-

城市尾水经过深度处理后可作为地表水体的重要补给来源[1]。然而部分沿海城市污水处理厂的尾水存在含盐量过高导致现有深度处理工艺无法达到理想的处理效果,进而影响尾水的再生回用,同时含盐尾水的排放也会对水生态环境产生巨大影响。故需要进一步寻求能够对城市污水处理厂含盐尾水进行深度脱盐处理的新技术。

目前高盐废水处理方法主要有间歇曝气膜生物反应器技术[1-2]、人工湿地法[3]、机械式蒸汽再压缩技术蒸发技术[4-5]、生物膜厌氧折流板反应器法[6]、膜生物反应器(membrane bio-reactor,MBR)污泥驯化法[7-8]等,但普遍存在操作技术难、成本高、进水浓度不宜过高等问题。电容去离子(capacitive deionization, CDI)技术作为一种新型污水处理技术,通过形成双电层吸附离子以去除污染物,其脱盐性能卓越、使用寿命长久、能源消耗极低、且不会对环境造成污染 [9-10]。

电极材料对于CDI技术十分关键。目前常用的电极材料有活性碳颗粒、活性炭纤维、碳气凝胶、碳纳米管、石墨烯、金属氧化物等,但具有成本高、环境要求高、容易产生性能限制等缺点[11-17]。生物炭电极材料以其低廉的成本、广泛的原料来源和丰富的活性官能团等优点,成为一种新型的环保材料,被广泛应用于污染治理领域,在处理废水方面显示出了广阔前景[18]。花生壳作为中国主要农业副产物之一,目前处理方式多为直接燃烧或丢弃,利用率较低[19]。以花生壳作为生物炭原材料,可使其资源化利用。然而,初期炭材料的孔隙结构相对较为狭窄,且其吸附能力受到一定限制,需要进一步改性以增加其孔体积、比表面积和官能团数量[20]。KOH改性可以增加炭材料中羟基、羧基等官能团的含量,提高炭材料孔隙结构,改变其吸附性能[21-22],其常见改性方法有浸渍法和熔融法[23]。其中,浸渍法因操作简便、绿色节能等优点受到广泛关注[24]。本研究选取花生壳粉末为原材料,通过炭化和KOH浸渍改性制备一种孔径结构和表面官能团更为丰富、电吸附性能更好的电极材料,构建和优化CDI系统,以青岛沿海某污水处理厂为例,将优化后的CDI装置和KOH改性炭电极用于对污水处理厂高盐尾水中Cl−的去除,使Cl−可达排放标准。

-

花生壳粉末(江苏连云港);氢氧化钾(KOH)、氯化钠(NaCl)、N-N二甲基乙酰胺(DMAC)、聚偏氟乙烯(PVDF)均为分析纯;实验用水为超纯水。

-

1)炭材料的炭化过程采用两步炭化法。第1步:花生壳粉末装入方玉瓷舟,放置于管式炉中进行炭化。通入氮气(纯度为99.9%)20 min,保证炉内无氧。以10 ℃·min−1的速率升温至400 ℃,并进行2 h保温处理,待其温度降至室温后,即可将炭材料取出,研磨过筛(100目)。第2步:将第1步制得的炭材料装入瓷舟,置于管式炉中,在氮气气氛下,以10 ℃·min−1的速率升温至目标炭化温度 (分别为700、800、900和1 000 ℃) ,并进行2 h保温处理,待降至室温后取出。制备的炭材料分别命名为BPS700、BPS800、BPS900、BPS1000。

2)炭材料的KOH改性。筛选出最佳炭化温度后,将该炭材料在2 mol·L−1KOH中浸渍12 h,用超纯水洗至电导率小于2 µS·cm−1,将过滤后的炭材料于60 ℃烘干24 h,并保存在干燥器中。改性后的炭材料命名为KBPS+炭化温度,如KBPS1000。

-

采用比表面积孔隙率分析仪(BET, ASAP 2460, 美国麦克)分析炭材料的比表面积;采用扫描电子显微镜 (SEM, MIRA LMS, 捷克泰思肯)、傅立叶红外光谱仪(FTIR, Nicolet iS20,美国赛默飞世尔)、X 射线粉末衍射仪(XRD, MiniFlex600, 日本微纳)、光电子能谱仪(XPS, K-Alpha, 美国赛默飞世尔)分析炭材料微观形态、官能团、晶体结构和元素组成;采用接触角测量仪 (DSA25,德国克吕士) 分析炭材料浸润性。

-

1)电极制备。以制备的炭材料作为电极材料, PVDF为粘结剂,二者以9∶1的质量比混合,然后将混合物溶于DMAC,搅拌至混合均匀。将此混合物均匀涂覆在接触面尺寸为7 cm×7 cm的钛板上,然后将制备好的炭材料电极置于鼓风干燥箱中于60 ℃烘干12 h,以去除炭材料电极中所残留的DMAC试剂。每对炭材料电极上炭材料的质量约为0.4 g。

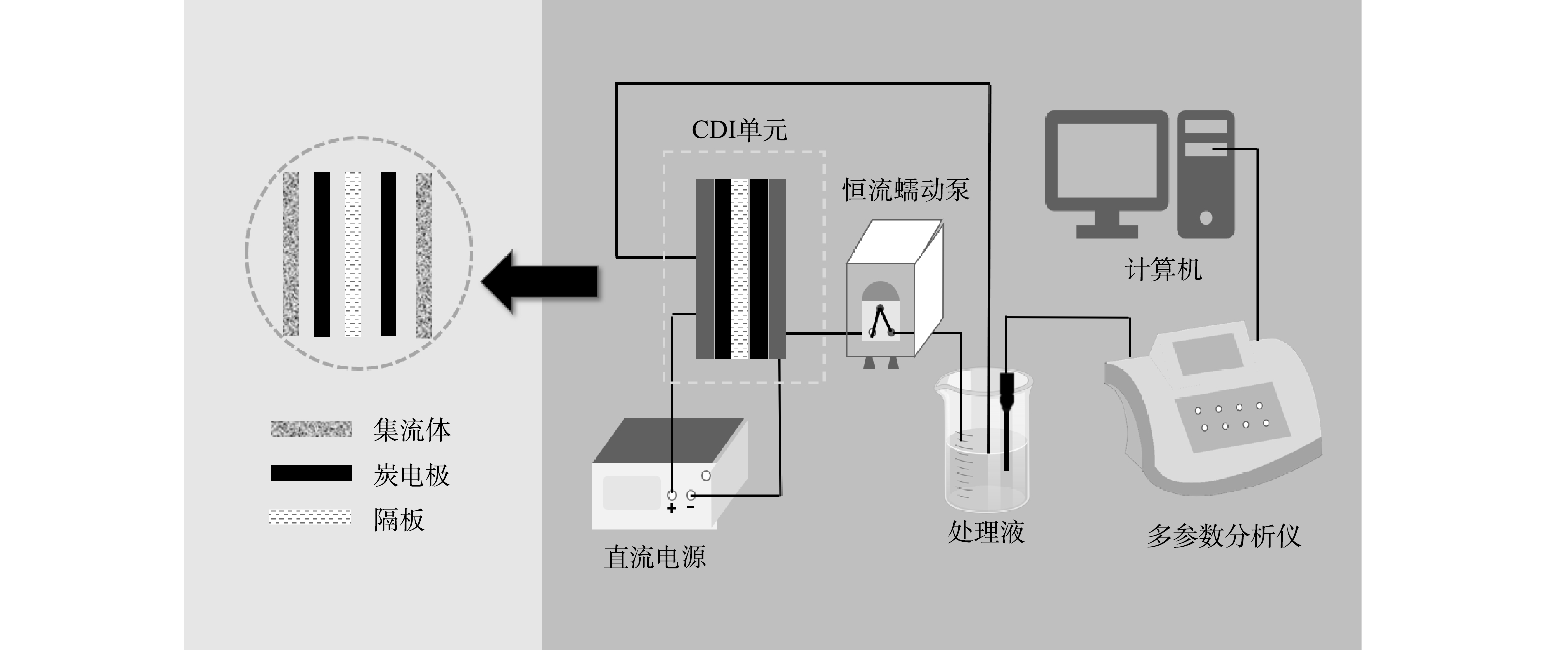

2)CDI装置的组装与运行。电吸附(capacitive deionization,CDI)装置的示意图如图1所示。CDI系统由CDI单元、恒流蠕动泵、直流稳压电源和配备有电导电极的多参数分析仪串联组成,使用电脑监测记录实验过程中电压和电流的变化。在探究KOH改性效果阶段,尝试在CDI单元中加入阴阳离子交换膜以改善脱盐性能。具体操作是在2个涂有炭材料的正、负电极表面分别覆盖一层阴、阳离子交换膜,在直流电场的作用下,使进水的阴阳离子分别通过阴阳离子交换膜,积聚在正负碳电极的表面。

-

溶液为Cl−浓度为500 mg·L−1的NaCl溶液,溶液体积为80 mL。在恒温条件下,以流速10 mL·min−1、电压1.2 V、极板间距3 mm条件进行电吸附实验,按等时间间隔(10 s)监测溶液的电导率值和电流值。实验步骤如下:在不加电压条件下,对Cl−进行吸附直到达到平衡,即电导率值不再变化;在1.2 V电压条件下继续完成吸附实验,直至平衡;移除电压,进行解吸,当电导率值达到平衡后,结束实验。炭材料对氯离子的吸附量可由式(1)计算。

式中:qe为吸附平衡时吸附剂上的吸附量,mg·g−1;c0为溶液初始浓度,mg·L−1;ct为t时刻溶液浓度,mg·L−1;V为溶液体积,mL;m为电极板所使用的炭材料的质量,g。

在极板间距为3 mm、工作电压为1.2 V、溶液流速为10 mL·min−1条件下,对80 mLCl−浓度为为500 mg·L−1的NaCl溶液进行吸附-脱附实验。多次循环后电极再生率根据式(2)进行计算。

式中:ω为电极再生率,%;μz为再生后溶液电导率,μS·cm−1;μ0为溶液初始电导率,μS·cm−1。

-

CDI装置是电流驱动的除盐装置,因此,电耗是运行成本的主要来源。可根据式(3)计算电耗。

式中:E为电耗,kWh·m3;U为工作电压,V;I为工作电流,A;V为处理溶液体积,m3。

-

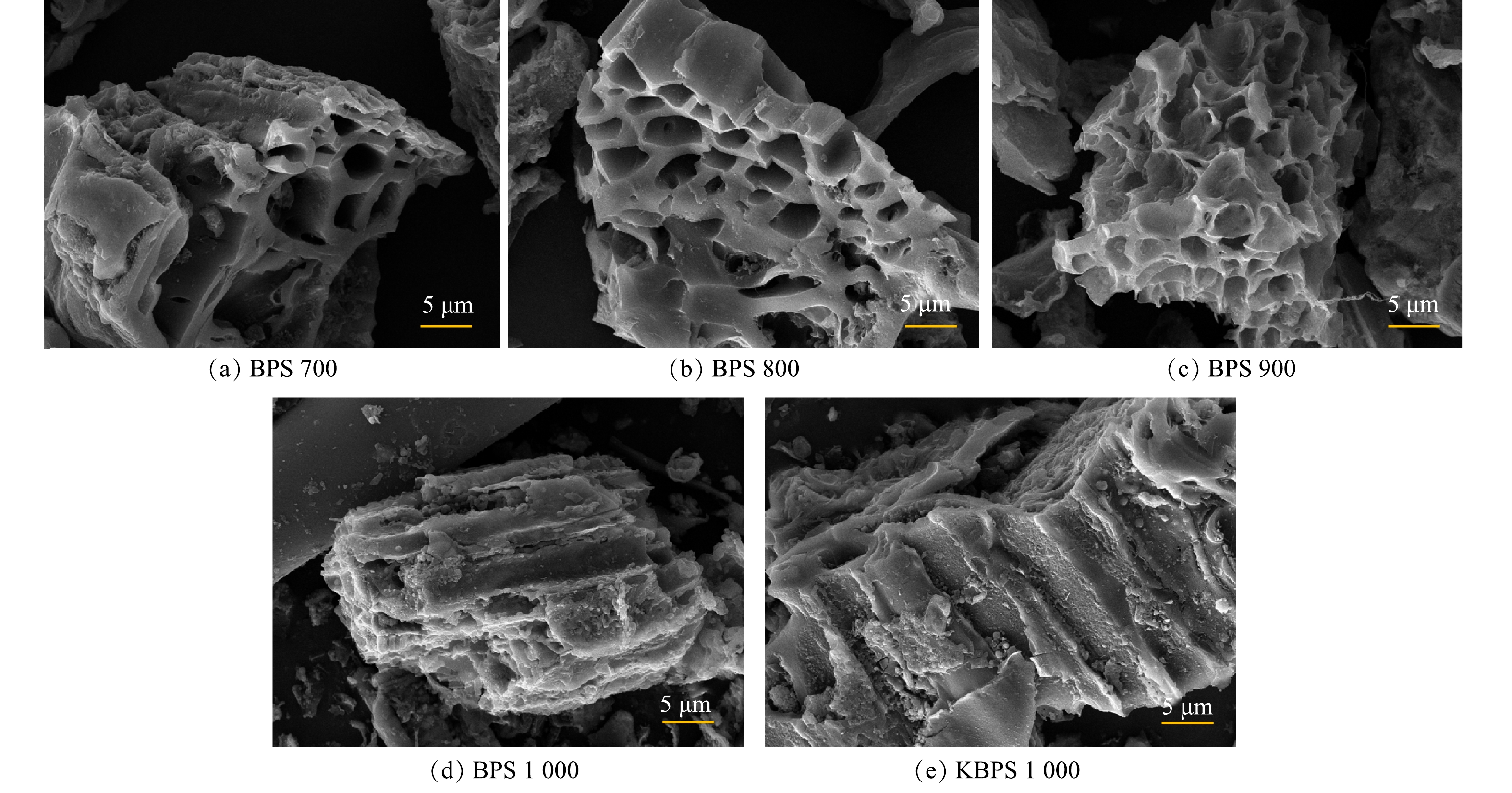

1) SEM/EDS分析 。图2为炭材料的扫描电镜图。如图2所示,各温度下制备的炭材料表面均有丰富的孔隙结构。相比于BPS700和BPS800,BPS900和BPS1000碎片化加剧,BPS1000碎片化尤为明显,断面不平整,呈表面粗糙的柱状或块状。其中BPS700和BPS900表面褶皱程度更高,这与下述BET表征结果相符。与BPS1000相比,KPBS1000表面出现更多褶皱及小颗粒突起,有利于增大炭材料的比表面积。BPS1000和KBPS1000的元素质量分数如表1所示。BPS1000和KBPS1000的最主要组成元素均为C,其次是O,同时含有少量P和S。KBPS1000中C含量由73.4%增加到90.1%,而氧含量由24.9%下降至8.1%,P和S含量占比变化较小。

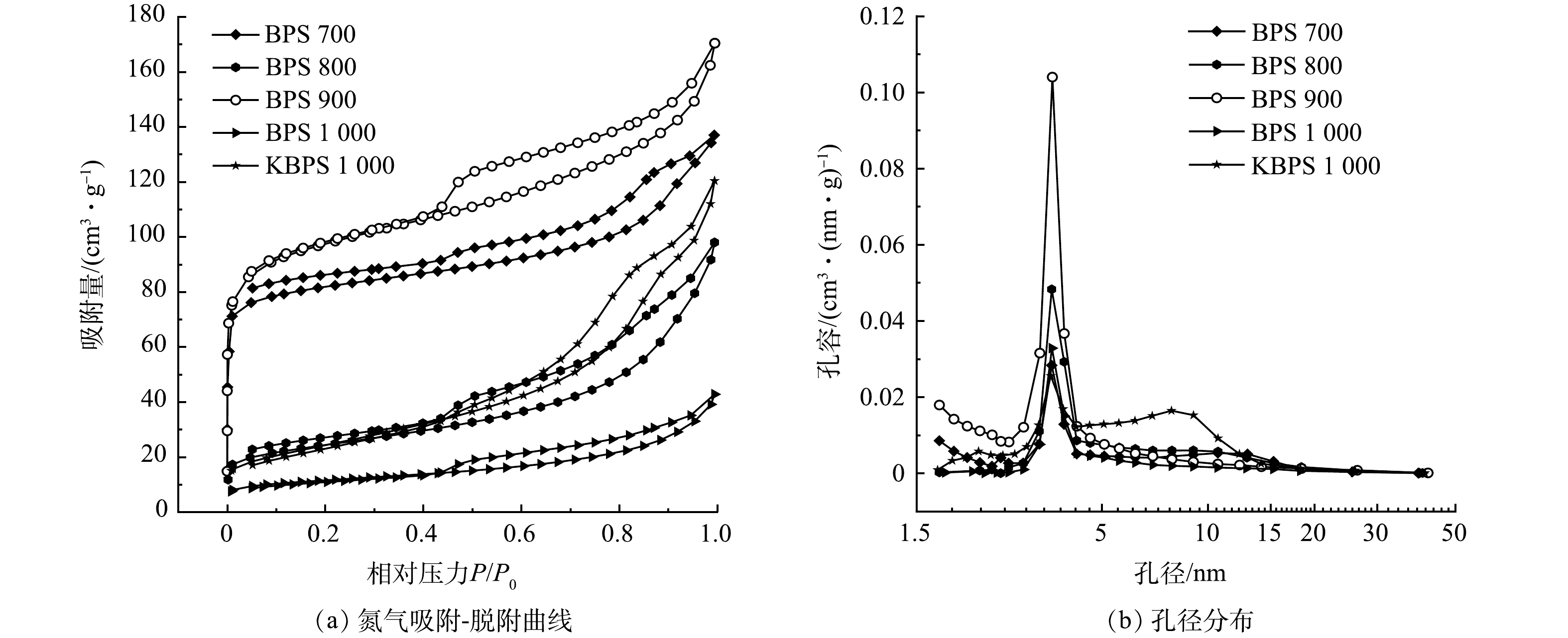

2) BET分析。各炭材料的氮气吸附-脱附曲线和孔径分布见图3。如图3(a)所示,吸附阶段,BPS900和BPS700曲线在低压区吸附曲线上升较快,这是由于样品中含有部分微孔,微孔内吸附力场叠加,吸附势能较高[25]。当P/P0为0.4~1时,各炭材料吸脱附曲线不再重合,出现回滞环,说明炭中含有丰富的介孔[26]。由图3(b)可知,各炭材料的孔径主要为3~5 nm的介孔,BPS700和BPS900存在少量微孔,KBPS1000炭材料中5~10 nm的介孔数明显高于未改性炭材料。各炭材料比表面积、平均孔径及孔容见表2,未改性炭材料比表面积与孔容由大到小依次为BPS900、BPS700、BPS800、BPS1000,孔径大小则恰好相反,这与图3(a)中各样品吸附量结果吻合。在后续实际污染物吸附实验中,各炭化温度下的炭材料吸附能力并未完全遵循此规律,这可能与炭材料的表面化学性质、极性及所带电荷有关[27];而对比KBPS1000和BPS1000,发现KOH改性炭材料的比表面积、平均孔径、孔容均大幅增加,更有利于污染物的吸附。

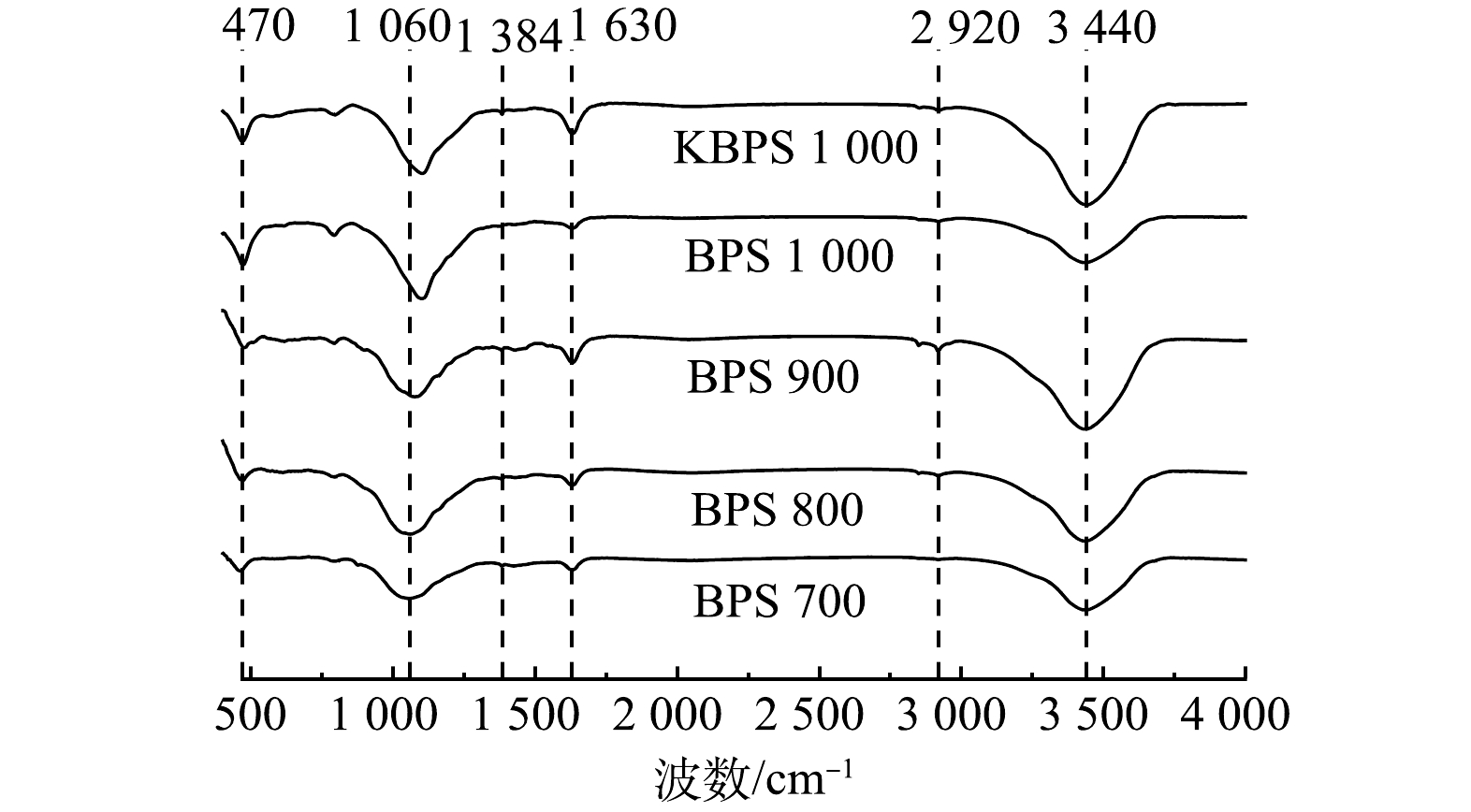

3) FTIR分析。图4为各炭材料的红外光谱图。在3 440 cm−1 、2 920 cm−1处的吸收峰分别对应于羟基吸收峰[28]、亚甲基吸收峰[29],1 630 cm−1、1 060 cm−1处的吸收峰为芳环以及稠环芳烃中C=C、C—O的拉伸振动,1 384 cm−1、470 cm−1处的吸收峰为C—H、C—C弯曲振动。随着温度升高,1 060 cm−1处C—O的拉伸振动增强[30-32],说明炭材料中的官能团逐渐被热解。与BPS1000相比,KBPS1000在1 060 cm−1处C—O的拉伸振动减少,这与KOH促进木质素中醚键的断裂有关[33]。而在3 440 cm−1的羟基吸收峰强度增强[28],表明KBPS1000羟基的含量增加,亲水性增强。KOH改性未改变炭材料表面官能团的种类,说明官能团大部分存在于主体结构中。

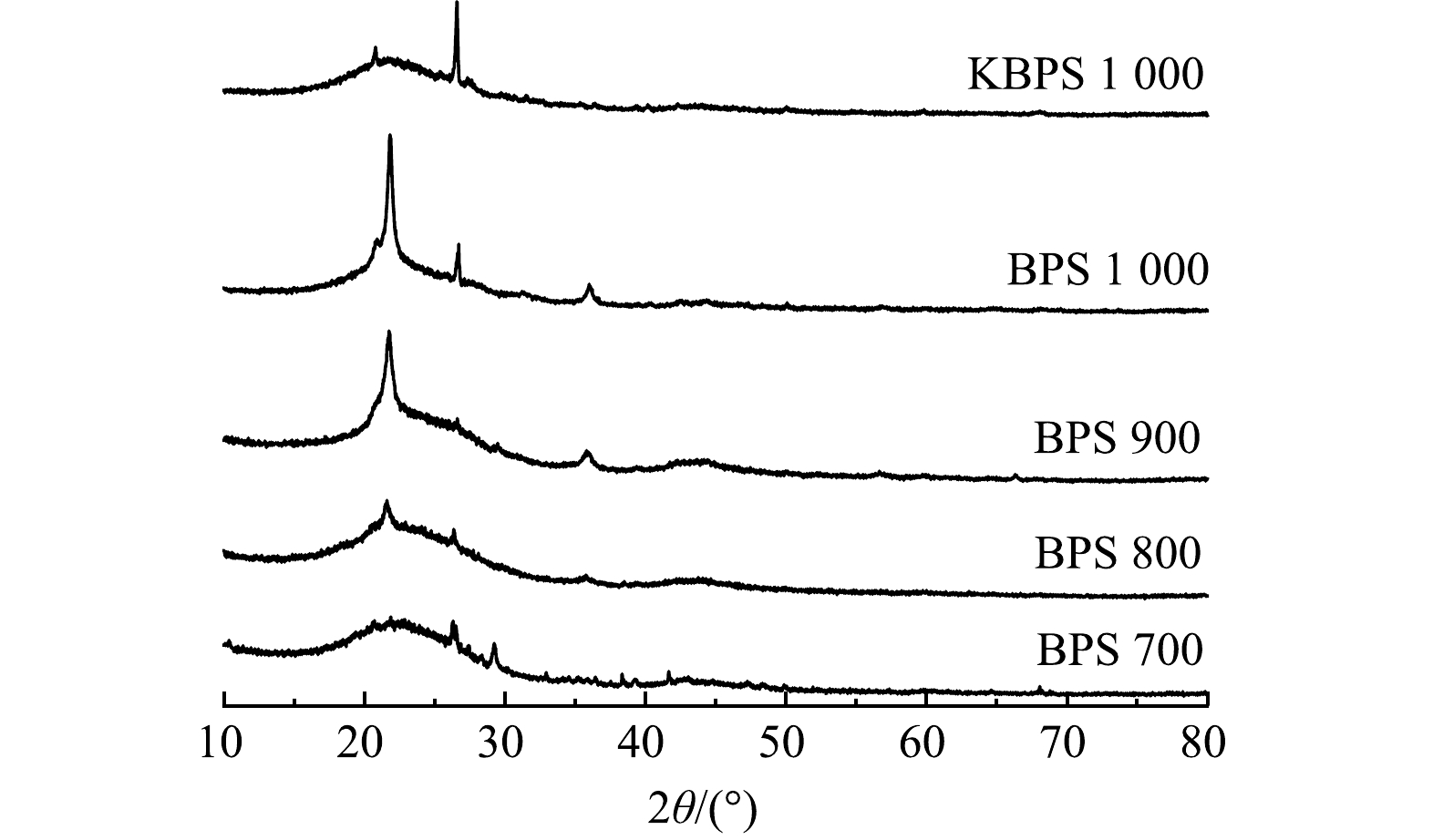

4) XRD分析。图5为各炭材料的XRD谱图。可以看出,各炭材料的XRD谱图大体走势相似,温度升高后其晶能结构无较大变化。2θ=22º左右的衍射峰为炭材料的(002)晶面,对应蜂窝结构的杂化碳原子[34]。2θ=22º左右的宽峰与2θ=26º左右的衍射峰分别对应于无定形的炭结构[35-36]和高度石墨化炭[37]。且随温度升高,2θ=22º处的衍射峰变尖锐且强度明显提高,说明炭材料的石墨化程度进一步增强,有利于导电性的提高[38]。KBPS1000在2θ=22º处的衍射峰强度降低,在2θ=26º左右明显提高,说明改性后炭材料高度石墨化,导电性提高[38]。炭材料在高温处理的石墨化过程中,相邻炭层边缘的部分碳原子发生结合,使乱层结构转变为有序的层状结构。炭层边缘的氢原子被逐步去除,碳氢键的电子保留在碳上,未配对的碳原子通过电子能带跃迁产生正电荷载流子,使炭材料表面电子传递加快[39]。

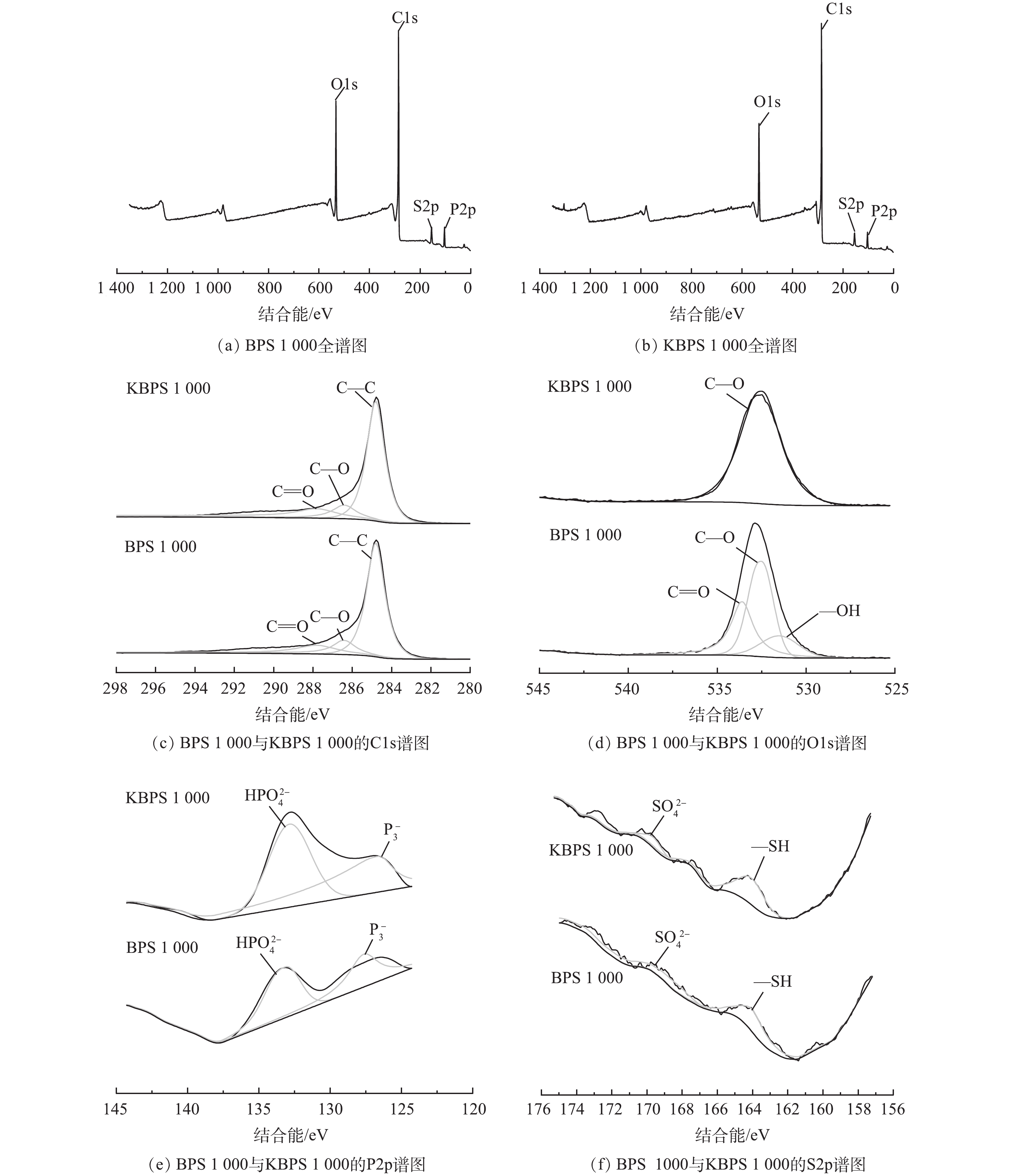

5) XPS分析。图6为BPS1000和KBPS1000的XPS图谱,从图6(a)~(b)中可以看出,BPS1000和KBPS1000中主要存在C、O、P、S元素。C1s分峰拟合结果如图6(c)所示。可见在284.8、286.5、287.8 eV分别对应于C—C、C—O、C=O[40]。此外,可以发现改性后C含量略有增加。对其O1s分峰拟合结果如图6(d),BPS1000在531.5、532.5、533.6 eV分别对应于—OH、C—O、C=O结构[41],而KBPS1000的电子峰只出现在532.5 eV处,对应有机C—O结构[41],且改性后O含量略有降低,这与SEM和EDS分析结果一致。其原因可能是在较高温度下,KOH与炭材料反应生成K2CO3,同时KOH会和某些热解中间体反应,促进其裂解生成气体产物,因此导致炭材料中O减少[42]。对其P2p分峰拟合结果如图6(e)所示,在128.5 eV和132.9 eV分别对应金属磷化物和金属磷酸盐结构[43],改性后P含量变化不大。如图6(f)所示,在169.21 eV和164.0 eV分别对应金属硫酸盐和-SH结构[44-45],改性后S含量变化不大。

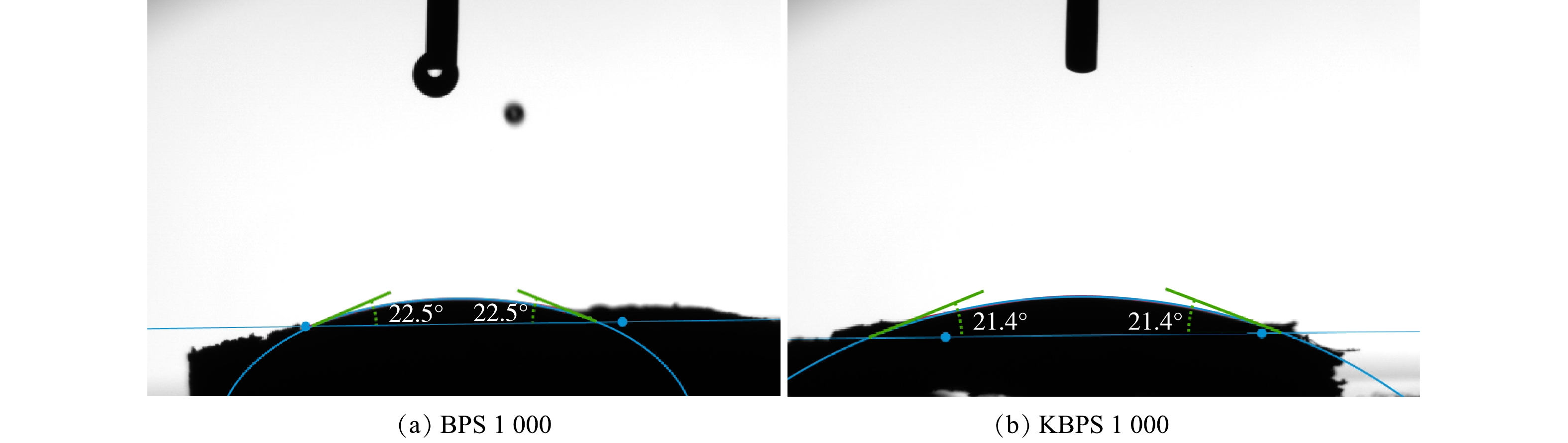

6)接触角分析。图7为BPS1000和KBPS1000的接触角形态图。如图7所示,BPS1000和KBPS1000的接触角都明显低于90度,表现出亲水性,但KBPS1000的接触角角度变小,亲水性更高。说明经KOH改性后炭材料更易被电解液浸润,有利于降低电极与电解液之间的接触电阻,易于吸附带电粒子。

-

图8(a)为BPS700、BPS800、BPS900、BPS1000对Cl−浓度为500 mg·L−1的 NaCl溶液进行电吸附处理的结果。如图8(a)所示,在不加电压的条件下,4种炭材料均具有一定的物理吸附能力,其中BPS1000吸附量最小。结合BET表征结果,BPS1000的比表面积最小,而非电吸附部分主要与生物炭比表面积、孔径等有关。BPS800的比表面积同样较小,但却并未在非电吸附部分与BPS700、BPS900形成差距,其原因可能是BPS800中3~5 nm的介孔较多,利于非电吸附。在1.2 V电压的条件下,BPS1000的电吸附量最大,这是因为随温度升高,炭材料石墨化程度增强,从而使其导电性提高。综合考虑,BPS1000具有最佳吸附性能,故选择1000 ℃下制备改性炭材料KBPS1000。

-

图8(b)为BPS1000和KBPS1000对Cl−浓度为500 mg·L−1的 NaCl溶液进行电吸附处理的结果。在不加电压的条件下,KBPS1000的吸附量相比于BPS1000提高了40.96%,这是因为KOH改性使炭材料比表面积、孔径、孔容等增大,且改性后炭材料5~10 nm的介孔数明显增加,有利于增强非电吸附能力。在1.2 V电压的条件下,BPS1000与KBPS1000吸附能力相当,这是由于改性前后的炭材料均为高度石墨化,且炭材料表面官能团丰富,具有丰富的吸附特性。

-

图8(c)为KBPS1000电极多次吸附-脱附曲线。如图8(c)所示,每个循环电导率下降值均在20~25 μS·cm−1,此部分吸附的Cl−在脱附阶段均能重新解吸在溶液中,但相比于第1个循环,第2~9个循环过程平衡时间变长。9次循环后,计算电极再生率为98.41%,原因是第1次循环中有部分因非电吸附被吸附到电极上的Cl−无法通过反接电极的方式脱附,但从整体效果来看,KBPS1000电极的循环再生能力稳定。

-

极板间距、工作电压、溶液流速和溶液初始浓度是影响电吸附效果的重要因素。其中,极板间距影响CDI系统内阻大小。缩短极板间距可减小系统内阻,使电流增大,电吸附能力增强。然而,在流量一定的情况下,极板间距过小会导致溶液流速过高,不利于电吸附[46]。故选用3 mm作为极板间距,采用单因素实验探究工作电压、溶液流速和溶液初始浓度等运行参数对除盐效果的影响,并进行CDI系统最佳运行条件的确定。该部分实验中电极均为一对,溶液体积均为80 mL。

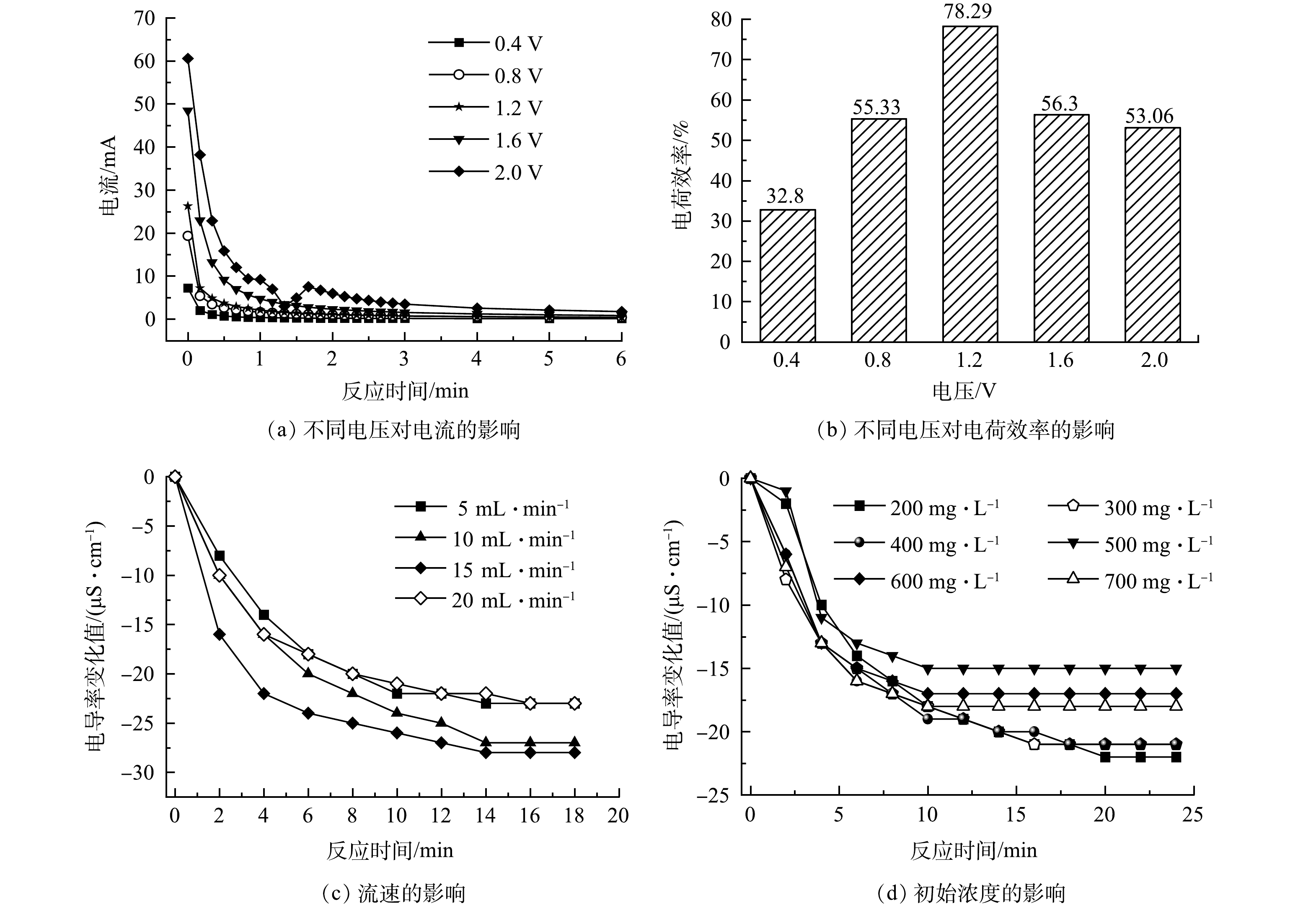

1)电压优化。图9(a)~(b)为不同电压下的电流变化和电荷效率。从图9(a)可以看出,随电极两端施加的工作电压增大,电流也随之增大,即溶液中离子移动增加,Cl−去除率逐渐升高。根据平板电容器理论,电极所带电荷与施加电压呈正相关,电压越大,极板所带电荷越多,电极板与溶液界面形成的双电层结构越厚,离子吸附量随之增加[47]。虽然Cl−去除效果随电压升高得到有效提升,但电荷效率随工作电压增大,呈现先升高后降低的趋势,且在工作电压为1.2 V处达到最高。综合考虑,选择1.2 V为最佳工作电压。

2)流速优化。图9(c)为不同流速对KBPS1000电吸附效果的影响,可以看出,18 min后实验均达到吸附平衡。流速为5、10、15、20 mL·min−1时,溶液电导率分别下降23、27、28、23 μS·cm−1,在15 mL·min−1时电导率下降值最高。不同流速还会影响溶液的电吸附速率。电吸附速率可由电导率变化速率体现,从图9(c)中可看出,流速为15 mL·min−1时,曲线的斜率最大,即电吸附速率最快。综合考虑,选择15 mL·min−1为最佳溶液流速。

3)初始浓度对CDI系统的影响。图9(d)为溶液初始浓度对KBPS1000电吸附效果的影响,可以看出,当初始浓度较低时,其电吸附效果比浓度较高时更佳。此外初始浓度越高,电吸附平衡时间越短,这是因为在电压一定时,溶液和电极表面的浓度差与初始浓度成正比,初始浓度越大,离子被吸附可能性越大[48]。同时因存在静电引力,Cl−被快速压缩,在极板间形成的双电层结构变得更紧密,更易被电极捕捉吸附,因此电极对Cl−的吸附速率随之提升,电吸附平衡时间缩短。

-

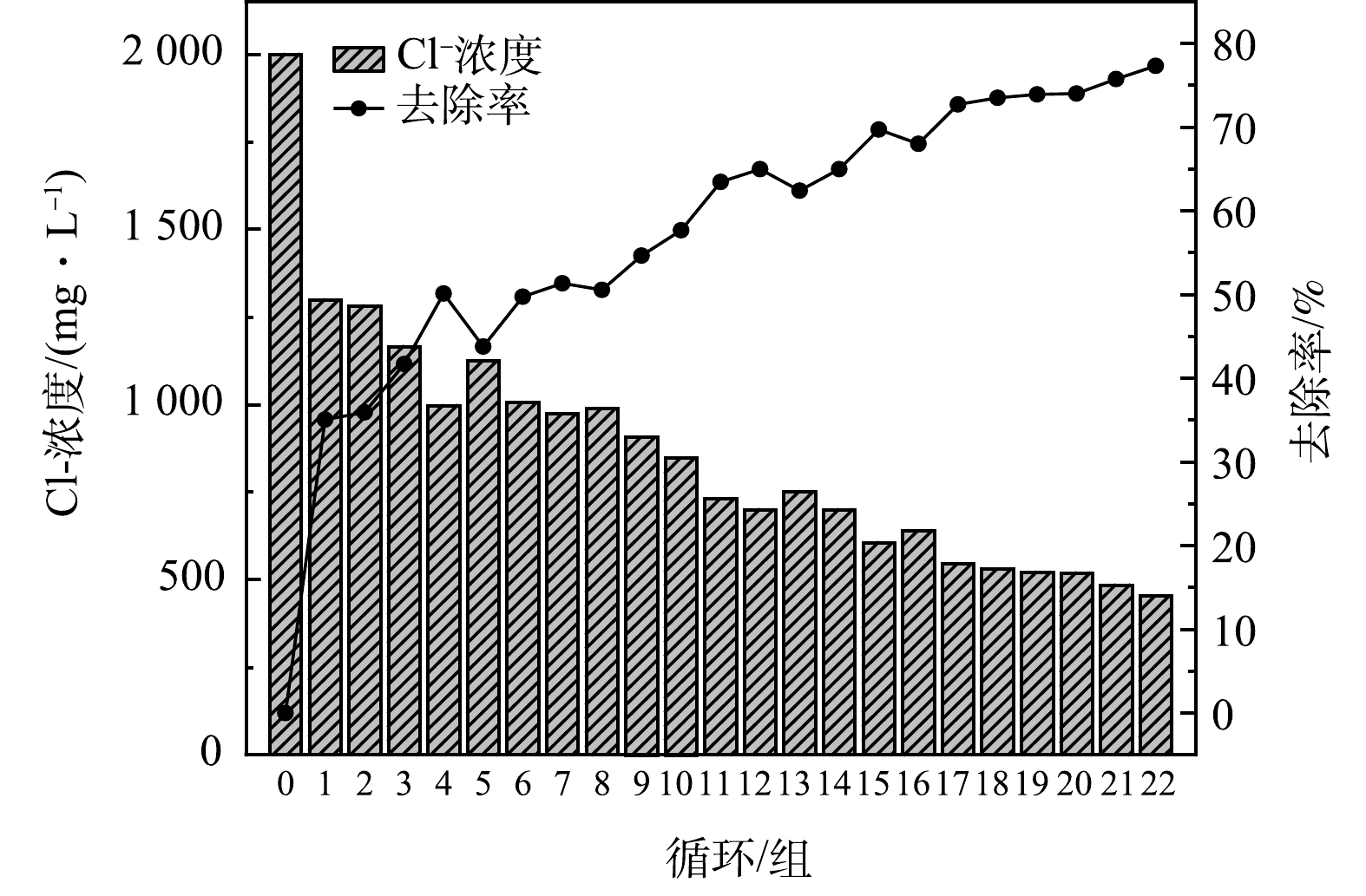

经前期调研,青岛某沿海污水处理厂尾水电导率为6.26 mS·cm−1,Cl−浓度为2 058 mg·L−1。配制Cl−浓度为2 000 mg·L−1的NaCl溶液,以5对电极板为一组循环,在最优条件下进行电吸附实验,结果如图10所示。实验结果表明,CDI系统对于高盐溶液有较好的吸附效果,经过22组循环后,Cl−浓度可降至454 mg·L−1,Cl−去除率可达77.3%。根据污水排入城镇下水道水质标准(GB_T 31962-2015),氯化物排放A级标准限值为500 mg·L−1,即处理后水质已达到氯化物排放的A级标准。试验过程中通过台式数字万用表记录22个循环过程中的电流,根据式(3)计算出整个过程总能耗为0.4 kWh·m3。目前大工业电价为0.6 元·kWh−1,计算出处理成本为0.24 元·m3。

-

1)电吸附实验结果表明,BPS700、BPS800、BPS900、BPS1000吸附量分别为0.575、0.328、0.328、1.806 mg·g−1,即BPS1000吸附性能最佳。表征结果证实,BPS1000具有丰富的孔隙结构,且石墨化程度最高。

2)与BPS1000相比,改性后KBPS1000吸附量提升了30%。经KOH改性后,炭材料比表面积、孔径、孔容均有增加,表面元素分布更加均匀,石墨化程度和亲水性增加。KBPS1000电极9次循环后,电极再生率为98.41%,再生性能稳定。

3)基于KBPS1000电极构建的CDI系统的最佳工作条件为极板间距3 mm,电压1.2 V,溶液流速15 mL·min−1。将优化后的CDI系统用于对实际尾水浓度Cl−的去除,以5对电极板为一组循环,经过22组循环后,Cl−浓度由2 000mg·L−1下降至454 mg·L−1,Cl−去除率可达77.3%。处理过程能耗为0.4 kWh·m3,每吨水处理成本为0.24元。

改性花生壳炭电极的电容去离子技术对高盐尾水中Cl−的去除性能

Cl− removal performance from high salt tailwater by capacitive deionization based on modified peanut shell carbon electrode and its application

-

摘要: 以废弃花生壳为原料,探究了炭化条件和KOH改性对炭材料电吸附性能的影响。利用电容去离子(capacitive deionization, CDI)技术,探究KOH改性炭电极(KBPS)对于青岛污水处理厂高盐尾水中Cl−的去除效果。通过SEM、BET、FTIR、XRD、XPS、接触角手段对炭材料理化性质进行了表征。结果表明,随炭化温度增高,炭材料石墨化程度与有序度提升。KOH改性可改善炭材料的比表面积、石墨化程度和亲水性。电吸附实验结果表明,在1 000 ℃下炭化的KOH改性炭电极(KBPS1000)吸附量为11.097 mg·g−1,相比BPS1000提升了30%。在溶液流速为15 mL·min−1、工作电压为1.2 V时KBPS1000的电吸附性能最佳。经过9次吸附-脱附循环后,KBPS1000电极再生率为98.41%,电极再生性能稳定。配制Cl−浓度为2 000 mg·L−1的NaCl溶液,以5对电极板为一组循环,经22组循环后,Cl−浓度由2 000 mg·L−1降至454 mg·L−1,Cl−去除率可达77.3%。Abstract: In this study, the effects of carbonization conditions and KOH modification on the electroabsorption performance of carbon materials were investigated using waste peanut shells as raw materials. Capacitive deionization (CDI) was used to investigate the effect of KOH-modified carbon electrode (KBPS) on the removal of Cl− from the high-salt tailwater of Qingdao wastewater treatment plant. The physical and chemical properties of the carbon materials were characterized by SEM, BET, FTIR, XRD, XPS and contact angle. The result showed that the graphitization and orderliness of the carbon materials increased with the increase of carbonization temperature. The KOH modification improved the specific surface area, graphitization and hydrophilicity of the carbon material. The electrosorption experiments showed that the adsorption capacity of KOH modified carbon electrode KBPS1000 carbonized at 1000 ℃ was 11.097 mg·g−1, which was 30% over that of BPS1000. The best electrosorption performance was achieved at a solution flow rate of 15 mL·min−1 and an operating voltage of 1.2 V. After nine adsorption-desorption cycles, the regeneration rate of KBPS1000 electrode was 98.41%, and the electrode regeneration performance was stable. The NaCl solution with Cl− concentration of 2000 mg·L−1 was prepared, and a set of cycle was performed using 5 pairs of electrodes, the Cl− concentration could decrease from 2 000 mg·L−1 to 454 mg·g−1 after 22 sets of cycles, and the Cl− removal rate could reach 77.3%.

-

-

表 1 BPS1000和KBPS1000中主要元素的质量分数

Table 1. Content of main elements in BPS1000 and KBPS1000

样品 C/% O/% P/% S/% BPS1000 73.4 24.9 1.5 0.3 KBPS1000 90.1 8.1 1.6 0.2 表 2 炭材料的比表面积、平均孔径及孔容

Table 2. Specific surface area, average pore size and pore volume of carbon materials

样品 比表面积/(m2·g−1) 平均孔径/nm 孔容/(cm3·g−1) BPS700 308.02 2.62 0.196 3 BPS800 84.77 6.28 0.121 4 BPS900 354.96 2.72 0.229 7 BPS1000 40.04 5.53 0.050 3 KBPS1000 85.73 7.57 0.151 8 -

[1] JOHIR M A H. Effect of salt concentration on membrane bioreactor(MBR) performances: Detailed organic characterization[J]. Desalination, 2013, 322: 13-20. doi: 10.1016/j.desal.2013.04.025 [2] 张磊. IAMBR处理高盐污水的效能及其微生物群落结构分析[J]. 膜科学与技术, 2020, 40(5): 101-110. [3] LIANG Y X, ZHU H, BANUELOS G, et al. Removal of nutrients in saline wastewater using constructed wetlands: Plant species, influent loads and salinity levels as influencing factors[J]. Chemosphere, 2017, 187: 52-61. doi: 10.1016/j.chemosphere.2017.08.087 [4] 滕丽. VR技术在含盐废水处理领域的运用策略[J]. 环境与发展, 2020, 32(11): 75-76. [5] 武超, 梁鹏飞, 张冲, 等. MVR技术处理高盐废水应用进展[J]. 化学工程与装备, 2020(2): 202-203. [6] 伊学农, 夏翰生, 王晨, 等. 生物膜厌氧折流板反应器处理高盐有机废水研究[J]. 化工设计通讯, 2020, 46(3): 256-258. doi: 10.3969/j.issn.1003-6490.2020.03.167 [7] 林玉科, 张洁, 吴志国, 等. MBR污泥驯化和在高盐废水处理中的应用[J]. 膜科学与技术, 2017, 37(4): 86-92+99. [8] 张宇坤, 王淑莹, 董怡君, 等. NaCl盐度对氨氧化细菌活性的影响及动力学特性[J]. 中国环境科学, 2014, 35(2): 465-470. [9] LI Z, SONG B, WU Z, et al. 3D porous graghene with ultrahigh surface area for microscale capacitive deionization[J]. Nano Energy, 2015, 11: 711-718. doi: 10.1016/j.nanoen.2014.11.018 [10] 吕晓丽, 肖荣林, 吴浩波, 等. 炭电极电容去离子技术研究进展[J]. 水处理技术, 2020, 46(8): 17-21+33. [11] WANG J, WANG Y X. Progress in Research on electroadsorption desalination technology[J]. Chemical Enterprise Management, 2019(10): 97-98. [12] 张思韬, 韩严和, 张晓飞, 陈家庆. 用于处理工业废水的电极材料研究进展[J]. 工业水处理, 2019, 39(11): 1-6+57. [13] LI X H, LI H Y, XU X J, et al. Preparation of a Reduced Graphene Oxide @ Stainless Steel Net Electrode and Its Application of Electrochemical Removal Pb(II)[J]. Chemical Engineering Journal, 2015, 271: 252-259. doi: 10.1016/j.cej.2015.03.001 [14] ZOU Y, WANG Y, WU F, et al. Controllable synthesis of Ca-Mg-Al layered double hydroxides and calcined layered double oxides for the efficient removal of U(VI) from wastewater solutions[J]. ACS Sustainable Chemistry & Engineering, 2017, 5: 1173-1185. [15] LEI C, ZHU X, ZHU B, et al. Superb adsorption capacity of hierarchical calcined Ni/Mg/Al layered double hydroxides for Congo red and Cr(VI) ions[J]. Journal of Hazardous Materials, 2017, 321: 801-811. doi: 10.1016/j.jhazmat.2016.09.070 [16] YADAV M S. Metal oxides nanostructure-based electrode materials for supercapacitor application[J]. Journal of Nanoparticle Research, 2020, 22(12): 1-18. [17] 卞维柏, 潘建明. 电吸附技术及吸附电极材料研究进展[J]. 化工学报, 2021, 72(1): 304-319. [18] TAN X, LIU Y, ZENG G, et al. Application of carbon materials for the removal of pollutants from aqueous solutions[J]. Chemosphere, 2015, 125: 70-85. doi: 10.1016/j.chemosphere.2014.12.058 [19] 宋香琳, 李亚科, 李栋, 等. 花生壳生物炭的改性及其吸附Pb2+性能研究[J]. 生物质化学工程, 2022, 56(6): 43-50. doi: 10.3969/j.issn.1673-5854.2022.06.007 [20] 吴鸿伟, 陈萌, 黄贤金, 等. 改性炭材料对水体中头孢噻肟的吸附机制[J]. 中国环境科学, 2018, 38(7): 2527-2534. doi: 10.3969/j.issn.1000-6923.2018.07.018 [21] CHEN W, GONG M, LI K X, et al. Insight into KOH activation mechanism during biomass pyrolysis: Chemical reactions between O-containing groups and KOH[J]. Applied Energy, 2020, 278: 115730. doi: 10.1016/j.apenergy.2020.115730 [22] JIN H M, HANIF M U, CAPAREDA S, et al. Copper(Ⅱ) removal potential from aqueous solution by pyrolysis carbon materials derived from anaerobically digested algae-dairy-manure and effect of KOH activation[J]. Journal of Environmental Chemical Engineering, 2016, 4(1): 365-372. doi: 10.1016/j.jece.2015.11.022 [23] 钟来元, 廖荣骏, 刘付宇杰, 等. KOH改性花生壳生物炭对盐酸四环素的吸附性能及其机理[J/OL]. 农业环境科学学报: 1-15[2023-07-26]. http://kns.cnki.net/kcms/detail/12.1347.S.20230630.1331.002.html. [24] 张学杨, 徐浩亮, 戴欢涛, 等. 微波辐照木质素浸渍生物炭吸附CO2性能[J/OL]. 中国环境科学: 1-11 [2023-07-26].https://doi.org/10.19674/j.cnki.issn1000-6923.20230327.001. [25] HAN J L, CHEN K, WU B, et al. Preparation of mesoporous magnetic composite carbon spheres with high adsorption properties[J]. Fine Chemicals, 2020, 37(4): 689-695,709. [26] LU W, ZHANG S P, LIU X Z, et al. Effects of pretreatment methods on properties of activated carbon from rice husk[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(S1): 157-163. [27] 王炯, 张品, 张舒晴, 等. 温度对秸秆炭材料理化特性和电化学特性的影响[J]. 太阳能学报, 2022, 43(5): 399-404. [28] CHEN B L, ZHOU D D, ZHU L Z. Transitional adsorption and partition of nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperatures[J]. Environmental Science and Technology, 2008, 42(14): 5137-5143. doi: 10.1021/es8002684 [29] LI Y C, SHAO J G, WANG X H, et al. Characterization of modified biochars derived from bamboo pyrolysis and their utilization for target component (furfural) adsorption[J]. Energy Fuels, 2014, 28(8): 5119-5127. doi: 10.1021/ef500725c [30] CHEN B, JOHNSON E J, CHEFETZ B, et al. Sorption of polar and nonpolar aromatic organic contaminants by plant cuticular materials: The role of polarity and accessibility[J] Environmental Science and Technology, 2005, 39(16): 6138-6146. [31] BOGUTA P, SOKOLOWSKA Z, SKIC K, et al. Chemically engineered carbon materials- effect of concentration and type of modifier on sorption and structural properties of carbon materials from wood waste[J]. Fuel, 2019, 256: 115893. doi: 10.1016/j.fuel.2019.115893 [32] 张继义, 李金涛, 鲁华涛, 等. 小麦秸秆生物碳质吸附剂从水中吸附硝基苯的机理[J]. 环境科学研究, 2012, 25(3): 333-339. doi: 10.13198/j.res.2012.03.92.zhangjy.015 [33] HUANG H, TANG J C, GAO K, et al. Characterization of KOH modified biochars from different pyrolysis temperatures and enhanced adsorption of antibiotics[J]. RSC Advances, 2017, 24(7): 14640-14648. [34] 李博文, 汪若蘅, 黎丽, 等. 碱活化多孔碳用于分离甲苯及活化/吸附机理[J]. 高等学校化学学报, 2020, 41(2): 284-292. doi: 10.7503/cjcu20190496 [35] QIE L, CHEN W M, WANG Z H, et al. Nitrogen-doped porous carbon nanofiber webs as anodes for lithium ion batteries with a superhigh capacity and rate capability[J]. Advanced Materials, 2012, 24(15): 2047-2050. doi: 10.1002/adma.201104634 [36] DAI Y J, LI J J, SHAN D X. Adsorption of tetracycline in aqueous solution by carbon materials derived from waste Auricularia auricula dregs[J]. Chemosphere, 2020, 238: 124432-124439. doi: 10.1016/j.chemosphere.2019.124432 [37] RAMAMOORTHY M, RAGUPATHY S, SAKTHI D, et al. Synthesis of SnO2 loaded on corn cob activated carbon for enhancing the photodegradation of methylene blue under sunlight irradiation[J]. Journal of Environmental Chemical Engineering, 2020, 8(5): 104331. doi: 10.1016/j.jece.2020.104331 [38] NIU P, WANG P, XU Y, et al. Tuning the electronic conductivity of porous nitrogen-doped carbon nanofibers with graphene for high-performance potassium-ion storage[J]. Inorganic Chemistry frontiers, 2021, 8: 3926-3933. doi: 10.1039/D1QI00664A [39] BARROSO B A. Understanding and tuning the electrical conductivity of activated carbon: A state-of-the-art review[J]. Critical Reviews in Solid State and Materials Sciences, 2019, 46: 1-37. [40] 徐琰. 柠檬酸改性炭材料表征特性及其对亚甲基蓝吸附性能研究[D]. 长沙: 湖南大学, 2017. [41] 张婧懿. 花生壳炭材料电极制备和水处理电化学性能[D]. 武汉: 中南民族大学, 2019. [42] WILLIAMS E N, NUR P A. KOH modified Thevetia peruviana shell activated carbon for sorption of dimethoate from aqueous solution[J]. Journal of environmental science and health. Part B, Pesticides, food contaminants, and agricultural wastes, 2008, 54(1): 1-13. [43] 崔蒙蒙. 水铁矿对含磷废水的吸附性能及机理分析[D]. 苏州: 苏州科技大学, 2017. [44] 陈鹏. 应用XPS研究煤中有机硫在脱硫时的存在形态[J]. 洁净煤技术, 1997(2): 17-20. doi: 10.13226/j.issn.1006-6772.1997.02.003 [45] PIETRZAK R, WACHOWSKA H. The influence of oxidation with HNO3 on the surface composition of high sulphur coals XPS study[J]. Fuel Process Technology, 2006, 87(11): 1021-1029. doi: 10.1016/j.fuproc.2006.08.001 [46] DU Z Y, TIAN W J, QIAO K L, et al. Improved chlorine and chromium ion removal from leather processing wastewater by biocharcoal-based capacitive deionization[J]. Separation and Purification Technology, 2020(233): 116024. [47] 温萍, 刘圣勇, 王炯等. 乙酸锌改性稻壳炭材料电容及电吸附Cu2+性能[J]. 精细化工, 2023, 40(4): 902-910. [48] 曾茶菊. 电场作用下重金属Cu(Ⅱ)在生物炭上的吸附和解吸[D]. 上海: 上海大学, 2021. -

下载:

下载: