-

印染废水中含有多种染料、浆料、表面活性剂等复杂化学物质,具有水质成分复杂、水量变化大、有机污染物浓度高、可生化性较差、色度高等特点[1]。在印染行业中,每年约生产7~10×105 t染料,向水体排放的染料约2.8×105 t。亚甲基蓝(methylene blue,MB)和刚果红(congo red,CR)作为典型的阳离子染料和阴离子染料,是印染废水中所含的主要污染物之一。因此,对2种染料的去除至关重要。

印染废水的处理方法有物理法、化学法和生物法。其中生物法中的膜生物反应器(membrane bioreactor,MBR)因具有出水水质稳定、剩余污泥产量少、占地面积小等优点[2-3],受到很多学者和工程技术人员的关注。DEOWAN等[4]采用一体式膜生物反应器(submerged membrane bioreactor,SMBR)系统处理模拟印染废水,发现当渗透通量为4 L·(m2·h)−1、污泥质量浓度(mixed liquor suspended solids,MLSS)为12 g·L−1、水力停留时间(hydraulic retention time,HRT)为40~80 h时,COD去除率为90%,对酸性红4和雷马唑亮蓝R的去除率分别为25%~70%和20%~50%。丁岚等[5]设计了缺氧/好氧MBR装置并对模拟印染废水进行了处理,结果表明,系统对COD的去除率达到85%以上,对活性艳红染料X-3B的去除率为60%~73%,出水仍具有少量色度。邢奕等[6]采用MBR-反渗透(RO)工艺对印染废水进行了深度处理,在MBR系统运行过程中,对COD、SS和色度的去除率分别为89.9%、100%和87.5%,出水未满足生产回用的要求。SARI等[7]对传统MBR和移动床膜生物反应器(moving bed membrane bioreactor,MB-MBR)工艺处理印染废水进行了比较,结果表明,MBR和MB-MBR系统对COD和活性红的去除率几乎相同;但在MBR中,分别每隔1 d和15 d进行1次物理和化学膜清洗,MB-MBR系统可减缓膜污染。YURTSEVER等[8]对比了厌氧膜生物反应器(anaerobic membrane bioreactor,AnMBR)和好氧膜生物反应器(aerobic membrane bioreactor,AeMBR)处理偶氮染料的效果,发现AnMBR在9 L·(m2·h)−1下可稳定运行,且在通量为4.5 L·(m2·h)−1下50 d内无需化学清洗;而AeMBR在通量为20 L·(m2·h)−1下可稳定运行,且该系统经过化学清洗后的膜阻力与新膜相近。

综上所述,现有研究侧重于MBR对印染废水中的处理性能和膜污染控制,而考察印染废水水质对MBR性能影响的研究较少。本文采用MBR对2种不同类型的染料废水进行了处理,在相同的染料浓度条件下,探究了染料类型对MBR去除效果、活性污泥特性及膜污染的影响,以期为MBR系统针对性处理不同类型染料废水提供参考。

-

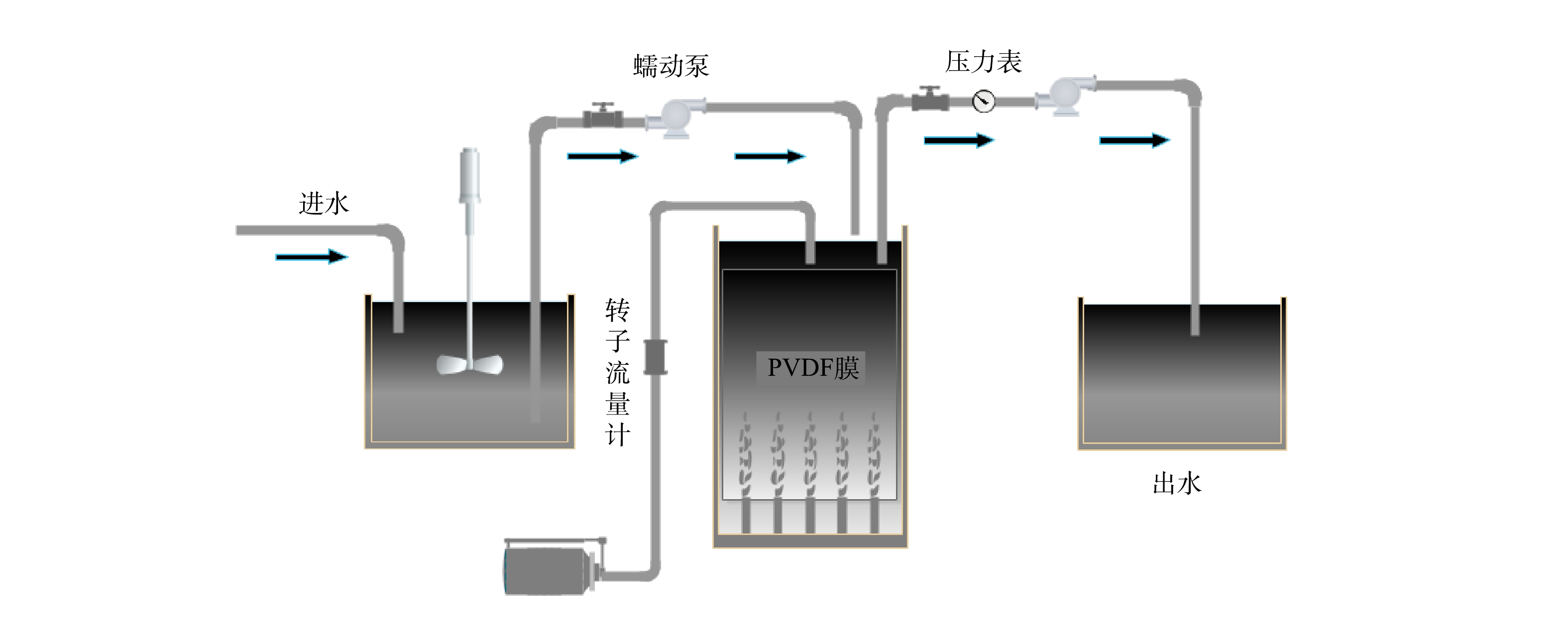

MBR由有机玻璃制成,有效体积为8.5 L,膜材质为聚偏氟乙烯(polyvinylidene fluoride,PVDF),膜孔径为0.1 μm,有效膜面积为0.1 m2,实验装置如图1所示。R1为处理未含染料模拟废水的对照系统;R2以含阳离子染料MB的模拟废水为进水;R3以含阴离子染料CR的模拟废水为进水。出水泵恒定出水通量为8.5 L·(m2·h)−1,运行模式为工作8 min,停歇2 min。曝气强度为200 L·h−1,HRT为10 h,整个运行期间除取样外反应器未经过人为排泥。

-

根据已有研究[9-10]中使用MBR处理印染废水的方法,确定模拟废水的组成为:700 mg·L−1葡萄糖,700 mg·L−1可溶性淀粉,120 mg·L−1氯化铵,30 mg·L−1蛋白胨,32 mg·L−1磷酸二氢钾,50 mg·L−1MB和CR。模拟废水的目标水质参数为:800 mg·L−1 COD,50 mg·L−1

${\rm{NH}}_4^ + $ -N,20 mg·L−1${\rm{PO}}_4^{3 - }$ −P,50 mg·L−1 MB和CR。 -

模拟废水中的总去除率、生物去除率和膜截留去除率分别按式(1)、式(2)和式(3)进行计算。其中,COD、

${\rm{NH}}_4^ + $ -N、MB、CR等指标均采用标准方法测定。MLSS和挥发性污泥浓度(mixed liquid volatile suspended solids,MLVSS)按照文献[11]中描述的方法测量。使用多糖(polysaccharides,PS)和蛋白(protein,PN)浓度之和表征胞外聚合物(extracellular polymeric substances,EPS)和溶解性微生物产物(soluble metabolic products,SMP),PS和PN的分析方法分别为蒽酮法和考马斯亮蓝比色法[12];采用粒度分析仪(辽宁丹东百特仪器有限公司BT800S)对污泥粒径进行检测。根据达西公式(4),在本实验采用恒通量J=8.5 L·(m2·h)−1操作下检测跨膜压差(transmembrane pressure,TMP)获得膜污染发生和发展的宏观信息;此外,扫描电子显微镜(scanning electron microscope,SEM)、过滤阻力[13-14]、傅立叶变换红外(fourier transform infrared spectrometer,FTIR)对膜进行表征以获得膜污染的微观信息。式中:R总为总去除率,%;R生物为生物去除率,%;R膜截留为膜截留去除率,%;C进水为进水COD、

${\rm{NH}}_4^ + $ -N和MB/CR的质量浓度,mg·L−1;C上清液为上清液COD、$ {\rm{NH}}_4^ + $ -N和MB/CR的质量浓度,mg·L−1;C出水为出水COD、${\rm{NH}}_4^ + $ -N和MB/CR的质量浓度,mg·L−1。式中:J为膜通量,L·(m2·h)−1;P为TMP,kPa;μ为粘度,Pa·s;R为过滤阻力,m−1。

-

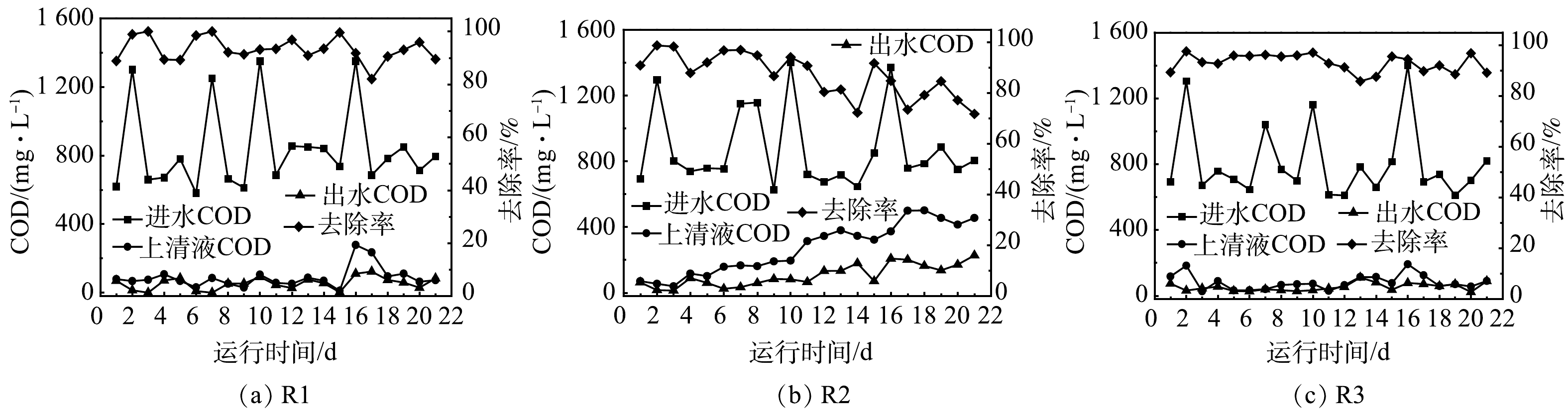

图2反映了MBR中COD及其去除率随时间的变化。由计算得出,MBR对COD的总去除率达到80%以上,去除途径以生物去除为主,出水COD低于70 mg·L−1;MB对MBR中生物处理性能有较大的影响,而CR对其影响较弱。相比无添加染料的R1,R2中添加50 mg·L−1的MB后,COD总去除率为83.07%。其中,R2中生物去除率为63.67%,显著低于R1(85.54%)。由图2(b)可以看出,在运行后期上清液中的COD持续升高。这说明MB的加入使得MBR中微生物的活性降低,进而降低了其对有机物的降解能力。此外,膜截留去除率为19.40%。这表明MBR处理含MB废水时,膜对出水水质具有重要贡献。

相比R1,R3中添加50 mg·L−1的CR后,COD总去除率为88.93%。这说明CR对微生物降解有机物的能力影响较小,表现在生物去除率增加了0.4%,但膜截留去除率却降低了0.55%。FRIHA等[15]采用MBR对含阴离子染料纺织废水的处理进行了处理,COD去除率为98%;YURTSEVER等[8]采用AnMBR和AeMBR对含有1 000 mg·L−1 COD 和100 mg·L−1偶氮染料的纺织废水进行了处理,COD的去除率为97%。

对比R2和R3,在相同的投加量下,阳离子染料MB比阴离子染料CR对MBR的影响更显著,尤其是对生物去除率的影响,而膜截留对保证MBR出水水质具有积极作用。JI等[16]采用传统MBR对含孔雀石绿(MG)的纺织废水进行处理,TOC总去除率为67%,传统活性污泥的生物处理过程受到抑制;采用嗜水气单胞菌(LZ-MG14)强化生物处理后,TOC总去除率显著提高至82%。

由计算得出,R1和R3对

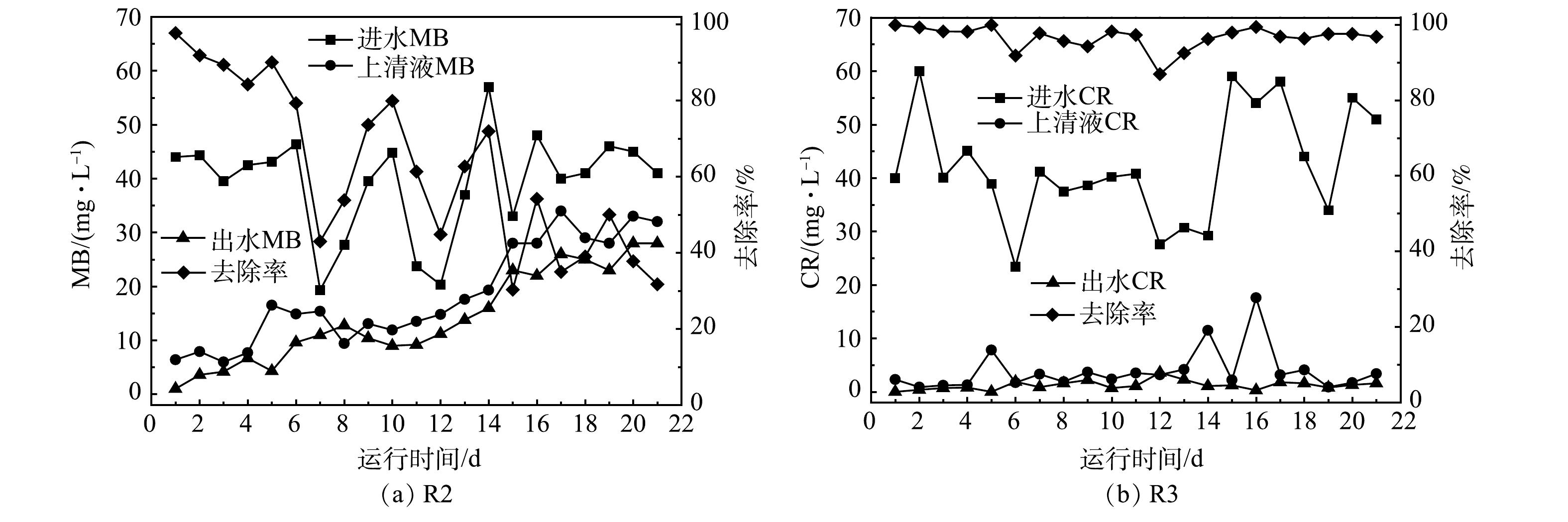

$ {\rm{NH}}_4^ + $ -N的总去除率分别为90.90%和87.44%,生物去除率分别为87.26%和82.79%,膜截留去除率分别为3.64%和4.65%,出水$ {\rm{NH}}_4^ + $ -N平均质量浓度均低于4 mg·L−1。这说明CR的加入并不会影响微生物对$ {\rm{NH}}_4^ + $ -N的硝化和反硝化作用,膜截留作用有效地促进了缓慢生长硝化微生物的增殖[17]。R2中$ {\rm{NH}}_4^ + $ -N总去除率为25.11%,远低于R1(90.90%)。其中,R2中生物去除率为21.97%,显著低于R1(87.26%),出水$ {\rm{NH}}_4^ + $ -N平均质量浓度为43.7 mg·L−1。由图3(b)可以看出,随着运行时间的延长,MBR对$ {\rm{NH}}_4^ + $ -N的去除率逐渐降低。这是由于MB具有较强的毒性,去除效果易受毒性的影响。曹靖[18]的研究表明,硝化活性易受有毒物质的影响,实际染料废水毒性较高,使得污水处理系统中的硝化受到抑制。RAVADELLI等[9]在采用电絮凝辅助缺氧/好氧膜生物反应器处理含50 mg·L−1雷马唑亮紫5R的印染废水过程中也发现,$ {\rm{NH}}_4^ + $ -N去除率的降低是由于硝化作用的减弱。膜对离子形态氨氮的截留作用较弱[19-20],去除率为3.23%。对比R2和R3,在相同投加量下,MB比CR对MBR去除$ {\rm{NH}}_4^ + $ -N的影响更显著,尤其是对生物去除率的影响。由图4(a)可以看出,R2中总去除率为59.26%,出水MB平均质量浓度为14.18 mg·L−1;R3中总去除率为92.39%,出水CR平均质量浓度为1.23 mg·L−1。MBR对MB的总去除率显著低于对CR的总去除率;MB和CR的去除途径主要以生物去除为主,但MB的生物去除率(占总去除率的82.1%)低于CR的生物去除率(占总去除率的93.3%)。此外,R2上清液和出水中的MB浓度变化趋势一致,说明膜截留作用的去除率较为稳定,约10%左右。DEOWAN等[21]采用MBR对红色染料进行了去除实验,得出MBR系统中染料去除的主要机制是活性污泥降解和吸附。本研究中上清液MB的浓度在MBR运行期间持续增加,这说明阳离子染料MB的可生化性较差,其去除途径主要依靠活性污泥的吸附。而R3中的出水水质较好,且几乎无色。这与KONSOWA等[22]采用好氧浸没式中空纤维MBR处理阴离子染料C81获得的结果一致。

-

为了探究染料对MBR中活性污泥性能的影响,系统运行期间,在相同条件下,对污泥浓度、污泥代谢产物和污泥粒度分布进行了检测。

1) MLSS、MLVSS和MLVSS/MLSS。MBR运行过程中MLSS、MLVSS的浓度及MLVSS/MLSS随时间的变化如图5所示。MLSS的初始质量浓度在7.0 g·L−1左右,MBR系统运行期间,MLSS的平均浓度分别为7.8、7.6和7.0 g·L−1,MLVSS的平均浓度分别为6.2、6.0和5.4 g·L−1,说明污泥浓度无明显增殖和降低。R1、R2和R3中MLVSS/MLSS的值分别为0.79、0.78和0.77,均在稳定范围内,这说明无机物没有明显累积。MLSS、MLVSS是活细胞(Ma)、微生物内源代谢的残留物(Me)和无机物的总和。因此,造成污染物去除性能变化的原因可能归结为微生物活性和其代谢产物的量。为此,实验中还检测了EPS和SMP的浓度。

2)污泥代谢产物的比较。EPS提供细胞在生物絮凝物和生物膜中的粘附,形成屏障以保护细胞免受废水中有害物质的侵害,并通过吸附积累营养物质[23-24]。EPS和SMP在MBR的膜污染过程中也起着重要作用,是导致滤饼层和凝胶层形成的重要因素之一[25-26]。PN和PS为EPS、SMP的主要成分,通常以PN和PS的浓度之和表征EPS和SMP的含量[17,23]。PN是疏水性物质,PS是亲水性物质,PN等疏水性EPS对于微生物聚集体的形成非常重要,PN和PS的浓度以及疏水性的不同被认为是污泥颗粒稳定性的重要因素[27]。EPS的PN和PS随时间的变化如图6所示。

相比EPS中的PS和PN的平均含量,R1中的PS和PN分别为8.7 mg·g−1(以MLSS计)和39.3 mg·g−1,而R2中分别为10.4 mg·g−1和48.2 mg·g−1,即R2中EPS平均浓度高于R1中EPS的数值。这一结果说明,阳离子染料MB的加入对MBR中微生物有毒性,导致EPS释放,非活性微生物量较高[28]。计算各自的PN/PS分别为4.5和4.6,这说明R2中活性污泥整体的疏水性较R1增加,较高的PN/PS会造成较严重的膜污染[29]。R3中PS和PN的平均浓度分别为8.0 mg·g−1和23.7 mg·g−1,即EPS平均浓度低于R1中EPS的数值。2个反应器EPS中的PS平均浓度基本一致,而R3中PN平均浓度明显降低,计算的PN/PS为3.0。这说明阴离子CR的加入对MBR中微生物生长影响较小,相比R1,活性污泥整体的疏水性较小,发生膜污染的程度减小。

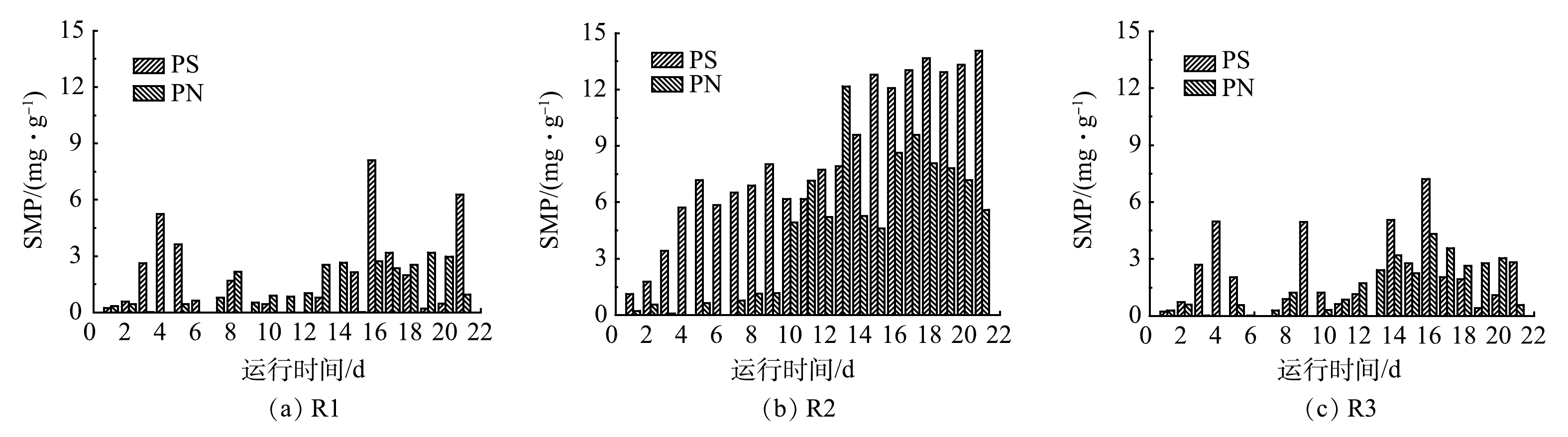

MBR在整个操作过程中SMP的PN和PS含量随时间的变化如图7所示。此结果表明,R1中PN和PS的平均含量分别为1.3 mg·g−1和1.8 mg·g−1,R2中PN和PS的平均含量分别为4.3 mg·g−1和8.4 mg·g−1,R3中PN和PS的平均含量分别为1.5 mg·g−1和2.0 mg·g−1。相比R1,R2中PN和PS均增加,即SMP总量显著增加。这说明阳离子染料MB的加入会导致微生物细胞破裂,增加SMP的产生。SMP通过吸附易造成膜孔堵塞[30],膜的截留使SMP在膜表面积累形成凝胶层,导致混合液的过滤性能较差,进而发生更严重的膜污染[31]。R3中PN、PS和SMP总量较R1无明显差异。这说明MB比CR更容易增加MBR中SMP的量和加重膜污染。R2中污泥代谢产物总量(EPS+SMP)为71.43 mg·g−1,显著高于R3的值35.22 mg·g−1,在污泥浓度增幅一致的情况下,R2中污泥的活性低于R3。

3)污泥粒径。有研究[32]表明,小颗粒具有较高的抗压能力,会降低滤饼层的孔径,从而导致较高的滤饼阻力。因此,颗粒尺寸对于滤饼层结垢特性很重要。在本研究中,3个MBR接种同样初始粒径的污泥。图8反映了MBR运行末期活性污泥的粒度分布情况。图中差异线表示不同尺寸粒径的百分比含量,累积线指某一尺寸粒径之前所有颗粒百分比含量的累积量,D10指当累积粒径含量为10%时对应的絮体粒径,中位粒径D50是指当累积粒径含量为50%时对应的絮体粒径,D90指当累积粒径含量为90%时对应的絮体粒径。

R1和R2中的D10分别为22.46 μm和29.37 μm。这表明R2小颗粒污泥絮体较多,由于其受到的剪切力小、回输速度低,故造成膜表面沉积形成滤饼的概率增加。R1和R2中的D50分别为112.7 μm和110.9 μm。这表明阳离子染料MB的加入使污泥粒度整体降低,R2比R1更容易在膜表面形成密实的滤饼层,从而导致R2中膜污染严重。R3中D10和D50分别为28.7 μm和119.7 μm,高于R1中对应的数值。这说明MBR处理含阴离子染料CR的废水时,活性污泥的可滤性未受到明显影响。3个反应器中的D90相差不大。

-

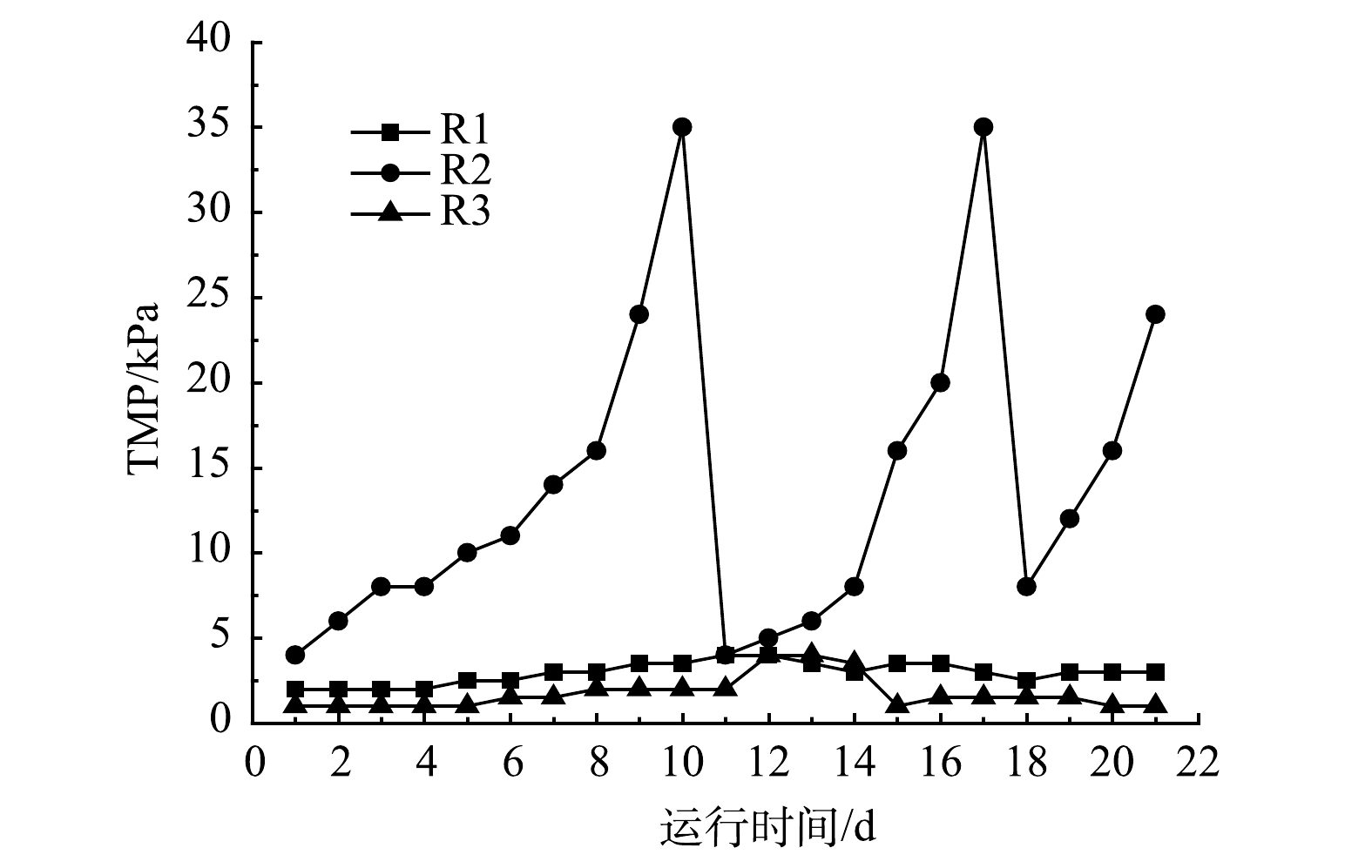

通过分析EPS和SMP的含量可知,R2中EPS和SMP总量大于R1,R3小于R1。此结果表明,R2更容易在膜表面形成密实的滤饼层,这将造成严重的膜污染。因此,本实验对TMP进行了检测。

1) TMP的变化。3个MBR系统在相同HRT下运行,将膜取出进行清洗的TMP设定为35 kPa,MBR系统在恒定出水通量为8.5 L·(m2·h)−1下运行,TMP随时间的变化如图9所示。此结果表明,在运行期间,R2分别在第10和17天的TMP达到35 kPa,且对其进行了2次膜的物理清洗,而R1和R3中的膜未进行物理清洗。结合COD、

${\rm{NH}}_4^ + $ -N和染料的去除效果可知,R1和R3中较高的微生物活性可降低废水中有机物对膜的污染负荷,MB对R2中微生物活性的抑制造成MBR更易于发生严重的膜污染,从而增加膜清洗周期,缩短运行时间。R2中TMP整体数值最高,且TMP增加速率最大;R1中TMP整体数值略高于R3,二者的TMP变化趋势平稳。这说明R2中污泥混合液的可滤性能较差,可能有更多的胶态堵塞了膜孔、更细小的污泥絮体在膜表面沉积形成滤饼。因此,对污染膜的SEM、阻力分布进行了分析。2) SEM及阻力分布。在运行21 d后,对3个MBR的污染膜取样且进行SEM分析,结果如图10所示。可以看出,R1、R2和R3膜表面均覆盖着一层连续的污染层,R2膜表面的形貌看起来比R1和R3更致密且无孔。对比3个MBR污染膜断面的SEM图可以看出,R2的断面厚度为137 μm,明显高于R1(109 μm)和R3(115 μm)。此结果说明R2的污泥沉积严重,这归因于R2中较高的粘性物质(EPS和SMP)以及较小的污泥粒径。对比清洗后的3个MBR污染膜(图10(c)、图10(f)和图10(i))可以看出,3个MBR的膜孔轮廓清晰程度依次为R3>R1>R2,表明R2膜孔堵塞较严重。

为进一步考察膜孔堵塞情况,计算了膜过滤阻力分布及相对阻力贡献(表1)。可见,R2中Rc和Rp的值均大于R1和R3。这表明R2膜面滤饼层厚度和膜孔堵塞情况比R1和R3严重。

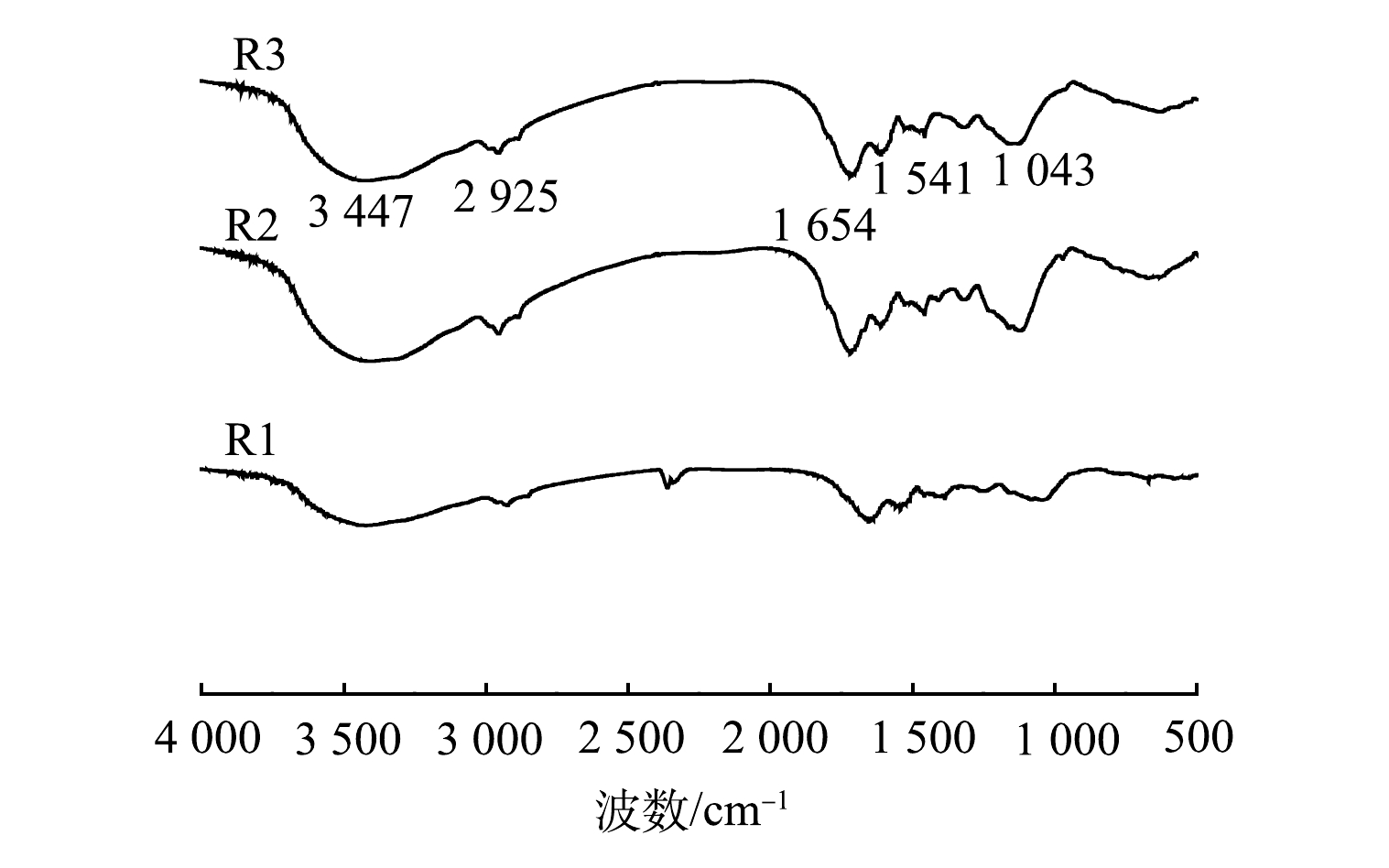

3)滤饼层污染物的红外分析。为了确定滤饼层的组成,采用FTIR对其进行了表征。如图11所示,3个MBR系统中所含物质的特征峰位置基本一致。在3 447 cm−1左右的吸收峰是由于O—H伸缩振动引起的,证明滤饼层中有多糖存在[33];在2 925 cm−1处的吸收峰是由脂肪族C—H伸缩振动引起的,表明存在脂类物质[34];在1 654 cm−1和1 541 cm−1处的峰是由于酰胺C=O伸缩振动和酰胺N—H弯曲振动引起的,证明滤饼层中存在蛋白质[35]。因为模拟进水的成分很容易被生物降解,滤饼层中多糖和蛋白质的存在主要来自微生物代谢产物EPS和SMP。以上结果表明,多糖和蛋白质是造成外部污染的主要来源。

-

1)阳离子染料MB较阴离子染料CR会导致MBR废水处理性能下降。通过比较污泥浓度和微生物代谢产物,证明污泥活性降低是导致MBR废水处理性能下降的主要原因。

2)污泥粒径的减小和较高含量的微生物代谢产物的共同影响会造成膜面滤饼层增厚和膜孔堵塞加重,并表现为较高的TMP值及其快速增长。

3)膜面污染物主要来自微生物代谢产物EPS和SMP。

染料类型对膜生物反应器性能的影响

Influence of dye type on the performance of membrane bioreactor

-

摘要: 为了考察染料类型对膜生物反应器(MBR)处理性能的影响,在相同的染料浓度条件下,探究了阳离子染料MB和阴离子染料CR对MBR去除效果、活性污泥特性及膜污染的影响。结果表明,MBR对亚甲基蓝印染废水中的COD、

${{\rm{NH}}_4^ + } $ -N和亚甲基蓝的去除率分别为83.07%、25.11%和52.26%,均低于处理刚果红印染废水中的相应污染物去除率(88.93%、87.44%和92.39%)。前者系统中污泥代谢产物为71.43 mg·g−1,高于后者的35.22 mg·g−1,且D50为110.9 μm,导致系统分别在第10和17天的TMP达到清洗压力。扫描电子显微镜、阻力分析和红外光谱表征结果表明,处理亚甲基蓝印染废水的MBR滤饼层较厚(137 μm),膜孔阻力较大(9.01%),污染物主要成分为多糖和蛋白质。Abstract: In order to investigate the effect of dye types on the performance of membrane bioreactor (MBR), at the same dye concentrations, the effects of cationic dye MB and anionic dye CR on MBR removal efficiency, activated sludge characteristics and membrane fouling were studied. The results showed that the removal rates of COD,$ {\rm{NH}}_4^ + $ -N and methylene blue were 83.07%, 25.11% and 52.26% by MBR treating printing and dyeing wastewater with methylene blue, respectively, which were all lower than 88.93%, 87.44% and 92.39% by MBR treating printing and dyeing wastewater congo red. The sludge metabolite of the former system was 71.43 mg·g−1 , being higher than 35.22 mg·g−1 of the latter system, and the D50 was 110.9 μm, which caused the system TMP reaching the cleaning pressure on the 10th and 17th day, respectively. The results of scanning electron microscope, resistance analysis and infrared spectroscopy showed the filter cake layer of MBR treating printing and dyeing wastewater with methylene blue was thicker (137 μm), the membrane pore resistance was larger (9.01%), and the main contaminants were polysaccharides and proteins.-

Key words:

- membrane bioreactor /

- methylene blue /

- Congo red /

- removal effect /

- activated sludge /

- membrane fouling

-

-

表 1 MBR中膜过滤阻力分布及相对阻力贡献

Table 1. Membrane filtration resistance distribution and relative resistance contribution in MBR

MBR 阻力/(109 m−1) 相对阻力贡献/% Rt Rm Rc Rp Ri Rm Rc Rp Ri R1 2.72 2.23 0.35 0.10 0.04 81.98 12.87 3.68 1.47 R2 4.33 2.26 1.58 0.39 0.10 52.19 36.49 9.01 2.31 R3 2.85 2.19 0.40 0.17 0.09 76.84 14.04 5.96 3.16 -

[1] 宋箭, 赵秋燕, 伍昌年, 等. 复合式动态膜生物反应器处理印染废水效能及膜污染控制[J]. 环境工程学报, 2016, 10(5): 2193-2200. doi: 10.12030/j.cjee.201510224 [2] 金诚, 杨波, 李方, 等. 好氧颗粒污泥自生动态膜生物反应器处理碱减量印染废水[J]. 环境工程学报, 2014, 8(9): 3819-3824. [3] 公言飞, 刘鹏, 郅立鹏. 膜生物反应器(MBR)研究现状及发展趋势[J]. 中国资源综合利用, 2021, 39(3): 90-93. doi: 10.3969/j.issn.1008-9500.2021.03.026 [4] DEOWAN S A, GALIANO F, HOINKIS J, et al. Submerged membrane bioreactor (SMBR) for treatment of textile dye wastewatertowards developing novel MBR process[J]. APCBEE Procedia, 2013, 5: 259-264. doi: 10.1016/j.apcbee.2013.05.045 [5] 丁岚, 谢元华, 钟圣俊, 等. 膜生物反应器法处理模拟印染废水[J]. 环境保护科学, 2013, 39(1): 6-10. doi: 10.3969/j.issn.1004-6216.2013.01.002 [6] 邢奕, 鲁安怀, 洪晨, 等. 膜生物反应器(MBR)-反渗透(RO)工艺深度处理印染废水的实验研究[J]. 环境工程学报, 2011, 5(11): 2583-2586. [7] SARI ERKAN H, ÇAGLAK A, SOYSALOGLU A, et al. Performance evaluation of conventional membrane bioreactor and moving bed membrane bioreactor for synthetic textile wastewater treatment[J]. Journal of Water Process Engineering, 2020, 38: 101631. doi: 10.1016/j.jwpe.2020.101631 [8] YURTSEVER A, SAHINKAYA E, AKTAS O, et al. Performances of anaerobic and aerobic membrane bioreactors for the treatment of synthetic textile wastewater[J]. Bioresource Technology, 2015, 192: 564-573. doi: 10.1016/j.biortech.2015.06.024 [9] RAVADELLI M, DA COSTA R E, Lobo-Recio M A, et al. Anoxic/oxic membrane bioreactor assisted by electrocoagulation for the treatment of azo-dye containing wastewater[J]. Journal of Environmental Chemical Engineering, 2021, 9(4): 105286. doi: 10.1016/j.jece.2021.105286 [10] FENG F, XU Z, LI X, et al. Advanced treatment of dyeing wastewater towards reuse by the combined Fenton oxidation and membrane bioreactor process[J]. Journal of Environmental Sciences, 2010, 22(11): 1657-1665. doi: 10.1016/S1001-0742(09)60303-X [11] JOHIR M A, SHANMUGANATHAN S, VIGNESWARAN S, et al. Performance of submerged membrane bioreactor (SMBR) with and without the addition of the different particle sizes of GAC as suspended medium[J]. Bioresource Technology, 2013, 141: 13-18. doi: 10.1016/j.biortech.2013.03.032 [12] WANG Y, ZHONG C, HHUANG D, et al. The membrane fouling characteristics of MBRs with different aerobic granular sludges at high flux[J]. Bioresource Technology, 2013, 136: 488-495. doi: 10.1016/j.biortech.2013.03.066 [13] CHANG I S, KIM S N. Wastewater treatment using membrane filtration: Effect of biosolids concentration on cake resistance[J]. Process Biochemistry, 2005, 40(3): 1307-1314. [14] KIM J Y, CHANG I S, PARK H H, et al. New configuration of a membrane bioreactor for effective control of membrane fouling and nutrients removal in wastewater treatment[J]. Desalination, 2008, 230(1): 153-161. [15] FRIHA I, BRADAI M, JOHNSON D, et al. Treatment of textile wastewater by submerged membrane bioreactor: In vitro bioassays for the assessment of stress response elicited by raw and reclaimed wastewater[J]. Journal of Environmental Management, 2015, 160: 184-192. [16] JI J, KULSHRESHTHA S, KAKADE A, et al. Bioaugmentation of membrane bioreactor with Aeromonas hydrophila LZ-MG14 for enhanced malachite green and hexavalent chromium removal in textile wastewater[J]. International Biodeterioration & Biodegradation, 2020, 150: 104939. [17] ZHANG D, TRZCINSKI A P, KUNACHEVA C, et al. Characterization of soluble microbial products (SMPs) in a membrane bioreactor (MBR) treating synthetic wastewater containing pharmaceutical compounds[J]. Water Research, 2016, 102: 594-606. doi: 10.1016/j.watres.2016.06.059 [18] 曹靖. 升流式水解反硝化-好氧工艺处理实际染料废水中试研究[D]. 北京: 北京化工大学, 2020. [19] LIU Y, NGO H H, GUO W, et al. Autotrophic nitrogen removal in membrane-aerated biofilms: Archaeal ammonia oxidation versus bacterial ammonia oxidation[J]. Chemical Engineering Journal, 2016, 302: 535-544. doi: 10.1016/j.cej.2016.05.078 [20] LAUTERBOCK B, NIKOLAUSZ M, LV Z, et al. Improvement of anaerobic digestion performance by continuous nitrogen removal with a membrane contactor treating a substrate rich in ammonia and sulfide[J]. Bioresource Technology, 2014, 158: 209-216. doi: 10.1016/j.biortech.2014.02.012 [21] DEOWAN S A, GALIANO F, HOINKIS J, et al. Novel low-fouling membrane bioreactor (MBR) for industrial wastewater treatment[J]. Journal of Membrane Science, 2016, 510: 524-532. doi: 10.1016/j.memsci.2016.03.002 [22] KONSOWA A H, ELOFFY M G, EL-TAWEEL Y A. Treatment of dyeing wastewater using submerged membrane bioreactor[J]. Desalination and Water Treatment, 2013, 51(4/5/6): 1079-1090. [23] KUNACHEVA C, STUCKEY D C. Analytical methods for soluble microbial products (SMP) and extracellular polymers (ECP) in wastewater treatment systems: A review[J]. Water Research, 2014, 61: 1-18. doi: 10.1016/j.watres.2014.04.044 [24] LASPIDOU C S, RITTMANN B E. A unified theory for extracellular polymeric substances, soluble microbial products, and active and inert biomass[J]. Water Research, 2002, 36(11): 2711-2720. doi: 10.1016/S0043-1354(01)00413-4 [25] ZHANG W, LIU F, WANG D, et al. Impact of reactor configuration on treatment performance and microbial diversity in treating high-strength dyeing wastewater: Anaerobic flat-sheet ceramic membrane bioreactor versus upflow anaerobic sludge blanket reactor[J]. Bioresource Technology, 2018, 269: 269-275. doi: 10.1016/j.biortech.2018.08.126 [26] MENG F, ZHANG S, OH Y, et al. Fouling in membrane bioreactors: An updated review[J]. Water Research, 2017, 114: 151-180. doi: 10.1016/j.watres.2017.02.006 [27] CHEN M Y, LEE D J, TAY J H. Distribution of extracellular polymeric substances in aerobic granules[J]. Applied Microbiology Biotechnology, 2007, 73(6): 1463-1469. doi: 10.1007/s00253-006-0617-x [28] AQUINO S F, STUCKEY D C. Soluble microbial products formation in anaerobic chemostats in the presence of toxic compounds[J]. Water Research, 2004, 38(2): 255-266. doi: 10.1016/j.watres.2003.09.031 [29] TIAN Y, LU Y, LI Z. Performance analysis of a combined system of membrane bioreactor and worm reactor: Wastewater treatment, sludge reduction and membrane fouling[J]. Bioresource Technology, 2012, 121: 176-182. doi: 10.1016/j.biortech.2012.06.071 [30] TEYCHENE B, GUIGUI C, CABASSUD C, et al. Toward a better identification of foulant species in MBR processes[J]. Desalination, 2008, 231(1): 27-34. [31] ROSENBERGER S, LAABS C, LESJEAN B, et al. Impact of colloidal and soluble organic material on membrane performance in membrane bioreactors for municipal wastewater treatment[J]. Water Research, 2006, 40(4): 710-720. doi: 10.1016/j.watres.2005.11.028 [32] ERSAHIN M E, OZGUN H, TAO Y, et al. Applicability of dynamic membrane technology in anaerobic membrane bioreactors[J]. Water Research, 2014, 48: 420-429. doi: 10.1016/j.watres.2013.09.054 [33] YURTSEVER A, SAHINKAYA E, ÇINAR Ö. Performance and foulant characteristics of an anaerobic membrane bioreactor treating real textile wastewater[J]. Journal of Water Process Engineering, 2020, 33: 101088. doi: 10.1016/j.jwpe.2019.101088 [34] YURTSEVER A, BASARAN E, UCAR D, et al. Self-forming dynamic membrane bioreactor for textile industry wastewater treatment[J]. Science of The Total Environment, 2021, 751: 141572. doi: 10.1016/j.scitotenv.2020.141572 [35] CHEN W, LUO J, CAO R, et al. Effect of macroporous adsorption resin-membrane bioreactor hybrid system against fouling for municipal wastewater treatment[J]. Bioresource Technology, 2017, 224: 112-117. doi: 10.1016/j.biortech.2016.11.094 -

下载:

下载: