-

大规模工业发展排放出的大量挥发性有机化合物 (VOCs) [1]是形成臭氧和二次有机气溶胶的重要前驱体,会造成雾霾、光化学烟雾等大气污染[2]。部分VOCs具有刺激性和毒性[3],对人体器官和神经系统会造成严重危害。因此,为落实工业VOCs污染减排,挥发性有机物综合整治工程被列为“十四五”期间我国节能减排综合工作的重点工程[4]。

催化燃烧是利用催化剂的活化作用在较低温度下将有机物彻底氧化分解的一项高级氧化技术[5],其中微波与吸波型催化剂相结合的微波催化燃烧技术因微波热点效应而具有VOCs矿化效率高的优点[6]。因此,该技术与电加热的结合将成为高效处理工业VOCs废气的一项新技术。催化剂是催化燃烧技术的核心。目前,整体式蜂窝状催化剂因具有机械强度高、气流阻力小和传热传质效率高等优点,被广泛应用于实际工业VOCs废气的催化燃烧。整体式催化剂一般由载体、涂层和活性组分3部分构成,堇青石蜂窝体 (CH) 是目前最常用的催化剂载体,其价廉、耐高温且结构稳定;多组分过渡金属氧化物具有催化活性高、抗氯中毒能力强和价格远低于贵金属等优点,是当前活性组分研究的一大热点。CH负载CuMnCeOx的整体式催化剂已被课题组证实具有良好的VOCs微波催化燃烧活性[7]。催化剂涂层一般为TiO2、CeO2和γ-Al2O3等金属氧化物[8],起承载和分散活性组分颗粒的作用,涂层的表面积大小及其与载体结合的牢固度是影响催化剂性能的重要因素。γ-Al2O3具有比表面积大和多孔的特性,是整体式催化剂中最为广泛应用的涂层材料[9];溶胶凝胶法可在低温下制备纳米级均匀高活性γ-Al2O3薄膜,可控易行,对其理化性质、表面形貌、晶体结构、稳定性、抗中毒性和助催化作用等方面做了大量研究工作[10];适用于载体的活性涂层,但制备过程较为繁琐且易发生团聚,原材料昂贵,不易实现工业化生产[11]。目前,添加粘结剂以提高涂层附着力及均匀性是涂层制备中亟待解决的问题。聚乙二醇200 (PEG200) 是一种常用的有机粘合剂,其多羟基结构对铝溶胶分子具有分散性和粘结性,PEG200粘性和交联作用适中,对涂层的均匀性和结合性有良好的作用。田久英等[12]发现在溶胶中添加小分子量的PEG所制备的溶胶粒径小、涂层均匀、附着牢固且比表面积大,然而有机粘合剂在涂层中的作用机理及对催化剂结构与催化活性的影响尚有待进一步探究。

本研究在堇青石载体表面涂覆牢固的γ-Al2O3涂层,以PEG200为粘合剂来优化铝溶胶制备参数,探究PEG200在γ-Al2O3涂层中的作用机理及对CuMnCeOx/Al2O3/CH催化剂结构和催化性能的影响,以期为高性能催化剂的制备提供参考。

-

堇青石蜂窝体 (100 mm×100 mm×50 mm) ,沧州合程环保设备有限公司;硝酸 (65%~68%) ,广东光华科技股份有限公司;硝酸锰 (50%) 、硝酸铜、聚乙二醇200,天津市大茂化学试剂厂;硝酸铈,上海阿拉丁生化科技股份有限公司;低钠型拟薄水铝石,德州市晶火技术玻璃有限公司;甲苯,国药控股陕西有限责任公司;丙酮、乙酸乙酯,天津天力化学试剂有限公司。

-

溶胶凝胶法制备铝溶胶:量取7.5 g拟薄水铝石和定量硝酸溶于80 mL纯水中,60 ℃下磁力搅拌1 h,搅拌过程中滴加PEG200得到前驱体溶液,老化72 h后形成稳定的氧化铝前驱体溶胶。

Al2O3/CH制备:10%硝酸溶液浸泡切割后的堇青石载体 (Φ26 mm×50 mm) 10 h后水洗至中性,以此去除堇青石表面的金属杂质及浮灰;烘干后的CH载体浸入稳定的氧化铝前驱体溶胶内,超声浸渍30 min后取出,吹掉表面多余的溶胶以防止堵塞孔道;干燥箱内80 ℃过夜烘干,马弗炉内650 ℃下焙烧4 h,自然降温后即可获得Al2O3薄膜涂层;试验中采用多次循环浸渍-煅烧法使氧化铝涂层的涂覆量达到CH的5% (质量分数) ,从而获得Al2O3/CH载体。

CuMnCeOx/Al2O3/CH制备:称取质量比为3.25%∶3.25%∶1% (相比于CH载体) 的Cu(NO3)2·3H2O,50%Mn(NO3)2和Ce(NO3)3·6H2O溶于10 mL的纯水中,将Al2O3/CH载体多次浸渍-烘干直到活性组分前驱液被全部吸收,在450 ℃下焙烧5 h,自然冷却后得到整体式CuMnCeOx/Al2O3/CH催化剂。

采用热重红外联用仪 (Tensor ii型,德国布鲁克) 分析溶胶组分中PEG200热分解过程;使用Zeta电位仪 (ZS90型,英国马尔文) 和黏度仪 (LVDV型,美国Brookfield) 测量铝溶胶的电位、粒度和黏度;通过扫描电子显微镜 (SEM,JSM-6510LV型,日本电子) 及场发射透射电镜 (TEM,Talos F200i型,美国赛默飞) 观察催化剂形貌和活性颗粒的大小与分布和材料内部缺陷。使用比表面积及孔径分析仪 (BET,V-sorb2800p型,北京金埃谱) 测定催化剂的比表面积、孔结构参数与孔径分布;通过X射线衍射仪 (XRD,D8ADVANCE,德国布鲁克) 测定活性组分的晶体组成与晶粒大小;采用X射线光电子能谱仪 (XPS,TSFE 250Xi型,美国赛默飞世尔) 测定催化剂的表面元素价态分布。

-

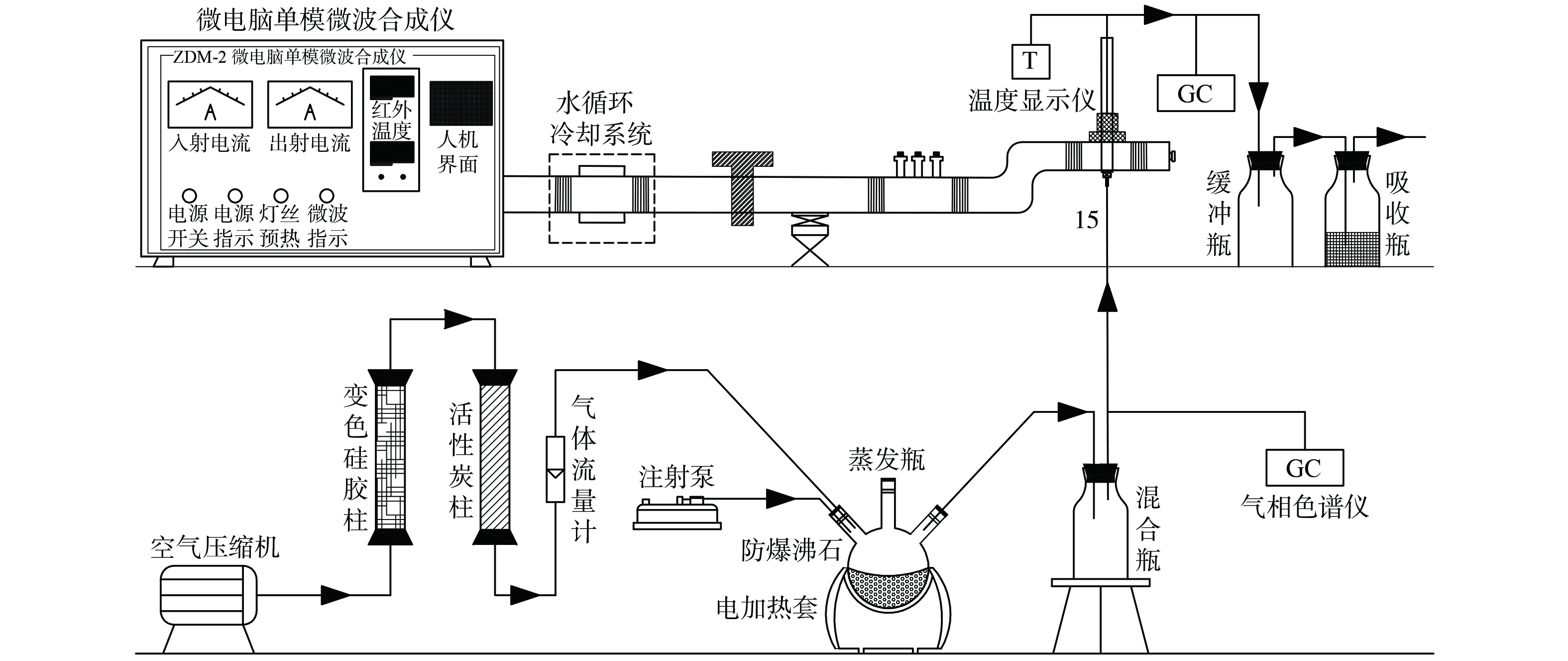

微波催化燃烧VOCs实验在常压下进行,由配气、催化燃烧和尾气吸收3个阶段组成。实验装置见图1。在配气阶段,空气在气体流量计的控制下由气泵鼓入,通过变色硅胶柱干燥和活性炭柱吸附去除有机质后进入三颈烧瓶,液态甲苯 (或甲苯、丙酮及乙酸乙酯混合液) 通过微量注射泵注入三颈烧瓶内被加热气化,随即被空气带出进入缓冲混合瓶。在催化燃烧阶段中,固定床反应器由上下叠放的2块催化剂放置于石英管中组成,垂直安装于微波单模腔通道中,石英管上端插入热电偶探针实时监测床层温度并经温度显示仪给出,石英管的上下端连接管处分别设置进、出气取样口,利用气相色谱仪测定催化燃烧前后VOCs的质量浓度变化;单模微波合成仪发射功率可调的微波,经波导管单方向传输作用于固定床反应器,反射波被水循环冷却系统吸收;缓冲瓶中混合好的VOCs从石英管下端进入高温的固定床反应器,VOCs在催化剂表面发生氧化反应,燃烧后的气体从上端进入气体缓冲瓶。在尾气吸收阶段,处理后的VOCs由缓冲瓶进入NaOH碱液吸收瓶以吸收残余微量VOCs,然后通过通风橱高空排出。

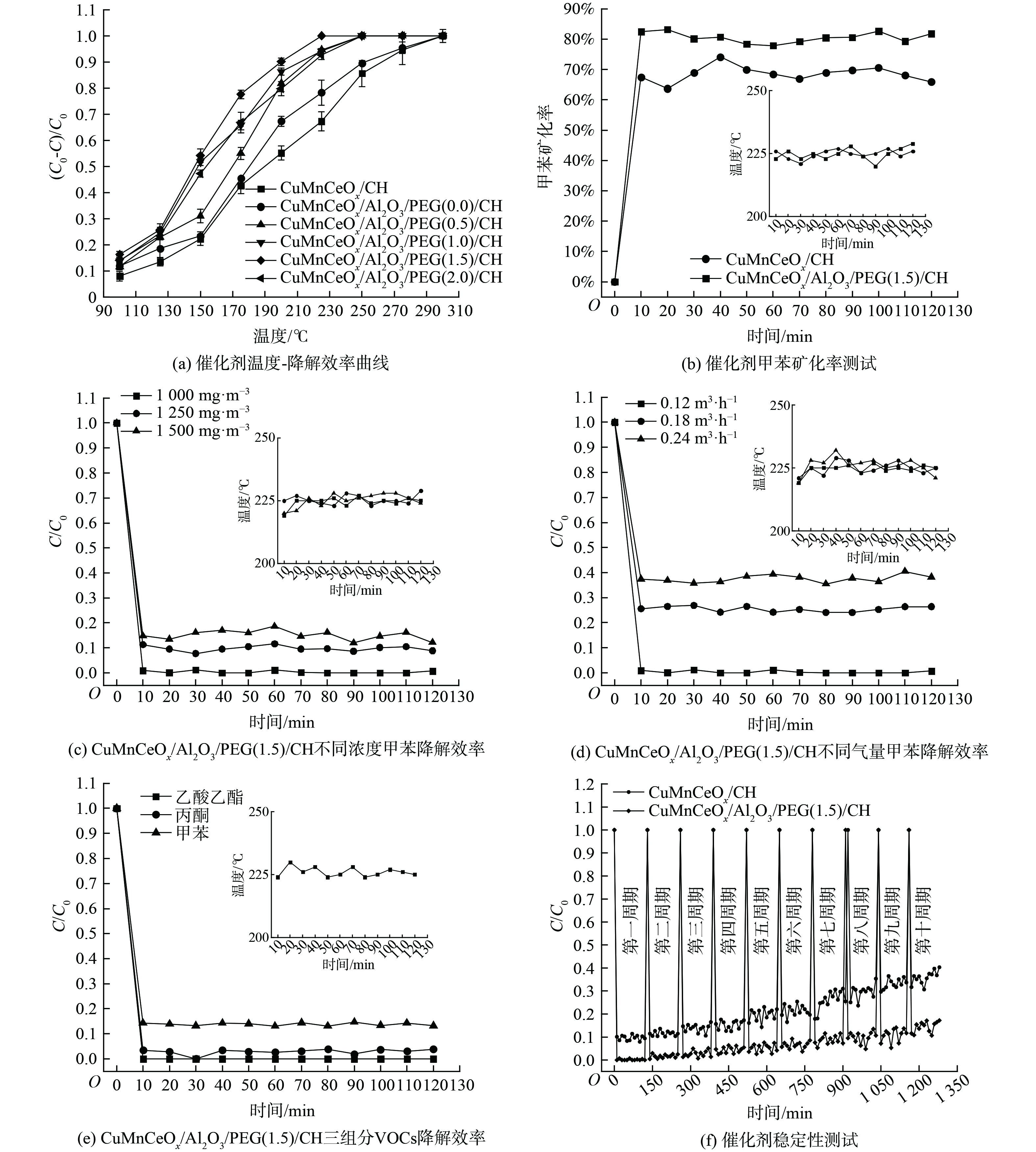

通过测试Al2O3/CH浸渍超声30 min前后的质量变化来计算涂层的脱落率,通过测试AlOOH溶胶的Zeta电位、粒径和黏度及涂层涂覆率和脱落率来确定拟薄水铝石和PEG200的最佳添加量。在微波辐照下,测试CuMnCeOx/CH和CuMnCeOx/Al2O3/CH等催化剂在不同床层温度下对VOCs的去除效率,以此考察催化剂活性;恒定床层温度 (225 ℃) 下,分别考察甲苯气体不同流量 (0.12、0.18和0.24 m3·h−1) 、不同初始质量浓度 (1 000、1 250和1 500 mg·m−3) 及三组分VOCs混合气体 (各组分初始质量浓度均为1 000 mg·m−3) 的微波催化燃烧去除与矿化效果;考察10个连续周期 (20 h) 内微波催化燃烧甲苯实验的稳定性。实施3组平行实验,文中数据为平均值并绘制误差棒,以减小实验误差的影响。

-

利用安捷伦气相色谱仪 (FID检测器) 对VOCs质量浓度进行定量测试。气体进样量为300 μL,检测条件:进样口加热器温度为190 ℃,检测器温度300 ℃,分流比50∶1,以氮气为载气,压力8 2737.084 Pa (12 Psi) 。测量单组分甲苯时柱箱初始温度设定为100 ℃,以20 ℃·min−1的速率升温至180 ℃后保持3 min,单次样品检测时间为7 min;测定3组分混合VOCs时柱箱初始温度为120 ℃,然后以6 ℃·min−1升至180 ℃并保存1 min,样品检测时间为11 min;外标法计算甲苯或三组分中各污染物质量浓度,以此分析VOCs的去除效率。实验中利用傅里叶变化红外光谱仪 (TGS检测器) 测试反应前后气体中二氧化碳质量浓度,测试时设定300 cm−1中红外波段,分辨率为0.5 cm−1,测定温度165 ℃,单次测试时长为15 s。

涂层涂覆率的计算公式为式 (1) 。

式中:Q1为氧化铝涂层的涂覆率;A0和A1分别为载体和浸渍溶胶煅烧后载体的质量,g。

涂层脱落率计算公式为式 (2) 。

式中:Q2为氧化铝涂层的脱落率;A2为水中超声30 min,烘干后载体的质量,g。

VOCs去除率计算公式为式 (3) 。

式中:η为催化剂对VOCs的去除率;C0和C分别为反应器进气口和出气口污染物质量浓度,mg·m−3。

甲苯矿化率计算公式为式 (4) 。

式中:R为催化剂对甲苯的矿化率;Pin和Pout为进口气体和出口气体的二氧化碳质量浓度,mg·m−3;P0为进口气体的甲苯质量浓度,mg·m−3。

-

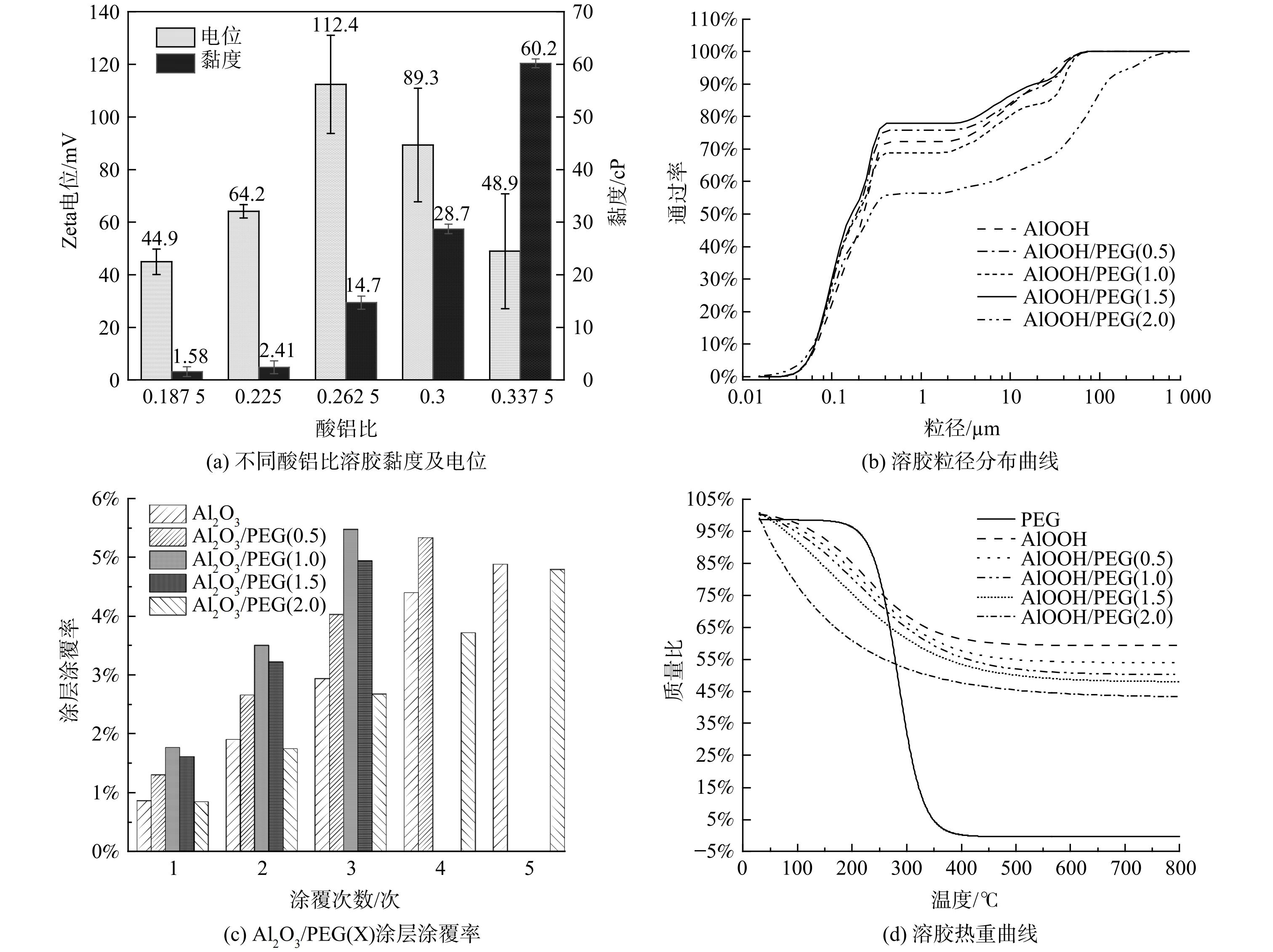

酸铝比 (

$ {{\text{n}}_{{H^+}}}/{{\text{n}}_{A{l^{3+}}}} $ ) 和PEG200添加量X ($ {\text{X}} = {{\text{m}}_{PEG200}}/{{\text{m}}_{A{\text{l}}OOH}} $ ) 的变化对铝溶胶的存在形式、溶胶状态和粒径大小有显著的影响[13-14]。根据图2(a)所示,黏度和酸铝比呈正比关系,Zeta电位值随酸铝比的增加先增大后减小。当酸铝比较小时,溶胶出现分层现象而没有均匀分散,黏度和Zeta电位较小;当酸铝比高达0.337 5时,溶胶的流动性和均匀性变差,此时黏度值为60.2 cP,Zeta电位下降至48.9 mV;当酸铝比为0.262 5时,黏度值为14.7 cP,Zeta电位达到最大值115 mV,此时该溶胶体系最为稳定。如图2(b)所示,随着PEG200添加量的增加,即图例括号中数值的增大,溶胶粒径先减小再增大;在AlOOH/PEG(1.5)条件下,溶胶粒径最小,0.409 μm以下的颗粒占比77.84%,比AlOOH提高了8.06%,这说明添加PEG200后可使得溶胶粒子的颗粒尺寸变小和更好地分散;然而随着PEG200添加量继续增大,譬如AlOOH/PEG(2.0)胶体中粒径小于0.409 μm的占比仅剩50%。分析认为冗余的PEG200分子的粘结作用会使得颗粒团聚,从而导致体系中颗粒尺寸的增大。图2(c)给出了不同PEG200添加量下涂覆次数与涂层涂覆率之间的关系。Al2O3/PEG(1.0)、Al2O3/PEG(1.5)、Al2O3/PEG(0.5)、Al2O3和Al2O3/PEG(2.0)依次呈现出由好到差的涂覆效果;随着涂敷次数的增加,涂层涂覆率呈现增加趋势。在最佳PEG200投加量X=1.5时,3次循环涂覆可实现载体质量5%的有效涂覆率,相较于单独的Al2O3涂覆量提升明显。分析认为是由于PEG分子吸附在AlOOH粒子表面,并且通过氢键将氧乙烯基与铝溶胶表面的羟基连接,使溶胶胶粒之间的交联作用增强,溶胶的黏性和分散性增加,从而增强了涂层的可涂覆性[12]。将焙烧后的涂层载体浸渍水中超声30 min后烘干称重计算其涂层脱落率时发现,随着PEG添加量的增大 (0~2.0) ,脱落率数据依次为:5.69%、0.66%、0.49%、0.27%和0.60%,X=1.5的涂层脱落率最小。这证实了氧化铝本身与载体之间结合力较弱,加入PEG200后黏度增大而有利于溶胶在载体表面上的粘附,使得涂层结合力增强。

图2(d)给出了PEG及AlOOH/PEG(X)的热重分析 (TGA) 曲线。在180 ℃以下主要是样品表面水分蒸发导致质量损失,PEG200在200 ℃时开始热解,并且在380 ℃时完全热解。单独铝溶胶热解后的质量损失约为38%,而随着铝溶胶体系内PEG200质量浓度增加,溶胶的质量损耗也逐渐增大,在AlOOH/PEG(2.0)时损失达到最大值51%。研究表明,X值较小时,PEG200存在于AlOOH粒子之间抑制溶胶团聚[15],进而在煅烧过程中大部分PEG热分解后使得氧化铝粒子均匀分散在堇青石表面,为下一步活性组分的负载提供更多的附着位点。然而,当X值过大时,PEG残余导致了涂层质量更大程度的损耗,进而不利于体系的稳定性。

铝溶胶制备实验表明:在酸铝比0.262 5和PEG(1.5)最优添加条件下,溶胶粒径小且电位大,此时溶胶处于稳定状态;3次循环涂覆可完成质量分数5%的涂层涂覆率;焙烧后在堇青石表面生成了牢固且均匀涂覆的γ-Al2O3涂层。

-

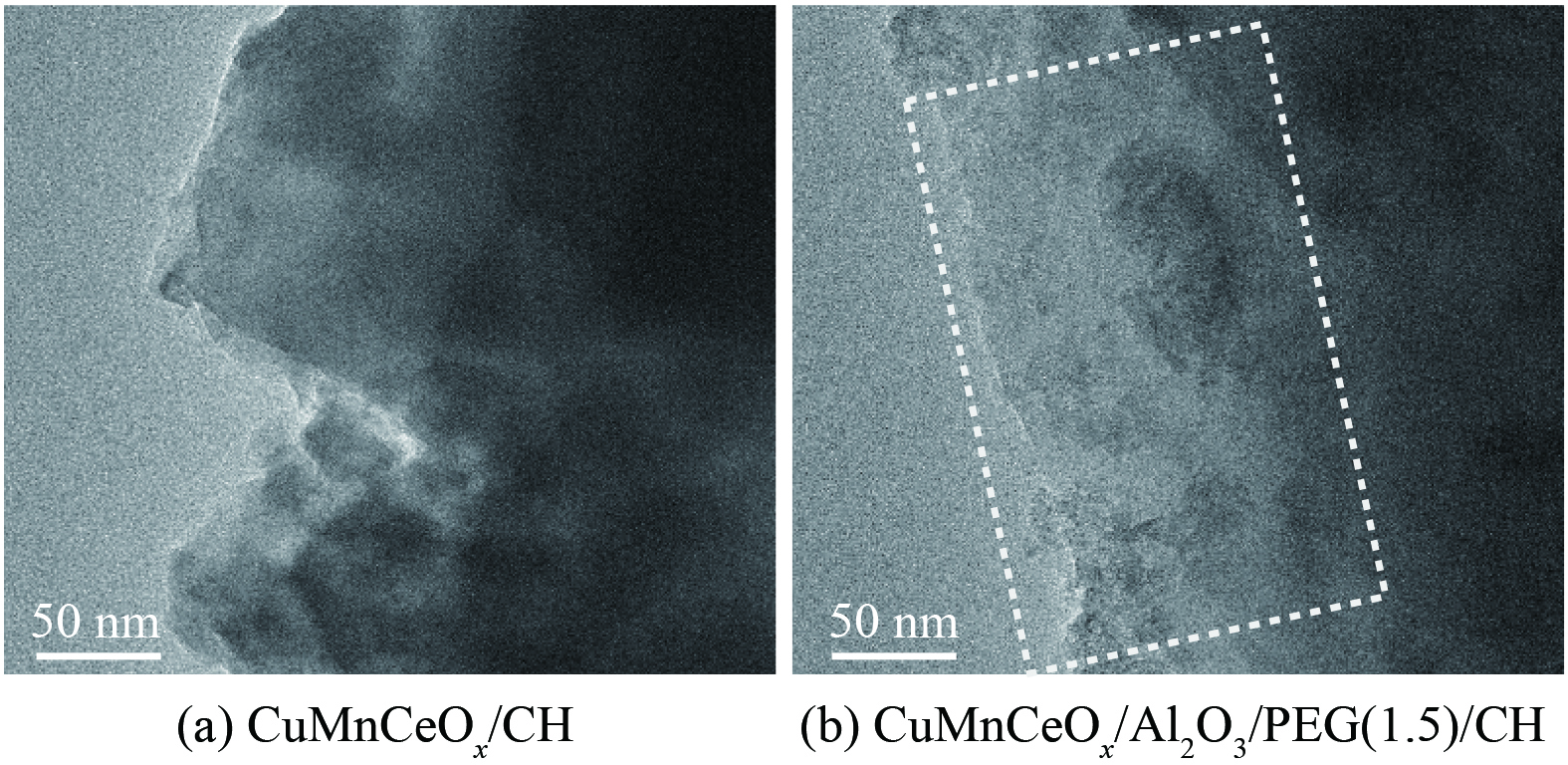

1) SEM-EDS/TEM。图3为载体和催化剂的表面形貌及活性组分分布状况。CH载体呈现紧密的层状结构而不利于活性组分的分散负载[16]。然而,在涂覆γ-Al2O3后 (图3(b)~(f)所示) 形成了一层不均匀的片状结构涂层;当PEG200添加量不足时,溶胶粘结作用较弱而覆盖在CH表面,焙烧后出现龟裂现象;但过多的添加会由于去PEG化影响较大而造成涂层表面形成较大的裂缝,从而对催化剂的活性产生负面作用;图3(e)显示的Al2O3/PEG(1.5)/CH表面涂层涂覆均匀且改善了由于PEG热解导致的裂缝问题,再次证实PEG200添加的最优值为X=1.5。图3(g)~(j)表明CuMnCeOx/CH催化剂表面活性组分颗粒的粒径较大且活性组分Cu、Ce等分布不均匀。Al2O3涂层有效提高了活性组分的分散性而使得活性颗粒尺寸减小 (图3(h)),但活性组分的分布仍然存在不均匀性 (图3(k)) 。图3(i)~(l)给出了最优PEG200添加量下的CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂表面形貌和活性组分分布,这表明催化剂表面具有均匀致密的孔洞结构。结合图4中2种催化剂分别展示出130~40 nm和60~10 nm的颗粒尺寸,图4(a)显示活性组分团聚在载体上,图4(b)图像中清晰可见均匀涂覆的Al2O3涂层,且活性组分颗粒分散在材料表面,没有团聚。CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂中活性组分颗粒粒径小且分布更加均匀,不同活性组分之间充分复合而均匀地分布于催化剂表面。

2) BET。表1给出了不同PEG200添加量下载体及催化剂的比表面积和孔径参数。CH载体的比表面积及总孔体积均较小,故不利用活性组分的负载。Al2O3粉末的比表面积为140.71 m2·g−1,在添加PEG后Al2O3/PEG(1.5)粉末的比表面积增大至219.05 m2·g−1,为前者的1.5倍,PEG作用显著。因此,在γ-Al2O3和PEG200共同作用下,Al2O3/PEG(1.5)/CH的比表面积5.25 m2·g−1值明显大于CH的0.83 m2·g−1,其平均孔径及总孔体积都明显增大,这与Al2O3/PEG(1.5)涂层在CH表面生成微孔和介孔的新孔道有关。CuMnCeOx活性颗粒的负载也能显著增加催化剂的比表面积,CuMnCeOx/CH-1催化剂7.83 m2·g−1的比表面积是CH载体的近10倍,这与活性颗粒强的吸附性能有关,但其对平均孔径和总孔体积的增大效果不如Al2O3/PEG(1.5)涂层的增效作用。相较于CuMnCeOx/CH-1催化剂,CuMnCeOx/Al2O3/PEG(1.5)/CH-1催化剂的比表面积、平均孔径和总孔体积进一步增大。分析认为,比表面积的增加是涂层和活性组分的共同作用,涂层对平均孔径和总孔体积的增大效果强于活性组分。进一步证实了PEG200热分解的造孔作用及涂层对活性组分颗粒的分散作用。甲苯微波催化燃烧试验后催化剂CuMnCeOx/CH-2和CuMnCeOx/Al2O3/PEG(1.5)/CH-2的比表面积、平均孔径和总孔体积与新催化剂相比均有一定程度的下降,推测与持续高温反应下催化剂结构的稳定化和微波热点效应诱使叠加或连接的活性组分颗粒之间互相团聚有关[17-18]。CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂展现出较大的比表面积和丰富的孔结构,从而有利于VOCs分子的吸附和与活性颗粒的接触,进而促进VOCs的催化燃烧降解,提高了催化剂活性。

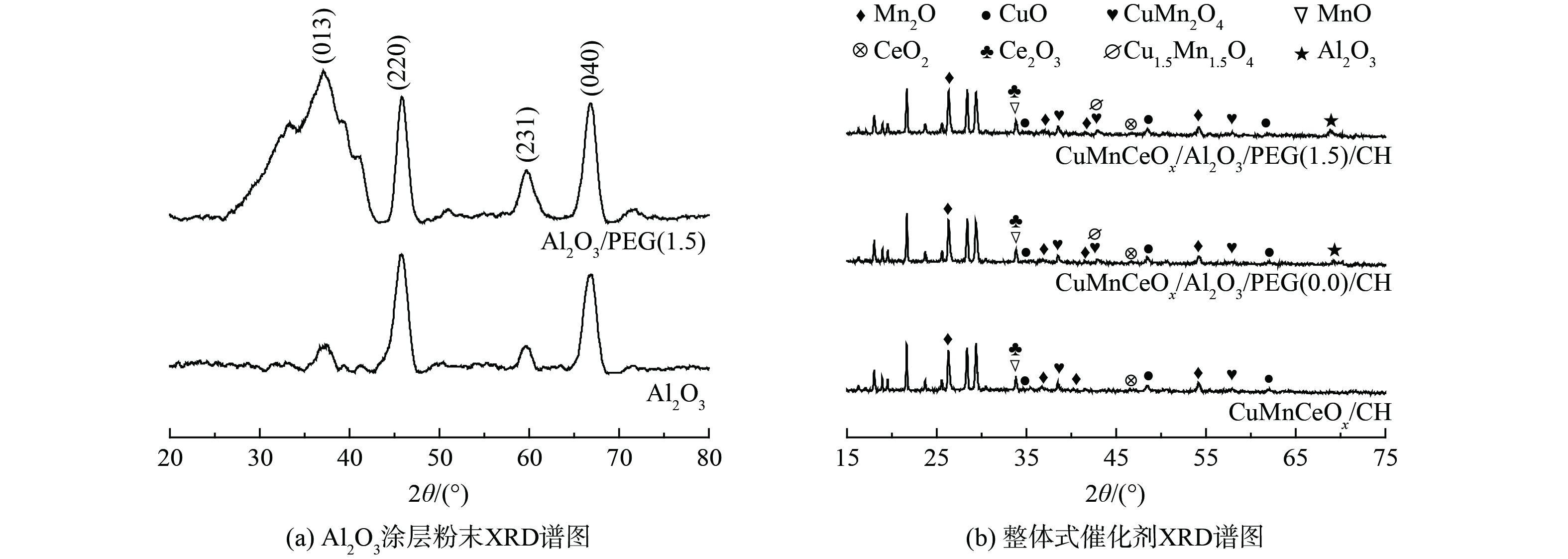

3) XRD。图5展示了Al2O3、Al2O3/PEG(1.5)粉末及CuMnCeOx/CH、CuMnCeOx/Al2O3/PEG(0.0)/CH和CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂表面活性组分的晶型和晶体构成。图5(a)表明γ-Al2O3特征峰型对应的(013)、(220)、(231)和(040)4个不同晶面,纯Al2O3粉末的晶型峰较小,推测γ-Al2O3晶体中部分以无定形态存在;Al2O3/PEG(1.5)的晶体衍射峰强度明显增大,这表明加入PEG200后γ-Al2O3晶体的晶粒尺寸增大且结晶度良好,PEG200的添加有利于γ-Al2O3晶体的形成与生长。图5(b)中3种催化剂表面均检测到Mn2O、CuO、MnO、CeO2、Ce2O3和CuMn2O4氧化物等晶体,Ce3+和Ce4+的存在表明催化剂表面具有丰富的氧空位而有利于表面晶格氧的传递[19],同时高活性CuMn2O4尖晶石的存在则可有效促进VOCs的矿化反应[20]。另外,CuMnCeOx/Al2O3/PEG(0.0)/CH和CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂表面还检测到γ-Al2O3特征峰和Cu1.5Mn1.5O4尖晶石的特征峰,并且发现金属氧化物晶体特征峰的强度增大了。这表明氧化铝涂层会影响过渡金属氧化物的结晶度而使晶体含量增多,铝原子可增加氧原子的电负性而促进CuMnCeOx活性组分之间的电荷传递[21];Cu1.5Mn1.5O4尖晶石中Cu和Mn间存在着电子传递[22],从而展现出良好的氧化还原能力[23],可有效增强催化剂降解VOCs的活性。

4) XPS。通过XPS对CuMnCeOx/CH和CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂表征,检测元素价态光谱如图6所示。图6(a)在930~935 eV和950~955 eV内存在Cu2p3/2和Cu2p1/2轨道,催化剂中Cu以Cu+和Cu2+形式存在。图6(b)表明,Mn2p3/2和Mn2p1/2主峰对应的结合能为642.2 eV和653.7 eV。其中,Mn2p3/2拟合为表示Mn2+、Mn3+和Mn4+离子的 (641.9±0.3) eV、 (642.4±0.2) eV和 (643.9±0.3) eV3个分峰,2种催化剂表面Mn2+、Mn3+和Mn4+占比分别38.8%、34.4%、26.9%和38.3%、9.2%、52.4%。CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂Mn4+质量浓度高,Mn4+与Cu+发生氧化还原反应伴随更多的氧空位的产生,有利于表面吸附氧的转化,促进催化燃烧VOCs反应的进行。图6(c)显示了催化剂Ce3d的8个光谱峰属于Ce3d3/2和Ce3d5/2能级,V' (884.6eV) 和U' (904.7eV) 属于Ce3+离子的特征峰,其他特征峰处属于Ce4+[24]。这表明Ce3+与Ce4+共存于催化剂表面,且主要以Ce4+形式存。CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂表面的Ce3+/Ce值大,表明表面氧空位的产生,为氧分子的吸附及活化提供位点,促进表面活性氧的生成[25]。图6(d)中催化剂O1s谱图拟合分解为晶格氧 (Olatt) 和表面吸附氧 (Oads) ,CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂表面Olatt/O值较高,丰富的晶格氧增强催化剂低温下催化活性,与催化剂性能测试结果保持一致。

-

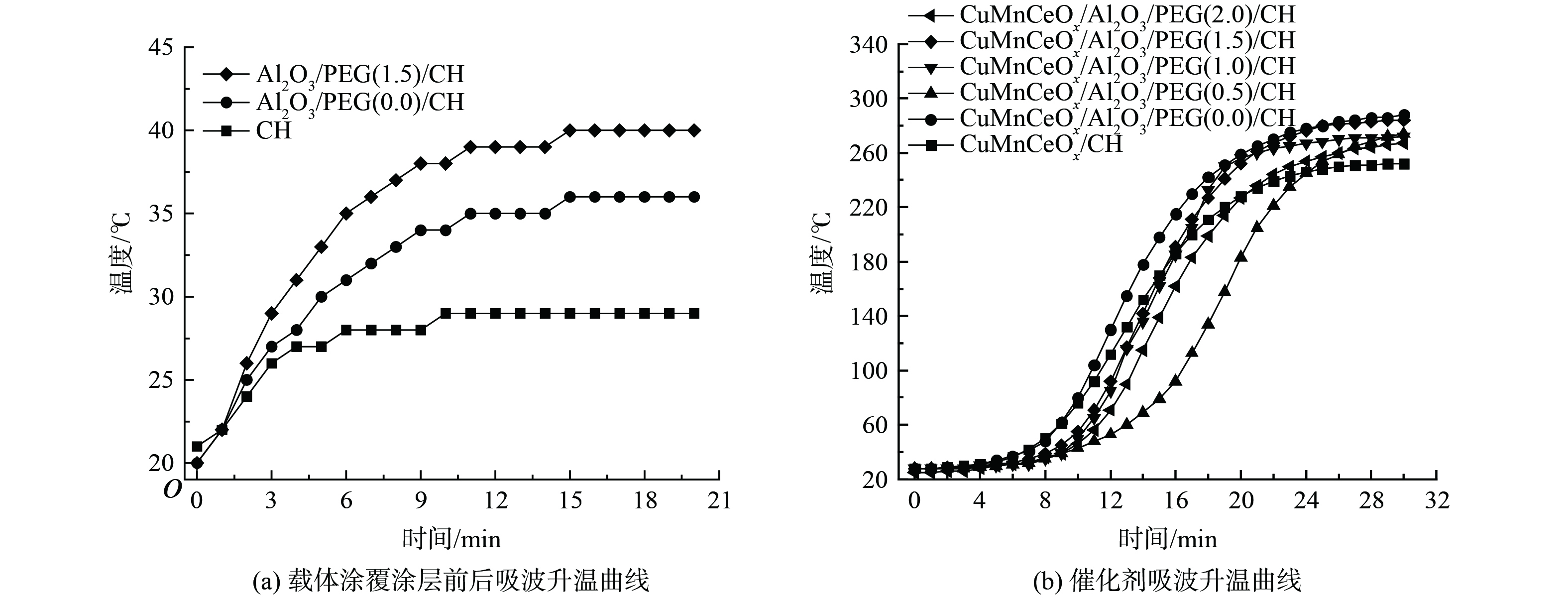

1) 催化剂吸波性能分析。在70 W微波功率照射下,所测试的CH、Al2O3/CH载体和催化剂吸波升温曲线如图7所示。CH载体几乎不吸波,微波照射下由室温仅增加到28 ℃;添加Al2O3涂层和PEG后的Al2O3/PEG(0.0)/CH和Al2O3/PEG(1.5)/CH在微波照射20 min后温度升高至36 ℃和40 ℃并趋于稳定,这表明氧化铝粒子具有较弱的吸波性[26],PEG的造孔作用也能略微增加Al2O3/CH的吸波能力。然而,6种负载CuMnCeOx活性组分后的整体式催化剂在微波照射下的升温效果明显 (图7(b)) ,微波照射30min后催化剂表面温度升高至250~285 ℃。催化剂吸波升温由高到低依次为:CuMnCeOx/Al2O3/PEG(0.0)/CH>CuMnCeOx/Al2O3/PEG(1.5)/CH>CuMnCeOx/Al2O3/PEG(1.0)/CH>CuMnCeOx/Al2O3/PEG(0.5)/CH>CuMnCeOx/Al2O3/PEG(2.0)/CH>CuMnCeOx/CH。分析认为,铜锰铈及其金属氧化物为主要吸波物质[27],另外活性颗粒尺寸大小及其分散程度也会对其吸波性能产生影响。与CuMnCeOx/CH催化剂相比,CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂的吸波升温能力提高了32 ℃。在微波照射30min后其表面温度达到284 ℃,推测认为γ-Al2O3涂层和PEG200造孔效应共同作用下活性组分的分散性得到了有效提高,从而使得活性颗粒尺寸变小而微波热点增多,催化剂的吸波性能也随之得以提升。

2) 催化剂活性。在甲苯初始质量浓度为1 000 mg·m−3、进气流量为0.12 m3·h−1的实验条件下,催化剂对甲苯的去除效率随床层温度的变化曲线如图8(a)所示。6种催化剂均能完全降解甲苯,其T90(甲苯去除效率为90%时的催化剂表面温度)分别为:200、212、217、220、253和262 ℃。与CuMnCeOx/CH催化剂相比,CuMnCeOx/Al2O3/CH催化剂对甲苯表现出更高的催化活性,CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂的活性最高,在225 ℃下即可实现对甲苯的100%去除。刘翻艳[28]以不同铝源制备Pd/γ-Al2O3/堇青石催化剂,当床层温度485~503 ℃时对甲苯转化率为90%,550 ℃时才能达到完全去除;并发现以拟薄水铝石为原料制备的催化剂活性最好。结合表1和图3可知,γ-Al2O3涂层和PEG200能增大载体比表面积和孔体积,提高活性颗粒的分散度,从而增加甲苯与活性颗粒的接触机会,提高了催化剂对甲苯的去除效率。然而,当PEG添加不足或过量时出现的涂层裂缝会导致活性位点减少,从而降低催化剂活性。由于CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂在床层温度225 ℃下可完全降解甲苯,故定量分析了床层温度225 ℃左右时CuMnCeOx/CH和CuMnCeOx/Al2O3/PEG(1.5)/CH两种催化剂微波催化燃烧甲苯的矿化情况 (图8(b))。该床层温度下CuMnCeOx/Al2O3/PEG(1.5)/CH对初始质量浓度1 000 mg·m−3甲苯气体的矿化率约为80%,高于CuMnCeOx/CH催化剂的70%,又一次证实了前者的催化活性高于后者和γ-Al2O3涂层对催化剂活性的提高作用;在此温度下,甲苯已在CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂表面被完全降解,但仍残留少量的中间产物,可通过提高床层温度使这部分中间产物被彻底地氧化分解掉。

图8(c)与图8(d)为当床温225 ℃ (该温度下初始质量浓度1 000 mg·m−3、进气流量0.12 m3·h−1的甲苯气体可被完全降解) 时,CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂对不同初始质量浓度和不同气量下甲苯的催化活性。随着甲苯初始质量浓度增大,催化剂对甲苯的去除效率降低,由1 000 mg·m−3时的100%降至1 500 mg·m−3时的85%;同样地,随着处理气量的增大,催化剂对甲苯的去除效率也下降了,由0.18 m3·h−1时的75%下降至0.24 m3·h−1时的62%。分析认为,催化剂表面活性位点一定,增大甲苯质量浓度会降低污染物与催化剂活性位点之间的接触概率,进而导致甲苯去除效率的降低。气体流量的增加意味着污染物在催化剂表面的停留时间缩短,即甲苯与活性颗粒接触时间不足,进而导致其降解效率的降低。另外,气量增大导致气体带出的热量增加,从而引起床层温度的波动加剧,同样不利于甲苯的氧化降解。比较图8(c)与图8(d)可知,气体流量变化对催化剂活性的影响大于初始质量浓度变化对催化剂活性的影响。

图8(e)为在进气流量0.12 m3·h−1、床层温度225 ℃实验条件下,CuMnCeOx/Al2O3/PEG(1.5)/CH对三组分VOCs混合气体 (甲苯、丙酮及乙酸乙酯,各组分初始质量浓度均为1 000 mg·m−3) 的催化活性。2种催化剂对三组分VOCs的去除效率由高到低依次为:乙酸乙酯 (100%) >丙酮 (97%) >甲苯 (86%) 。苯环断裂所需能量为530 kJ·mol−1,而丙酮的甲基和乙酸乙酯的C—O键断裂则分别需要413 kJ·mol−1和335 kJ·mol−1的能量[29-30],故甲苯难以降解、丙酮次之而乙酸乙酯最易氧化分解。与单一组分相比较,当VOCs总质量浓度增加时 (即添加其他2种VOCs) ,催化剂对甲苯的去除效率也有所下降。这表明在催化剂填充量一定时,多组分污染物对催化剂表面的活性氧存在竞争关系,同时有更多的副产物产生而侵占活性位点,进而导致目标污染物与活性颗粒的接触机会减少;另外,乙酸乙酯、丙酮等含氧有机物更易被催化剂吸附活化[31],多组分之间的干扰抑制效应使不易吸附活化的污染物去除效率进一步降低[32]。图8(f)测试了床层温度225 ℃、进气流量0.12 m3·h−1、甲苯初始质量浓度1 000 mg·m−3实验条件下CuMnCeOx/CH和CuMnCeOx/Al2O3/PEG(1.5)/CH两种催化剂连续10个实验周期内对甲苯的催化活性。CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂在前3个实验周期内对甲苯的催化燃烧效率保持在97%,随后缓慢下降。在连续10个周期结束后,其对甲苯的去除效率仍保持在85%,具有良好的催化活性。然而,CuMnCeOx/CH催化剂在连续10个周期结束后对甲苯的去除效率下降至70%。TAO[22]制备CuMnCeOx/CHC-16催化剂在经过连续14 h作用后对甲苯的去除率从99%逐渐下降到80%。因此,CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂对甲苯的催化活性高且稳定性良好。催化剂活性的下降一方面与高温条件下结构的稳定化有关,另一方面甲苯矿化生成的水蒸气与VOCs竞争吸附于催化剂表面的活性位处[33],部分活性位点被水蒸气覆盖,从而导致甲苯与活性位点的接触几率降低而影响其去除效率。表1中数据表明,在微波均匀加热下,CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂实验后仍具有较大比表面积和稳定孔径与总孔体积。这表明γ-Al2O3涂层和PEG200共同作用下活性粒子高度分散在催化剂表面,从而保证了催化剂活性的长期稳定。

-

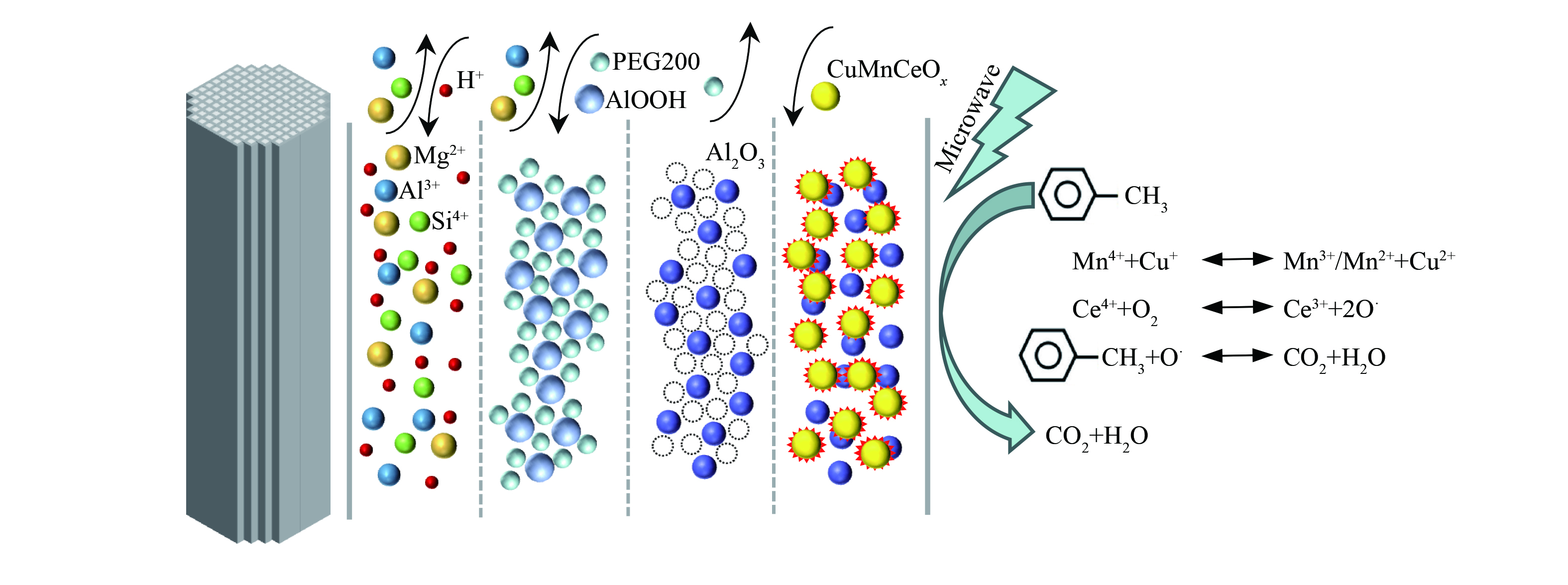

通过上述的催化剂表征与活性测试,CuMnCeOx/Al2O3/CH催化剂表面甲苯的微波催化燃烧降解机理如图9所示。首先,柱状的CH蜂窝载体经HNO3预处理后会将CH中部分的Mg2+、Al3+和Si4+离子溶出而留下缺陷位;其次,预处理后的CH放入PEG粘结的铝溶胶内超声浸渍时,其酸性条件会进一步使CH表面的Mg2+、Al3+和Si4+离子等溶出,AlOOH粒子在烘干煅烧后生成了γ-Al2O3粒子,而PEG在煅烧时热分解掉而留下大量空隙,从而增大了Al2O3涂层的比表面积与总孔体积;再次,通过浸渍法在Al2O3/CH载体表面负载上CuMnCeOx活性组分颗粒,这些活性组分离子均匀分布在γ-Al2O3涂层表面,微波照射下活性颗粒因具有吸波性能而形成高温热点,这些热点处的温度远高于催化剂床层的平均温度;最后,甲苯分子在催化剂表面与活化的氧分子反应而被彻底氧化为CO2和H2O后脱附排空。催化剂表面发生着Cu++Mn4+ ↔Mn2+/Mn3++Cu2+的氧化还原反应[6],存在着丰富的晶格氧。同时,因Ce4+/Ce3+的转化会形成氧空位[22],气体中的氧分子在氧空位处被吸附活化,形成一个活性氧消耗和再生的循环,VOCs的降解符合MvK机理[34]。

-

1) CH表面溶胶法制备Al2O3涂层时添加PEG200可有效增大涂层的比表面积和总孔体积,最优PEG200添加量下铝溶胶粒径减小而分散均匀,γ-Al2O3涂层无裂缝而脱落率显著降低;Al2O3涂层和PEG200的造孔效应使得活性颗粒更均匀地分散在载体表面,提高了金属氧化物晶体及活性更高的尖晶石类晶体的含量。

2) 与CuMnCeOx/CH催化剂相比,CuMnCeOx/Al2O3/CH催化剂比表面积、平均孔径和孔容增大,其对甲苯的降解、矿化和稳定性效果均优于前者,体现出涂层对催化剂活性的促进作用。CuMnCeOx/Al2O3/CH催化剂对三组分VOCs展现出良好的微波催化燃烧活性,其降解效果排序为乙酸乙酯>丙酮>甲苯,分析认为与其各自的键能大小有关。

3) CH载体表面碱性金属离子的酸溶出为铝溶胶粒子向内迁移及氧化铝涂层的牢固涂覆提供了先决条件,促进了活性组分颗粒在催化剂表面的均匀分布。Cu、Mn、Ce间的电子迁移促进了分子氧的活化,微波热点效应强力提高了催化剂对甲苯的去除和矿化活性。

CuMnCeOx/Al2O3/CH催化剂的制备及微波催化燃烧VOCs性能

Preparation and performance of CuMnCeOx/Al2O3/CH catalyst in microwave catalytic combustion of VOCs

-

摘要: 针对整体式催化剂载体比表面积小和涂层脱落等问题,采用聚乙二醇200 (PEG200) 为粘结剂在蜂窝堇青石 (CH) 载体表面涂覆氧化铝 (Al2O3) 涂层,等体积浸渍法制备CuMnCeOx/Al2O3/CH催化剂,微波催化燃烧VOCs以考察其催化性能。结果显示,当酸铝比 (

$ {{\text{n}}_{{H^+}}}/{{\text{n}}_{A{l^{3+}}}} $ ) 为 0.262 5、$ {{\text{m}}_{PEG200}}/{{\text{m}}_{A{\text{l}}OOH}} $ 为1.5时,PEG200与AlOOH以氢键连接得到分散度高的铝溶胶,涂覆煅烧后PEG的造孔效应改善了载体形貌,为活性组分的负载提供了更多附着位点。在甲苯初始质量浓度1 000 mg·m−3和处理气量0.12 m3·h−1的实验条件下,CuMnCeOx/Al2O3/PEG(1.5)/CH催化剂降解甲苯的T90为200 ℃,比CuMnCeOx/CH和CuMnCeOx/Al2O3/PEG(0.0)/CH催化剂分别降低了62 ℃和53 ℃。SEM、BET和XRD等表征发现,片状γ-Al2O3涂层增大了载体比表面积和孔容,活性粒子更均匀地分布于催化剂表面,为VOCs氧化提供更多的有效活性位点;过渡金属氧化物表面丰富的活性位点和Cu+/Cu2+与Mn3+/Mn4+间价态转化产生的氧空穴提高了催化剂的催化活性和VOCs的矿化效果。该研究结果可为高活性催化剂的制备及其微波催化燃烧VOCs技术应用提供参考。-

关键词:

- 氧化铝涂层 /

- 聚乙二醇 /

- CuMnCeOx/Al2O3/CH催化剂 /

- 微波催化燃烧 /

- 挥发性有机物

Abstract: To solve the problems of small specific surface area and coating detachment for the carrier of monolithic catalyst, polyethylene glycol 200 (PEG200) was selected as a binder to prepare alumina (Al2O3) coating onto the surface of cordierite honeycomb (CH) carrier. Subsequently, CuMnCeOx/Al2O3/CH catalyst was prepared by an equivalent –volume impregnation method, and its activity was checked by microwave catalytic combustion of VOCs. Results showed that PEG200 and AlOOH were connected by hydrogen bond to form aluminum sol with high dispersion under conditions of 0.262 5 of acid aluminum ratio ($ {{\text{n}}_{{H^+}}}/{{\text{n}}_{A{l^{3+}}}} $ ) and 1.5 of mPEG200/mAlOOH, and the carrier morphology was improved by the pore-forming effect of PEG after coating and calcinations, which provided more attachment sites for the load of active components. Under experimental conditions of gas flow rate at 0.12m3·h−1 and initial concentration of toluene at 1 000 mg·m−3, the T90 of CuMnCeOx/Al2O3/PEG(1.5)/CH catalyst for toluene degradation was 200 ℃, which lessened by 62 ℃ and 53 ℃while compared with CuMnCeOx/CH catalyst and CuMnCeOx/Al2O3/PEG(0.0)/CH catalyst, respectively. Based on characterization of SEM, BET and XRD, it was revealed that plate-like γ-Al2O3 coating increased the specific surface area and pore volume of the carrier, which promoted more uniform distribution of active particles on the catalyst surface and provided more effective active sites for VOCs oxidation. The abundant active sites on transition metal oxides’ surface along with oxygen vacancies that generated by valence transformation between Cu+/Cu2+and Mn2+/Mn4+, enhanced effectively catalytic activity of the catalyst and mineralization performance of VOCs. The study provides a theoretical base on the preparation of high-performance catalyst and the application of microwave catalytic combustion technology for VOCs treatment. -

-

表 1 不同载体及催化剂的比表面积和孔径参数

Table 1. Specific surface area and pore size parameters of different carriers and catalysts

样品 比表面积/

(m2·g−1)平均孔径/

nm总孔体积/

(cm3·g−1)CH 0.83 8.28 0.000 6 Al2O3 140.71 4.04 0.215 0 Al2O3/PEG(1.5) 219.05 6.46 0.522 5 Al2O3/PEG(0.0)/CH 4.39 45.39 0.047 3 Al2O3/PEG(1.5)/CH 5.25 50.23 0.122 7 CuMnCeOx/CH-1 7.83 16.74 0.047 5 CuMnCeOx/CH-2 5.40 14.68 0.024 3 CuMnCeOx/Al2O3/PEG(1.5)/CH-1 10.12 46.34 0.218 5 CuMnCeOx/Al2O3/PEG(1.5)/CH-2 9.89 44.25 0.198 7 注:CuMnCeOx/CH-1、CuMnCeOx/Al2O3/PEG(1.5)/CH-1是新催化剂,CuMnCeOx/CH-2、CuMnCeOx/Al2O3/PEG(1.5)/CH-2是反应后催化剂。 -

[1] ZENG X T, TONG Y F, CUI L, et al. Population-production-pollution nexus based air pollution management model for alleviating the atmospheric crisis in Beijing, China[J]. Journal of Environmrntal Management, 2017, 197: 507-521. [2] 孙豆, 王云刚, 戴艳俊, 等. 挥发性有机物治理现状及处理技术分析[J]. 动力工程学报, 2023, 43(5): 641-654. [3] 王博磊, 钟和香, 张晶, 等. 陶瓷基整体式催化剂催化燃烧挥发性有机物的研究进展[J]. 材料导报, 2022, 36(14): 124-132. [4] 国务院关于印发"十四五"节能减排综合工作方案的通知[R/OL]. (2022-01-24)[2023-08-23]中国政府网.https://www.mee.gov.cn/zcwj/gwywj/202201/t20220124_968089.shtml. [5] KAMAL M S, RAZZAK S A, HOSSAIN M M. Catalytic oxidation of volatile organic compounds (VOCs)-A review[J]. Atmospheric Environment, 2016, 140: 117-134. [6] 陈瑾, 卜龙利, 张丹庆, 等. 微波催化燃烧印刷包装VOCs废气的矿化途径与降解机理[J]. 中国环境科学, 2021, 41(11): 5104-5113. [7] BO L L, SUN S Y. Microwave-assisted catalytic oxidation ofgaseous toluene with a Cu–Mn–Ce/cordierite honeycomb catalyst[J]. Frontiers of Chemical Science and Engineering, 2019, 13(2): 385–392. [8] RODRIGUES C P, SILVA V T, SCHMAL M. Partial oxidation of ethanol on Cu/Alumina/cordierite monolith[J]. Catalysis Communications, 2009, 10(13): 1697-1701. [9] 牟维琦. 挥发性有机物催化燃烧整体式催化剂研究与中试方案设计[D]. 北京: 北京化工大学, 2010. [10] 安琴. 陶瓷蜂窝载体γ-Al2O3涂层的技术途径研究[D]. 北京: 北京理工大学, 2000. [11] 闫慧忠, 孔繁清, 赵增祺, 等. 溶胶凝胶法制备金属基γ-Al2O3活性涂层的研究[J]. 中国稀土学报, 2002(S2): 88-91. [12] 田久英, 卢菊生, 吴宏. 添加剂聚乙二醇对堇青石蜂窝陶瓷载体γ-Al2O3涂层性能的影响[J]. 高校化学工程学报, 2010, 24(1): 167-170. [13] 段宁, 张湘泰, 陆成龙, 等. 硝酸对溶胶-凝胶法制备AlOOH胶粒粒度的影响[J]. 硅酸盐通报, 2021, 40(9): 3105-3113. [14] 魏士龙, 闵敬丽, 井良霄. 浅谈氧化铝溶胶制备中溶胶黏度的变化[J]. 中国新技术新产品, 2022, 460(6): 66-68. [15] YANG W L, XU J L, NIU L, et al. Dispersion stability of nano-Sb2O3 particles modified with polyethylene glycol[J]. Particulate Science and Technology, 2018, 36(7): 844-849. [16] 梁文俊, 李庆磊, 任思达. 酸预处理对整体式催化剂载体性能的影响研究[J]. 中国环境科学, 2020, 40(12): 5237-5245. [17] 张佳瑾, 李建伟, 朱吉钦, 等. 助剂对Cu-Mn复合氧化物整体式催化剂催化低浓度甲烷燃烧反应性能的影响[J]. 催化学报, 2011, 32(8): 1380-1386. [18] WANG X X, ZHANG B Q, YU M X, et al. Enhanced microwave absorption capacity of hierarchical structural MnO2@NiMoO4 composites[J]. RSC Advances, 2016, 6(43): 36484-36490. [19] 刘鹏. 多孔矿物负载型/过渡金属复合型锰氧化物热催化氧化挥发性有机物的研究[D]. 北京: 中国科学院大学, 2019. [20] 胡旭睿, 郭斌, 王欣. 碳化硅负载Cu-Mn-CeO x 催化剂的制备及其微波场中诱导甲苯氧化分解[J]. 现代化工, 2018, 38(3): 133-137. [21] SUBEDI K N, PRASAI K, KOZICKI M N, et al. Structural origins of electronic conduction in amorphous copper-doped alumina[J]. Physical Review Materials, 2019, 3(6): 065605. [22] TAO W Y, BO L L, LI M X, et al. Preparation, characterization and activity of CuMnCeO x/CHC catalyst in microwave catalytic combustion of toluene[J]. Catalysis Letters, 2022, 152(12): 3795-3806. [23] MURUGAN B, RAMASWAMY A V, SRINIVAS D, et al. Nature of manganese species in Ce1- xMn xO2-δ solid solutions synthesized by the solution combustion route[J]. Chemistry of Materials, 2005, 17(15): 3983-3993. [24] ZUO S F, YANG P, WANG X Q. Efficient and environmentally friendly synthesis of AlFe-PILC-supported MnCe catalysts for benzene combustion[J]. ACS omega, 2017, 2(8): 5179-5186. doi: 10.1021/acsomega.7b00592 [25] CHEN J, CHEN X, YAN D X, et al. A facile strategy of enhancing interaction between cerium and manganese oxides for catalytic removal of gaseous organic contaminants[J]. Applied Catalysis B:Environmental, 2019, 250: 396-407. doi: 10.1016/j.apcatb.2019.03.042 [26] 汪旭文. 聚合物基复合材料导热吸波性能研究[D]. 武汉: 华中科技大学, 2021. [27] 张婷婷, 卜龙利, 宁轲, 等. 催化剂载体的优化及微波催化燃烧甲苯特性[J]. 环境工程学报, 2020, 14(12): 3468-3479. [28] 刘翻艳. 堇青石表面改性对Pd基整体式催化剂结构和性能的影响[D]. 北京: 北京化工大学, 2014. [29] GANDHE A R, REBELLO J S, FIGUEIREDO J L, et al. Manganese oxide OMS-2 as an effective catalyst for total oxidation of ethyl acetate[J]. Applied Catalysis B Environmental, 2007, 72(1/2): 129-135. [30] MO J H, ZHANG Y P, XU Q J, et al. Determination and risk assessment of by-products resulting from photocatalytic oxidation of toluene[J]. Applied Catalysis B Environmental, 2009, 89(3/4): 570-576. [31] 李涛. VOCs催化燃烧催化剂的制备及反应系统研究[D]. 上海: 华东理工大学, 2015. [32] 陈嘉文, 孟庆洁, 翁小乐, 等. 多组分VOCs催化燃烧反应特征研究进展[J]. 能源环境保护, 2022, 36(6): 1-10. [33] SHAO J M, LIN F W, WANG Z H, et al. Low temperature catalytic ozonation of toluene in flue gas over Mn-based catalysts: Effect of support property and SO2/water vapor addition[J]. Applied Catalysis B Environmental, 2020, 266: 118662. [34] LEE J E, OK Y S, TSANG D. C. W, et al. Recent advances in volatile organic compounds abatement by catalysis and catalytic hybrid processes: A critical review[J]. Science of the Total Environment, 2020, 719: 137405. -

下载:

下载: