-

好氧颗粒污泥表面光滑、边界清晰、结构密实,且沉降性能良好[1-2],对污染物有良好的去除效果[3]。好氧颗粒污泥性能的影响因素包括有机负荷、表观上升气流速度、沉降时间、进水水质、碱度等[4-5]。好氧颗粒污泥的形成过程实际上是絮体污泥结构和性能的转变过程,可利用数学模型来进行解析。已有学者将研究数据与数学模型相结合,对好氧污泥颗粒化过程的影响因素[6-9]和运行参数[10-11],以及其相互关系进行了深入分析,为预测好氧污泥颗粒化的过程提供了思路。

好氧污泥颗粒化过程与微生物的增长、有机物的降解、溶解氧的消耗和氮等营养物质的迁移转化过程密不可分。可通过建立好氧颗粒污泥生物动力学模型来分析这些过程的反应速率及其相互影响关系。为准确有效地模拟计算各生物反应过程及其速率,除去初始营养物质和污泥浓度外,反应过程中各动力学参数和化学计量参数的确定显得尤为重要[12]。SU等[13-14]、NI等[15]、倪丙杰[16]、ZHOU等[17]对成熟稳定期好氧颗粒污泥的动力学参数和化学计量参数进行了测定,并以修订的活性污泥三号模型(Activated Sludge Modeling 3,ASM3)为基础,模拟分析了好氧颗粒污泥的增长过程后发现,ASM3模型模拟结果与实验结果相符合。然而,好氧污泥颗粒化是絮体污泥结构和性能的转变过程,污泥颗粒化过程中有关微生物增长的研究尚未见报道,且此过程中不同表观气速对动力学参数和化学计量参数的影响也尚不清楚。

反应器内形成螺旋上升的小尺度漩涡有利于好氧污泥颗粒化,而反应器内流态的发展与表观气速大小相关[18-19]。当反应器内的表观气速为2.0~4.0 cm·s−1时,可形成结构稳定的好氧颗粒污泥。当表观气速3.0 cm·s−1时,反应器内的漩涡尺度与2.0 cm·s−1时相比,量级变化均匀,有利于颗粒污泥的快速生长。基于此,为考察表观气速对动力学参数和化学计量参数的影响,本研究建立2个高径比120/6、结构相同的鼓泡序批式反应器(sequencing batch reactor, SBR),分别在表观气速为2.0 cm·s−1和3.0 cm·s−1的条件下培养好氧颗粒污泥,并对好氧颗粒污泥形成过程中(t=4 d、10 d、16 d、22 d、28 d、35 d)的动力学参数、化学计量参数、溶解氧(DO)、好氧速率(OUR)等参数的变化,以及化学需氧量(COD)、氨氮(NH4+-N)的降解过程进行检测,从而分析不同表观气速对好氧污泥颗粒化生物动力学过程的影响,利用修订ASM3模型作为基础模拟好氧颗粒污泥的增长过程,以期为进一步完善好氧污泥颗粒化模型提供参考。

-

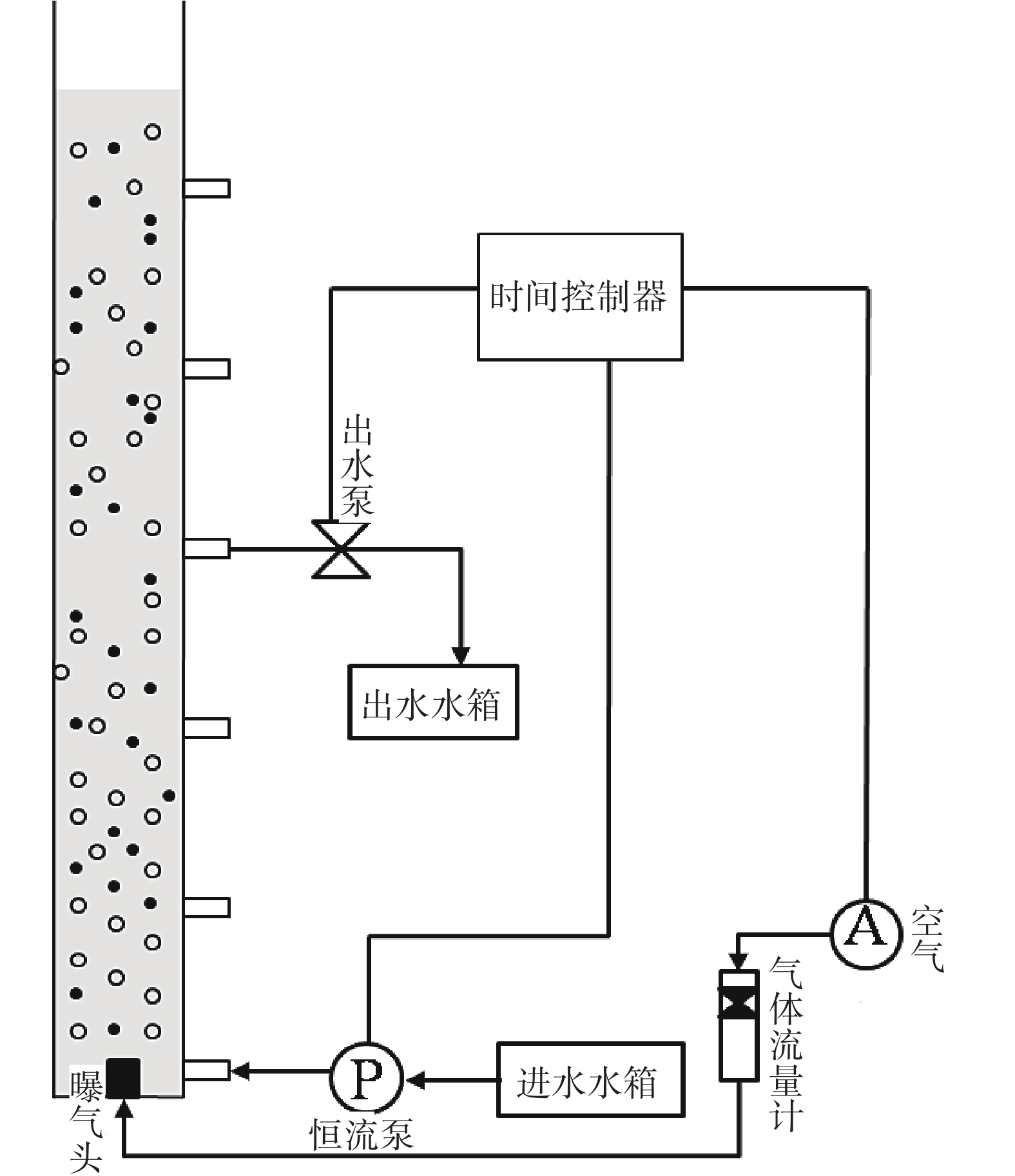

采用2个结构尺寸相同的SBR反应器(图1),材质为有机玻璃。反应器的有效水深1.2 m,内径0.06 m,高径比为20,有效体积为3.4 L,体积交换率为50%。在整个反应器运行过程中,利用时间控制器进行自动控制,系统温度维持在22~25 ˚C。反应器内pH维持在(7.0±0.2)。好氧颗粒污泥培养过程中,每天按8个周期运行,每个周期3 h。其中,进水2 min;曝气时间155~172 min;沉降时间由20 min逐渐降至3 min;出水2 min;其余时间闲置。污泥龄维持在6 d。曝气头设在反应器底部。通过气体转子流量计使反应器内的曝气量分别维持在200 L·h−1(表观气速(superficial gas velocity,SGV) =2.0 cm·s−1)和300 L·h−1 (SGV=3.0 cm·s−1)。

-

取西安市第四污水处理厂好氧池末端污泥作为接种污泥进行好氧颗粒污泥的培养。实验进水为人工配制的模拟废水,分别以无水乙酸钠为碳源、氯化铵为氮源、磷酸二氢钾为磷源。各营养元素的配比参考文献[20]。

-

DO采用便携式溶解氧仪(HACH-HQ40d)测定。COD和NH4+-N分别采用重铬酸钾法和钠式试剂光度法测定。污泥沉降比(SV5和SV30)采用沉降法,在100 mL的量筒中测定[21]。好氧污泥颗粒化过程中,污泥的均值粒径采用激光粒度仪(LS230/SVM, Beckman, USA)测定,粒径测定范围为0~2 000 μm;污泥形态变化由电子显微镜(Nikon ECLIPSE 50i, Japan)测定;颗粒污泥的微观结构采用扫描电子显微镜(Scanning Electron Microscope, SEM, JSM-6510LV)观察分析。好氧污泥颗粒化过程中,污泥的密实度(D2)和规则程度(Dpf)参考文献[20]的方法进行测定和计算。

-

基质降解动力学参数的检测方法同样参考文献[20]。以乙酸钠作为碳源,取40 mL好氧污泥颗粒化过程中的污泥,使其置于500 mL锥形瓶中,同时加入200 mL不同COD的模拟废水。在充分曝气1 h后,测定出水COD[20]。在反应系统中,基质的降解速率与好氧颗粒污泥微生物量及基质的浓度密切相关,其表达式类似于Monod方程,见式(1)。

式中:v为比降解速率,h−1;vmax为最大比降解速率,h−1;Ks为半饱和常数(以COD表征),g·m−3;S为基质浓度,mg·L−1。

根据比降解速率的定义可得式(2)。

式中:S0为基质的起始浓度,mg·L−1;Se为反应器运行时间t后基质的出水质量浓度,mg·L−1;Xt为微生物质量浓度,mg·L−1。

对式(1)取倒数,并将式(2)代入,得到式(3)。

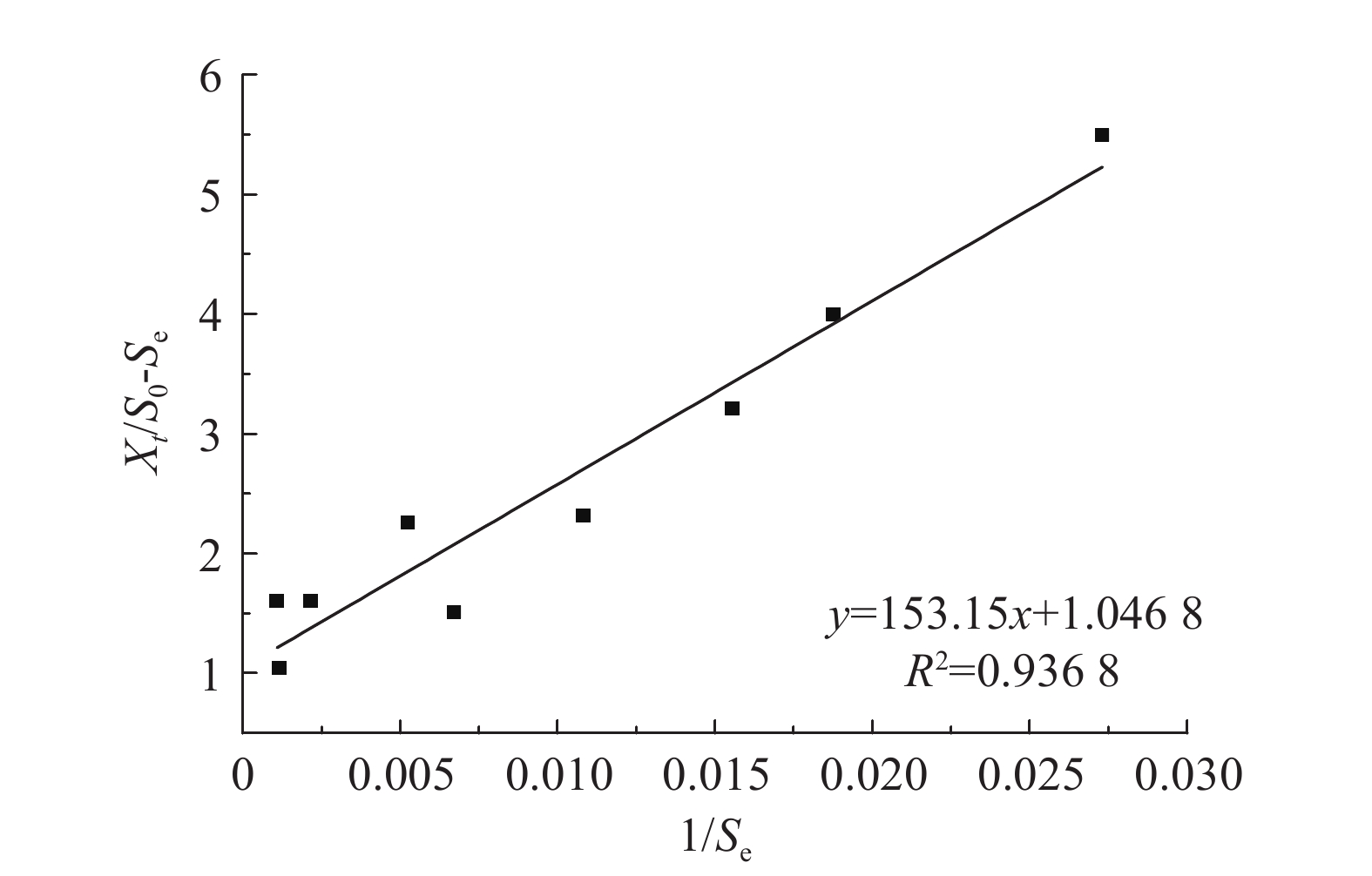

根据式(3),以1/Se和Xt/S0-Se分别为横坐标x和纵坐标y对监测得到的数据进行线性拟合,结果见图2。此时,直线斜率为Ks/vmax,截距为1/vmax。由此计算出vmax和Ks。

衰减速率的检测方法同样参考文献[20]。在微生物反应过程中,当外源底物耗尽后,微生物进入内源呼吸阶段。此时,微生物随时间的变化可表示为式(4)。

式中:X为活性微生物的质量浓度,mg·L−1;Kd为一级衰减速率常数,d−1;t为时间,d。

内源代谢阶段,只有微生物体自身氧化引起氧的消耗。耗氧速率可表示为式(5)。

式中:fvc为氧化单位重量污泥VSS所消耗的氧气当量,g·g−1。

对式(4)进行积分,代入式(5),取对数可得式(6)。

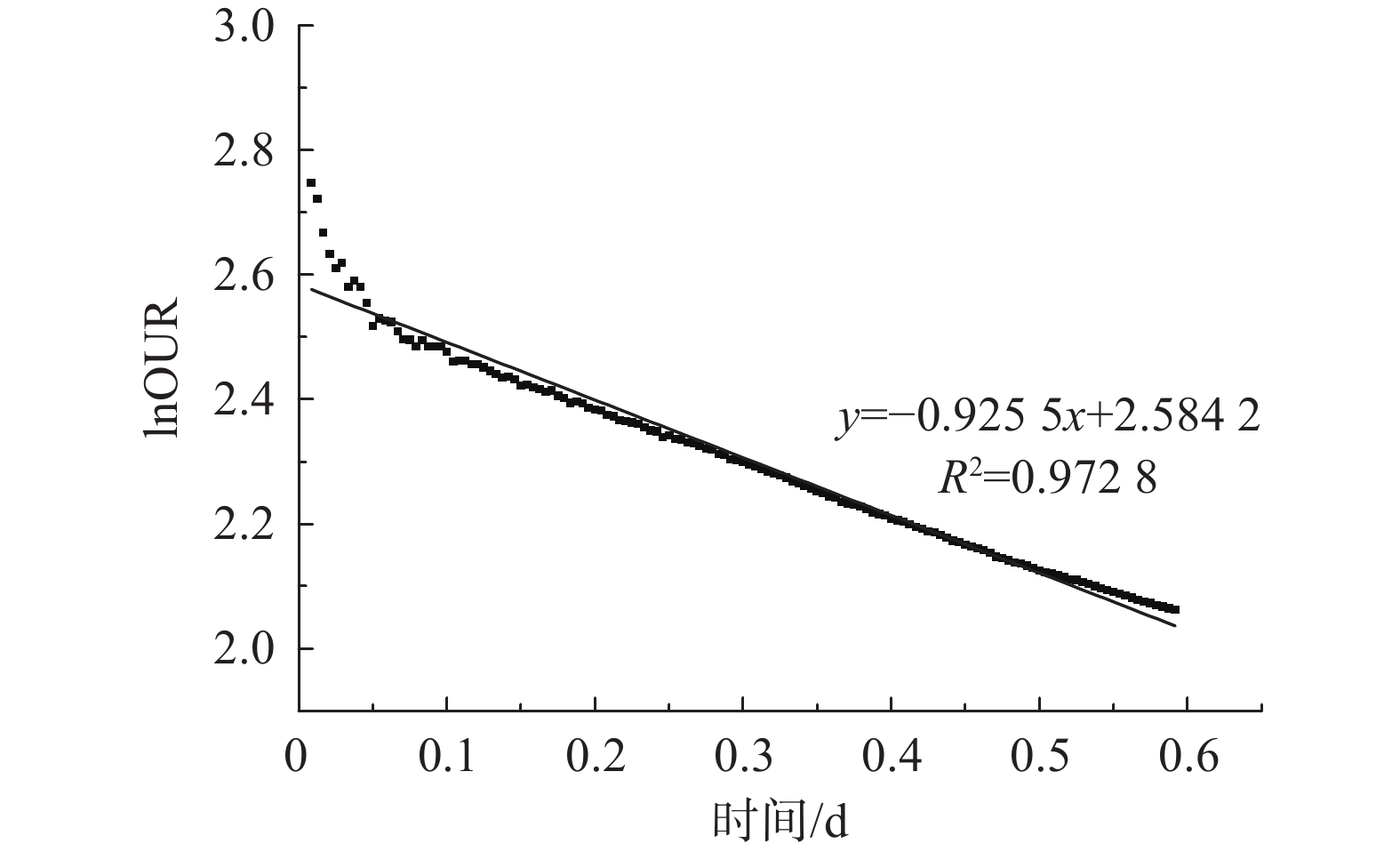

以时间与耗氧速率的对数作线性拟合图(图3),其斜率即为Kd。

最终内源呼吸速率bH可根据式(7)计算。

式中:YH为异养菌产率系数(以消耗COD表征),g·g−1。fI为活性微生物转化为细胞残留物的比例,取ASM3中的推荐值0.08 g·g−1。

在DO和底物均富足的条件下,SBR反应器内任意时刻的OUR均可用式(8)[22]表示。

式中:μH为异养菌最大比增殖速率系数,h−1;XH(t)为t时刻异养微生物质量浓度,mg·L−1;XH(t)的变化速率可表示为式(9)。

将式(8)代入式(9),取对数得到式(10)。

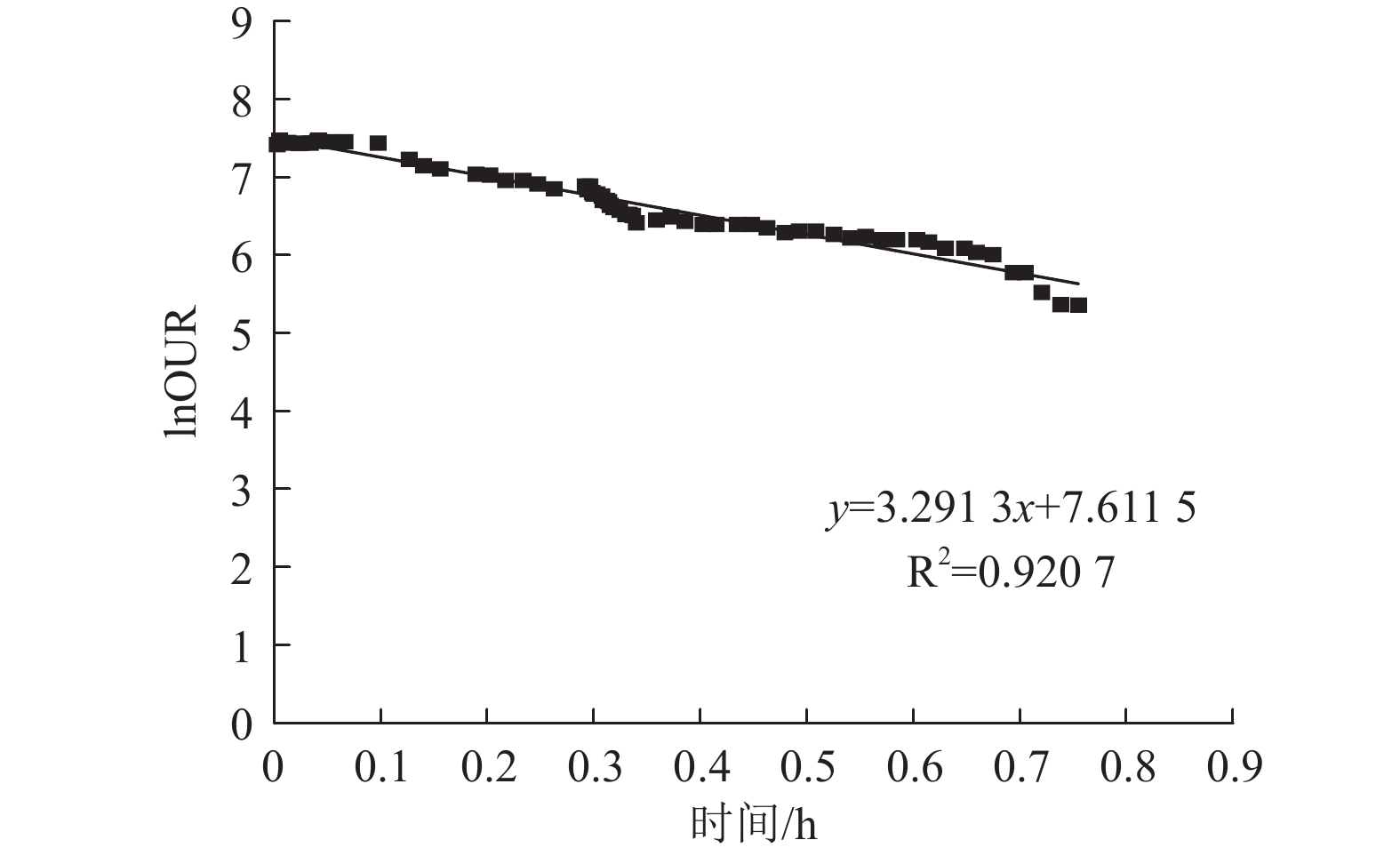

根据式(10),以时间t为横坐标x,OUR对数值为纵坐标y,对反应过程中测得的DO进行数据线性拟合(图4),得到方程的斜率μH-bH,已知bH即可求出μH。

XH的最大贮存速率kSTO参考文献[23]和[24]的方法进行检测和计算。刚加入底物时,微生物快速开启利用SS进行储存和生长的过程,此时微生物的量尚未发生变化,OUR可表示为式(11),可求得kSTO。

-

产率系数YH根据单位质量COD形成的异养菌生物的COD计算。按施汉昌等[12]的方法进行测定和计算。在密闭反应器中加入一定量基质和污泥,开始生化反应后,反应初始好氧速率处于较高水平。随着基质逐渐被降解,好氧速率基本不变。此时,可认为反应器中的微生物处于内源呼吸阶段。在反应结束后,测定此过程中消耗的COD,并根据此过程中好氧速率随时间的变化求得微生物耗氧量,两者之差即生成的微生物COD量,即计算式可表达为式(12)。

式中:ΔCOD为反应过程中消耗的COD,mg·L−1;∫OUR(t)dt为反应过程中的耗氧量,mg·L−1。

产率系数YSTO同样参考文献[23]和[24]的方法进行检测和计算。在底物富足时期,微生物利用SS进行同步储存和生长,此时OUR可通过式(13)计算。

与底物富足期结束相对应,OUR曲线存在一个拐点,可直接利用SS用于生长微生物的消耗量ΔSSgrow计算,计算式为式(14)。

式中:tI为底物富足期的时长,h。而微生物利用SS生长过程中消耗的溶氧量ΔSOgrow,可用式(15)来计算。储存过程中的耗氧量ΔSOsto可用式(16)来计算。

由此得到,产率系数YSTO的计算式见式(17)。

-

自制OUR测定仪对DO进行测定[25],并通过最小二乘法拟合得到DO变化速率,即为OUR。好氧污泥颗粒化过程中,初始微生物量XH0参考文献[24]和[25]的方法进行检测和计算。在加入底物前,反应器处于内源呼吸阶段,此时OUR可表示为式(18)。根据ASM3模型,将f取为0.2 g·g−1,已知bH后即可求得初始生物量XH0。

OUR=(1-f)bHXH0 (18)

在好氧颗粒污泥的形成过程中,微生物生长模型按修订ASM3模型进行。生物动力学模型中异养和自养微生物的化学计量矩阵、生化反应过程速率表达式与文献[15]和[16]相一致。在模型计算过程中,参数校准采用AQUASIM软件进行[26-27]。结合不同运行工况验证模型的正确性和有效性,在此基础上模拟并分析有机废水在好氧污泥颗粒化过程中的代谢。

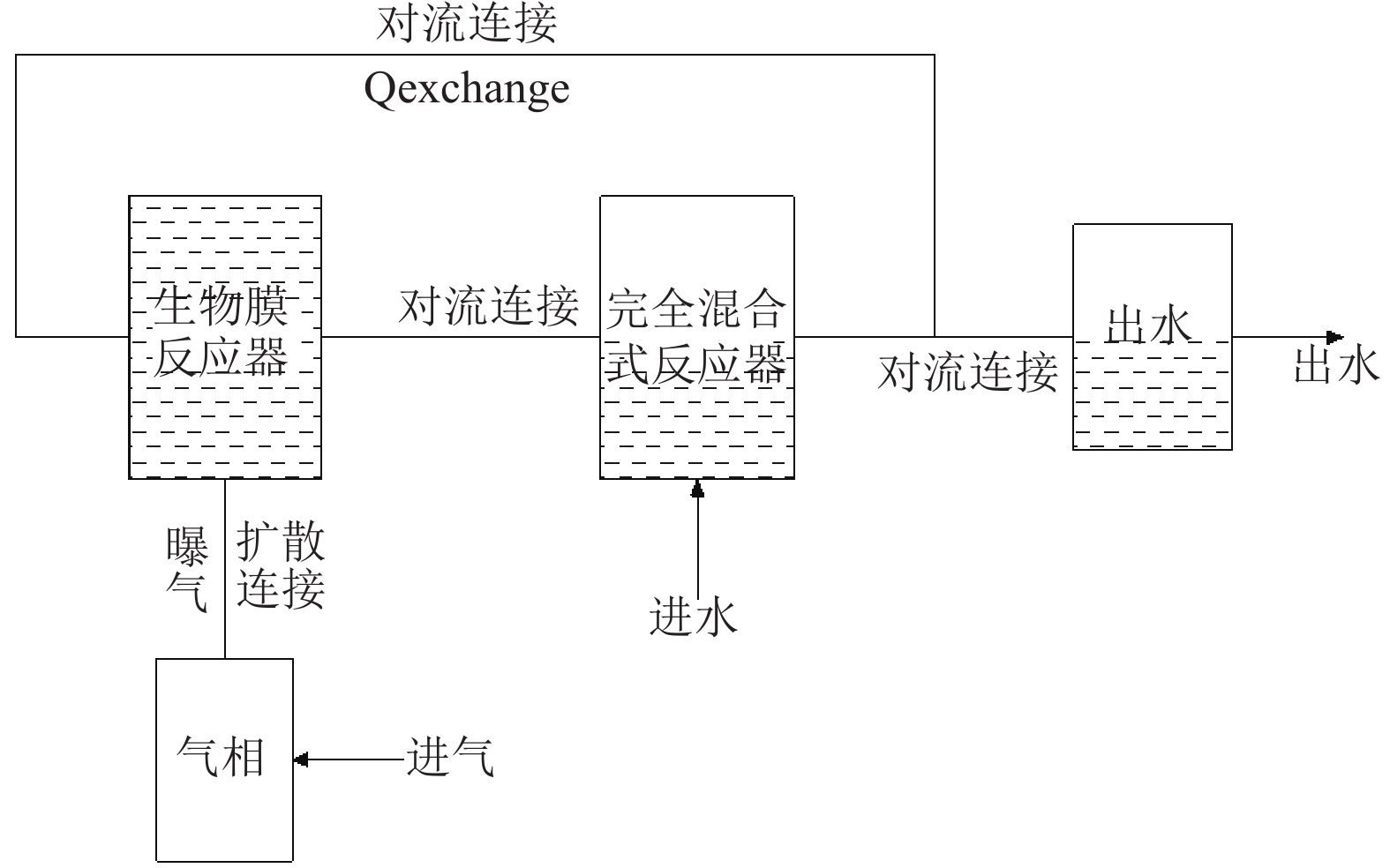

采用文献[15]、[16]和[28]中的方法,在AQUASIM软件中定义SBR反应器进水、出水的特殊模式,分别设置了1个生物膜反应器和3个完全混合式反应器。其中,生物膜反应器的体积不可变。为模拟反应过程,生物膜反应器以平流传输的模式链接1个完全混合式反应器(continuous stirred-tank reactor,CSTR),且两者之间形成回流,设置高回流比(Qexchange,500),以维持2个反应器中的液相体积。其中,生物膜反应器体积包含了污泥体积和部分液相体积,且一直保持不变,为1.7 L。而CSTR则包含了剩余液相体积,其最大有效体积为1.7 L。为模拟SBR反应器的排水过程,引入另1个CSTR,仍采用平流传输的模式链接。而曝气过程则通过CSTR与生物膜反应器以扩散传输的模式进行链接。AQUASIM软件中模拟好氧颗粒污泥SBR反应器的链接示意图见图5。

-

AQUASIM软件中,模型采用“absolute-relative”敏感性方程评估[27],具体见式(19)。

式中:

$ \delta _{y,p}^{\alpha ,r} $ 为参数的敏感性分析输出结果;y为任意模型变量,如SS或XH等;p为模型参数,如YH、S等。方程描述在p的100%变化条件下y的绝对变化情况。参数校准的目标函数,如式(20)计算[27]。

式中:ymeas为实测值;y(p)为给定参数值对应的模型输出结果;σmeas为标准方差。

-

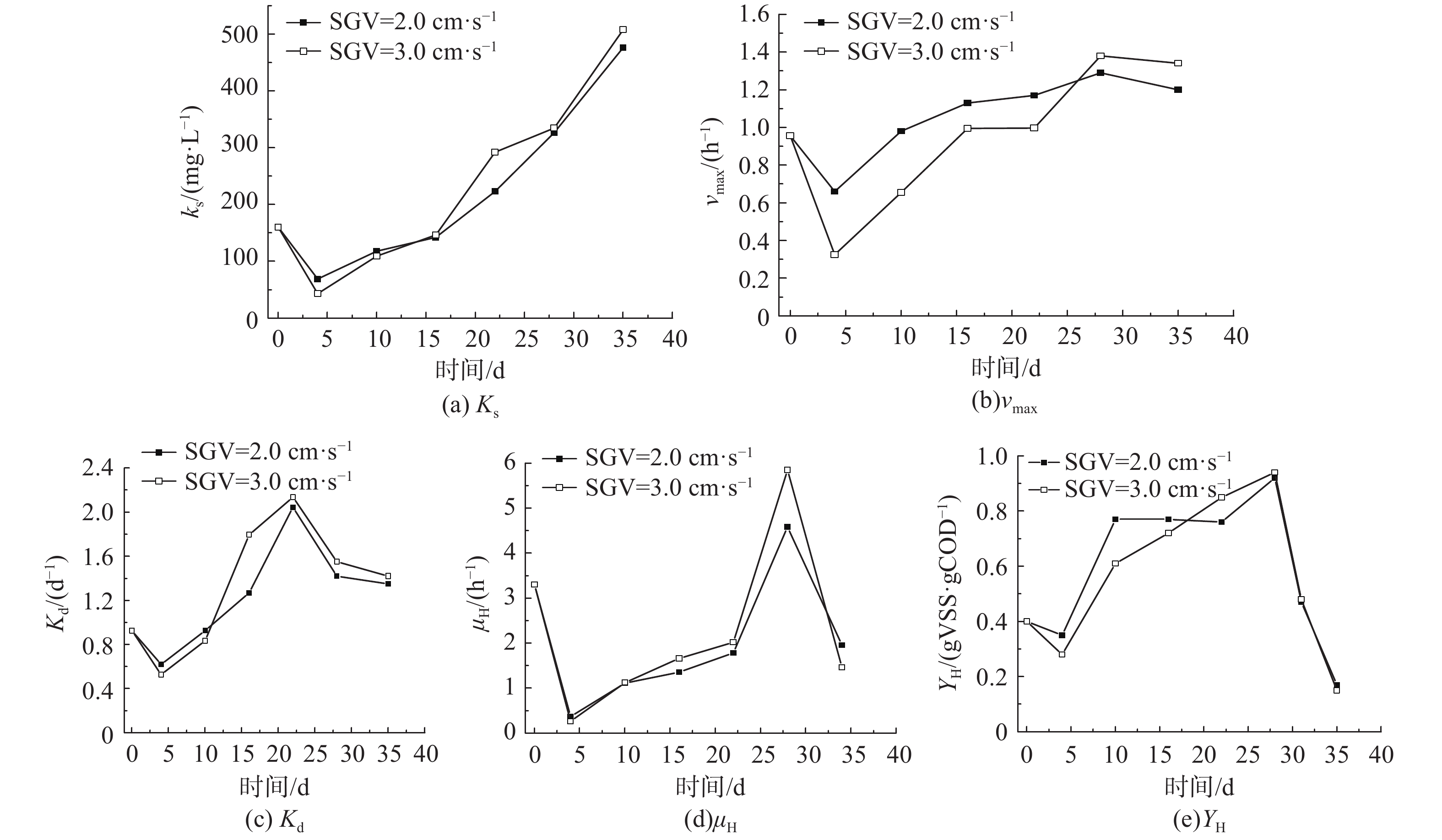

好氧污泥颗粒化时,动力学参数vmax、Kd、μH、KS和化学计量参数YH的变化如图6所示,表观气速分别为2.0 cm·s−1和3.0 cm·s−1。KS随好氧污泥颗粒化的过程逐渐增大,而vmax、Kd、μH、YH则呈先增加后减小的趋势。在2个反应器内分别接种浓度和体积相同的活性污泥。在运行3 d后,检测2个SBR反应器内的动力学参数和化学计量参数。运行初期(t=4 d),在表观气速为2.0 cm·s−1的反应器内,动力学参数KS、vmax、Kd、μH和化学计量参数YH均大于表观气速为3.0 cm·s−1的反应器,但却小于接种的活性污泥絮体。分析其原因,污泥絮体进入不同表观气速反应器后,污泥的周围环境发生了变化。而当反应器内的表观气速较低时,污泥更易适应环境的改变。随着初始好氧颗粒的形成(10~28 d),2个反应器内动力学参数和化学计量参数均逐渐增大,且动力学参数和化学计量参数值在表观气速为3.0 cm·s−1时逐渐高于表观气速为2.0 cm·s−1时,尤其对KS、μH和Kd的影响十分明显。这表明此时微生物处于对数生长期。当絮体污泥全部颗粒化后(28 d),2个反应器内的动力学参数vmax、Kd、μH和化学计量参数YH均出现不同程度减小,微生物逐渐进入稳定期。好氧污泥全部颗粒化后,2个反应器内的化学计量参数YH小于活性污泥的YH,而vmax、KS和Kd却远高于污泥絮体。因此,好氧污泥颗粒化后剩余污泥量减小,而污泥活性及其对污染物的去除速率增大,这与刘喆[29]和李永林[20]的研究结果一致。

-

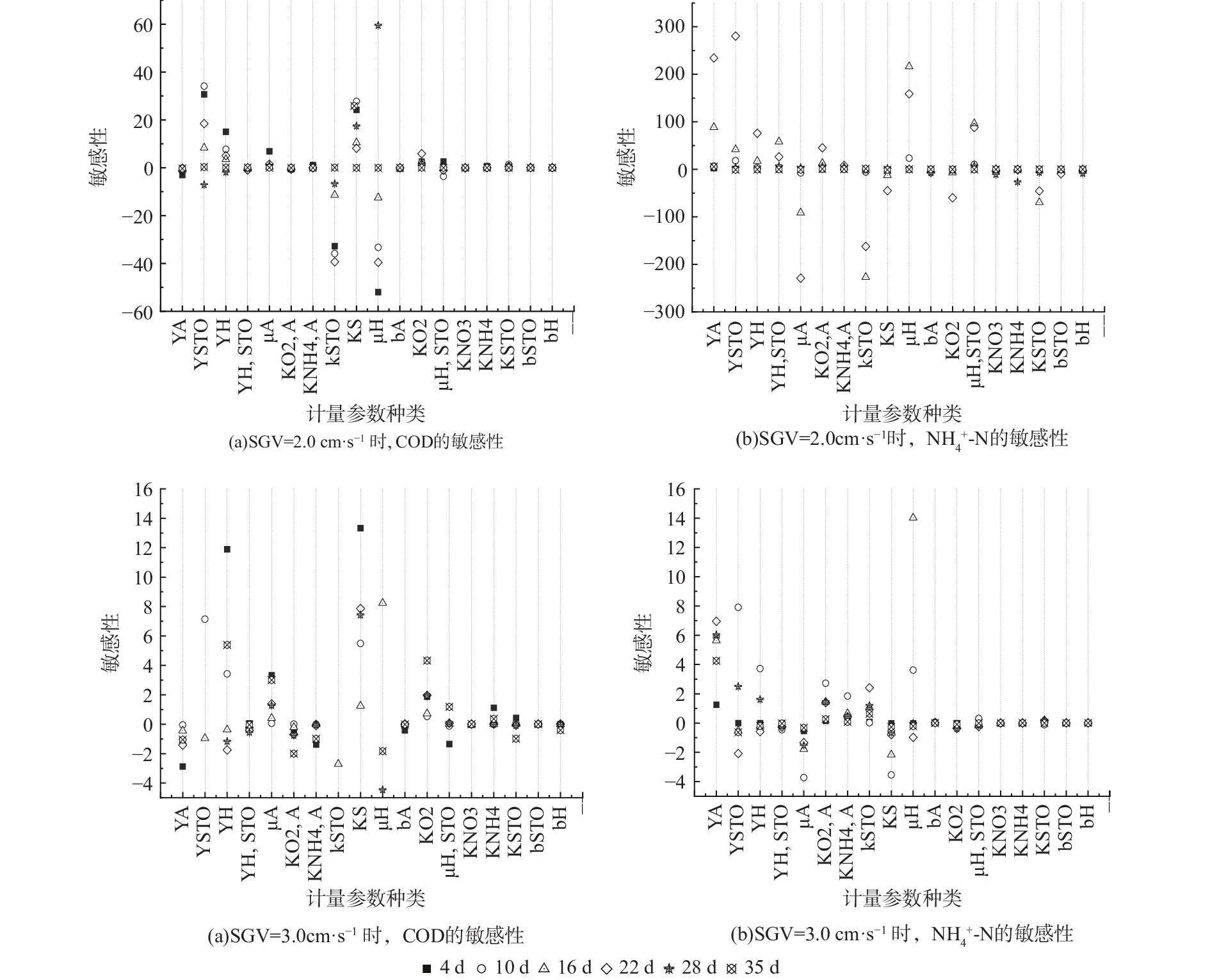

为提升模型的可行性和有效性,对新建任意模型的部分参数进行敏感性分析,并对输出结果影响较大的参数进行参数校准。以COD和NH4+-N为目标函数,对参数的敏感性进行分析(图7),表观气速分别为2.0 cm·s−1和3.0 cm·s−1。在好氧颗粒污泥形成过程中,表观气速为2.0 cm·s−1时,动力学参数和化学计量参数对模型的敏感性更高,尤其当目标函数为NH4+-N时,部分参数敏感性大于100,远高于该参数对COD的影响。而当反应器的表观气速为3.0 cm·s−1时,针对目标函数,参数的敏感性均维持在-5~16。这是由于在表观气速较低时,污泥更易适应周围环境的改变。此时反应器内的微生物会维持在相对快速增殖状态,而增殖所对应的动力学和化学计量参数也在迅速变化。然而,在实际检测过程中,反应运行及颗粒污泥形成初期,微生物对COD和NH4+-N的降解效率较低,这导致各参数对目标函数的敏感性提升。

此外,在好氧颗粒污泥形成过程中,各参数对COD和NH4+-N的敏感性主要集中在反应器运行初期和好氧颗粒污泥形成初期。在污泥全部颗粒化后,参数对模型的敏感性降低。这是由于在絮体污泥结构和性能的转变过程中,各参数也逐渐趋于稳定。相较于COD,各参数对NH4+-N的敏感性主要集中在初始颗粒污泥形成阶段。这是由于硝化细菌为慢速增长的微生物。当其目标函数为COD时,对模型输出结果影响较大的动力学参数为KS、μH和kSTO,化学计量参数为YH和YSTO。而当目标函数为NH4+-N时,对模型输出结果影响较大的动力学参数则为μH、μH,STO、kSTO,化学计量参数为YA、YSTO、YH、YH,STO。调节各运行周期动力学参数KS、μH、kSTO和μH,STO,化学计量参数YA、YH、YSTO和YH,STO,使目标函数COD和NH4+-N的模型预测值较好地与实测结果相吻合。模型校准后得到的各动力学参数和化学计量参数结果见表1~3。

-

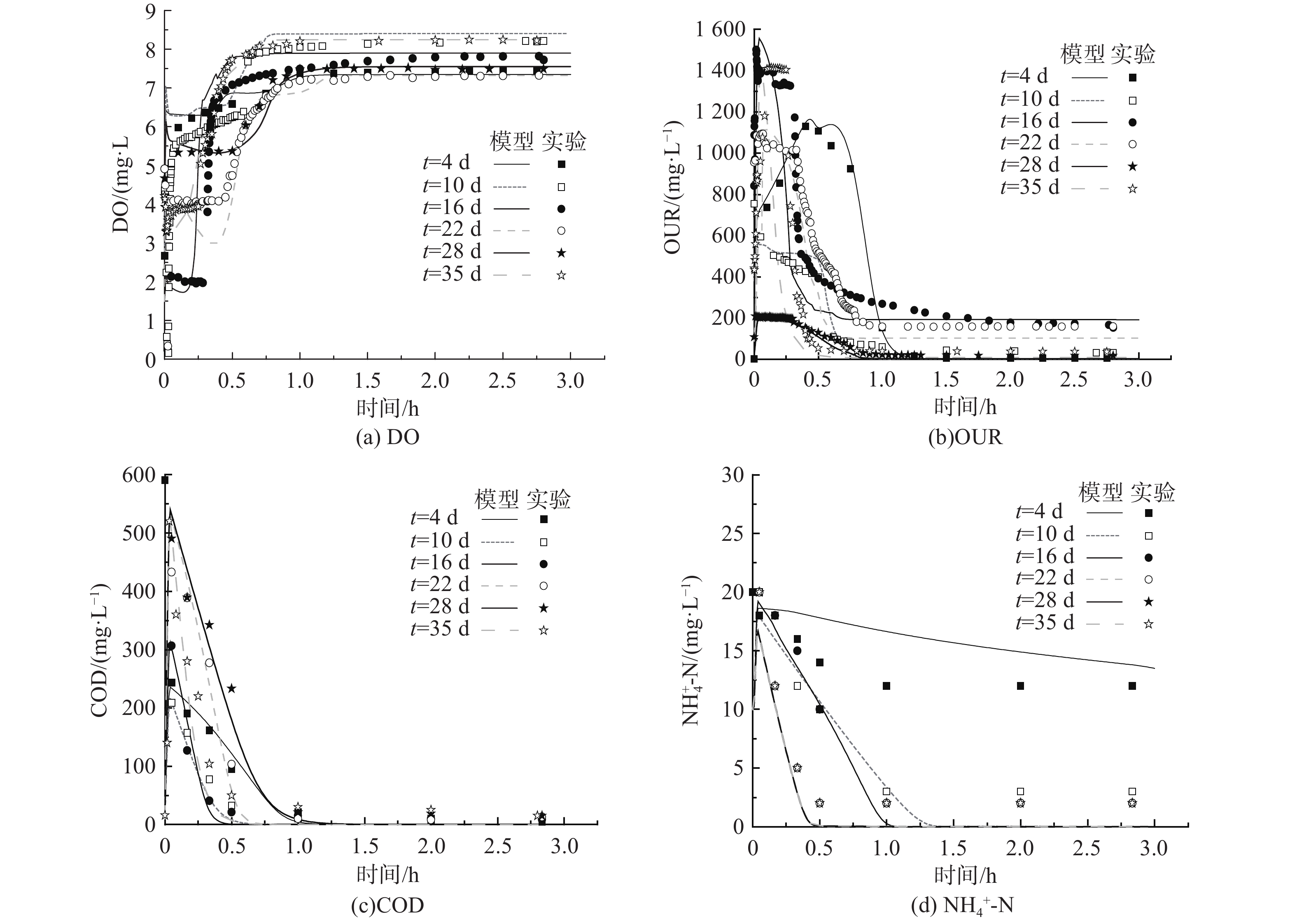

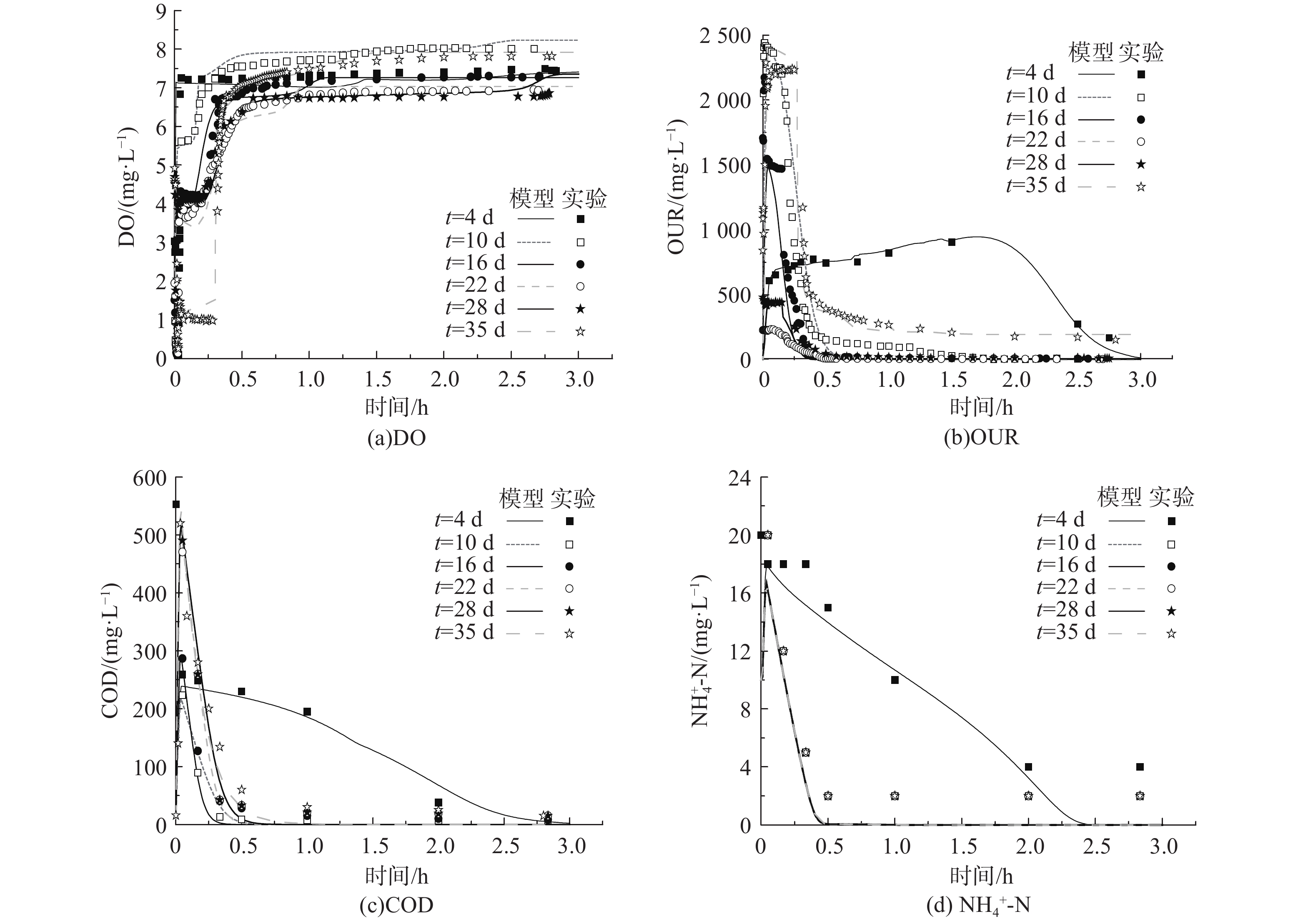

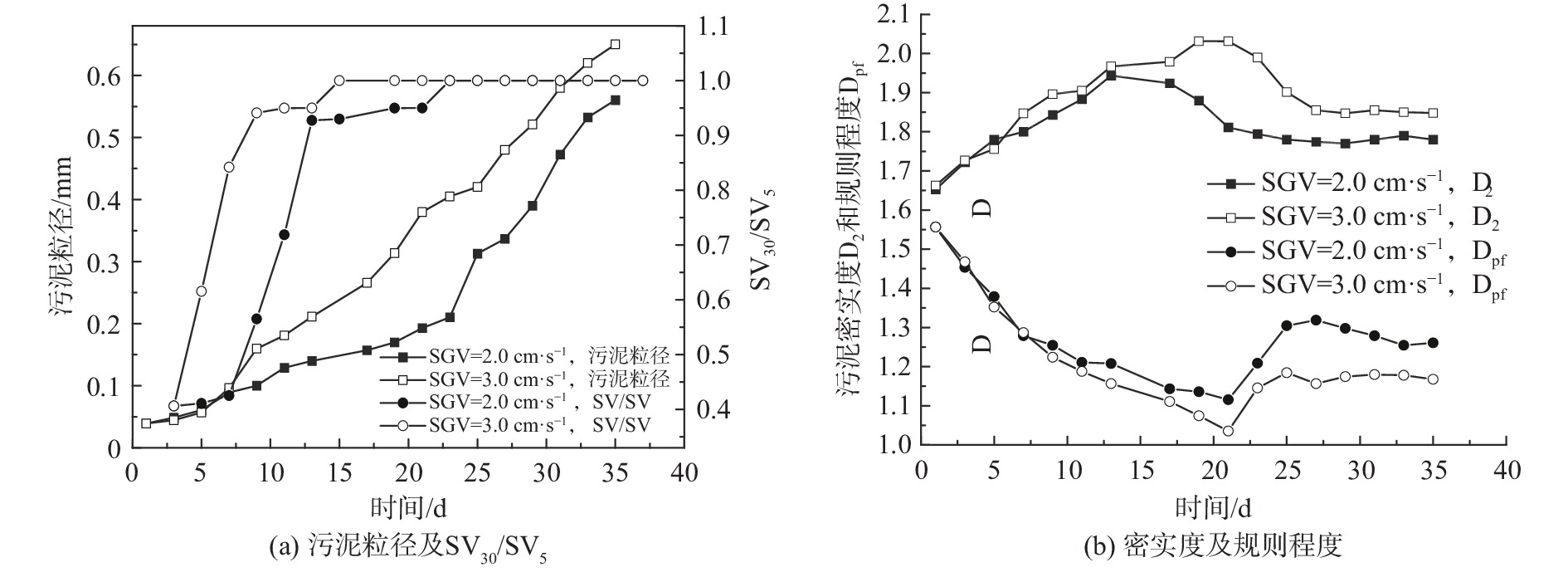

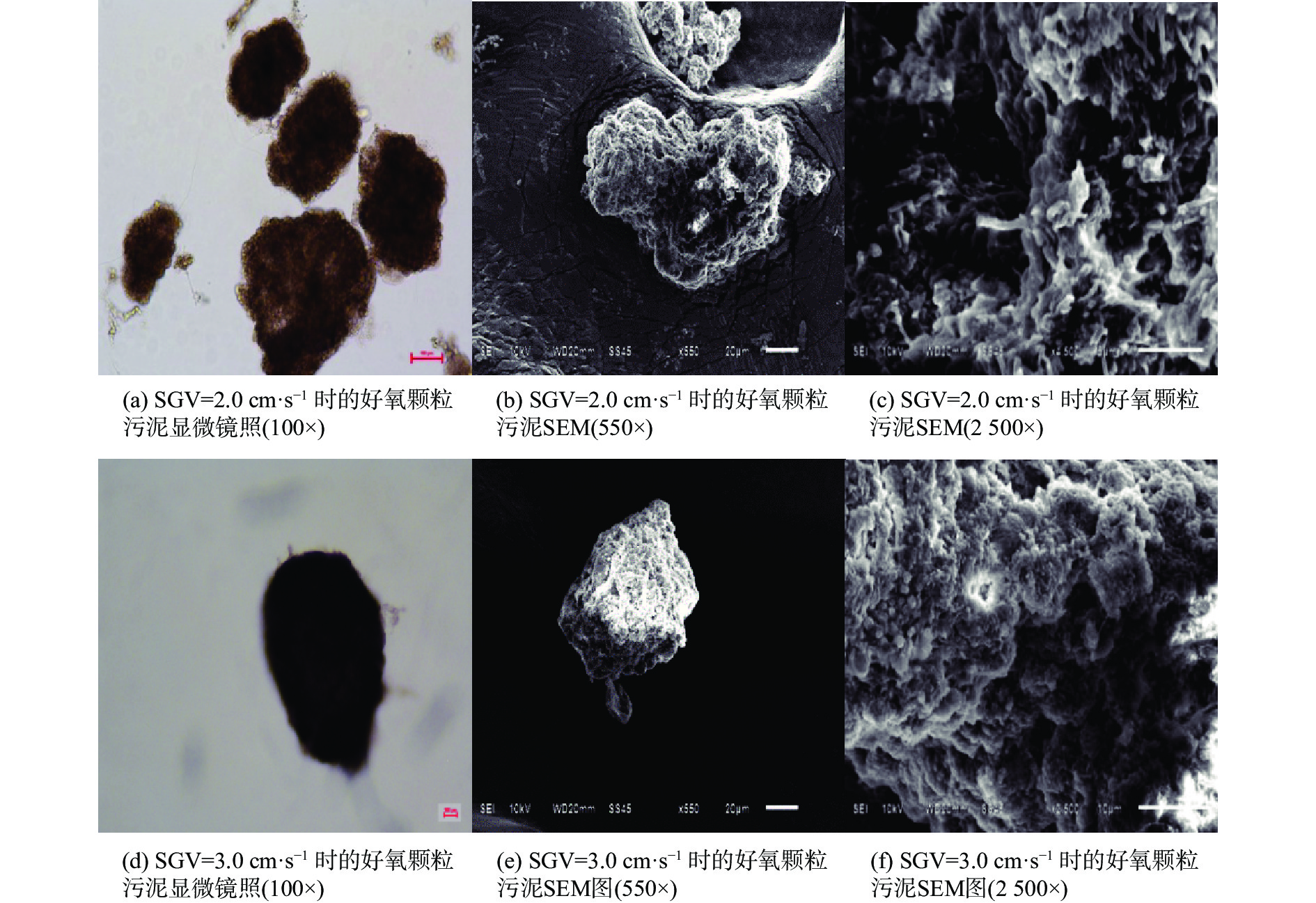

在参数校准后,当SGV分别为2.0和3.0 cm·s−1时,好氧污泥颗粒化过程中DO、OUR、COD和NH4+-N的变化见图8和9,而图10为好氧污泥颗粒化过程中,污泥的沉降性能SV30/SV5、污泥粒径、污泥密实度D2和规则程度Dpf的变化。由不同周期内DO、OUR、COD和NH4+-N的变化可见,模型的预测值基本与实测值吻合,这说明模型预测具备可行性和有效性。在好氧污泥初始颗粒化后,各周期内的OUR及DO传质速率均减小。分析其原因,在SBR反应器运行初期,污泥絮体粒径较小(约100 μm),而在此时的反应器内由于曝气而形成的漩涡尺度大于絮体污泥粒径,故水力剪切作用对大部分污泥并未产生影响。这就使得污泥粒径由于微生物的增殖而逐渐增大,而相应的DO传质速率由于污泥粒径增加逐渐下降,从而延长了污染物在污泥中的传递时间,最终导致反应器内污泥OUR下降。随着反应器内污泥粒径逐渐增大,污泥受到水力剪切作用,使得粒径增长速度减小,而DO传质系数升高,但DO传质系数仍低于絮体污泥。这也侧面说明好氧颗粒污泥的孔隙率在减小,即好氧颗粒污泥密实度D2(D2越接近于2,说明污泥越密实)大于活性污泥絮体。

此外,随着污泥粒径增大,反应器内OUR亦增大,且大于活性污泥絮体。这说明单位时间内微生物对DO的利用率增加,即污染物去除效率得以提升。另外,内源衰减的OUR逐渐提高则说明SBR反应器内微生物衰减速率逐渐提高。这与动力学参数Kd的变化规律相一致。在不同表观气速条件下,SV30/SV5、污泥粒径、污泥密实度和规则程度变化速率不同。比较而言,表观气速为2.0 cm·s−1时,在反应器运行初期(4 d),污泥粒径增大速率和污泥的规则程度Dpf (Dpf越接近于1,说明污泥的表面越光滑)更好。这说明此时的污泥更易接受环境的变化,微生物的增长较快,但污泥的沉降性能SV30/SV5也因此较表观气速3.0 cm·s−1时更小,密实度也降低。随着反应的运行,好氧污泥初始颗粒化后,在表观气速为3.0 cm·s−1的条件下,污泥粒径的增长速率、污泥的密实度D2、规则程度Dpf和沉降性能SV30/SV5均优于2.0 cm·s−1条件对应数值,且逐渐趋于平稳。这与2.1中各动力学参数的变化情况相似。

在反应器运行初期(t=4 d),表观气速为2.0 cm·s−1时SBR反应器内微生物对COD和NH4+-N的降解速率优于表观气速为3.0 cm·s−1时。这也说明在反应器运行初期,微生物在表观气速2.0 cm·s−1时更易适应环境变化。而当好氧污泥初始颗粒化后(t=10~28 d),表观速率为3.0 cm·s−1时微生物对COD和NH4+-N的降解速率优于表观速率为2.0 cm·s−1时。这是性能良好的好氧颗粒污泥在较大剪切速率条件下造成的结果。这也与表观气速为2.0和3.0 cm·s−1时,反应器内流态的变化结果一致[18]。这说明好氧污泥颗粒化过程中,微生物生长与流态的发展相适应。

图11为35 d时好氧颗粒污泥的显微镜和SEM图。在初始表观气速较高时形成的好氧颗粒污泥更光滑密实,与污泥密实度D2和规则程度Dpf的变化结果一致。这是由于好氧颗粒污泥的形成过程中,反应器内表观气速不同会影响微生物的生长动力学参数及反应器内的物质流态,从而导致污泥特性和结构发生了变化,最终使得SV30/SV5、污泥粒径、污泥密实度D2、规则程度Dpf,以及COD和NH4+-N等参数出现差异。待好氧颗粒污泥形成后,反应器内微生物对COD和NH4+-N的去除效率均可达到90%以上。

综上所述,修订的ASM3模型可模拟好氧颗粒SBR反应器中DO、OUR、COD、NH4+-N的变化。在好氧污泥颗粒化的各阶段,模型数据与实测结果具有一致性,表明该模型可很好地模拟SBR反应器中的生化反应过程。尽管好氧颗粒污泥可在不同反应器、不同表观气速条件下形成,但无论运行参数如何改变,从水力学的微观角度分析,螺旋上升的小尺度漩涡是好氧污泥颗粒化的必要条件。因此,微生物的生长模型中动力学参数变化应与流态的发展规律相适应。另外,好氧颗粒污泥的形成过程不仅与微生物的生长代谢相关,还与反应器中流态变化有关。因此,合理有效地将微生物生长模型与水力模型相耦合,可更直观有效地从数学模型角度反映好氧颗粒污泥的形成过程。本研究结果亦可为将微生物生长代谢过程模拟引入微生物-水动力耦合模型奠定良好基础。

-

1)在好氧污泥颗粒化过程中,KS逐渐增加,而动力学参数vmax、Kd、μH和化学计量参数YH则先增加后减小。好氧颗粒污泥形成后,污泥的YH小于活性污泥,而动力学参数vmax、KS和Kd却远高于污泥絮体。这表明好氧污泥颗粒化后剩余污泥量会减小,而污泥活性及其对污染物的去除速率有所提高。

2)在运行初期(t=4 d),表观气速3.0 cm·s−1条件下反应器内动力学参数KS、vmax、Kd、μH和化学计量参数YH均小于表观气速2.0 cm·s−1条件下的参数值。这表明微生物在表观气速2.0 cm·s−1时更易适应环境变化。随着初始好氧颗粒的形成(t=10~28 d),2个SBR反应器内动力学参数的值逐渐增大,且表观气速为3.0 cm·s−1时的参数值会大于表观气速为2.0 cm·s−1时,对KS、μH和Kd的影响尤其明显。

3)用ASM3模型建立COD和NH4+-N的去除过程修正模型。该模型可模拟好氧颗粒SBR反应器中DO、OUR、COD、NH4+-N的变化。在好氧污泥颗粒化各阶段,模型数据与实测值具有一致性。这表明该模型可很好地模拟SBR反应器中的生化反应过程。

4)在好氧颗粒污泥的形成过程中,反应器内表观气速不同,影响了微生物生长的动力学参数及反应器内的流态,从而导致污泥特性和结构的变化,最终使得SV30/SV5、污泥粒径、污泥密实度D2、规则程度Dpf,以及COD和NH4+-N等参数出现差异。

表观气速对好氧污泥颗粒化过程中生化动力学模型参数变化的影响

Effect of superficial gas velocity on the variation of biochemical kinetic model parameter of the aerobic sludge granulation processes

-

摘要: 在高径比120/6,结构相同的2个SBR反应器中培养好氧颗粒污泥,并以修订ASM3模型为基础进行反应过程模拟,并分析表观气速(2.0 cm·s−1和3.0 cm·s−1)对好氧污泥颗粒化过程中动力学参数的影响。结果表明,反应器运行初期(t=4 d),表观气速2.0 cm·s−1时的半饱和系数KS、基质降解动力学参数vmax、污泥衰减系数Kd、污泥比增殖速率μH和污泥的产率系数YH均大于表观气速3.0 cm·s-1时的参数值,说明微生物在表观气速2.0 cm·s−1时更易适应环境变化。然而,随着初始好氧颗粒的形成(t=10~28 d),各参数值在表观气速3.0 cm·s−1时变得更高,尤其对KS、μH及Kd的影响更明显。修订的ASM3可模拟好氧颗粒污泥形成过程中溶解氧DO、好氧速率OUR、COD、NH4+-N的变化,说明模型预测的可行性和有效性。反应器内表观气速不同,影响了微生物生长的各动力学参数和反应器内的流态,从而导致污泥的特性和结构发生了变化,最终使得SV30/SV5、污泥粒径、污泥密实度D2和规则程度Dpf,COD和NH4+-N等参数出现差异。本研究结果可为运用数学模型反映生物反应器中参数变化以优化反应过程提供参考。Abstract: The aerobic granular sludge was cultivated in two bubble SBRs with same structure and a height-diameter ratio of 120/6. The simulation was established based on the revised ASM3 model, and the effect of different superficial gas velocity(SGV) (2.0 cm·s-1 and 3.0 cm·s-1) on the biological kinetic parameter of the aerobic sludge granulation was analyzed. The results showed that, at the initial stage( t= 4 d), the KS, vmax, Kd, μH and YH at the SGV of 2.0 cm·s-1 were higher than those at the SGV of 3.0 cm·s-1, indicating that microorganisms were more likely to adapt to the changes of the surrounding environment at the SGV of 2.0 cm·s-1. However, with the formation of initial aerobic granules ( t= 10~28 d), the values of parameters became higher at the SGV of 3.0 cm·s-1, especially for KS, μH and Kd. The revised ASM3 can simulate the variation of dissolved oxygen DO, aerobic rate OUR, COD and NH4+-N during the formation of aerobic granular sludge, indicating the feasibility and effectiveness of the model prediction. The difference of SGVs influenced the dynamic parameters of microbial growth and the flow pattern, resulting in the changes of the characteristics and structure of the sludge, finally, the differences in parameters such as SV30/SV5, sludge diameter, sludge density D2 and regular degree Dpf, COD and NH4+-N were observed. The results of this study can provide reference for optimizing the reaction process by using mathematical model to reflect the variation of parameters in bioreactor.

-

Key words:

- aerobic granular sludge /

- SBR /

- kinetic parameter /

- activated sludge modeling 3

-

-

表 1 20 ℃时主要的动力学参数和化学计量参数

Table 1. Main kinetic and stoichiometric parameters at 20 ℃

类型 参数 定义 数值 单位 文献 化学计量参数 YA XA的产率系数 0.24 g·g−1 [30] ηNOX 缺氧校正因子 0.55 — [15] fI 内源呼吸中XI的产率 0.20 g·g−1 [31] iN,BM XH、XA中N含量 0.07 g·g−1 [31] iN,XI XI中N含量 0.02 g·g−1 [31] YH,STO XH 基于 XSTO生长的产率系数 0.68 g·g−1 [30] 动力学参数 KSTO XSTO的半饱和系数 1.0 g·g−1 [31] $ {K_{{O_2}}} $ $ {S_{{O_2}}} $ 0.2 g·m−3 [31] $ {K_{N{H_4}}} $ $ {S_{N{H_4}}} $ 0.01 g·m−3 [31] $ {K_{N{O_3}}} $ SNO的半饱和系数 0.5 g·m−3 [31] bSTO XSTO的好氧衰减速率 0.016 h−1 [15] $ {K_{{O_2},A}} $ 硝化菌的氧半饱和系数 0.5 g·m−3 [31] $ {K_{N{H_4},A}} $ XA氨氮半饱和系数 1 g·m−3 [15] μA XA的最大生长速率 0.05 h−1 估算值 bA XA的内源衰减速率 0.006 3 h−1 [15] 表 2 SGV为2.0 cm·s−1时的动力学参数和化学计量参数(20 ℃)

Table 2. Kinetic and stoichiometric coefficients at the SGV of 2.0 cm·s −1 (20 ℃)

参数 定义 运行周期 单位 备注 t=4 d t=10 d t=16 d t=22 d t=28 d t=35 d YH XH 的产率系数 0.35 0.77 0.77 0.76 0.92 0.47 g·g-1 实测值 Ks SS的半饱和系数 68.74 117.73 142.23 222.97 326.33 476.16 g·m-3 实测值 μH XH基于SS的最大生长速率 1.983 2.091 5 4.99 4.9 1.993 3 1.39 h-1 实测值 bH XH的好氧衰减速率 0.005 0.014 0.0147 0.015 0.022 0.048 d-1 实测值 kSTO XH的最大贮存速率常数 3.002 9.75 9.74 9.53 6.93 4.17 h-1 估算值 YSTO XH 贮存的产率系数 0.99 0.575 0.143 0.108 0.42 0.35 g·g-1 估算值 μH,STO XH 基于XSTO的最大生长速率 0.645 0.937 7 0.843 0.953 3 0.8 0.256 h-1 估算值 表 3 SGV为3.0 cm·s−1时的动力学参数和化学计量参数(20 ℃)

Table 3. Kinetic and stoichiometric coefficients at the SGV of 3.0 cm·s −1 (20 ℃)

参数 定义 运行周期 单位 备注 t=4 d t=10 d t=16 d t=22 d t=28 d t=35 d YH XH的产率系数 0.28 0.614 0.72 0.94 0.85 0.63 g·g-1 实测值 Ks SS的半饱和系数 42.84 109.14 146.3 292.2 299.34 617.39 g·m-3 实测值 μH XH基于SS的最大生长速率 1.98 3.53 3.66 3.824 2.27 1.34 h-1 实测值 bH XH的好氧衰减速率 0.006 0.008 7 0.021 0.026 0.043 0.12 d-1 实测值 kSTO XH的最大贮存速率 7.939 9.029 5.64 6.66 6.079 3.85 h-1 估算值 YSTO XH 贮存的产率系数 0.81 0.76 0.42 0.46 0.42 0.58 g·g-1 估算值 μH,STO XH 基于XSTO的最大生长速率 0.15 0.767 0.762 0.762 0.914 0.2 h-1 估算值 -

[1] TAY J H, LIU Q S, LIU Y. The effects of shear force on the formation, structure and metabolism of aerobic granules[J]. Applied Microbiology & Biotechnology, 2001, 57(1/2): 227-233. [2] LIU Z, LIU Y, ZHANG A, et al. Study on the process of aerobic granule sludge rapid formation by using the poly aluminum chloride (PAC)[J]. Chemical Engineering Journal, 2014, 250: 319-325. doi: 10.1016/j.cej.2014.04.025 [3] LIU J, LI J, WANG X D, et al. Rapid aerobic granulation in an SBR treating piggery wastewater by seeding sludge from a municipal WWTP[J]. Journal of Environmental Science, 2017, 51(1): 332-341. [4] LIU Y Q, TAY J H. Fast formation of aerobic granules by combining strong hydraulic selection pressure with overstressed organic loading rate[J]. Water Research, 2015, 80: 256-266. doi: 10.1016/j.watres.2015.05.015 [5] DAHALAN F A, ABDULLAH N, YUZIR A, et al. A proposed aerobic granules size development scheme for aerobic granulation process[J]. Bioresource Technology, 2015, 181: 291-296. doi: 10.1016/j.biortech.2015.01.062 [6] 张鸿雁, 张志政, 王元. 流体力学[M]. 北京: 科学出版社, 2004. [7] LIU Y, WANG Z W, LIU Y Q, et al. A generalized model for settling velocity of aerobic granular sludge[J]. Biotechnology Progress, 2005, b,21: 621-626. [8] 周丹, 张涛. 颗粒污泥沉降动力学模型研究[J]. 环境污染与防治, 2008, 30(3): 36-38. doi: 10.3969/j.issn.1001-3865.2008.03.011 [9] YANG S F, LIU Q S, TAY J H, et al. Growth kinetics of aerobic granules developed in sequencing batch reactors[J]. Letter Applied Microbiology, 2004, 38: 106-112. doi: 10.1111/j.1472-765X.2003.01452.x [10] SU K Z, YU H Q. Formation and characterization of aerobic granules in a sequencing batch reactor treating soybean-processing wastewater[J]. Environmental Science & Technology, 2005, 39: 2818-2828. [11] NI B J, YU H Q. Mathematical modeling of aerobic granular sludge: A review[J]. Biotechnology Advances, 2010, 28: 895-909. doi: 10.1016/j.biotechadv.2010.08.004 [12] 施汉昌, 邱勇. 污水生物处理的数学模型与应用[M]. 北京: 中国建筑工业出版社, 2014. [13] SU K Z, YU H Q. A generalized model of aerobic granule-based sequencing batch reactor I: Model development[J]. Environmental Science & Technology, 2006, a,40: 4703-4708. [14] SU K Z, YU H Q. A generalized model for aerobic granule-based sequencing batch reactor II: Parametric sensitivity and model verification[J]. Environmental Science & Technology, 2006, b,40: 4709-4713. [15] NI B J, YU H Q, SUN Y J. Modeling simultaneous autotrophic and heterotrophic growth in aerobic granules[J]. Water Research, 2008, 42: 1583-1594. doi: 10.1016/j.watres.2007.11.010 [16] 倪丙杰. 好氧颗粒污泥的培养过程、作用机制及数学模拟[D]. 合肥: 中国科学技术大学. 2009. [17] ZHOU M, GONG J Y, YANG C Z, et al. Simulation of the performance of aerobic granular sludge SBR using modified ASM3 model[J]. Bioresource Technology, 2013, 127: 473-481. doi: 10.1016/j.biortech.2012.09.076 [18] FAN W W, YUAN L J, LI Y L. CFD simulation of flow pattern in a bubble column reactor for forming aerobic granules and its development[J]. Environmental Technology, 2019, 40(27): 3652-3667. doi: 10.1080/09593330.2018.1484522 [19] FAN W W, YUAN L J, QU X Y. CFD simulation of hydrodynamic behaviors and aerobic sludge granulation in a stirred tank with lower ratio of height to diameter[J]. Biochemical Engineering Journal, 2018, 137: 78-94. doi: 10.1016/j.bej.2018.05.012 [20] 李永林. 气升流速变化对SBR污泥颗粒化的作用及机理[D]. 西安: 西安建筑科技大学, 2017. [21] 国家环保局. 水和废水监测分析方法 [M]. 北京: 中国环境科学出版社, 2005. [22] 于静洁, 马超, 李莉等. ASM1中化学计量系数与动力学参数的测定[J]. 环境污染与防治, 2006, 28(5): 334-336. doi: 10.3969/j.issn.1001-3865.2006.05.005 [23] HENZE M, GUJER W, MINO T, et. al. . Activated Sludge Models. ASM1, ASM2, ASM2d and ASM3. London: IWA Publishing, 2000. [24] 关梦龙, 黄钧, 毕京芳等. 好氧颗粒污泥代谢高浓度有机废水的数学模拟[J]. 应用与环境生物学报, 2014, 20(6): 1063-1069. [25] XAVIER J B, PICIOREANU C, VAN LOOSDRECHT MCM. A framework for multi dimensional modeling of activity and structure of multi species biofilms[J]. Environmental Microbiology, 2005, 7: 1085-1103. doi: 10.1111/j.1462-2920.2005.00787.x [26] RRICHERT P. AQUASIM 2.0-Tutorial [M]. Technical Report, Swiss Federal Institute for Environmental Science and Technology (EAWAG), CH-8600 Dübendorf, Switzerland, 1998. [27] RRICHERT P. AQUASIM 2.0-User Manual [M]. Technical Report, Swiss Federal Institute for Environmental Science and Technology (EAWAG), CH-8600 Dübendorf, Switzerland, 1998. [28] BEUN J J, HEIJNEN J J, VAN LOOSDRECHT M C M. N-removal in a granular sludge sequencing batch airlift reactor[J]. Biotechnology, 2001, 75: 82-91. [29] 刘喆. 好氧污泥混凝强化造粒的操作控制条件及其作用机制[D]. 西安: 西安建筑科技大学, 2015. [30] SIN G, GUISASOLA A, PAUW D J W D, et al. A new approach for modelling simultaneous storage and growth processes for activated sludge systems under aerobic conditions[J]. Biotechnology and Bioengineering, 2005, 92(5): 600-613. doi: 10.1002/bit.20741 [31] GUJER W, HENZE M, MINO T, et al. Activated sludge model No. 3[J]. Water Science and Technology, 1999, 39(1): 183-193. doi: 10.2166/wst.1999.0039 -

下载:

下载: