-

颗粒物是主要的大气环境污染物[1-2],对全球气候和环境变化有重要影响[3]。国内城市大气颗粒物污染来源解析表明[4-5],城市环境大气颗粒物的主要来源包括燃煤源、工业源、机动车尾气及扬尘。在不同的城市,由于能源供给、产业结构的差异,不同污染源对颗粒物浓度的贡献占比不同。其中,燃煤工业锅炉、燃煤发电锅炉等燃煤源是大气细颗粒物的主要排放源。中国是世界上最大的煤炭消费国[6],应重点关注燃煤锅炉排放颗粒物的排放控制。

燃煤锅炉排放的总颗粒物 (total particulate matter, TPM) 主要分为可过滤颗粒物 (filterable particulate matter, FPM) 、可凝结颗粒物 (condensable particulate matter, CPM) 两大类。FPM是以固态或液态存在,在常温状态下可被滤膜 (或滤筒) 过滤截留的颗粒物[7]。美国环保署 (USEPA) 对可凝结颗粒物定义为:该物质在初始烟道温度状态下为气态,离开烟道后在正常环境状态下降温数秒后凝结成液态或者固态[8]。CPM中组分特征及其在湿法脱硫系统 (wet flue gas desulfurization, WFGD) 等相关净化设备中的转化是目前该领域研究热点。裴冰[9]、CORIO等[10]发现燃煤电厂CPM、FPM二者比例接近1∶1;CPM在燃煤锅炉、燃气锅炉PM10中的占比分别约为76%、50%。学者对国内燃煤锅炉烟气排放水溶性离子特征研究发现,CPM水溶性离子中阳离子主要为Na+、Ca2+,阴离子主要为F−、Cl−、NO3−、SO42−;CPM中有机物占比50.90%~93.17%,其中烃类主要为正构烷烃,脂类主要为邻苯二甲酸酯[11-13];CPM所包含的元素中Na、Ca、K、Mg占所测金属总含量95%以上[12,14]。杨柳等[15]对超低排放下燃煤烟气排放特征研究表明:湿式电除尘装置 (wet electrostatic precipitator,WESP) 对CPM的脱除效果优于WFGD对CPM的脱除效果;WFGD+WESP对CPM的脱除效率达78.90%;WFGD+WESP对CPM有机组分的脱除效率高于对CPM无机组分的脱除效率。

目前,我国针对CPM的监测较为匮乏,故对此类颗粒物的防控研究尚存在诸多不足,无法满足当前大气环境改善的需求。本研究以燃煤烟气中CPM颗粒物为对象,分析其主要金属元素及6种水溶性离子的质量浓度和种类,以及湿法脱硫系统对可过滤颗粒物及可凝结颗粒物的转化作用,以期梳理供热厂可凝结颗粒物的源头排放控制策略,并为有效防控燃煤颗粒污染提供参考。

-

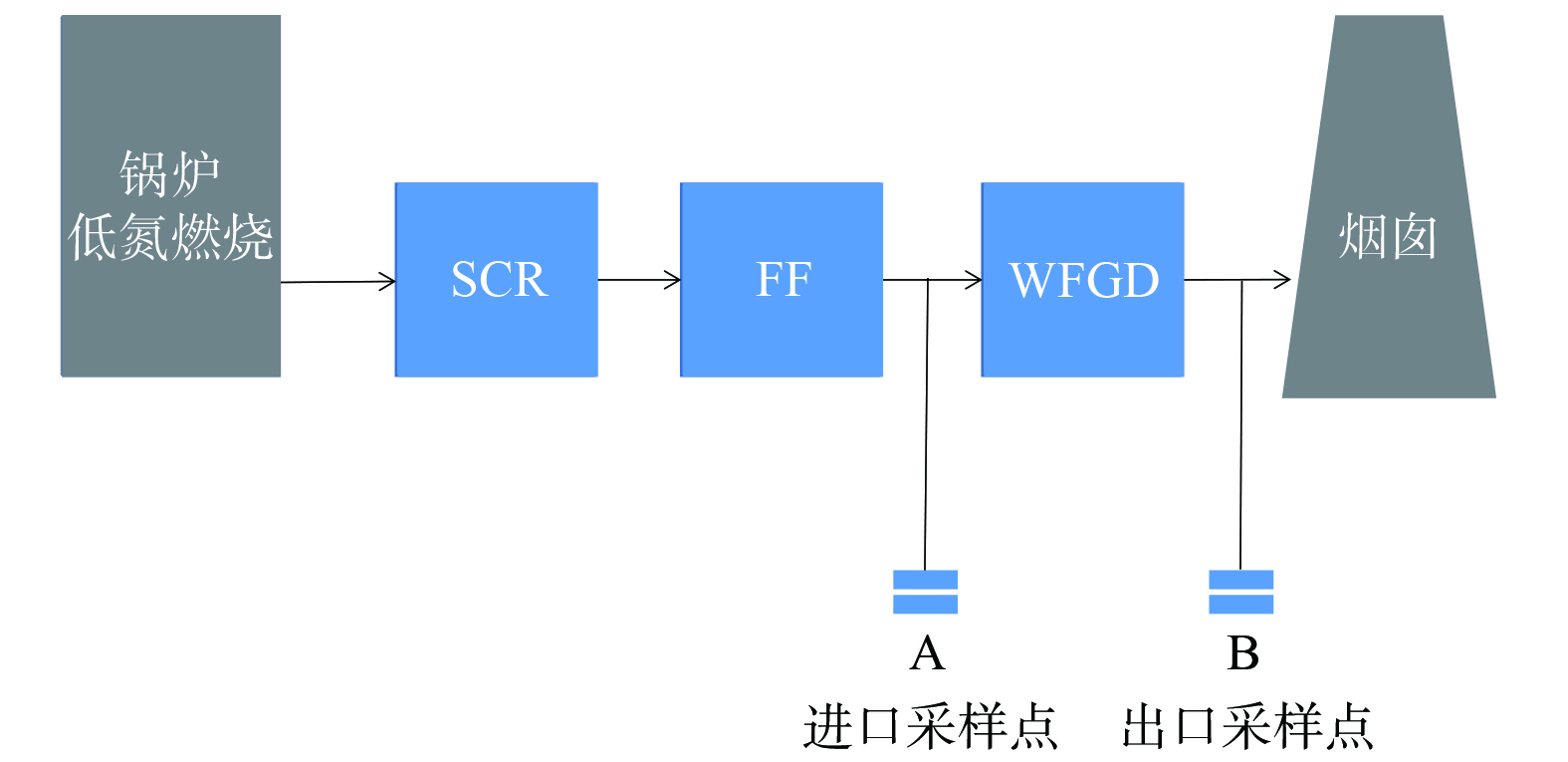

以内蒙古呼和浩特市某家燃煤供热厂2台机组负荷均为150 t·h−1的燃煤锅炉为研究对象,对煤种进行工业分析,其中水分占12.85%、挥发分占37.31%、灰分占16.2%、固定碳占11.52%、硫分占0.47%、发热量为15.3 MJ·kg−1;对煤灰成分进行分析,其中二氧化硅占38.27%、三氧化二铝占14.12%、三氧化二铁占3.9%、三氧化硫占12.4%、二氧化锰占0.47%、氧化镁占1.39%、氧化钙占25.35%、氧化钛占0.72%。该供热厂锅炉具体烟气流程为:低氮燃烧→选择性催化还原技术 (SCR) →布袋除尘器 (FF) →湿法脱硫系统 (WFGD) 。其中,SCR的催化剂均使用蜂窝式,催化剂基材为TiO2,FF型号为MC-64,处理风量为5 000 m3·h−1,过滤面积为51.2 m2,WFGD采用石灰石-石膏法。根据现场实际情况,将采样点设置在WFGD装置进口及出口,如图1所示。所有可凝结颗粒物样品采集均在工厂锅炉运行工况、机组负荷、烟气流量、烟气流速等稳定的情况下进行。

-

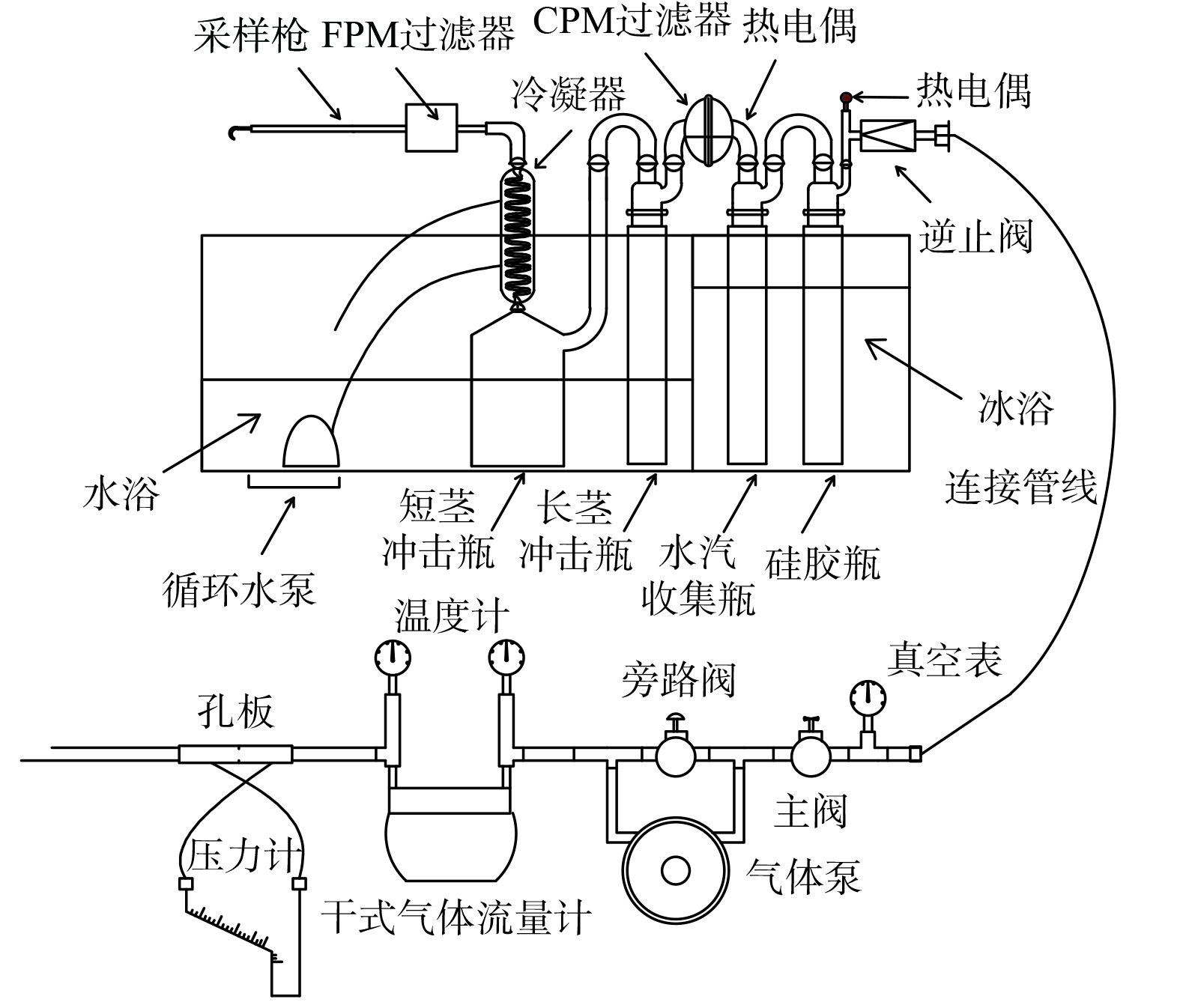

为研究该燃煤供热厂CPM的排放情况及WFGD对其迁移转化的影响,将采样点设置在WFGD的进口与出口处。CPM样品采集采用美国环保署的EPA Method 202,采样装置如图2所示。

烟气经采集进入装置,经FPM过滤器,进入CPM收集系统。再经冷凝器进入短茎冲击瓶、长茎冲击瓶、CPM过滤器。采集样品用高纯氮气吹扫后,将短茎冲击瓶、长茎冲击瓶的水溶液倒入容量瓶中,并用去离子水清洗 (各3次) ,将去离子水冲洗液收集于该容量瓶中,作好无机样品标识。分别用丙酮和正己烷做上述相同处理。收集冲洗液于容量瓶中,作好有机样品标识。

采样前后FPM滤膜烘干至恒重,结合烟气采集量计算质量浓度。将CPM滤膜折成1/4置于烧杯中,添加去离子水至滤膜完全浸没,经超声波震荡提取后转移至无机样品中。使用正己烷采用相同方法震荡提取,萃取液转移至有机样品中。将无机样品溶液转移至分液漏斗中,加正己烷充分震荡后静置分层。下层水溶液保存于无机样品瓶中,将上层正己烷萃取液移至有机样品瓶中,共萃取3次。将萃取得到的无机样品溶液与有机样品溶液分别取出置于西林瓶中,并密封低温保存,用于CPM成分待测。

-

使用离子色谱仪 (型号DIONEX ICS-2100) 定量检测选中的阴离子 (SO42−、Cl−、NO3−、F−) 。使用离子色谱仪 (型号DIONEX ICS-1500) 定量检测选中的阳离子 (Ca2+、Na+) 。使用电感耦合等离子体质谱仪 (型号NexIon 1000) 进行金属元素定性定量分析。使用原子荧光光度计 (型号:AFS-9561 216076) 对Hg进行定量检测。质控程序参考美国(标准参考物质)校准,使用地球化学一级标准物质GSS2校正,回收率介于95.5%~105.5%,相对标准偏差(RSD)控制<10%。

-

为保证样品分析结果的准确可靠,每次采样开始前,用去离子水、丙酮、正己烷分别冲洗冷凝器、干式冲击瓶、连接玻璃器皿与CPM滤膜固定器前半部 (各3次) 。收集去离子水冲洗液,倒入干净密封容量瓶中,作为无机物空白。收集丙酮、正己烷冲洗液,倒入干净密封容量瓶中,作为有机物空白。装置组装后,检查装置气密性。测试时,每个取样点至少取5个平行样,剔除异常数据后,最终测试结果取平均值。

-

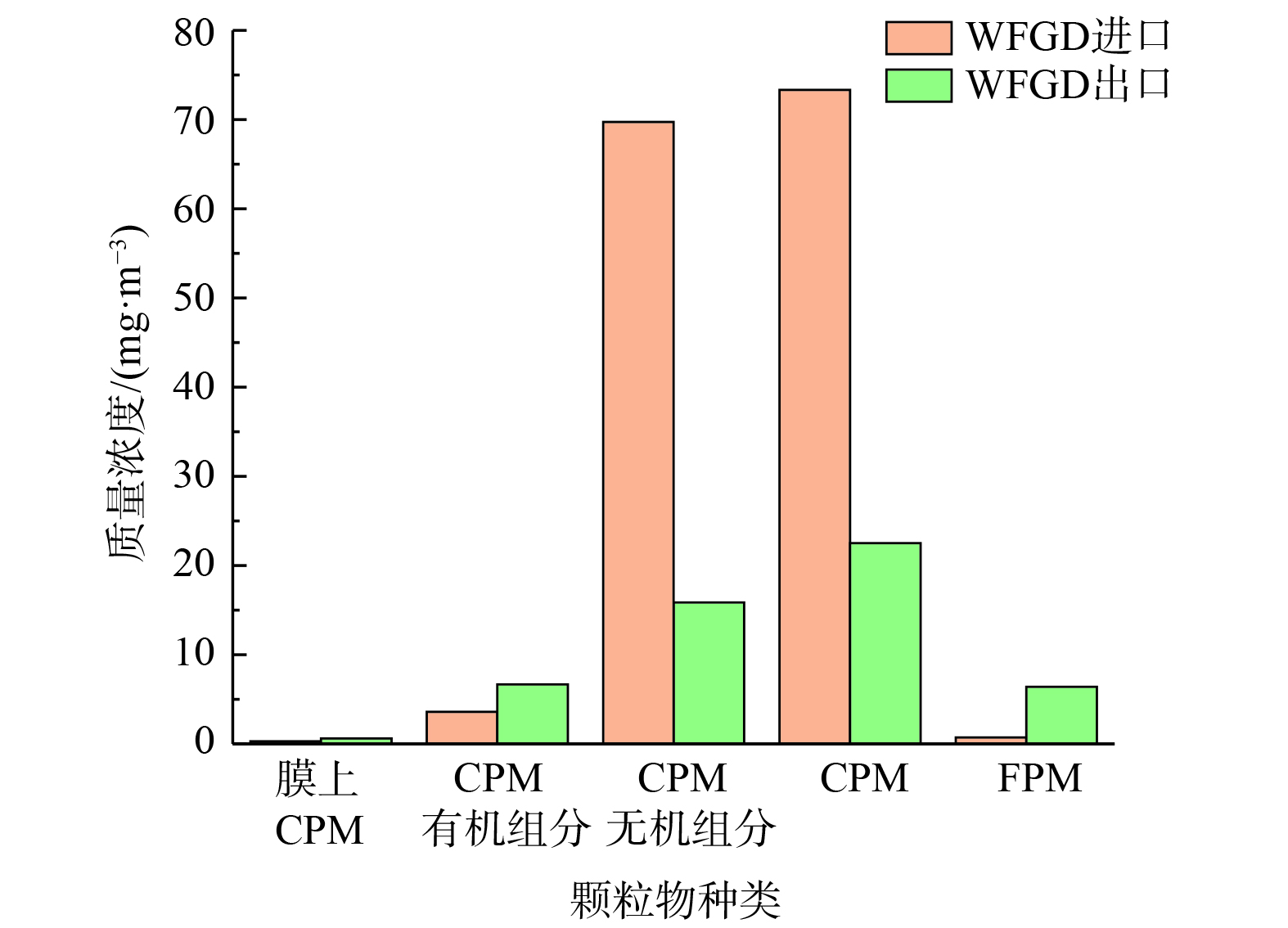

采用EPA Method 202对WFGD进口及出口烟气CPM、FPM进行监测,结果如图3所示。在WFGD进口处,CPM滤膜上捕集到的CPM占总CPM的0.39%,烟气中CPM平均质量浓度占TPM的99.03%,FPM平均质量浓度占TPM的0.97%;CPM有机组分的平均质量浓度占总CPM平均质量浓度的4.90%,CPM无机组分平均质量浓度占总CPM平均质量浓度的95.10%。在WFGD出口处,CPM滤膜上捕集到的CPM占总CPM的2.66%,烟气中CPM平均质量浓度占TPM的77.84%,FPM平均质量浓度占TPM的22.16%;CPM有机组分的平均质量浓度占总CPM平均质量浓度的29.62%,CPM无机组分平均质量浓度为占总CPM平均质量浓度的70.38%。

通过分析发现,WFGD进口及出口排放的烟气中,CPM质量浓度均远高于FPM质量浓度,且WFGD出口较WFGD进口相比,CPM质量浓度大幅度降低,FPM质量浓度升高;在CPM中,无机组分平均质量浓度均远高于有机组分平均质量浓度,且WFGD出口较WFGD进口相比,无机组分质量浓度大幅度降低,有机组分质量浓度升高。以上规律表明,烟气排放的颗粒物中以CPM为主,且主要以排放CPM中的无机组分为主。多位学者也得出相似结论,CORIO[10]对CPM排放特征研究发现,燃煤锅炉排放的CPM占PM10的约76%。YANG[16]对多家燃煤电厂及工厂研究发现,CPM中无机组分是CPM排放的主要部分,CPM无机组分质量浓度在CPM排放中的占比最低,为72.3%,最高达到95.4%。PEI等[17]通过重量法测得CPM中无机组分含量达到79%~99%。这表明CPM的排放应当引起足够重视。

-

为探究CPM中的金属元素,在检测燃煤供热厂烟气CPM中的金属元素,使用电感耦合等离子质谱法对其进行元素定性定量分析;使用原子荧光法对Hg、As、Se、Sb、Bi定量分析。其中,非金属元素中C、N含量较高,B元素存在,但质量浓度极小,不足0.01 μg·m−3,其他非金属元素未检出,故本研究不进行非金属元素的讨论。在金属元素中,Mo、Ag、Cd、Sn、Hg等元素均未检出;而金属元素中Cu、Co、V、Be等元素量极少;在其他研究中,Mg为CPM的主要金属元素[18]。然而,对超过一半以上样品进行检测时均未检出Mg,故在本研究中将Mg元素舍去。经筛选去除未检出及含量极小元素后选取CPM中金属元素含量较高的10种元素 (Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti) 进行特征分析。

对燃煤供热厂WFGD进口及出口CPM无机组分中含量较高10种金属元素进行分析,所得金属元素质量浓度如图4示。在WFGD进口处,Na、Ca、Al三种金属元素的质量浓度最高,而Ti、Fe、K含量较高。金属元素的总质量浓度占WFGD进口总CPM质量浓度的5.00%;10种金属元素质量浓度占总金属元素的98.1%;Na、Ca、Al三种金属元素的质量浓度占10种金属元素的82.04%。在WFGD出口处:Na、Ca、Al三种金属元素的质量浓度最高,Fe、K含量较高。金属元素的总质量浓度占WFGD出口总CPM的7.24%;10种金属元素质量浓度占总金属元素的98.77%;Na、Ca、Al三种金属元素的质量浓度占10种金属元素的89.44%。

WFGD出口较WFGD进口相比,Na、Ca、Al三种金属的降低浓度占总金属降低浓度的74.27%。相关规律表明,Na、Ca、Al三种金属元素是CPM排放的主要金属元素,但金属元素在总CPM中的占比并不高,不是CPM的最主要成分。有学者研究表明,Na元素是CPM金属元素中含量最高的元素[18-19]。目前,对可凝结颗粒物中无机组分的研究大多针对水溶性离子,对金属元素的研究较少。部分学者对特定的金属,如Se、Cr等进行了研究[20-22],而本研究对CPM无机组分金属元素进行全面检测时发现,Se、Cr等元素的含量对比Na、Ca、Al来说极少。

-

对燃煤供热锅炉WFGD进口及出口CPM无机组分中含量较高的6种水溶性离子 (Na+、Ca2+、F−、Cl−、SO42−、NO3−) 进行定量检测分析。所得水溶性离子浓度如表1所示。

在WFGD进口处:CPM水溶性离子主要成分为SO42−、F−和Cl−,分别占CPM总水溶性离子的59.49%、22.59%和11.53%,其余水溶性离子组分占比为0.45%~3.21%,在CPM总水溶性的占比之和为6.38%。在WFGD出口处:CPM水溶性离子主要成分为SO42−、Ca2+,水溶性离子的质量浓度分别占CPM总水溶性离子的81.07%、8.70%,其余水溶性离子组分占比为1.79%~3.58%,在CPM总水溶性的占比之和为10.23%。

分析WFGD进口及WFGD出口CPM中水溶性离子排放情况发现,SO42−在进出口的含量最高,且其减少浓度数值最大。这表明SO42−在水溶性离子中始终占据主导地位,且其为CPM主要排放的水溶性离子。文献[15]表明,CPM水溶性呈酸性,与本研究结果一致。有研究认为CPM中的SO42−主要来自于所排烟气中的SO3[23],烟气中的CPM与SO3都可以采用控制冷凝及惯性撞击的方法来收集,故采集中很容易出现交叉的现象,烟气中的SO3具有可凝结颗粒物的属性,在烟道内的状态为蒸汽态,离开烟道以后会冷凝或与阳离子反应生产硫酸盐溶液或固态颗粒物[24]。因此,众多学者[17,25-26]也认为采用干式冲击瓶冷凝法采集CPM会使测得的SO42−偏高。

-

本研究对供热厂WFGD的进口与出口进行CPM的检测,以此来检验WFGD对CPM的脱除效果。WFGD的进口与出口FPM、CPM浓度及CPM化学组分对比如图3所示。经过WFGD各颗粒物的脱除效率如表2所示。CPM在WFGD进口与出口处的质量浓度分别为73.32、22.52 mg·m−3。经过WFGD之后,CPM的质量浓度明显减少,脱除效率为69.29%。这表明WFGD对CPM具有较好的脱除效果。孙和泰等[19,27]发现,燃煤电厂WFGD对CPM的脱除效率为47.20%。此外,WFGD进口与WFGD出口CPM中有机组分质量浓度分别为3.59 mg·m−3、6.67 mg·m−3,具有上升趋势。FPM在WFGD进口与WFGD出口质量浓度分别为0.72 mg·m−3、6.41 mg·m−3,经过WFGD后质量浓度具有明显的上升趋势。本研究中WFGD对CPM有机组分和FPM的脱除效率均为负。

本研究中WFGD对CPM的脱除主要是针对CPM的无机组分,脱除效率高达77.27%,而对CPM有机组分并无脱除效果,反而使CPM有机组分的质量浓度上升。有机组分不减反增的趋势还需进一步研究确定。有机组分的成分复杂多样,物理化学性质难以确定,并且大部分的有机组分具有疏水性,使用传统的烟气净化工艺难以对有机组分进行脱除。另外,推测其原因为WFGD进口之前的烟气温度比较高,约为130 ℃,故有机物大多数处于气态。虽然在检测过程中,温度会出现降低,但其变温为骤降,有机物很可能没有完全被捕集;在经过WFGD后,烟气随着脱硫过程温度也降下来,出口温度接近50 ℃,这是一个缓慢的降温过程,有机物在这个过程中很可能被完全冷却,因此在出口处捕集的CPM有机组分的质量浓度更高。

烟气经过WFGD后,FPM的质量浓度具有明显上升。推测原因可能是,经过WFGD后,烟气里不可避免携带了部分脱硫浆液,脱硫浆液里溶解有脱硫剂或脱硫产物,这些物质经过干燥之后便析出,造成颗粒物增加。烟气经过WFGD后,CPM无机组分在总CPM中的占比由95.10%减小为70.38%;CPM在TPM中的占比由99.03%减小为77.84%。这说明WFGD对CPM中无机组分的影响大于对CPM中有机组分,对TPM来说,WFGD的作用对CPM的影响大于FPM。

-

目前,对于CPM中金属元素的研究很少,而研究污染治理设施对CPM中金属元素脱除效果的更是少之又少。针对供热厂燃煤锅炉WFGD进口与出口CPM中金属元素的质量浓度如图4所示,对各个金属元素的脱除效率如表3所示。供热厂燃煤锅炉WFGD进口CPM中金属元素含量较高的10种元素 (Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti) 总质量浓度为3.62 mg·m−3,WFGD出口CPM中金属元素含量较高的10种元素 (Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti) 总质量浓度为1.61 mg·m−3,WFGD对这10种金属元素的脱除效率为55.52%。这说明WFGD对金属元素的脱除效果较好。10种金属元素中,Ti的脱除效率高达98.89%;对Zn、Al、Ba、Fe、K、Na的脱除效率在50%以上;对Ca的脱除效率为39.67%,脱除效果一般;对Cr的脱除效率为7.04%,脱除效果较差;对Mn的脱除效率为负,这说明WFGD对Mn没有起到脱除效果。

总体上,CPM中金属元素的质量浓度偏低,Zn、Mn、Cr、Ba在WFGD进口质量浓度不超过0.10 mg·m−3。而在WFGD出口,这4种金属元素的质量浓度均不超过0.02 mg·m−3;Ti元素在WFGD进口处质量浓度为0.22 mg·m−3,出口处为0.002 5 mg·m−3,其质量浓度有大幅下降,但其本身质量浓度也并不高,降低比率虽大,差值并不大。总的来说,金属元素在CPM中的质量浓度很小,WFGD对CPM中金属元素有一定效果的脱除,但金属元素的脱除对总CPM来说影响不大。

-

供热厂燃煤锅炉WFGD进口及出口6种水溶性离子 (Na+、Ca2+、F−、Cl−、SO42−、NO3−) 质量浓度如表1,WFGD对各个水溶性离子的脱除效率如表4所示。供热厂燃煤锅炉WFGD进口总水溶性离子的质量浓度为18.39 mg·m−3、WFGD出口总水溶性离子的质量浓度为3.91 mg·m−3,WFGD对总水溶性离子的脱除效率为78.74%,说明WFGD对水溶性离子具有良好的脱除效果。在6种水溶性离子中,F−、Cl−的脱除效率均达到95%以上,脱除效果极好;对Na+、SO42−的脱除效率在70%以上,脱除效果较好;对Ca2+的脱除效率为42.37%,脱除效果一般;经过WFGD后,NO3−的质量浓度并没有发生改变,可能与本研究中NO3−质量浓度较低有关,其数据的波动较小,做平均值后恰好WFGD进口与出口处浓度相当。

烟气经过WFGD后,CPM中水溶性离子明显降低,其主要原因是气态CPM在WFGD中经过脱硫浆液的喷淋,水溶性离子会溶于脱硫浆液,进而随着排除浆液而被脱除。另外,Na+、Mg2+、Al3+等阳离子来源于PM0.3,PM0.3在WFGD系统中会被脱硫浆液喷淋洗涤而脱除一部分[28]。胡月琪[11]在对CPM中水溶性离子排放特征研究中发现,水溶性离子排放水平与烟气脱硫净化工艺、脱硫产物溶解度及脱硫方式有密切关系。以石灰/石灰石作为脱硫添加剂并不会增加Ca2+排放;以NaOH作为脱硫剂会显著增加Na+的排放水平;以MgO作为脱硫剂,Mg2+是烟气排放的特征离子。因此,在对CPM中水溶性离子的脱除上,对脱硫剂的选择值得探究。

-

1) 对供热厂燃煤烟气CPM进行收集时,CPM滤膜上截留的CPM较少,在总CPM浓度中平均占比不超过5%。

2) 在WFGD进口处与出口处排放的烟气中,CPM质量浓度均远高于FPM质量浓度,且质量CPM浓度呈下降趋势,FPM质量浓度呈上升趋势;CPM中的无机组分平均质量浓度均远高于有机组分的平均质量浓度,且无机组分质量浓度呈下降趋势,有机组分质量浓度呈上升趋势。以上转化规律表明,烟气排放的颗粒物中以CPM为主,且CPM中以无机组分为主。

3) 燃煤供热厂CPM中含量最高的10种元素为Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti,其中Na、Ca、Al三种金属元素占总金属的80%以上。WFGD进出口相比,Na、Ca、Al三种金属浓度的减降量占总金属浓度减降量的74.27%。因此,Na、Ca、Al是CPM排放的主要金属元素。鉴于金属元素总含量在CPM总含量中的占比仅为5%,故金属元素不是CPM的最主要成分。

4) 对CPM中6种水溶性离子Na+、Ca2+、F−、Cl−、SO42−、NO3−研究发现,WFGD进口及出口SO42−质量浓度远高于其他离子浓度,且SO42−浓度减小量最高。这说明SO42−在水溶性离子中始终占据主导地位,且其为CPM主要排放的水溶性离子。

5) 燃煤供热厂WFGD对CPM的脱除效率为69.29%,对CPM有机组分脱除效率为负,对CPM无机组分的脱除效率为77.27%。WFGD对10种金属元素的脱除效率为55.52%,WFGD对总水溶性离子的脱除效率为78.74%,其中对F−、Cl−的脱除效率均达到95%以上,对Na+、SO42−的脱除效率在70%以上。

供热厂燃煤烟气可凝结颗粒物排放特征及其在湿法脱硫系统中的转化

Emission characteristics of condensable particulate matter from coal-fired flue gas of heat supply plant and its transformation in WFGD

-

摘要: 燃煤源是城市环境大气颗粒物的重要来源,燃煤产生的颗粒物由可过滤颗粒物 (FPM) 与可凝结颗粒物 (CPM) 两部分组成,且CPM在排放的总颗粒物中占比较高。采用EPA Method 202方法,对燃煤供热厂湿法脱硫系统 (WFGD) 进口及出口烟气进行平行取样,并对燃煤烟气中CPM质量浓度、成分组分、金属元素、水溶性离子及WFGD对CPM的脱除作用进行研究。结果表明,WFGD进口与出口处CPM在TPM中均占有主导地位,且CPM中以CPM无机组分为主。CPM中含量较高的10种金属元素为Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti,其中Na、Ca、Al三种金属元素之和占总金属元素的80%以上。燃煤烟气CPM中水溶性离子以SO42−为主,其中WFGD进口处SO42−占CPM总水溶性离子的59.49%,WFGD出口处SO42−占CPM总水溶性离子的81.07%。通过对WFGD进口与出口处颗粒物浓度对比发现WFGD对CPM的脱除效率为69.29%,对CPM有机组分脱除效率为负,对CPM无机组分的脱除效率为77.27%。WFGD对10种金属元素的脱除效率为55.52%,WFGD对总水溶性离子的脱除效率为78.74%。本研究结果可为供热厂的可凝结颗粒物排放源头控制提供参考。Abstract: Coal burning source is an important source of atmospheric particulate matter in urban environment. The particulate matter produced by coal burning is composed of filterable particulate matter (FPM)and condensable particulate matter (CPM),and CPM accounts for a high proportion of the total particulate matter emitted. There is a lack of research on the emission and detection of CPM in China. In this study, EPA method 202 was used to sample the inlet and outlet flue gas of WFGD in coal-fired heating plant in parallel, and the CPM mass concentration, composition, metal elements, water-soluble ions and the removal effect of WFGD on CPM in coal-fired flue gas were studied. The results show that CPM at the inlet and outlet of WFGD plays a dominant role in TPM, and CPM inorganic component is the main component in CPM. The 10 metal elements with high content in CPM were Na, Ca, Al, K, Fe, Zn, Mn, Ba, Cr and Ti, and the sum of Na, Ca and Al accounted for more than 80% of the total metal elements. The water-soluble ions in CPM of coal-fired flue gas are mainly SO42−, of which SO42− at WFGD inlet accounts for 59.49% of the total water-soluble ions in CPM, and SO42− at WFGD outlet accounts for 81.07% of the total water-soluble ions in CPM. By comparing the particle concentration at the inlet and outlet of WFGD, it is found that the removal efficiency of WFGD for CPM is 69.29%, the removal efficiency of organic components of CPM is negative, and the removal efficiency of inorganic components of CPM is 77.27%.The removal efficiency of WFGD for 10 metal elements was 55.52%, and the removal efficiency of WFGD for total water-soluble ions was 78.74%.

-

颗粒物是主要的大气环境污染物[1-2],对全球气候和环境变化有重要影响[3]。国内城市大气颗粒物污染来源解析表明[4-5],城市环境大气颗粒物的主要来源包括燃煤源、工业源、机动车尾气及扬尘。在不同的城市,由于能源供给、产业结构的差异,不同污染源对颗粒物浓度的贡献占比不同。其中,燃煤工业锅炉、燃煤发电锅炉等燃煤源是大气细颗粒物的主要排放源。中国是世界上最大的煤炭消费国[6],应重点关注燃煤锅炉排放颗粒物的排放控制。

燃煤锅炉排放的总颗粒物 (total particulate matter, TPM) 主要分为可过滤颗粒物 (filterable particulate matter, FPM) 、可凝结颗粒物 (condensable particulate matter, CPM) 两大类。FPM是以固态或液态存在,在常温状态下可被滤膜 (或滤筒) 过滤截留的颗粒物[7]。美国环保署 (USEPA) 对可凝结颗粒物定义为:该物质在初始烟道温度状态下为气态,离开烟道后在正常环境状态下降温数秒后凝结成液态或者固态[8]。CPM中组分特征及其在湿法脱硫系统 (wet flue gas desulfurization, WFGD) 等相关净化设备中的转化是目前该领域研究热点。裴冰[9]、CORIO等[10]发现燃煤电厂CPM、FPM二者比例接近1∶1;CPM在燃煤锅炉、燃气锅炉PM10中的占比分别约为76%、50%。学者对国内燃煤锅炉烟气排放水溶性离子特征研究发现,CPM水溶性离子中阳离子主要为Na+、Ca2+,阴离子主要为F−、Cl−、NO3−、SO42−;CPM中有机物占比50.90%~93.17%,其中烃类主要为正构烷烃,脂类主要为邻苯二甲酸酯[11-13];CPM所包含的元素中Na、Ca、K、Mg占所测金属总含量95%以上[12,14]。杨柳等[15]对超低排放下燃煤烟气排放特征研究表明:湿式电除尘装置 (wet electrostatic precipitator,WESP) 对CPM的脱除效果优于WFGD对CPM的脱除效果;WFGD+WESP对CPM的脱除效率达78.90%;WFGD+WESP对CPM有机组分的脱除效率高于对CPM无机组分的脱除效率。

目前,我国针对CPM的监测较为匮乏,故对此类颗粒物的防控研究尚存在诸多不足,无法满足当前大气环境改善的需求。本研究以燃煤烟气中CPM颗粒物为对象,分析其主要金属元素及6种水溶性离子的质量浓度和种类,以及湿法脱硫系统对可过滤颗粒物及可凝结颗粒物的转化作用,以期梳理供热厂可凝结颗粒物的源头排放控制策略,并为有效防控燃煤颗粒污染提供参考。

1. 材料与方法

1.1 研究对象

以内蒙古呼和浩特市某家燃煤供热厂2台机组负荷均为150 t·h−1的燃煤锅炉为研究对象,对煤种进行工业分析,其中水分占12.85%、挥发分占37.31%、灰分占16.2%、固定碳占11.52%、硫分占0.47%、发热量为15.3 MJ·kg−1;对煤灰成分进行分析,其中二氧化硅占38.27%、三氧化二铝占14.12%、三氧化二铁占3.9%、三氧化硫占12.4%、二氧化锰占0.47%、氧化镁占1.39%、氧化钙占25.35%、氧化钛占0.72%。该供热厂锅炉具体烟气流程为:低氮燃烧→选择性催化还原技术 (SCR) →布袋除尘器 (FF) →湿法脱硫系统 (WFGD) 。其中,SCR的催化剂均使用蜂窝式,催化剂基材为TiO2,FF型号为MC-64,处理风量为5 000 m3·h−1,过滤面积为51.2 m2,WFGD采用石灰石-石膏法。根据现场实际情况,将采样点设置在WFGD装置进口及出口,如图1所示。所有可凝结颗粒物样品采集均在工厂锅炉运行工况、机组负荷、烟气流量、烟气流速等稳定的情况下进行。

1.2 样品采集与回收

为研究该燃煤供热厂CPM的排放情况及WFGD对其迁移转化的影响,将采样点设置在WFGD的进口与出口处。CPM样品采集采用美国环保署的EPA Method 202,采样装置如图2所示。

烟气经采集进入装置,经FPM过滤器,进入CPM收集系统。再经冷凝器进入短茎冲击瓶、长茎冲击瓶、CPM过滤器。采集样品用高纯氮气吹扫后,将短茎冲击瓶、长茎冲击瓶的水溶液倒入容量瓶中,并用去离子水清洗 (各3次) ,将去离子水冲洗液收集于该容量瓶中,作好无机样品标识。分别用丙酮和正己烷做上述相同处理。收集冲洗液于容量瓶中,作好有机样品标识。

采样前后FPM滤膜烘干至恒重,结合烟气采集量计算质量浓度。将CPM滤膜折成1/4置于烧杯中,添加去离子水至滤膜完全浸没,经超声波震荡提取后转移至无机样品中。使用正己烷采用相同方法震荡提取,萃取液转移至有机样品中。将无机样品溶液转移至分液漏斗中,加正己烷充分震荡后静置分层。下层水溶液保存于无机样品瓶中,将上层正己烷萃取液移至有机样品瓶中,共萃取3次。将萃取得到的无机样品溶液与有机样品溶液分别取出置于西林瓶中,并密封低温保存,用于CPM成分待测。

1.3 样品分析

使用离子色谱仪 (型号DIONEX ICS-2100) 定量检测选中的阴离子 (SO42−、Cl−、NO3−、F−) 。使用离子色谱仪 (型号DIONEX ICS-1500) 定量检测选中的阳离子 (Ca2+、Na+) 。使用电感耦合等离子体质谱仪 (型号NexIon 1000) 进行金属元素定性定量分析。使用原子荧光光度计 (型号:AFS-9561 216076) 对Hg进行定量检测。质控程序参考美国(标准参考物质)校准,使用地球化学一级标准物质GSS2校正,回收率介于95.5%~105.5%,相对标准偏差(RSD)控制<10%。

1.4 质量控制

为保证样品分析结果的准确可靠,每次采样开始前,用去离子水、丙酮、正己烷分别冲洗冷凝器、干式冲击瓶、连接玻璃器皿与CPM滤膜固定器前半部 (各3次) 。收集去离子水冲洗液,倒入干净密封容量瓶中,作为无机物空白。收集丙酮、正己烷冲洗液,倒入干净密封容量瓶中,作为有机物空白。装置组装后,检查装置气密性。测试时,每个取样点至少取5个平行样,剔除异常数据后,最终测试结果取平均值。

2. 结果与讨论

2.1 CPM、FPM质量浓度及化学组分

2.1.1 CPM、FPM颗粒物质量浓度及种类

采用EPA Method 202对WFGD进口及出口烟气CPM、FPM进行监测,结果如图3所示。在WFGD进口处,CPM滤膜上捕集到的CPM占总CPM的0.39%,烟气中CPM平均质量浓度占TPM的99.03%,FPM平均质量浓度占TPM的0.97%;CPM有机组分的平均质量浓度占总CPM平均质量浓度的4.90%,CPM无机组分平均质量浓度占总CPM平均质量浓度的95.10%。在WFGD出口处,CPM滤膜上捕集到的CPM占总CPM的2.66%,烟气中CPM平均质量浓度占TPM的77.84%,FPM平均质量浓度占TPM的22.16%;CPM有机组分的平均质量浓度占总CPM平均质量浓度的29.62%,CPM无机组分平均质量浓度为占总CPM平均质量浓度的70.38%。

通过分析发现,WFGD进口及出口排放的烟气中,CPM质量浓度均远高于FPM质量浓度,且WFGD出口较WFGD进口相比,CPM质量浓度大幅度降低,FPM质量浓度升高;在CPM中,无机组分平均质量浓度均远高于有机组分平均质量浓度,且WFGD出口较WFGD进口相比,无机组分质量浓度大幅度降低,有机组分质量浓度升高。以上规律表明,烟气排放的颗粒物中以CPM为主,且主要以排放CPM中的无机组分为主。多位学者也得出相似结论,CORIO[10]对CPM排放特征研究发现,燃煤锅炉排放的CPM占PM10的约76%。YANG[16]对多家燃煤电厂及工厂研究发现,CPM中无机组分是CPM排放的主要部分,CPM无机组分质量浓度在CPM排放中的占比最低,为72.3%,最高达到95.4%。PEI等[17]通过重量法测得CPM中无机组分含量达到79%~99%。这表明CPM的排放应当引起足够重视。

2.1.2 CPM金属元素质量浓度及种类

为探究CPM中的金属元素,在检测燃煤供热厂烟气CPM中的金属元素,使用电感耦合等离子质谱法对其进行元素定性定量分析;使用原子荧光法对Hg、As、Se、Sb、Bi定量分析。其中,非金属元素中C、N含量较高,B元素存在,但质量浓度极小,不足0.01 μg·m−3,其他非金属元素未检出,故本研究不进行非金属元素的讨论。在金属元素中,Mo、Ag、Cd、Sn、Hg等元素均未检出;而金属元素中Cu、Co、V、Be等元素量极少;在其他研究中,Mg为CPM的主要金属元素[18]。然而,对超过一半以上样品进行检测时均未检出Mg,故在本研究中将Mg元素舍去。经筛选去除未检出及含量极小元素后选取CPM中金属元素含量较高的10种元素 (Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti) 进行特征分析。

对燃煤供热厂WFGD进口及出口CPM无机组分中含量较高10种金属元素进行分析,所得金属元素质量浓度如图4示。在WFGD进口处,Na、Ca、Al三种金属元素的质量浓度最高,而Ti、Fe、K含量较高。金属元素的总质量浓度占WFGD进口总CPM质量浓度的5.00%;10种金属元素质量浓度占总金属元素的98.1%;Na、Ca、Al三种金属元素的质量浓度占10种金属元素的82.04%。在WFGD出口处:Na、Ca、Al三种金属元素的质量浓度最高,Fe、K含量较高。金属元素的总质量浓度占WFGD出口总CPM的7.24%;10种金属元素质量浓度占总金属元素的98.77%;Na、Ca、Al三种金属元素的质量浓度占10种金属元素的89.44%。

WFGD出口较WFGD进口相比,Na、Ca、Al三种金属的降低浓度占总金属降低浓度的74.27%。相关规律表明,Na、Ca、Al三种金属元素是CPM排放的主要金属元素,但金属元素在总CPM中的占比并不高,不是CPM的最主要成分。有学者研究表明,Na元素是CPM金属元素中含量最高的元素[18-19]。目前,对可凝结颗粒物中无机组分的研究大多针对水溶性离子,对金属元素的研究较少。部分学者对特定的金属,如Se、Cr等进行了研究[20-22],而本研究对CPM无机组分金属元素进行全面检测时发现,Se、Cr等元素的含量对比Na、Ca、Al来说极少。

2.1.3 CPM水溶性离子质量浓度及种类

对燃煤供热锅炉WFGD进口及出口CPM无机组分中含量较高的6种水溶性离子 (Na+、Ca2+、F−、Cl−、SO42−、NO3−) 进行定量检测分析。所得水溶性离子浓度如表1所示。

表 1 燃煤供热锅炉水溶性离子的数据Table 1. Data of water-soluble ions in coal-fired heating boilers水溶性离子种类 WFGD进口离子质量浓度/(mg·m−3) WFGD进口离子所占百分比 WFGD出口离子质量浓度/(mg·m−3) WFGD出口离子所占百分比 Na+ 0.50 2.72% 0.14 3.58% Ca2+ 0.59 3.21% 0.34 8.7% F− 4.16 22.59% 0.11 2.81% Cl− 2.12 11.53% 0.07 1.79% SO42- 10.94 59.49% 3.17 81.07% NO3− 0.08 0.45% 0.08 2.05% 在WFGD进口处:CPM水溶性离子主要成分为SO42−、F−和Cl−,分别占CPM总水溶性离子的59.49%、22.59%和11.53%,其余水溶性离子组分占比为0.45%~3.21%,在CPM总水溶性的占比之和为6.38%。在WFGD出口处:CPM水溶性离子主要成分为SO42−、Ca2+,水溶性离子的质量浓度分别占CPM总水溶性离子的81.07%、8.70%,其余水溶性离子组分占比为1.79%~3.58%,在CPM总水溶性的占比之和为10.23%。

分析WFGD进口及WFGD出口CPM中水溶性离子排放情况发现,SO42−在进出口的含量最高,且其减少浓度数值最大。这表明SO42−在水溶性离子中始终占据主导地位,且其为CPM主要排放的水溶性离子。文献[15]表明,CPM水溶性呈酸性,与本研究结果一致。有研究认为CPM中的SO42−主要来自于所排烟气中的SO3[23],烟气中的CPM与SO3都可以采用控制冷凝及惯性撞击的方法来收集,故采集中很容易出现交叉的现象,烟气中的SO3具有可凝结颗粒物的属性,在烟道内的状态为蒸汽态,离开烟道以后会冷凝或与阳离子反应生产硫酸盐溶液或固态颗粒物[24]。因此,众多学者[17,25-26]也认为采用干式冲击瓶冷凝法采集CPM会使测得的SO42−偏高。

2.2 WFGD对CPM的转化作用

2.2.1 WFGD对CPM颗粒物的转化作用

本研究对供热厂WFGD的进口与出口进行CPM的检测,以此来检验WFGD对CPM的脱除效果。WFGD的进口与出口FPM、CPM浓度及CPM化学组分对比如图3所示。经过WFGD各颗粒物的脱除效率如表2所示。CPM在WFGD进口与出口处的质量浓度分别为73.32、22.52 mg·m−3。经过WFGD之后,CPM的质量浓度明显减少,脱除效率为69.29%。这表明WFGD对CPM具有较好的脱除效果。孙和泰等[19,27]发现,燃煤电厂WFGD对CPM的脱除效率为47.20%。此外,WFGD进口与WFGD出口CPM中有机组分质量浓度分别为3.59 mg·m−3、6.67 mg·m−3,具有上升趋势。FPM在WFGD进口与WFGD出口质量浓度分别为0.72 mg·m−3、6.41 mg·m−3,经过WFGD后质量浓度具有明显的上升趋势。本研究中WFGD对CPM有机组分和FPM的脱除效率均为负。

表 2 WFGD对颗粒物的脱除效率Table 2. WFGD removal efficiency of particulate matterCPM有机组分脱除率 CPM无机组分脱除率 CPM脱除率 FPM脱除率 −85.79% 77.27% 69.29% −790.28% 本研究中WFGD对CPM的脱除主要是针对CPM的无机组分,脱除效率高达77.27%,而对CPM有机组分并无脱除效果,反而使CPM有机组分的质量浓度上升。有机组分不减反增的趋势还需进一步研究确定。有机组分的成分复杂多样,物理化学性质难以确定,并且大部分的有机组分具有疏水性,使用传统的烟气净化工艺难以对有机组分进行脱除。另外,推测其原因为WFGD进口之前的烟气温度比较高,约为130 ℃,故有机物大多数处于气态。虽然在检测过程中,温度会出现降低,但其变温为骤降,有机物很可能没有完全被捕集;在经过WFGD后,烟气随着脱硫过程温度也降下来,出口温度接近50 ℃,这是一个缓慢的降温过程,有机物在这个过程中很可能被完全冷却,因此在出口处捕集的CPM有机组分的质量浓度更高。

烟气经过WFGD后,FPM的质量浓度具有明显上升。推测原因可能是,经过WFGD后,烟气里不可避免携带了部分脱硫浆液,脱硫浆液里溶解有脱硫剂或脱硫产物,这些物质经过干燥之后便析出,造成颗粒物增加。烟气经过WFGD后,CPM无机组分在总CPM中的占比由95.10%减小为70.38%;CPM在TPM中的占比由99.03%减小为77.84%。这说明WFGD对CPM中无机组分的影响大于对CPM中有机组分,对TPM来说,WFGD的作用对CPM的影响大于FPM。

2.2.2 WFGD对CPM金属元素的转化作用

目前,对于CPM中金属元素的研究很少,而研究污染治理设施对CPM中金属元素脱除效果的更是少之又少。针对供热厂燃煤锅炉WFGD进口与出口CPM中金属元素的质量浓度如图4所示,对各个金属元素的脱除效率如表3所示。供热厂燃煤锅炉WFGD进口CPM中金属元素含量较高的10种元素 (Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti) 总质量浓度为3.62 mg·m−3,WFGD出口CPM中金属元素含量较高的10种元素 (Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti) 总质量浓度为1.61 mg·m−3,WFGD对这10种金属元素的脱除效率为55.52%。这说明WFGD对金属元素的脱除效果较好。10种金属元素中,Ti的脱除效率高达98.89%;对Zn、Al、Ba、Fe、K、Na的脱除效率在50%以上;对Ca的脱除效率为39.67%,脱除效果一般;对Cr的脱除效率为7.04%,脱除效果较差;对Mn的脱除效率为负,这说明WFGD对Mn没有起到脱除效果。

表 3 WFGD对金属元素的脱除效率Table 3. WFGD metal element removal efficiencyNa Ca Al Fe K Zn Mn Ba Cr Ti 总元素 52.26% 39.67% 68.11% 61.13% 54.81% 79.50% −36.72% 67.04% 7.04% 98.89% 55.52% 总体上,CPM中金属元素的质量浓度偏低,Zn、Mn、Cr、Ba在WFGD进口质量浓度不超过0.10 mg·m−3。而在WFGD出口,这4种金属元素的质量浓度均不超过0.02 mg·m−3;Ti元素在WFGD进口处质量浓度为0.22 mg·m−3,出口处为0.002 5 mg·m−3,其质量浓度有大幅下降,但其本身质量浓度也并不高,降低比率虽大,差值并不大。总的来说,金属元素在CPM中的质量浓度很小,WFGD对CPM中金属元素有一定效果的脱除,但金属元素的脱除对总CPM来说影响不大。

2.2.3 WFGD对CPM水溶性离子的转化作用

供热厂燃煤锅炉WFGD进口及出口6种水溶性离子 (Na+、Ca2+、F−、Cl−、SO42−、NO3−) 质量浓度如表1,WFGD对各个水溶性离子的脱除效率如表4所示。供热厂燃煤锅炉WFGD进口总水溶性离子的质量浓度为18.39 mg·m−3、WFGD出口总水溶性离子的质量浓度为3.91 mg·m−3,WFGD对总水溶性离子的脱除效率为78.74%,说明WFGD对水溶性离子具有良好的脱除效果。在6种水溶性离子中,F−、Cl−的脱除效率均达到95%以上,脱除效果极好;对Na+、SO42−的脱除效率在70%以上,脱除效果较好;对Ca2+的脱除效率为42.37%,脱除效果一般;经过WFGD后,NO3−的质量浓度并没有发生改变,可能与本研究中NO3−质量浓度较低有关,其数据的波动较小,做平均值后恰好WFGD进口与出口处浓度相当。

表 4 WFGD对水溶性离子的脱除效率Table 4. WFGD to water-soluble ions removal efficiencyNa+ Ca2+ F− Cl− SO42− NO3− 总水溶性离子 72.00% 42.37% 97.36% 96.70% 71.02% 0.00% 78.74% 烟气经过WFGD后,CPM中水溶性离子明显降低,其主要原因是气态CPM在WFGD中经过脱硫浆液的喷淋,水溶性离子会溶于脱硫浆液,进而随着排除浆液而被脱除。另外,Na+、Mg2+、Al3+等阳离子来源于PM0.3,PM0.3在WFGD系统中会被脱硫浆液喷淋洗涤而脱除一部分[28]。胡月琪[11]在对CPM中水溶性离子排放特征研究中发现,水溶性离子排放水平与烟气脱硫净化工艺、脱硫产物溶解度及脱硫方式有密切关系。以石灰/石灰石作为脱硫添加剂并不会增加Ca2+排放;以NaOH作为脱硫剂会显著增加Na+的排放水平;以MgO作为脱硫剂,Mg2+是烟气排放的特征离子。因此,在对CPM中水溶性离子的脱除上,对脱硫剂的选择值得探究。

3. 结论

1) 对供热厂燃煤烟气CPM进行收集时,CPM滤膜上截留的CPM较少,在总CPM浓度中平均占比不超过5%。

2) 在WFGD进口处与出口处排放的烟气中,CPM质量浓度均远高于FPM质量浓度,且质量CPM浓度呈下降趋势,FPM质量浓度呈上升趋势;CPM中的无机组分平均质量浓度均远高于有机组分的平均质量浓度,且无机组分质量浓度呈下降趋势,有机组分质量浓度呈上升趋势。以上转化规律表明,烟气排放的颗粒物中以CPM为主,且CPM中以无机组分为主。

3) 燃煤供热厂CPM中含量最高的10种元素为Na、Ca、Al、K、Fe、Zn、Mn、Ba、Cr、Ti,其中Na、Ca、Al三种金属元素占总金属的80%以上。WFGD进出口相比,Na、Ca、Al三种金属浓度的减降量占总金属浓度减降量的74.27%。因此,Na、Ca、Al是CPM排放的主要金属元素。鉴于金属元素总含量在CPM总含量中的占比仅为5%,故金属元素不是CPM的最主要成分。

4) 对CPM中6种水溶性离子Na+、Ca2+、F−、Cl−、SO42−、NO3−研究发现,WFGD进口及出口SO42−质量浓度远高于其他离子浓度,且SO42−浓度减小量最高。这说明SO42−在水溶性离子中始终占据主导地位,且其为CPM主要排放的水溶性离子。

5) 燃煤供热厂WFGD对CPM的脱除效率为69.29%,对CPM有机组分脱除效率为负,对CPM无机组分的脱除效率为77.27%。WFGD对10种金属元素的脱除效率为55.52%,WFGD对总水溶性离子的脱除效率为78.74%,其中对F−、Cl−的脱除效率均达到95%以上,对Na+、SO42−的脱除效率在70%以上。

-

表 1 燃煤供热锅炉水溶性离子的数据

Table 1. Data of water-soluble ions in coal-fired heating boilers

水溶性离子种类 WFGD进口离子质量浓度/(mg·m−3) WFGD进口离子所占百分比 WFGD出口离子质量浓度/(mg·m−3) WFGD出口离子所占百分比 Na+ 0.50 2.72% 0.14 3.58% Ca2+ 0.59 3.21% 0.34 8.7% F− 4.16 22.59% 0.11 2.81% Cl− 2.12 11.53% 0.07 1.79% SO42- 10.94 59.49% 3.17 81.07% NO3− 0.08 0.45% 0.08 2.05% 表 2 WFGD对颗粒物的脱除效率

Table 2. WFGD removal efficiency of particulate matter

CPM有机组分脱除率 CPM无机组分脱除率 CPM脱除率 FPM脱除率 −85.79% 77.27% 69.29% −790.28% 表 3 WFGD对金属元素的脱除效率

Table 3. WFGD metal element removal efficiency

Na Ca Al Fe K Zn Mn Ba Cr Ti 总元素 52.26% 39.67% 68.11% 61.13% 54.81% 79.50% −36.72% 67.04% 7.04% 98.89% 55.52% 表 4 WFGD对水溶性离子的脱除效率

Table 4. WFGD to water-soluble ions removal efficiency

Na+ Ca2+ F− Cl− SO42− NO3− 总水溶性离子 72.00% 42.37% 97.36% 96.70% 71.02% 0.00% 78.74% -

[1] 郭忻跃. 北京大气干沉降及PM2.5中重金属和有机物污染及来源研究[D]. 北京科技大学, 2018. [2] 孔少飞. 大气污染源排放颗粒物组成有害组分风险评价及清单构建研究[D]. 天津: 南开大学, 2012. [3] 姬亚芹. 城市空气颗粒物源解析土壤风沙尘成分谱研究[D]. 天津: 南开大学, 2006. [4] 贾琳琳. 北方寒冷地区大气颗粒物污染特征及源解析研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. [5] 杨健儿. 上海市近地表大气颗粒物污染特征及来源分析研究[D]. 上海: 华东师范大学, 2011. [6] 李振. 典型燃煤电厂烟气系统中PM2.5变化规律及排放特征研究[D]. 北京: 清华大学, 2017. [7] 寿志毅, 郑少亮, 刘含笑, 等. 燃煤电厂颗粒物测定方法研究[J]. 洁净煤技术, 2019, 25(4): 130-136. doi: 10.13226/j.issn.1006-6772.18072401 [8] 岳阳霞. 燃煤烟气中可凝结颗粒物排放特征与检测方法研究[D]. 辽宁: 辽宁工程技术大学, 2021. [9] 裴冰. 燃煤电厂可凝结颗粒物的测试与排放[J]. 环境科学, 2015, 36(5): 1544-1549. [10] CORIO L A, SHERWELL J, et al. In-stack condensable particulate matter measurements and issues[J]. Journal of the Air and Waste Management Association, 2000, 50(2): 207-218. doi: 10.1080/10473289.2000.10464002 [11] 胡月琪, 马召辉, 冯亚君, 等. 北京市燃煤锅炉烟气中水溶性离子排放特征[J]. 环境科学, 2015, 36(6): 1966-1974. doi: 10.13227/j.hjkx.2015.06.008 [12] ZHENG C, HONG Y, LIU S, et al. Removal and Emission Characteristics of Condensable Particulate Matter in an Ultralow Emission Power Plant[J]. Energy& Fuels, 2018, 32(10): 10586-10594. [13] 周晨阳. 燃煤烟气中可凝结颗粒物中有机污染物排放和分布特性研究[D]. 杭州: 浙江大学, 2019. [14] FENG Y, LI Y, LIN C. Critical review of condensable particulate matter[J]. Fuel, 2018, 224: 801-813. doi: 10.1016/j.fuel.2018.03.118 [15] 杨柳, 张斌, 王康慧, 等. 超低排放路线下燃煤烟气可凝结颗粒物在WFGD、WESP中的转化特性[J]. 环境科学, 2019, 40(1): 121-125. doi: 10.13227/j.hjkx.201805260 [16] YANG H H. Filterable and condensable fine particulate emissions from stationary sources[J]. Aerosol and Air Quality Research, 2014, 14(7): 2010-2016. doi: 10.4209/aaqr.2014.08.0178 [17] PEI B. Determination and emission of condensable particulate matter from coal-fired power plants[J]. Environ Sci, 2015, 36(5): 1544-1549. [18] 冯玉鹏. 典型煤种在沉降炉中燃烧可凝结颗粒物排放特性研究[D]. 青岛: 山东大学, 2020. [19] 孙和泰, 黄治军, 华伟, 等. 超低排放燃煤电厂可凝结颗粒物排放特性[J]. 洁净煤技术, 2021, 27(5): 218-223. [20] CONSTANCE L S, COERY A T, NOAH D M, et al. Selenium Partitioning and Removal Across a Wet FGD Scrubber at a Coal-Fired Power Plant[J]. Environmental Science& Technology, 2015, 49(24): 14376-14382. [21] PEEROV P K, CHARTERS J W, WALLSCHLAGER D. Identification and determination of selenosulfate and selenocyanate in flue gas desulfurization waters[J]. Environmental Science & Technology, 2012, 46(3): 1716-1723. [22] 焦峰. 超低排放燃煤电厂烟气重金属污染物排放特征浅析[J]. 低碳世界, 2019, 9(1): 11-13. doi: 10.3969/j.issn.2095-2066.2019.01.006 [23] 邓建国, 王刚, 张莹, 等. 典型超低排放燃煤电厂可凝结颗粒物特征和成因[J]. 环境科学, 2020, 41(4): 1589-1593. doi: 10.13227/j.hjkx.201910091 [24] 朱法华, 李军状. 我国燃煤电厂SO3和可凝结颗粒物控制存在问题与建议[J]. 环境影响评价, 2019, 41(3): 1-5. [25] CANO M, VEGA F, NAVARRETE B, et al. Characterization of emissions of condensable particulate matter in clinker kilns using a dilutionsampling system[J]. Energy& Fuels, 2017, 31(8): 7831-7838. [26] ZHENG C H, WANG Y F, LIU Y, et al. Formation, transformation, measurement, and control of SO3 in coal-firedpower plants[J]. Fuel, 2019, 24(1): 327-346. [27] 宋建武. 燃煤烟气中可凝结颗粒物有机组分分析及其迁移分布特性研究[D]. 杭州: 浙江大学, 2020. [28] 潘丹萍, 吴昊, 鲍静静, 等. 电厂湿法脱硫系统对烟气中细颗粒物及SO3酸雾脱除作用研究[J]. 中国电机工程学报, 2016, 36(16): 4356-4362. 期刊类型引用(3)

1. 韩军赞,张洁,闫威卓,王社扣,张妍,邓建国. 燃煤电厂和钢铁厂烧结烟气有色烟羽排放特征与管控建议. 环境工程. 2024(02): 144-151 .  百度学术

百度学术

2. 董占斌,刘青松,王荣,王帅,李海洪. 电力生产污染的燃煤烟气除尘脱硫处理工艺研究. 环境科学与管理. 2024(10): 115-119 .  百度学术

百度学术

3. 李冬燕,周晨沛,韩亚茹. 碳化硅纤维膜的制备及其含尘气体过滤性能. 膜科学与技术. 2023(06): 53-60 .  百度学术

百度学术

其他类型引用(0)

-

下载:

下载: