-

在全球的水资源储量中,淡水只占2.53%,而在这些淡水资源中,只有13%可被人类直接利用[1]。为了解决淡水资源紧缺问题,除了对现有的水资源保护、合理利用,还应积极开发利用其它水资源[2]。膜电容去离子是一种无需加入任何化学物质的新型脱盐技术,其原理是通过对电极两端施加电压,进水中的盐离子在电场力的作用下通过离子交换膜吸附在电极表面的双电层(electric double layer, EDL)上,出水得到净化,从而达到脱盐的目的[3]。与反渗透[4]、电渗析[5-6]、膜蒸馏[7]、离子交换[8]等传统脱盐方法相比,MCDI表现出装置简单、易操作、电极易再生、成本低,无污染、节能等优势,尤其是在低盐度盐水淡化中的优势更明显。离子交换膜具有高选择性的特点,能够阻碍反离子的通过,可有效避免同离子效应,提高电荷效率[9],且电极上不易发生有机污染[10-11]。除了脱盐,MCDI还实现了选择性去离子、资源回收等功能。目前对MCDI的研究主要集中在以下几个方面:离子迁移储存机制与模型、电极材料[12]、加电方式以及装置构型等[13]。

MCDI为低电压驱动运行,单级装置运行下,脱盐效率低,且出水水质难以达标。为了解决这一难题,很多学者采用了电极堆叠和膜堆叠的方法。LEE等[14]通过对多个电极堆叠的方式,进行了对每个电极都加电的单级和只对边缘电极加电的双极脱盐实验的研究,结果表明双极性堆叠的(capacitive deionization, CDI)电极具有较高的脱盐速率和能量损耗。MA等[15]组建了多对膜装置,比较了1对、2对和3对离子交换膜装置的脱盐性能,研究发现,2对膜的脱盐速率约为一对膜的2倍,3对膜装置的脱盐速度反而不如两对膜装置的,结果表明了靠无限制的膜堆叠提高脱盐性能的方法行不通。电极堆叠[16]和膜堆叠都能够提高脱盐速率,但受到单级装置的限制,其脱盐性能受限。还有一些学者通过MCDI装置串、并联的方法来提高脱盐性能,SALEEM等[17]将CDI技术与反电渗析技术(reverse electrodialysis, RED)相结合,对4个CDI装置进行了串联和并联操作,吸附过程中4个装置并联连接,解吸过程中4个装置串联连接。该工艺通过RED产生的能量能再次用于CDI脱盐,该系统将产水能耗从1.5 kJ·L−1降低到了0.58 kJ·L−1。CHENG等[18]将多个CDI装置串联,提高了电极的吸附性能。MCDI与传统脱盐技术相比,在适度脱盐上具有明显优势,在其他多级串联MCDI研究中,未曾对体系中的单级装置的脱盐过程进行单独调控,本工作创新性地提出通过对体系中的装置单独加电降低运行能耗,并从多角度对脱盐性能进行了优化研究。而且多装置在维护方面也更有优势,且单级装置维修时又不影响其它装置的运行,多级串联对于MCDI脱盐工程化具有深远意义。

本研究采用多级串联MCDI的方法,通过将各级进出水连接,不仅可以达到深度脱盐的目的,而且还能收集不同浓度的出水,以期适应不同需求。还能针对不同盐度的盐水采用不同的处理方式,避免脱盐不充分,能源浪费等问题。也可根据脱盐过程的具体要求,对不同级MCDI装置进行单独加电控制,以节省能耗。实验研究了一级、二级、三级串联MCDI装置出水水质的脱盐性能,从电压、水力停留时间和盐水质量浓度等方面等进行了优化,最后又分析了多级串联MCDI连续脱盐的稳定性。

-

超级电容活性炭(activated carbon, AC),购自福州益环碳素有限公司YEC-200D。炭黑(carbon black, CB),购自阿法埃莎(中国)化学有限公司;聚四氟乙烯(polytetrafluoroethylene, PTFE),购自东莞市展阳高分子材料有限公司;无水乙醇和氯化钠,购自天津市永大化学试剂有限公司,所用试剂均为分析纯,且未经二次处理。

-

活性炭电极按AC∶CB∶PTFE=8∶1∶1的比例构成,PTFE作为材料粘结剂。分别称取0.288 g AC和0.036 g CB放入25 mL烧杯中,加入0.036 μL的PTFE和适量无水乙醇搅拌混匀,材料粘结成橡皮泥状后均匀涂覆在45 mm×50 mm导电钛网上,用压片机(压力0.2 MPa)对电极材料进行压片,最后置于50 ℃烘箱中干燥5 min。

-

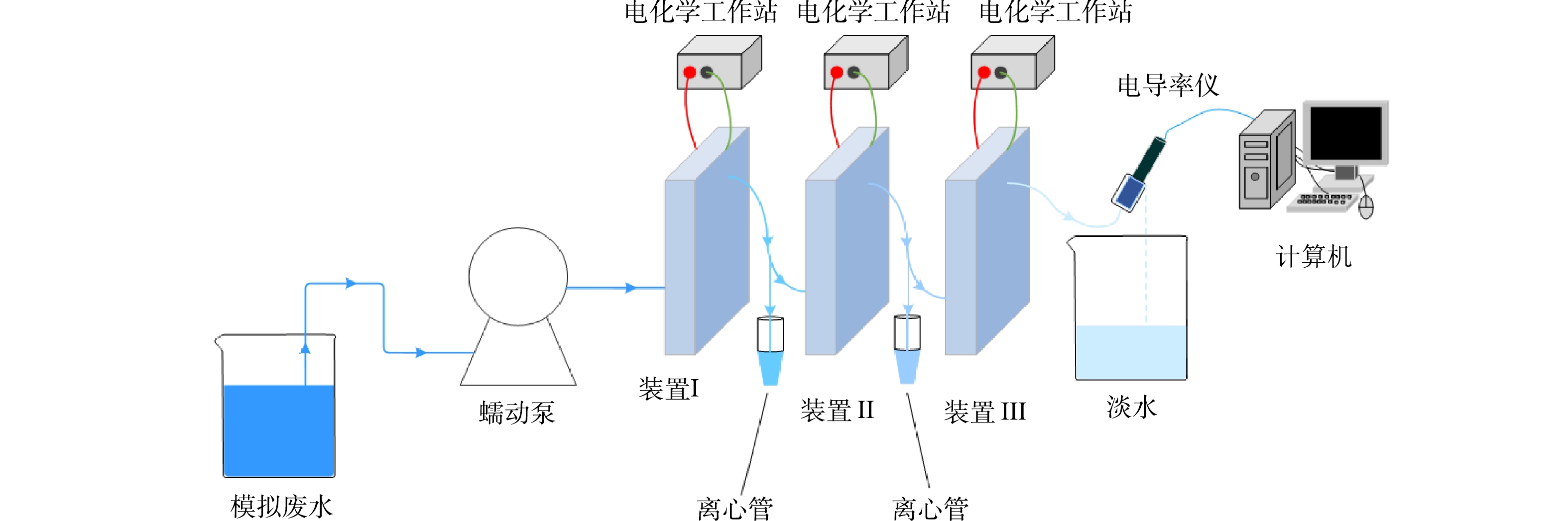

图1为多级串联MCDI示意图,本实验将3个MCDI装置进行串联,每个MCDI装置由一个中间腔室(45 mm×50 mm×0.5 mm),5个密封硅胶垫片,一对钛片,一对活性炭电极(45 mm×50 mm)和一对聚氯乙烯(poly vinyl chloride, PVC)塑料板组成。为了使盐水溶液在腔室中分布均匀,将100目尼龙片(45 mm×50 mm×0.5 mm)作为布水分隔。电极片与离子交换膜的有效接触面积为22.5 cm2。离子交换膜之间、PVC塑料板与钛片之间、钛片与离子交换膜之间都用硅胶垫隔开,装置末端用PVC塑料板固定。

-

实验系统如图2所示,所有的实验的进水采用单向流(single pass)模式[19],进水流采用下进上出式,盐水经蠕动泵(BT100-1L, 保定兰格恒流源有限公司)依次流入装置I、II、III,每个装置分别由电源单独控制。从装置III流出的水与电导率仪(S475-UMIX, 梅特勒seven excellence)探头连接,用于实时监测出水的电导率变化。装置I、II和装置II、III之间加入三通,分别在3、7、11、15、19 min时取约1 mL水样于10 mL离心管中,用于测定一级出水和二级出水时的电导率。装置电压通过电化学工作站(3605H, 深圳市艾维泰科仪器仪表有限公司)调节,对三级装置施加相同的直流恒定电压(constant voltage, CV)。所有装置同时加电180 s后,断电60 s,循环5次,总时间1 200 s,实际加电时间为900 s。水力停留时间通过调节蠕动泵的转速来实现。为确保实验数据的可靠性,每组实验至少进行2次平行实验。对比一、二、三级串联下脱盐性能的实验条件:电压0.8~1.2 V,水力停留时间0.25~0.5 min,进水质量浓度0.5~2.0 g·L−1。连续脱盐实验条件:电压1.2 V, 水力停留时间1.125 min, 进水溶液0.5 g·L−1。在连续脱盐过程中,不进行断电操作,不单独取样。

-

脱盐率(salt removal efficiency,SRE)、平均脱盐速率(average salt removal rate,ASRR)、单位能量脱盐量(energy normalization removal salt,ENRS)和吸附容量(salt adsorption capacity,SAC)等是衡量脱盐性能的几个重要指标。在低质量浓度时,NaCl质量浓度与电导率呈正比关系[20]。SRE根据式(1)计算;ASRR为单位腔室面积和单位时间内盐的去除量,根据式(2)计算;ENRS为每焦耳去除的离子量,根据式(3)计算;SAC为单位质量电极可以吸附盐的总量,根据式(4)计算。

式中:η为脱盐率,%;C0为进水溶液质量浓度,g·L−1;Ct为t时刻出水溶液质量浓度,g·L−1。

式中:α为平均脱盐速率,μmol·(cm2·min)−1;S为参与吸附的电极片的面积,cm2;V为脱盐溶液的体积,mL;t为实际加电时间,min。

式中:β为单位能量脱盐量,μmol·J−1;U为施加恒定电压的大小,V;I为加电时的感应电流,A。

式中:qe为吸附容量,mg·g−1;m为电极片的质量,g。

-

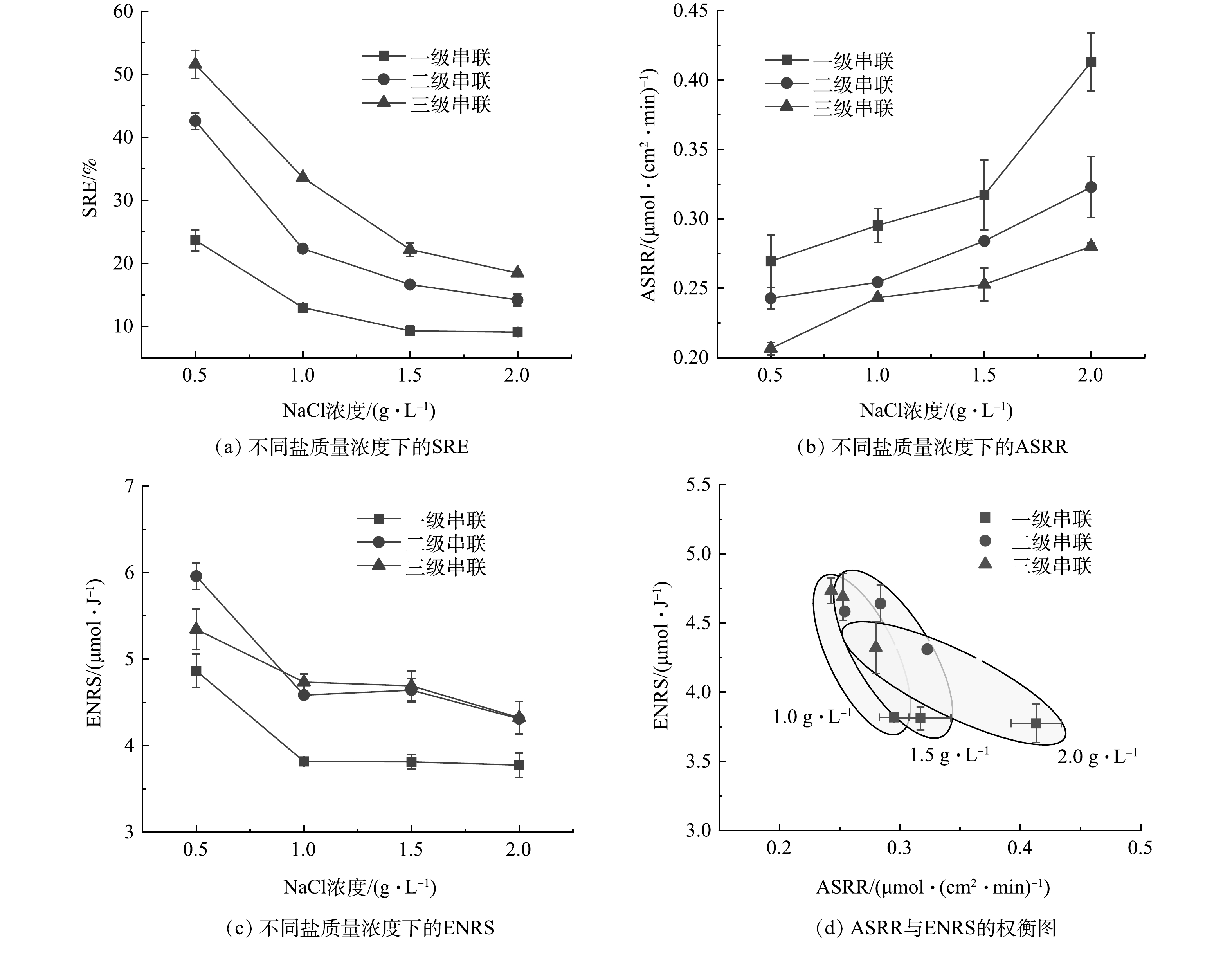

在吸附过程中,电极的孔径只有大于临界孔径时,离子才会被储存在电极孔隙中,从而达到脱盐的目的。而进水浓度直接影响了临界孔径值,进水浓度越高,临界孔径值越小,参与吸附的孔隙越多,离子吸附就越多[21]。图3反映了进水盐质量浓度对各级串联MCDI脱盐性能的影响。将3个装置的进水腔室串联,串联MCDI在不同NaCl质量浓度下的SRE如图3(a)所示。由图3(a)中可以看出,随着NaCl质量浓度的升高,各级串联MCDI的SRE都在下降。虽然进水NaCl质量浓度的升高增加了离子吸附量,但由于初始质量浓度的升高最终导致了SRE的降低。离子吸附量的增加可由图3(b)中的ASRR来反映,进水NaCl质量浓度越高,ASRR越高,表明离子吸附量越高。ENRS反映了单位能量去除的盐量,ENRS越高,装置越节能。不同进水盐质量浓度的下的ENRS如图3(c)所示,随着浓度的升高,串联MCDI的ENRS在上升。造成这一结果的原因可能是,NaCl浓度越高,参与吸附的孔隙越多,吸附离子所需的能量越多。

在相同进水质量浓度(0.5~2.0 g·L−1)下,随着串联级数的增加,SRE和ENRS值增高, ASRR值下降。说明串联MCDI能够有效提高脱盐率,节省能量。而ASRR下降的原因可能是,在吸附过程中,盐水在流出前一个装置时质量浓度下降,进入后续装置时质量浓度较低,吸附离子量下降。因为进水浓度越高,离子吸附越多,所以这种差距在浓度越高时越明显。而ENRS上升的原因可能是,后续装置进水浓度的下降使参与离子吸附的孔隙变少,离子吸附所消耗的能量减少。在进水质量浓度为0.5 g·L−1时,三级串联ENRS低于二级串联,原因可能是,装置III的进水质量浓度过低,导致了临界孔径值过大,参与吸附的孔隙过少,吸附离子量过少[22]。

不同进水浓度应按照串联级数严格控制,使脱盐速率和能耗达到最优,避免脱盐不充分和装置闲置等问题。利用进水质量浓度在1.0~2.0 g·L−1下数据构建了图3(d)的ASRR和ENRS的权衡图,权衡图反映了ASRR与ENRS的权衡关系,图中ASRR越高,其 ENRS越低。图3(d)结果显示,二级串联和三级串联具有相似的ENRS,但二级串联的ASRR较高,而一级串联虽然具有更高的ASRR,但其ENRS过低。在1.5 g·L−1时,二级串联的ENRS最高,其ASRR也较高。研究结果表明,进水质量浓度的升高,会使ASRR升高,ENRS下降。不同串联级数在不同盐质量浓度下也会表现出不同的脱盐性能,串联级数的增加,会导致ASRR降低。而二级串联和三级串联的ENRS相差很小(甚至在0.5 g·L−1时二级串联高于三级串联)。所以,二级串联MCDI在能耗方面表现出更优异的性能,比起三级串联更节省了装置成本与运行成本,尤其是在进水质量浓度为1.5 g·L−1时。

-

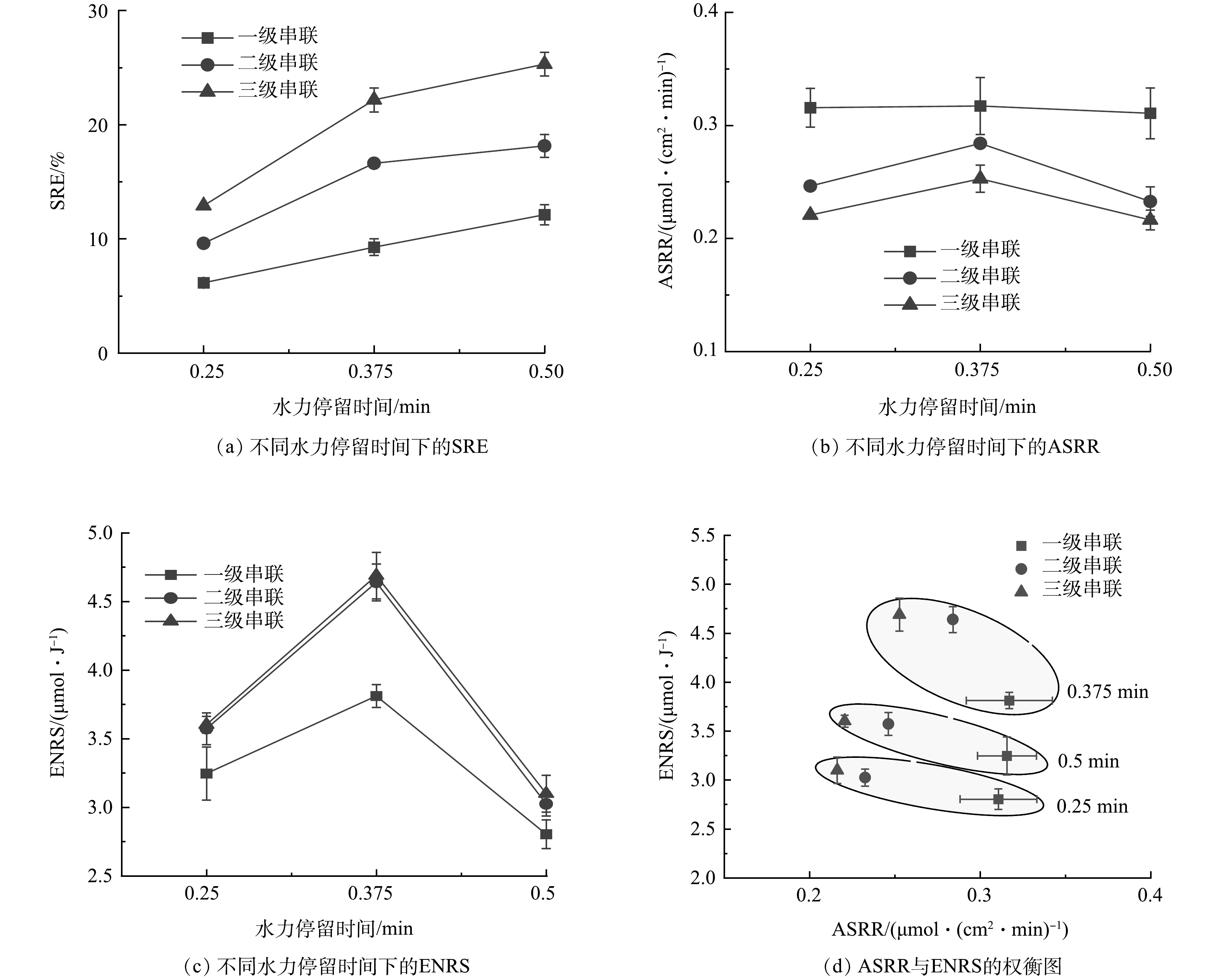

图4反映了水力停留时间对串联MCDI脱盐性能的影响。图4(a)随着水力停留时间的增加,SRE也增加,这是因为在相同时间内,离子在腔室内停留时间越长,离子从溶液中转移到电极材料表面的时间就越长,电极表面吸附的离子吸附量就越多[23],这也会导致ASRR和ENRS的升高。相同时间内,水力停留时间越长会导致流经腔室的溶液体积变少,这也会使SRE升高。如图4(b)和图4(c)所示,ASRR、ENRS的变化趋势相同,均是在0.375 min时最高,在0.5 min时最低,可见水力停留时间过短和过长都不利于脱盐。水力停留时间过短时,盐水更新速度快,离子还未吸附到电极表面就流出腔室,导致了离子吸附量的下降。水力停留时间太长时脱盐性能差的原因可能有2点:一是水力停留时间太长时,盐水更新速度慢,溶液中过多的离子被转移到电极表面上,导致溶液浓度较低,临界孔径值较大,参与吸附的离子孔隙变少,电极吸附离子减少;二是随着反应的进行,电极表面的孔隙内已经堆积了大量的盐离子,相同浓度的溶液再流入腔室后,离子因没有吸附位点而无法被吸附[22]。

不同水力停留时间下的ASRR与ENRS的权衡图如图4(d),水力停留时间在0.375 min时一、二、三级均具有更高的ASRR和ENRS,说明了水力停留时间在0.375 min时的脱盐性能更优。结果表明,二级串联具有更好的脱盐性能。多级串联MCDI实验中水力停留时间对脱盐性能影响较大,选择合适的水力停留时间才能发挥装置的最大性能,实现高脱盐率,低能耗的目标。

-

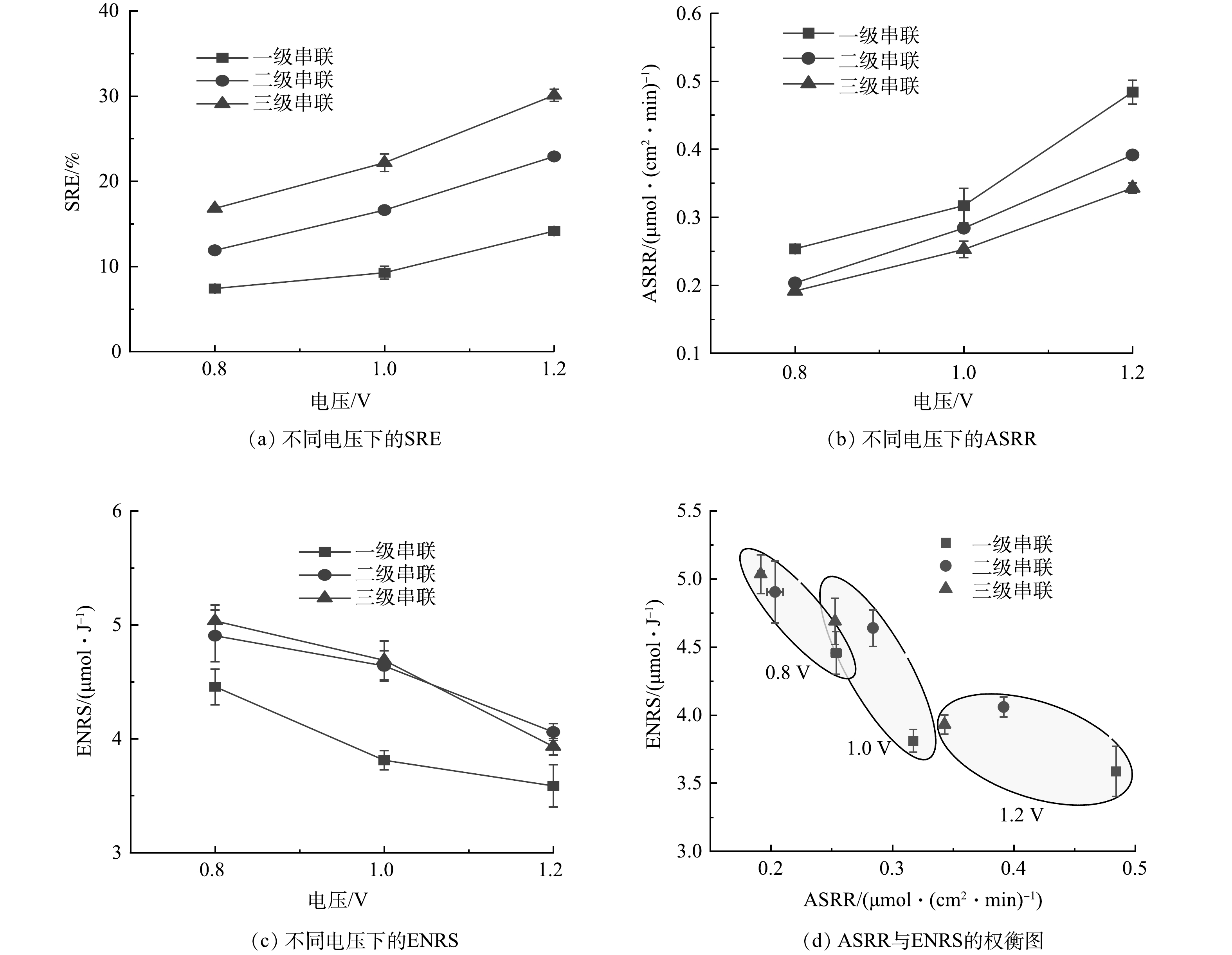

电压对串联MCDI装置的脱盐性能如图5所示,由图5(a)、图5(b)和图5(c)可以看出,SRE和ASRR随电压升高而变高,ENRS随电压升高而变低。可能的原因是,电压作为MCDI装置中的驱动力,电压的增加会增加双电层的厚度,使参与吸附的有效孔隙增加,增加了离子吸附量[24]。MCDI装置的充电过程也是能量储存过程,而能量被储存到MCDI装置中伴随着能量的损失,根据能量守恒定律,当电压增加,MCDI装置能够吸收储存的能量也增加,能量损失也增加。在MCDI的装置中电压的不宜过高,这是因为当电压超过1.23 V时,就会产生水解作用,影响电极吸附,降低盐去除效率,还会腐蚀电极板和离子交换膜[22]。

图5(d)为不同电压下ASRR和ENRS的权衡图。可见,当电压在0.8~1.2 V时,ASRR越高,ENRS越低。结果表明,电压的增加会使MCDI装置吸附更多的离子,但也要消耗更多的能量。串联级数的增加虽然会使脱盐总量上升,但会降低其脱盐速率,而二级串联和三级串联的能耗相似,均比一级串联更节能。

-

对多级串联MCDI装置进行了连续脱盐实验,一、二、三级ASRR和SAC计算区域为0~4 580、0~5 440、0~9 990 s,此时进、出水的盐质量浓度相同,表明电极吸附的离子已经饱和。图6(a)为多级串联MCDI装置出水的电导率图。二级串联相较于一级,能够有效降低出水的电导率,从481.75 μS·cm−1下降到79.72 μS·cm−1,到三级串联电导率下降到了31.57 μS·cm−1,表明多级串联MCDI装置能够得到含盐量更低的出水。三级串联虽然也能够降低出水的浓度,但ASRR较低。如图6(b)所示,二级串联装置性能最佳,比单级装置的SAC和ASRR分别提升了30%和11%,而三级串联的SAC只提升了6%,ASRR却降低了85%。这一结果可能的原因从脱盐过程分析,大致分为3个阶段。1)盐水在流出装置I和装置II后,盐水的浓度经两级装置吸附处理后过低,导致溶液流入装置III后的临界孔径值过大,可参与吸附的孔隙过少,离子吸附量过少。此阶段主要依靠装置I和装置II吸附离子。2)随着充电时间的增加,装置I和装置II电极表面的孔隙中已经吸附了一些离子,因吸附位点减少导致离子吸附量减少,此时流入装置III的盐水质量浓度升高,临界孔径值减小,参与吸附的孔隙增加,离子吸附量增加。此阶段3个装置同时吸附离子。3)随着充电时间再增加,装置III的表面也吸附了大量离子,这使得吸附离子的孔隙减少。而装置I和II的电极表面的孔隙先后吸附了大量的离子,离子因没有吸附位点而无法吸附,导致装置III的进水盐质量浓度再升高,参与吸附的孔隙增加,延长了MCDI吸附时间[21-22]。此阶段只有装置III在吸附离子。所以,在串联MCDI脱盐过程中,应尽量避免和减少第3阶段。如果要求出水水质要求达到自来水标准(500 μS·cm−1以下),二级串联就能以低电压达到很好的效果。在处理不同浓度的盐水时,应选择合适的MCDI串联级数,避免增加装置引来的经济效益和能量效益等问题。

-

1)研究采用多级串联MCDI装置的方法,大幅提高了脱盐性能。在不同操作条件下,二、三级串联的SRE都有较大提高,分别提高了约2倍和3倍。此外,对装置单独控制加电,还能够达到适度脱盐的目的。

2)考察了一、二、三级MCDI串联下进水盐质量浓度、水力停留时间、电压对脱盐性能的影响,通过探究脱盐率,平均脱盐速率、单位能量脱盐量等指标,对ASRR与ENRS的权衡图进行比较,确定了最佳串联级数为二级串联(二、三级串联脱盐速率更快,但三级串联能耗极大),最佳操作条件为1.5 g·L−1的进水盐质量浓度,0.375 min的水力停留时间,1.2 V的电压。

3)在连续脱盐实验中,多级串联MCDI装置可以连续稳定的去除盐离子,其吸附容量更优。本工作对多级MCDI脱盐工程化应用具有指导意义。

多级串联膜电容去离子装置的脱盐性能

Membrane capacitive deionization technology with multi-stage series connection for brine treatment

-

摘要: 膜电容去离子(membrane capacitive deionization, MCDI)技术具有的装置简单、易操作、易再生、成本低,无污染、节能等优势,使其成为一种新型的脱盐技术。为了提升MCDI的脱盐性能,将多个装置的进水串联,对每个装置单独加电来探究脱盐率,平均脱盐速率、单位能量脱盐量等指标对多级串联的影响。结果表明,在进水盐质量浓度、水力停留时间、电压等不同操作条件下,二、三级MCDI串联脱盐率都提高了约2、3倍,三级串联较二级串联的脱盐速率提升较小,但具有更高的能耗。综合比较,二级MCDI串联的脱盐性能更优,并获得了最佳的操作条件为1.5 g·L−1,0.375 min,1.2 V。在连续脱盐过程中,多级串联能够连续稳定的去除盐离子,并且具有较高的吸附容量,表明了连续脱盐的可行性。研究结果对多级MCDI脱盐工程化应用具有指导意义。Abstract: Membrane capacitive deionization (MCDI) technology has the advantages of simple device, easy operation, easy regeneration, low cost, no pollution, energy saving and so on, which makes it a new desalination technology. In order to improve the desalination performance of MCDI, the water influent of multiple devices was connected in series, and each device was charged separately to explore the influence of its salt removal efficiency (SRE), average salt removal rate (ASRR), energy normalization removal salt (ENRS), and other indicators on the multi-stage series connection. The results showed that under different operating conditions such as influent salt concentration, hydraulic retention time, and voltage, the desalination rate of the second and third stage MCDI series increased by about 2 to 3 times. The desalination rate of the third stage series was slightly improved compared to the second stage series, but it had higher energy consumption. Overall comparison, the desalination performance of the two-stage MCDI series connection was better, and the optimal operating conditions were obtained at 1.5 g·L−1, 0.375 min, 1.2 V. In the continuous desalination process, multi-stage series connection can continuously and stably remove salt ions, and has a high adsorption capacity, indicating the feasibility of continuous desalination. The research results have a guiding significance for the desalination engineering application of multi-stage MCDI.

-

-

[1] FRY L M, MIHELCIC J R, WATKINS D W. Water and non-water related challenges of achieving global sanitation coverage[J]. Environmental Science Technology, 2008, 42: 4298-4304. doi: 10.1021/es7025856 [2] SHANNON M A, BOHN P W, ELIMELECH M. et al. Science and technology for water purification in the coming decades[J]. Nature, 2008, 452: 301-310. doi: 10.1038/nature06599 [3] ZHAO X Y, WEI H X, ZHAO H C. et al. Electrode materials for capacitive deionization: A review[J]. Journal of Electroanalytical Chemistry, 2020, 873: 114416. doi: 10.1016/j.jelechem.2020.114416 [4] ATIA A A, ALLEN J, YOUNG E. et al. Cost optimization of low-salt-rejection reverse osmosis[J]. Desalination, 2023, 551: 116407. doi: 10.1016/j.desal.2023.116407 [5] DOORNBUSCH G J, TEDESCO M, POST J W. et al. Experimental investigation of multistage electrodialysis for seawater desalination[J]. Desalination, 2019, 464: 105-114. doi: 10.1016/j.desal.2019.04.025 [6] SHI J H, GONG L, ZHANG T. et al. Study of the seawater desalination performance by electrodialysis[J]. Membranes, 2022, 12(8): 12080767. [7] GOPI G, ARTHANAREESWARAN G, ISMAIL A F. Perspective of renewable desalination by using membrane distillation[J]. Chemical Engineering Research and Design, 2019, 144: 520-537. doi: 10.1016/j.cherd.2019.02.036 [8] ZHAO R J, XU J L, TAO P. et al. Clean water generation with switchable dispersion of multifunctional Fe3O4−reduced graphene oxide particles[J]. Progress in Natural Science:Materials International, 2018, 28: 422-429. doi: 10.1016/j.pnsc.2018.05.005 [9] YOON H, JO K, KIM K J. et al. Effects of characteristics of cation exchange membrane on desalination performance of membrane capacitive deionization[J]. Desalination, 2019, 458: 116-121. doi: 10.1016/j.desal.2019.02.009 [10] TSAI S W, HACKL L, KUMAR A. et al. Exploring the electrosorption selectivity of nitrate over chloride in capacitive deionization (CDI) and membrane capacitive deionization (MCDI)[J]. Desalination, 2021, 497: 114764. doi: 10.1016/j.desal.2020.114764 [11] WANG C Y, CHEN L, LIU S S. et al. Nitrite desorption from activated carbon fiber during capacitive deionization (CDI) and membrane capacitive deionization (MCDI)[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2018, 559: 392-400. [12] 刘洁, 王晓菊, 沈格, 等. 活性炭与炭黑混合电极的脱盐性能及相关工艺参数的优化[J]. 环境工程学报, 2022, 16(3): 875-885. [13] FOLARANMI G, BECHELANY M, SISTAT P. et al. Towards electrochemical water desalination techniques: A review on capacitive deionization, membrane capacitive deionization and flow capacitive deionization[J]. Membranes (Basel), 2020, 10(5): 10050096. [14] LEE J K, KIM Y E, KIM J. et al. Comparable mono and bipolar connection of capacitive deionization stack in NaCl treatment[J]. Journal of Industrial and Engineering Chemistry, 2012, 18(2): 763-766. doi: 10.1016/j.jiec.2011.11.119 [15] MA J X, MA J J, ZHANG C Y. et al. Flow-electrode capacitive deionization (FCDI) scale-up using a membrane stack configuration[J]. Water Research, 2020, 168: 115186. doi: 10.1016/j.watres.2019.115186 [16] PARK S K, CHOI J H. Desalination characteristics in a membrane capacitive deionization stack with carbon electrodes connected in series[J]. Separation and Purification Technology, 2019, 209: 152-158. doi: 10.1016/j.seppur.2018.07.032 [17] SALEEM M W, JANDE Y A C, KIM W S. Performance optimization of integrated electrochemical capacitive deionization and reverse electrodialysis model through a series pass desorption process[J]. Journal of Electroanalytical Chemistry, 2017, 795: 41-50. doi: 10.1016/j.jelechem.2017.04.025 [18] CHENG F, DING B, LI X. Research on double-stage and multi-stage capacitive deionization absorption air-conditioning system[J]. Processes, 2021, 9(2): 9020395. [19] 王祺, 房阔, 贺聪慧, 等. 流动电极电容去离子技术综述: 研究进展与未来挑战[J]. 化工学报, 2022, 73(3): 975-989. [20] 沈格, 刘洁, 王晓菊, 等. 膜电容去离子电极中导电剂类型及掺杂比对脱盐性能的影响[J]. 环境科学学报, 2022, 42(10): 293-302. [21] YING T Y, YANG K L, YIACOUMI S. et al. Electrosorption of ions from aqueous solutions by nanostructured carbon aerogel[J]. Journal of Colloid and Interface Science, 2002, 250(1): 18-27. doi: 10.1006/jcis.2002.8314 [22] 郭宁, 郭婷, 陈方方. 电容去离子脱盐影响因素的研究进展[J]. 四川化工, 2023, 26(3): 11-15. [23] MOSSAD M, ZOU L. A study of the capacitive deionisation performance under various operational conditions[J]. Journal of Hazardous Materials, 2012, 213-214: 491-497. doi: 10.1016/j.jhazmat.2012.02.036 [24] 代凯, 朱光平, 刘忠良, 等. 纳米碳管电吸附氯化钠性能的研究[J]. 化工新型材料, 2011, 39(3): 70-72. -

下载:

下载: