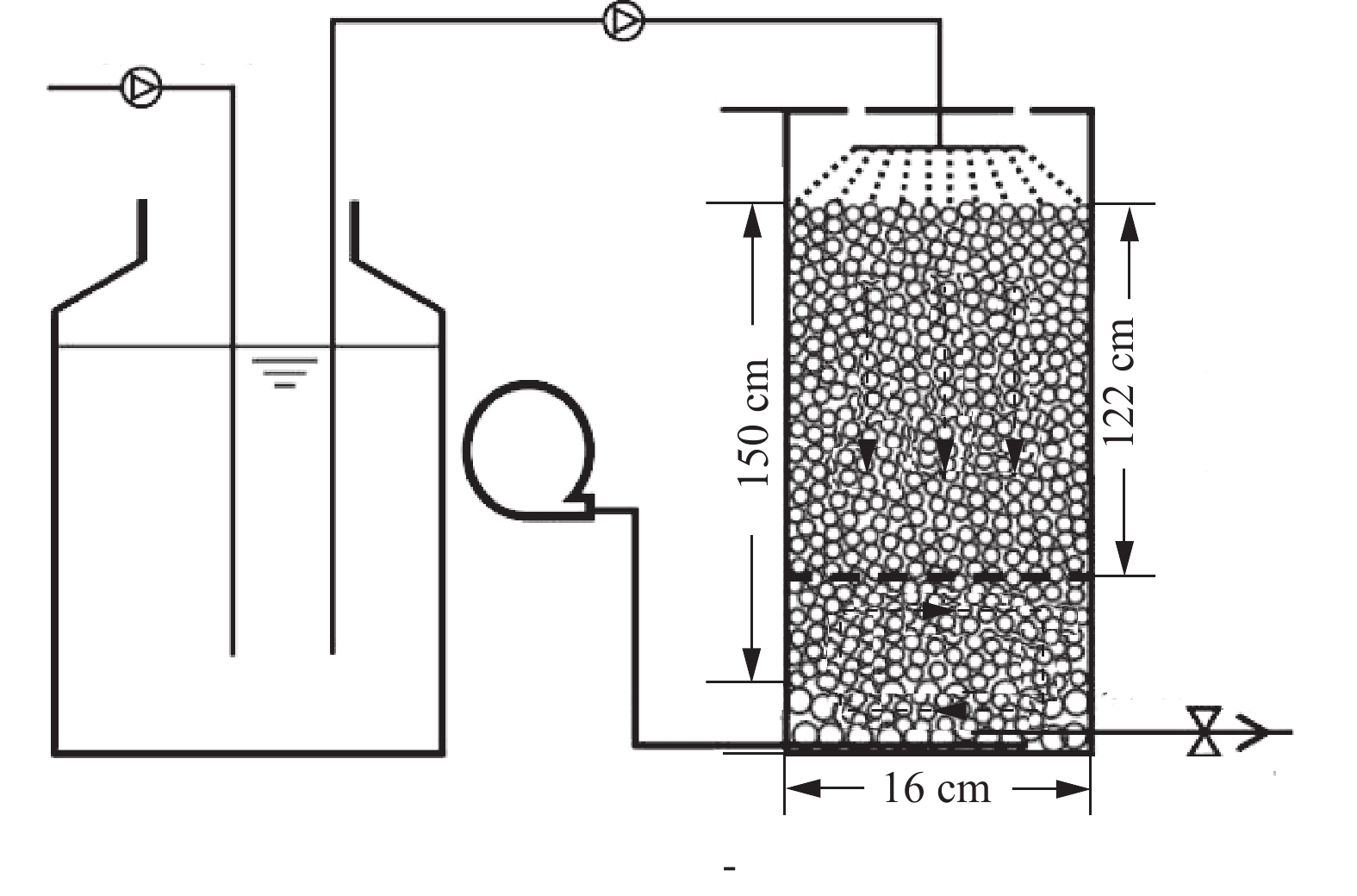

实验系统设置于浙江省嵊州市某生猪养殖场(规模为2 000头)露天场地内,主要包括混凝沉淀桶和V-TFCW实验柱(图1)。该猪场建有容积为750 m3的沼气池,其水力停留时间约20 d。用潜污泵定期将沼气池出水泵入混凝沉淀桶(聚乙烯材质,容积为600 L,垂直高度为96 cm),按照1 L污水投加50 mL的比例投加质量分数10%的聚合氯化铝溶液,然后进行搅拌和反应,以去除悬浮固体、总磷和部分有机物;混凝后的清液作为V-TFCW的进水。

V-TFCW实验柱由直径为16 cm、高为170 cm的PVC管制成,从上到下分为布水层、沸石层和排水层(图1)。其中,布水层安装有喷淋装置,可将污水均匀喷洒于填料表面;沸石层填充了150 cm天然沸石(粒径2~4 mm);排水层高度5 cm,填充了粒径15~20 mm的砾石。排水层还设置有开孔排水管和曝气管,排水管上安装有电磁阀控制系统排水,曝气管与高压风机连接,并装有球阀和泄压阀调节曝气量。计量泵、高压风机和电磁阀的开启与关闭均由时间控制器控制。

-

V-TFCW采用间歇性模式运行,每3 h为1个运行周期。每周期第0~10 min进水,每间隔40 min后曝气20 min,每周期共曝气2次,每周期结束前30 min电磁阀开启,系统排水,排水完毕后电磁阀关闭。实验运行时间从2018年7月至2019年3月,共分为3个阶段:第1阶段为挂膜期(1~23 d),实验柱未接种污泥,而是利用污水中的微生物自然挂膜;第2阶段为稳定运行期(24~144 d),这2个阶段的水力负荷均为66 cm·d−1(每周期进水1.5 L);第3阶段为低温运行阶段(145~247 d),水力负荷为33 cm·d−1(每周期进水0.75 L)。由于3个阶段淹水时间保持不变,因此,系统的水力停留时间一直是2.5 h。

-

${\rm{NH}}_4^{\rm{ + }} $ -N、${\rm{NO}}_3^ - $ -N、${\rm{NO}}_2^ - $ -N、COD和TP分别采用纳氏试剂分光光度法(HJ/T 535-2009)、紫外分光光度法(HJ/T 346-2007)、N-(1-萘基)乙二胺分光光度法(GB 7493-1987)、快速消解分光光度法(HJ/T 399-2007)和钼酸铵分光光度法(GB 11893-1989)测定;pH采用Sartorius PB-10 pH计测定。游离氨(FA)[28]、游离亚硝酸(free nitrite acid,FNA)[28]、亚硝态氮累积率(nitrite accumulation rate,NAR)、氨氮去除负荷(ammonia removal rate,ARR)和亚硝态氮产率(nitrite production rate,NPR)等参数分别按照式(1)~式(5)进行计算。式中:

$\rho ({\rm{FA}})$ 、$ \rho \left( {{\rm{FNA}}} \right)$ 分别为游离氨、游离亚硝酸的浓度,mg·L−1;$ {R_{{\rm{NO}}_2^ - }} $ 为亚硝态氮累积率;R1、R2分别为氨氮去除负荷和亚硝态氮产率,g·(m2·d)−1;$\rho ({\rm{NH}}_4^ + $ -N)、$\rho ({\rm{NO}}_3^ - $ -N)、$ \rho ({\rm{NO}}_2^ - $ -N)分别为${\rm{NH}}_4^{\rm{ + }} $ -N、${\rm{NO}}_3^ - $ -N、${\rm{NO}}_2^ - $ -N的浓度,mg·L−1;$\rho {({\rm{NH}}_4^ + {\text{-}} {\rm{N}})_\Delta }$ 为${\rm{NH}}_4^{\rm{ + }} $ -N去除浓度,mg·L−1;T为温度,℃;Q为人工湿地水力负荷,m·d−1。 -

根据V-TFCW进水

${\rm{NH}}_4^{\rm{ + }} $ -N浓度和预期的出水${\rm{NO}}_2^ - $ -N浓度,用NaNO2基准级试剂配制0~1 000 mg·L−1${\rm{NO}}_2^ - $ -N梯度溶液,采用快速消解分光光度法测定其COD;以${\rm{NO}}_2^ - $ -N浓度和测得的COD值分别为横、纵坐标作图,得出拟合方程(R2=0.998 2),方程如式(6)所示。由拟合方程的斜率可知,每增加1 mg

${\rm{NO}}_2^ - $ -N会引起COD值1.122 mg的变化。基于上述结果,本文采用式(7)对测得的COD值进行了校正。式中:

$ {\rho _{{\rm{COD}},{\text{校正}}}} $ 为校正后的COD值,mg·L−1;${\rho _{{\rm{COD}},{\text{实测}}}} $ 、$\rho ({\rm{NO}}_2^ - {\text{-}} {\rm{N}})$ 分别为测定的COD值和${\rm{NO}}_2^ - $ -N浓度,mg·L−1。 -

采用土壤基因组DNA提取试剂盒(MPBiomedicals,美国)提取填料表面生物膜样品的DNA。采用ABI7500型荧光定量PCR仪(LifeTechnologies,美国)对提取的DNA进行定量聚合酶链反应(quantitative polymerase chain reaction,qPCR),分别测定细菌、AOB、NOB和厌氧氨氧化菌的功能基因丰度值,计算单位干重填料上附着的生物膜中功能基因的拷贝数,各目标基因的引物序列如表1所示。

1.1. 实验装置及用水

1.2. 运行方案

1.3. 分析项目与方法

1.4.

${\bf{NO}}_2^ - $![]()

![]()

-N对COD测定影响的校正

1.5. 脱氮功能基因qPCR

-

养猪沼液中污染物浓度波动较大,

${\rm{NH}}_4^{\rm{ + }} $ -N浓度和COD值分别为552~1 312 mg·L−1和443~1 229 mg·L−1。该猪场采用的是干清粪工艺,与水泡粪工艺相比,具有污水量少、污染物浓度较低等特点[33]。清粪频次和程度、沼气池有效池容以及温度变化均会导致沼液中污染物浓度的波动。由表2可知,在不考虑有机氮的情况下,本研究沼液COD/TIN平均值仅为0.90±0.20,与部分文献中报道的数值[7]相近。沼液经混凝预处理后,COD平均值从747 mg·L−1降至465 mg·L−1,${\rm{NH}}_4^{\rm{ + }} $ -N平均浓度从846 mg·L−1降至734 mg·L−1。由于混凝预处理对COD的去除率高于对${\rm{NH}}_4^{\rm{ + }} $ -N的去除率,导致混凝出水中COD/TIN进一步降低至0.63±0.14。混凝预处理对TP的去除效果最明显,其平均浓度由53.5 mg·L−1降至14.9 mg·L−1,平均去除率为72.1%。 -

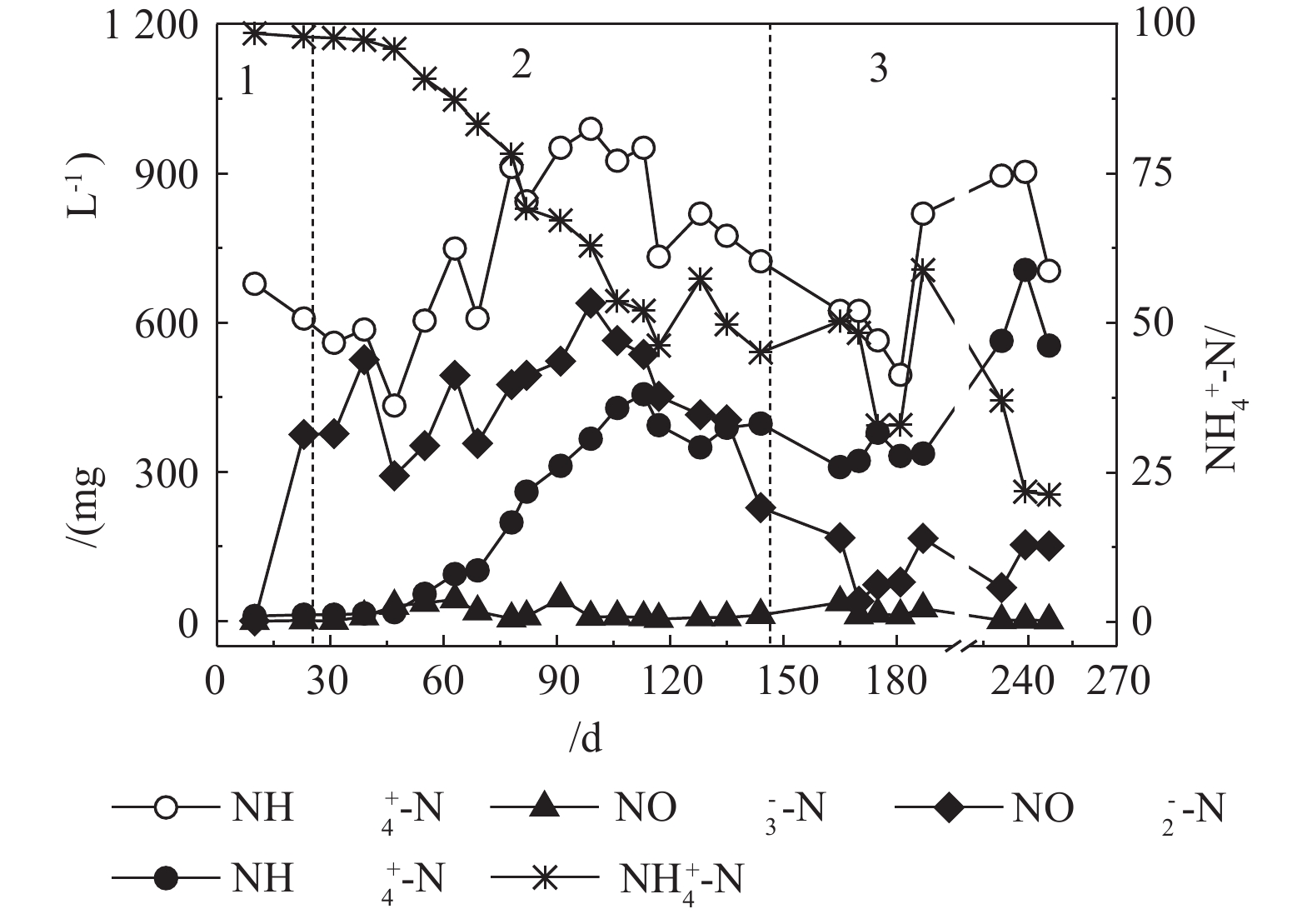

V-TFCW对混凝预处理后的养猪沼液处理效果如图2所示。在第1阶段挂膜期(1~23 d)第10天时,

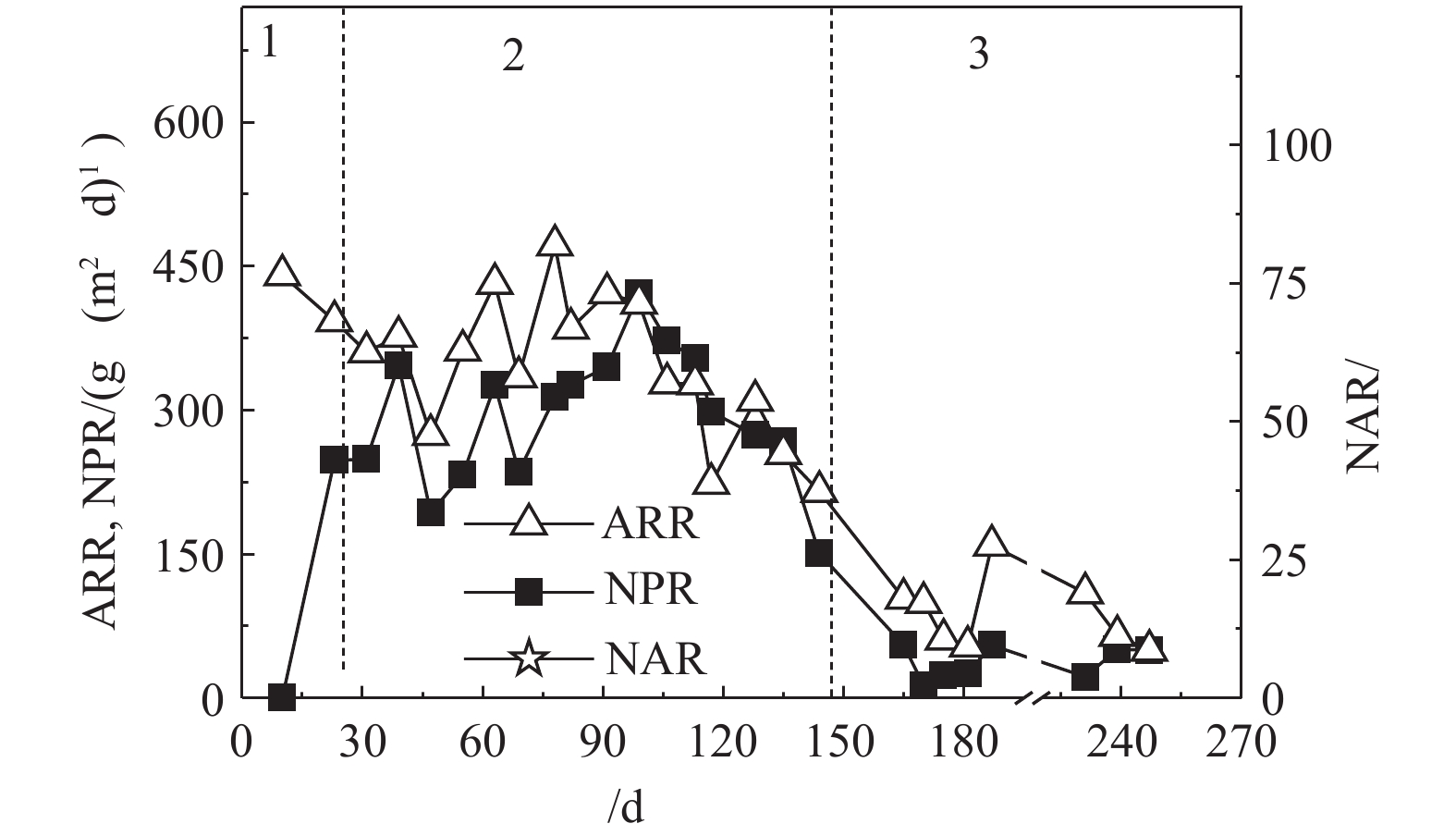

${\rm{NH}}_4^{\rm{ + }} $ -N浓度由进水的678 mg·L−1降至10.4 mg·L−1,但是出水中几乎不含${\rm{NO}}_3^ - $ -N和${\rm{NO}}_2^ - $ -N,这说明系统仍未挂膜成功,其对${\rm{NH}}_4^{\rm{ + }} $ -N的去除仍以沸石吸附为主[34];此时,COD值从进水的538 mg·L−1降至236 mg·L−1,去除率达到56.1%,显示出异养菌繁殖速率快于自养硝化菌。在第23天时,出水中${\rm{NH}}_4^{\rm{ + }} $ -N和${\rm{NO}}_3^ - $ -N仍维持在低浓度,而${\rm{NO}}_2^ - $ -N浓度达375 mg·L−1;此时NAR为99.7%,NPR为247.8 g·(m2·d)−1(图3),这说明系统在间歇性曝气供氧条件下,AOB增殖速度较快,而NOB由于被抑制未能培养起来,V-TFCW短程硝化成功启动。与此同时,系统对COD的去除率进一步提升至70.1%。目前,在污水处理相关的研究中,接种污泥和自然挂膜2种系统启动方式均有应用,前者更为普遍。YANG等[26]利用以沸石为基质的曝气生物滤池处理高氨氮废水时,以接种污泥的方式用时约30 d完成硝化菌挂膜;XUE等[35]在膜生物反应器中也用时约30 d将${\rm{NH}}_4^{\rm{ + }} $ -N浓度逐渐升高到目标浓度,完成短程硝化挂膜。而在处理真实污水的基于生物膜法的研究中,采用自然挂膜的方式启动系统也较常见。例如,在地下渗滤系统中异养菌和硝化菌的挂膜时间分别为7 d和15 d[19]时;在处理黑水的悬浮填料生物反应器中,则需要43 d完成硝化菌挂膜[36]。在本研究中,采用自然挂膜的方式启动短程硝化的时间约为20 d,略长于地下渗滤系统,但是略短于生物膜反应器和传统活性污泥系统。在第2阶段稳定运行期(24~144 d),水力负荷与挂膜期相同,为66 cm·d−1。由图2可知,进水

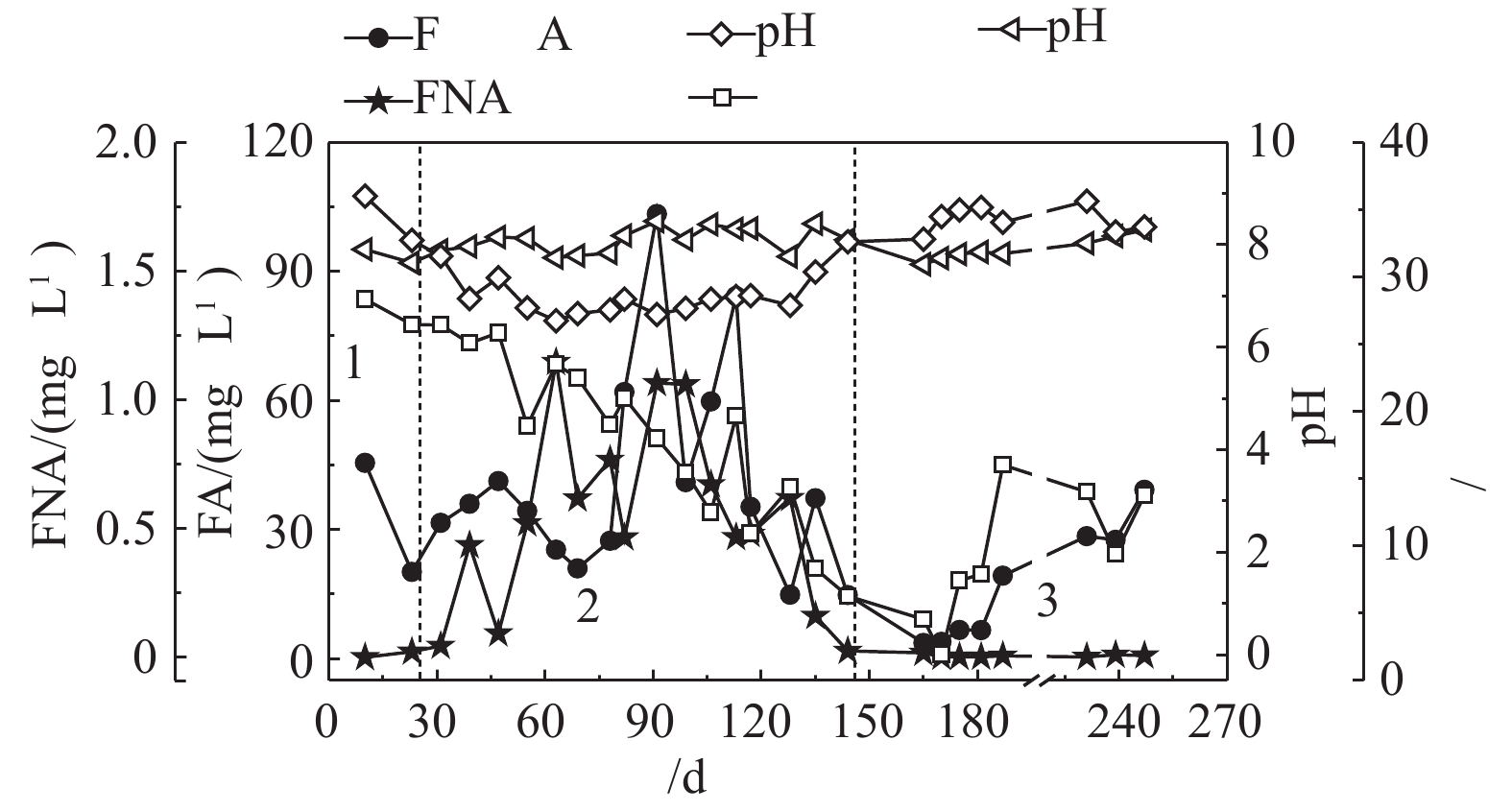

${\rm{NH}}_4^{\rm{ + }} $ -N浓度在此阶段呈现前期低、后期高的特征,平均浓度为760 mg·L−1 (表2)。出水${\rm{NH}}_4^{\rm{ + }} $ -N浓度从前期的约15 mg·L−1逐渐升高到第113天的456 mg·L−1,之后保持在380 mg·L−1左右,平均浓度为241 mg·L−1。与进出水浓度波动幅度较大不同,${\rm{NH}}_4^{\rm{ + }} $ -N去除量变化则相对较小(平均值为520 mg·L−1)。出水${\rm{NO}}_2^ - $ -N与进水${\rm{NH}}_4^{\rm{ + }} $ -N变化趋势相一致,随进水${\rm{NH}}_4^{\rm{ + }} $ -N浓度的增(减)而增(减),出水${\rm{NO}}_2^ - $ -N平均浓度为446 mg·L−1,而出水${\rm{NO}}_3^ - $ -N平均浓度仅为16.0 mg·L−1(表2)。由图3可知,V-TFCW在此阶段的NAR为90.6%~99.9%,这说明NOB已被彻底抑制,短程硝化非常稳定。此外,ARR和NPR平均值分别为343 g·(m2·d)−1和294 g·(m2·d)−1,且NPR/ARR值不断增加,这表明微生物对${\rm{NH}}_4^{\rm{ + }} $ -N去除的贡献越来越大,随着吸附逐渐达到平衡,沸石吸附发挥的作用越来越小。在此阶段后期,NPR一度高于ARR,推测其原因是,前期累积在沸石表面的${\rm{NH}}_4^{\rm{ + }} $ -N被AOB转化,而随污水新进入系统的${\rm{NH}}_4^{\rm{ + }} $ -N未能填补这些空位(或在曝气阶段被洗脱了下来),导致生成的${\rm{NO}}_2^ - $ -N高于去除的${\rm{NH}}_4^{\rm{ + }} $ -N。由图4可知,进水温度在第2阶段不断降低,同时V-TFCW对

${\rm{NH}}_4^{\rm{ + }} $ -N的去除负荷ARR也不断减少(图3),在第144天时(温度约为6 ℃)降至此阶段的最小值(215 g·(m2·d)−1),而出水${\rm{NO}}_2^ - $ -N浓度也仅为228 mg·L−1,远低于该阶段平均值(446 mg·L−1)。这表明冬季低温气候已经对V-TFCW的短程硝化产生了较明显的抑制作用。DELATOLLA等[37]对曝气生物滤池的研究表明,当温度由20 ℃降低至4 ℃时,${\rm{NH}}_4^{\rm{ + }} $ -N的去除率下降了56%。王思萌等[38]在对SBR进行梯度降温研究时也发现,当水温由30 ℃降至15 ℃时,${\rm{NH}}_4^{\rm{ + }} $ -N去除率由85.6%降至35.2%,TN去除率由76.4%降至30.7%。为了减弱低温对V-TFCW短程硝化的影响,本研究第3阶段系统水力负荷设置为33 cm·d−1。在第3阶段(145~247 d),温度在第170天左右时降到了实验过程中的最低值(约2 ℃),此时,系统出水中

${\rm{NO}}_2^ - $ -N和${\rm{NO}}_3^ - $ -N浓度仅为40.0 mg·L−1和11.3 mg·L−1(图2),表明AOB活性已经受到低温严重抑制。此后,随着温度逐渐回升,出水${\rm{NO}}_2^ - $ -N浓度不断升高;当温度升高至16 ℃时,出水${\rm{NO}}_2^ - $ -N浓度达到167 mg·L−1,但是仍低于第2阶段相近温度时的数值。此外,需要指出的是,此阶段${\rm{NH}}_4^{\rm{ + }} $ -N去除量的下降滞后于生成的${\rm{NO}}_2^ - $ -N,且ARR通常明显高于NPR(图3),这表明沸石在冬季低温条件下发挥了更重要的去除${\rm{NH}}_4^{\rm{ + }} $ -N的作用;但是这种吸附作用维持的时间有限,第239天和第247天的ARR仅略高于或低于NPR(图4),表明吸附作用再次由于达到相对平衡而难以发挥直接去除${\rm{NH}}_4^{\rm{ + }} $ -N的功能。由图3可知,NAR在第3阶段经历了先降低后升高的过程,且后期基本与第2阶段数值相近。综上所述,低于10 ℃的低温对V-TFCW的短程硝化作用产生了显著抑制(P<0.01),而低于5 ℃的低温则可使该系统基本失去短程硝化功能,并且低温对短程硝化的抑制具有可逆性;随着温度的回升,系统短程硝化功能逐渐增强,然而短期的温度回升并不能使系统恢复到最佳运行状态。此外,降低水力负荷在抵消低温对V-TFCW内硝化菌的抑制方面作用不大,这与饱和淹水的移动床生物膜反应器具有明显差异[39];从水力停留时间角度分析,降低V-TFCW的水力负荷并没有延长水力停留时间,而饱和淹水系统的水力负荷与水力停留时间呈反比,降低水力负荷可以增加微生物与污染物的接触时间,从而提升处理效果。因此,对于不饱和的人工湿地,难以调节水力停留时间,今后应开展通过增温、保温的方式应对低温气候的研究,如可以通入热风增温,改为地埋式保温等。

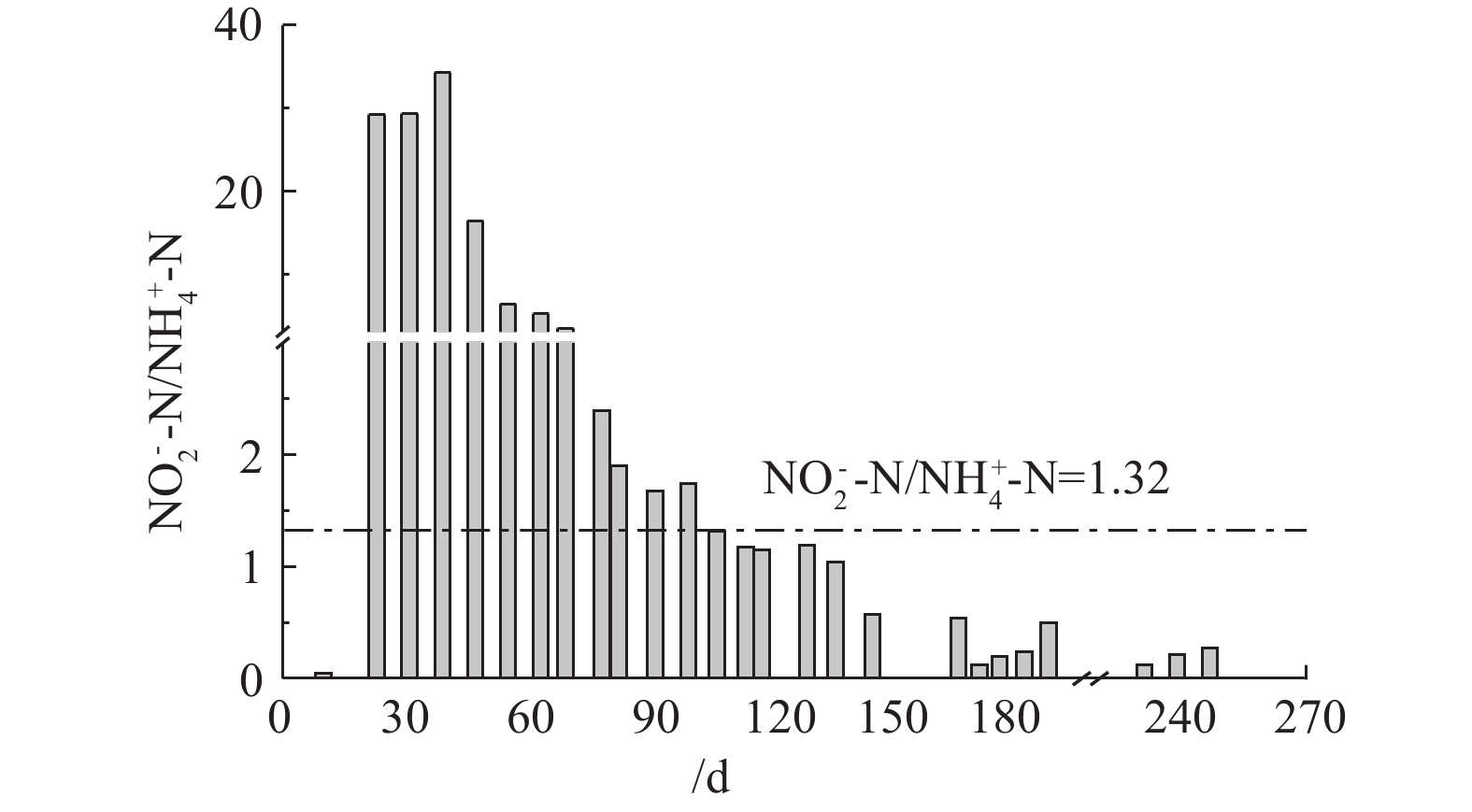

为了评估V-TFCW出水中氮素比值是否满足厌氧氨氧化的化学计量关系[40](式(8)),对3个阶段出水中

${\rm{NO}}_2^ - $ -N/${\rm{NH}}_4^{\rm{ + }} $ -N比值进行了分析(图5)。由式(8)可知,厌氧氨氧化反应底物

${\rm{NO}}_2^ - $ -N/${\rm{NH}}_4^{\rm{ + }} $ -N的理论比值为1.32。如图5所示,在系统运行前期(23~78 d),沸石对${\rm{NH}}_4^{\rm{ + }} $ -N的过量吸附导致${\rm{NO}}_2^ - $ -N/${\rm{NH}}_4^{\rm{ + }} $ -N比值远高于厌氧氨氧化方程理论比值。在第82~135天,出水${\rm{NO}}_2^ - $ -N和${\rm{NH}}_4^{\rm{ + }} $ -N平均浓度分别为(504±79.2) mg·L−1和(369 ±62.8) mg·L−1,两者比值为1.40±0.32,接近1.32;之后随着温度降低,系统短程硝化作用减弱,出水${\rm{NO}}_2^ - $ -N/${\rm{NH}}_4^{\rm{ + }} $ -N比值远低于1.32。因此,在排除低温影响的前提下,V-TFCW稳定运行以后,其出水能够满足厌氧氨氧化反应对底物氮素比的要求,基于该系统运行模式及${\rm{NH}}_4^{\rm{ + }} $ -N去除原理可以推测,调整系统水力负荷能够进一步调节系统出水${\rm{NO}}_2^ - $ -N/${\rm{NH}}_4^{\rm{ + }} $ -N比值。然而,大量研究表明,过高的${\rm{NO}}_2^ - $ -N浓度(> 40~280 mg·L−1)对厌氧氨氧化具有强烈的抑制作用[41];通过对前人工作的对比分析,JIN等[41]将进水和出水${\rm{NO}}_2^ - $ -N浓度分别控制在280 mg·L−1和100 mg·L−1作为厌氧氨氧化受到抑制的警戒值。本研究V-TFCW出水中${\rm{NO}}_2^ - $ -N浓度远高于280 mg·L−1,如此高的${\rm{NO}}_2^ - $ -N浓度是否会对基于人工湿地的厌氧氨氧化形成抑制仍需进一步研究。 -

短程硝化的主要影响因素包括FA[42]、FNA[42]、DO[43]和温度[44]。SEUNTJENS等[44]发现AOB在高温(30~40 ℃)下的生长速度要优于NOB;XUE等[35]的研究也表明,在15~25 ℃下为全程硝化,而将温度调控到(35±1) ℃后形成短程硝化。本研究结果则表明,不管温度多低,系统均以短程硝化为主,可见温度并非导致本实验NOB被抑制的因素。此外,V-TFCW上部为不饱和的垂直流区、下部为潮汐流区(图1),这种结构导致上部难以调节DO,而且并未调控下部淹水曝气时的DO,因此,可排除低DO(0.5~1.0 mg·L−1)实现短程硝化的可能性。

ANTHONISEN等[28]在1976年首次报道了FA浓度分别在10~150 mg·L−1和0.1~1.0 mg·L−1内对AOB和NOB活性产生抑制作用。VADIVELU等[42]在SBR中发现FA浓度达到7.5 mg·L−1时可以完全抑制NOB的活性。CHUNG等[45]在连续流反应器中的研究表明,进水FA为20~25 mg·L−1时,NAR能达到(90±5)%。可见在不同的系统中,抑制NOB的FA浓度范围有所差别。本实验3个阶段进水

${\rm{NH}}_4^{\rm{ + }} $ -N平均浓度分别为643、760和704 mg·L−1(表2),均导致了较高的FA浓度(图4)。在系统启动阶段,进水FA平均浓度为32.9 mg·L−1,高于文献中报道的NOB抑制浓度,因此,V-TFCW在很短的时间内就形成了短程硝化。在第2阶段稳定运行期,进水FA波动幅度较大,平均浓度为41.9 mg·L−1,大部分数值均高于20 mg·L−1,系统继续呈现良好的短程硝化效果。此阶段出水FNA平均值为0.54 mg·L−1,而FNA对NOB的起始抑制浓度为0.22~2.8 mg·L−1 [28],故FNA对NOB的抑制作用较微弱。由硝化方程[46]可知,将1 mol

${\rm{NH}}_4^ + $ 氧化到${\rm{NO}}_2^ - $ 会产生2 mol H+,如果不能中和新生成的H+,系统pH将会大幅降低。例如在处理生活污水的地下渗滤系统中,通过硝化反应去除约40 mg·L−1的${\rm{NH}}_4^{\rm{ + }} $ -N就能使出水pH降至3.5左右[19]。SUN等[47]在处理养猪废水时,部分下行流芦苇床单元出水也发生了明显的酸化,pH由进水的7.28降到了5.71,并且该低pH严重影响了后续单元污染物去除效能。类似的,VÁZQUEZ等[13]采用垂直流人工湿地处理养猪废水时(水力负荷为3.9 cm·d−1),当${\rm{NH}}_4^{\rm{ + }} $ -N由进水的232 mg·L−1降至出水的6.7 mg·L−1时,即使系统发生了良好的反硝化脱氮,pH仍从7.95降到了4.86。因此,在不饱和的生物膜系统中,良好的硝化作用易导致系统pH降低。污水中FA浓度与pH成正比,过低的pH不利于系统维持高FA。本实验在第2阶段产生约450 mg·L−1${\rm{NO}}_2^ - $ -N,而pH仅由进水的8.10小幅降至出水的7.03,这与养猪沼液具有较强的酸碱缓冲能力有关。此外,pH是影响硝化菌生长繁殖的关键参数之一,当其低于6.0和高于9.0均会抑制AOB的生长[48]。本研究中V-TFCW进出水pH均在6.5~8.9,可推断基质表面生物膜pH不会抑制AOB生长繁殖。因此,养猪沼液良好的酸碱缓冲能力对在系统内维持较高的FA和适宜的pH均至关重要。以上分析了外在因素对V-TFCW实现短程硝化的影响。下面分析其结构本身和运行模式的作用。污水经由喷淋装置进入上部垂直流区,在向下渗流穿过该层时,污水中的

${\rm{NH}}_4^{\rm{ + }} $ -N被沸石大量吸附,由于水力负荷高,使得进入下部潮汐流区的污水中仍含有较高浓度${\rm{NH}}_4^{\rm{ + }} $ -N,从而有利于在V-TFCW中形成FA抑制;在淹水曝气期间,垂直流区填料孔隙充满了新鲜空气,而潮汐流区填料中的污水也达到了饱和DO,在好氧条件下,亚硝化反应在沸石表面生物膜上高效进行;下一周期所进污水将之前生成的${\rm{NO}}_2^ - $ 淋洗下来,使沸石恢复了对${\rm{NH}}_4^ + $ 的吸附能力。因此,沸石在V-TFCW中具有离子吸附和生物膜载体双重作用,并且实现了原位再生,这对于实现高效短程硝化非常重要。前人采用沸石曝气生物滤池处理${\rm{NH}}_4^{\rm{ + }} $ -N浓度为250~550 mg·L−1的污水时也实现了高效短程硝化,NPR甚至高达760 g·(m2·d)−1 [26]。沸石对${\rm{NH}}_4^{\rm{ + }} $ -N的吸附作用有利于维持合适的FA浓度,从而在好氧条件下选择性抑制 NOB 的活性[26,49]。此外,间接淹水曝气和落干通风换气2种供氧方式在生物膜法系统中均有应用[18-19];在20 ℃时1 L空气中氧气约为280 mg,而1 L水中饱和溶解氧仅约9 mg,因此,落干通风换气供氧方式更高效、节能。但前提是,必须选择对

${\rm{NH}}_4^{\rm{ + }} $ -N吸附能力强的填料,否则${\rm{NH}}_4^{\rm{ + }} $ -N将随污水排出系统,导致落干时由于缺乏${\rm{NH}}_4^{\rm{ + }} $ -N而难以发生硝化作用。由图1可知,在V-TFCW下部是间歇性淹水曝气供氧,由于其氧气利用率很低,曝气排出的空气则给上部垂直流区供氧;而且,垂直流区沸石高度远高于潮汐流区,导致该区能够吸附更多的${\rm{NH}}_4^{\rm{ + }} $ -N,加之落干换气供氧更高效,因此,垂直流区在V-TFCW短程硝化中发挥了更重要的作用。不同人工湿地在处理养猪废水时对

${\rm{NH}}_4^{\rm{ + }} $ -N去除负荷以及短程硝化效率等参数见表3。饱和淹水的人工湿地由于供氧不足,水力负荷一般较低,并且难以实现短程硝化[8,50]。DU等[51]采用以沸石为基质的复合垂直流人工湿地处理养猪废水时,在水力负荷和水力停留时间分别为4 cm·d−1和7 d的条件下,取得了高于95%的${\rm{NH}}_4^{\rm{ + }} $ -N和TN去除率,而沸石吸附在脱氮中始终发挥了重要的作用。胡沅胜等[52]采用间歇曝气方式有效改善了潮汐-垂直潜流人工湿地的供氧,实现了较高的${\rm{NH}}_4^{\rm{ + }} $ -N去除率(97%)和ARR(37.3 g·(m2·d)−1),而且缺氧-好氧交替环境有利于实现短程硝化-反硝化,从而取得了90%的TN去除率。在较高水力负荷下运行的潮汐-垂直潜流人工湿地取得了更高的ARR(56.0 g·(m2·d)−1),并且发生了轻微的${\rm{NO}}_2^ - $ -N累积[16]。由表3可知,人工湿地较高的进水

${\rm{NH}}_4^{\rm{ + }} $ -N浓度以及由此产生的高FA并不一定能使系统实现短程硝化。其主要原因为,人工湿地为推流模式,在低水力负荷下,污水在湿地内部流动时${\rm{NH}}_4^{\rm{ + }} $ -N浓度不断降低,很难在整个剖面上实现高FA。与之相比,本研究设计的以沸石为基质的间歇曝气V-TFCW在高水力负荷(66 cm·d−1)下实现了高ARR (343 g·(m2·d)−1);同时,第2阶段出水中${\rm{NO}}_2^ - $ -N浓度均值高达446 mg·L−1,实现了高效的短程硝化。因此,在人工湿地等生物膜法系统中,实现短程硝化的关键是高效供氧以及在整个系统内维持较高的FA浓度,这意味着出水${\rm{NH}}_4^{\rm{ + }} $ -N浓度可能较高。 -

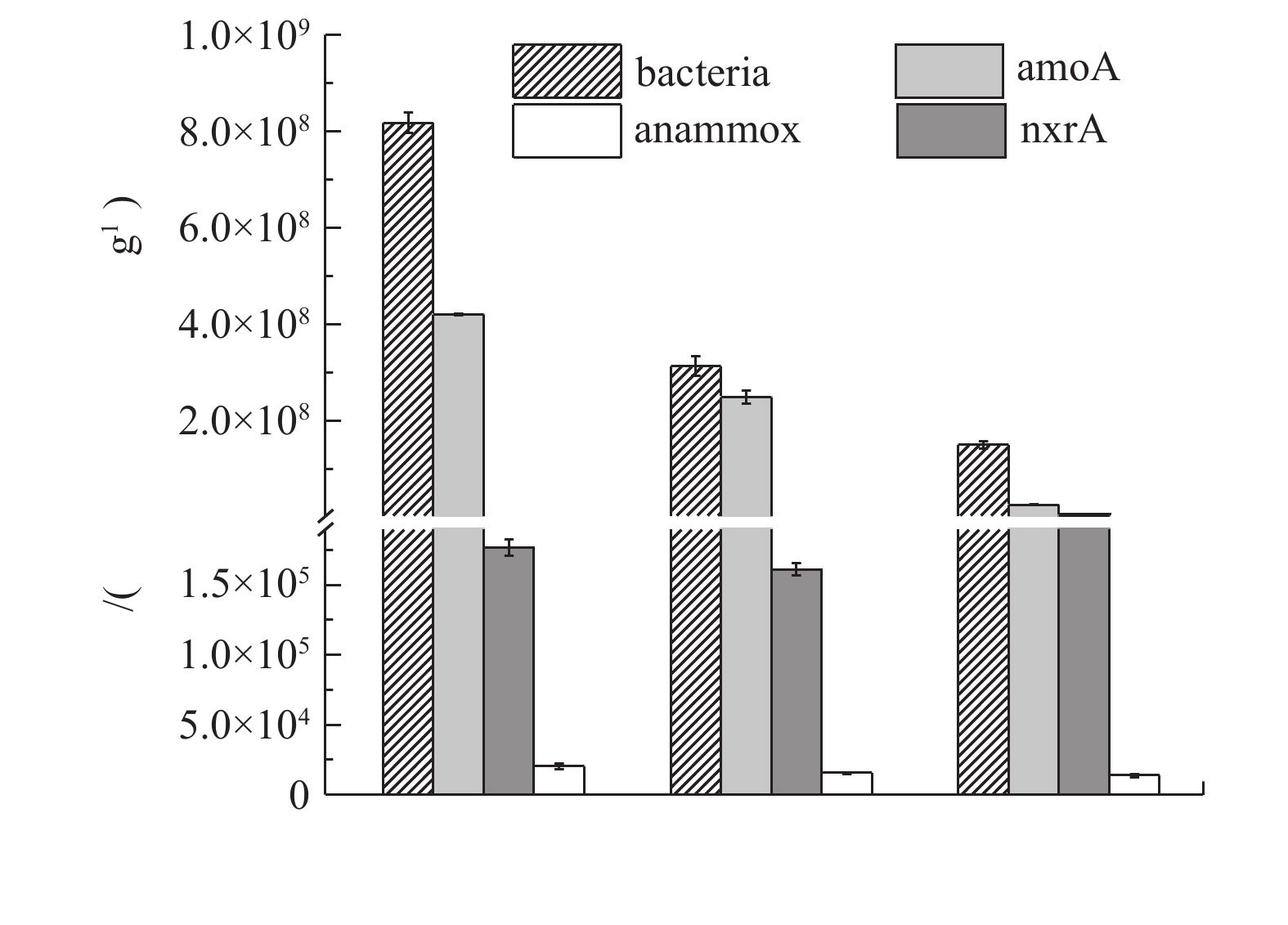

为进一步揭示V-TFCW装置沿程

${\rm{NH}}_4^{\rm{ + }} $ -N的转化途径,本研究在第2阶段结束时采集了V-TFCW沸石层上层(140 cm)、中层(75 cm)和下层(10 cm)的填料,对其表面生物膜中amoA基因、nxrA基因、anammox 16S rRNA基因及bacteria 16S rRNA基因进行了qPCR定量分析,结果如图6所示。氨单加氧酶编码基因amoA和亚硝酸盐氧化酶编码基因nxrA分别是${\rm{NH}}_4^{\rm{ + }} $ -N好氧氧化到${\rm{NO}}_2^ - $ -N和${\rm{NO}}_2^ - $ -N氧化到${\rm{NO}}_3^ - $ -N的功能标记[58];而anammox 16S rRNA基因则是在缺氧条件下将${\rm{NH}}_4^{\rm{ + }} $ -N和${\rm{NO}}_2^ - $ -N转化为N2的功能标记[32]。由图6可知,细菌绝对丰度从上层的8.2×108拷贝数·g−1逐渐减少至下层的1.5×108拷贝数·g−1,呈现出沿水流方向降低的趋势。amoA也表现出相似的趋势,其绝对丰度从上层的4.2×108拷贝数·g−1降至下层的2.7×107拷贝数·g−1。DU等[51]在种植物的复合垂直流人工湿地也有类似的发现,amoA丰度从进水侧的6.85×104拷贝数·g−1降至出水侧的1.92×104拷贝数·g−1。然而,nxrA在垂向分布上则表现不同,其绝对丰度在下层最高(3.7×106拷贝数·g−1),在上层和中层较低(1.8×105拷贝数·g−1和1.6×105拷贝数·g−1)。总体来看,在V-TFCW中AOB丰度均远高于NOB,且越靠近进水端两者的差值越大,表明NOB在上层被抑制程度最高,这与不同层位的

${\rm{NH}}_4^{\rm{ + }} $ -N浓度差异有关。养猪沼液在从表层进入V-TFCW向下渗滤的过程中,${\rm{NH}}_4^{\rm{ + }} $ -N由于被沸石吸附浓度不断降低,导致上层${\rm{NH}}_4^{\rm{ + }} $ -N浓度最高,下层${\rm{NH}}_4^{\rm{ + }} $ -N浓度最低,FA的变化趋势也一致。有研究[59]表明,AOB真正的底物是FA而不是${\rm{NH}}_4^ + $ 。V-TFCW上层更高的FA浓度为AOB提供了丰富的底物,促进了其新陈代谢,同时也抑制了NOB的活性;而下层较低的FA浓度则减轻了对NOB的抑制,这决定了AOB和NOB功能基因丰度在垂向上的分布。厌氧氨氧化菌为专性厌氧菌,在超过2 μmol·L−1氧时其新陈代谢就会被可逆的抑制[60]。V-TFCW系统以好氧为主,在局部会形成短时缺氧环境,显然,这种好氧为主的环境并不适合厌氧氨氧化菌繁殖,导致其基因的平均丰度仅为1.6×104拷贝数·g−1(图6)。

2.1. 混凝预处理对沼液水质的影响

2.2. V-TFCW短程硝化的启动及运行

2.3. V-TFCW短程硝化的实现机理及效率

2.4. 功能基因丰度

-

1)采用V-TFCW以自然挂膜的方式处理养猪沼液,约20 d左右成功启动短程硝化;稳定运行期间系统具有良好的短程硝化性能,出水氮素比可满足厌氧氨氧化对底物的要求。

2)低于10 ℃的低温对V-TFCW的短程硝化作用产生了显著抑制(P<0.01),而低于5 ℃的低温则可使该系统基本失去短程硝化功能,但低温对短程硝化的抑制具有可逆性。

3)较高的进水FA(32.9 mg·L−1和41.9 mg·L−1)是V-TFCW在启动和稳定运行阶段实现短程硝化的主要原因,养猪沼液良好的酸碱缓冲能力对于维持系统内适宜的pH和FA至关重要。

4)V-TFCW中AOB丰度自上而下逐渐降低,但均远高于NOB丰度,两者在垂向上的分布与不同层位FA的浓度有关。

下载:

下载: