-

随着原油劣质化加剧,石化行业含油废水水质呈现高浓度、难降解、生物毒性大的发展趋势[1-3];加之环境承载负荷降低,环保排放标准日趋严苛,导致含油废水处理压力不断增加[4]。含油废水处理通常采用预处理、生物处理和深度处理的组合工艺。相对生物处理和深度处理受到的高度关注和取得的长足进步[5-6],以“均质、隔油、气浮”为代表的常规预处理工艺及设施相对固化[7-8],其他诸如离心、旋流等常用预处理单元,也都主要通过物理分离与化学絮凝相结合以去除来水中的油分和悬浮物,但也同时存在产生浮渣等危废、消耗大量药剂、抗冲击性能差、操作繁琐、逸散VOCs等问题[9-13],模式消极且滋生邻避效应。

石化含油废水中包含浮油、乳化油、悬浮物等复合污染物,其脱固除油单元关乎下游生化单元的稳定运行、石化污水处理厂末端的达标排放以及炼化一体化企业的绿色低碳发展和区域环境与生态质量。依托材料、装备、控制等基础学科的持续发展,含油废水脱固除油理论体系、单元技术及装备研制取得了显著进步,相继衍生了组合装备结构优化、环保型药剂应用等代表性迭代成果,促成了资源化磁吸附、抗污染高效膜、电絮凝等新兴技术,但同时也普遍因技术成熟度不足而影响了实践应用。其中,深层过滤作为相对传统但成熟的污水处理工艺,目前大多用于尾水深度处理[14],而鲜有应用至预处理环节的报道。该技术的主要瓶颈包括受限于原水非溶解态污染物浓度所导致的分离负荷负担和连续高效反洗再生[15],而解决的出路则在于持续改进深层过滤介质和优化分离器结构。在过滤介质材质方面,胡桃壳、花生壳、锯末等生物质基材料作为相对成熟的选择[16],其可通过截滤、吸附和聚并以实现来水中油分的分离;同时也可通过制备特定尺寸或特定密度的均一化聚合材料颗粒,以避免过滤或反洗过程出现的颗粒破碎而影响分离效率。介质过滤设备结构设计则相对固定,目前的主流设计仍采用固定床结构维持床层稳定,并通过逆向来水带出床层中截滤的污染物,但深层介质过滤始终无法满足饱和吸附容量和乳化油分离等实际工程需求。进一步通过颗粒介质表面改性以实现特定的亲疏水性,包括超疏水强吸附改性等可重复使用的材料[17-18],则为含油废水过滤处理提供了全新的思路。但现有的介质过滤过程主要集中在单一床层介质,或者以调整孔道结构为导向的多介质床层,目前未见从颗粒介质接触微界面调控的角度尝试多介质过滤过程。限制深层过滤用于含油废水预处理的另一瓶颈则是分离装备的结构优化。常规的固定床结构在介质颗粒再生过程中,通过床层流化沸腾无法克服含油废水中油分或油泥对颗粒介质的粘附力,因而连续运行将造成分离效率持续衰减。通过多介质颗粒接触界面调控和分离设备介质再生强化,是实现含油废水深层过滤预处理的关键。

针对实际含油废水处理过程存在的预处理单元消耗大量化学絮凝药剂并相应产生危废、常规过滤单元无法实现油份与悬浮物协同分离等技术瓶颈,本研究通过改性石英砂颗粒,并与石英砂混合构建异质结颗粒群,系统开展了异质结颗粒群界面属性调控及其分离机理研究;同时,通过耦合异质结颗粒群微通道分离和旋流再生开发沸腾床分离器,并针对实际含油废水开展长周期分离性能及床层介质再生实验研究,以确保实现含油废水预处理过程的化学药剂近零消耗、危险废弃物近零填埋与污染物近零排放。

-

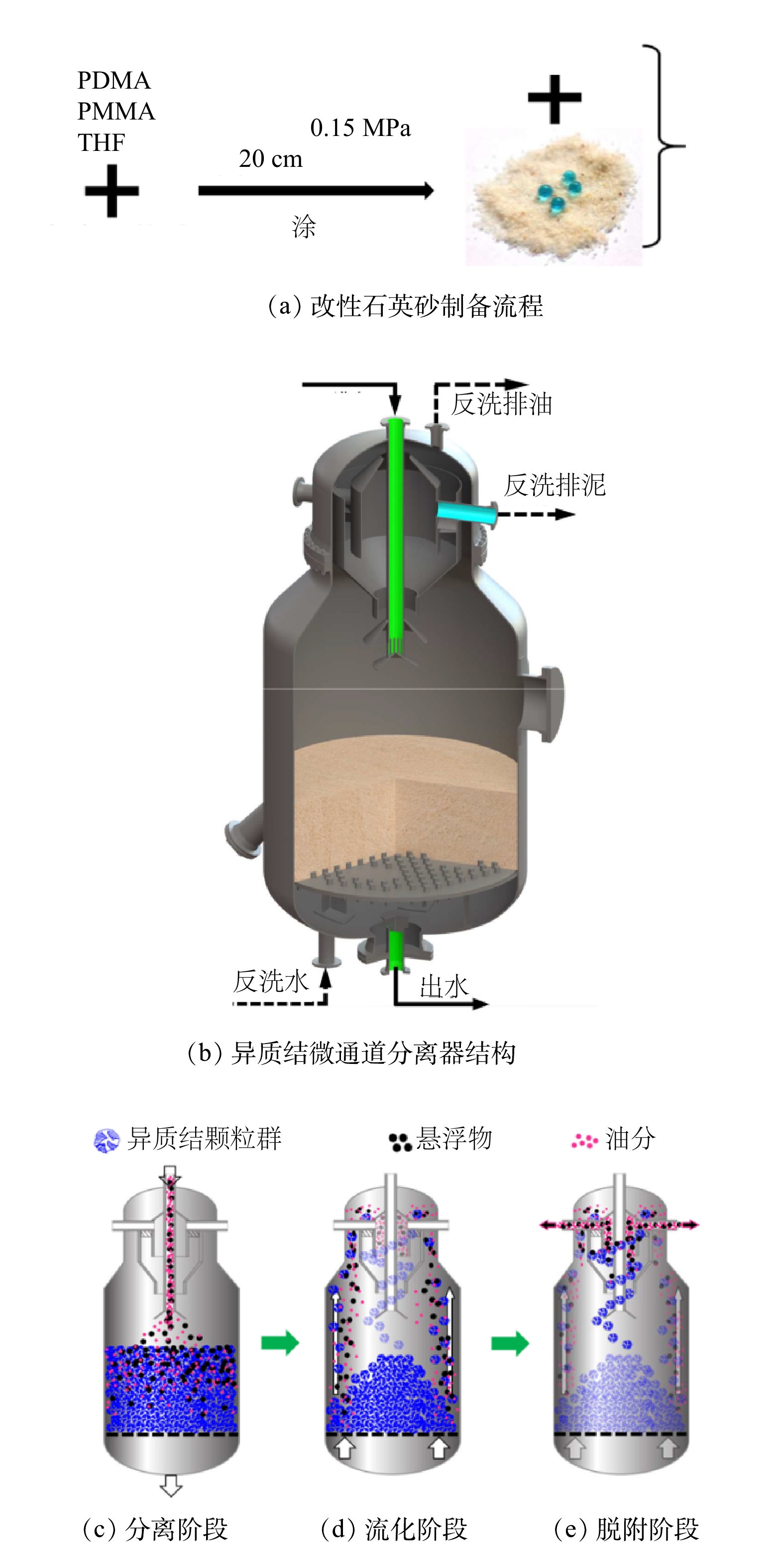

对粒径为200~500 μm的石英砂颗粒实施表面改性。如图1(a)所示,先将0.04 g·mL−1的聚二甲基硅氧烷(PDMS)加入四氢呋喃(THF),再将聚甲基丙烯酸甲酯(PMMA)与固化剂以10:1(质量比)的比例混入制成涂覆剂,并通过超声加速涂敷剂溶解;然后将石英砂颗粒置入乙醇和去离子水中采用超声清洗,通过喷枪以0.15 MPa的喷涂强度和20 cm的间距对石英砂进行喷涂,从而制得改性石英砂颗粒。将原始石英砂与改性石英砂颗粒按相应比例掺拌均匀,作为异质结颗粒群备用。

-

实验过程涉及模拟含油废水和实际含油废水。将四氯乙烯与水按1:99的质量比混合,并在8 000 r·min−1条件下高速搅拌5 min,充分乳化后制得模拟含油废水。实际含油废水为中石化上海石油化工股份有限公司电脱盐装置与焦化装置的混合废水。在稳定工况下,实际废水中的油浓度和悬浮物浓度通常小于100 mg·L−1;受上游装置原料变化、运行工况波动等影响,来水油分和悬浮物质量浓度为100~50 000 mg·L−1,且持续波动周期约占运行总时长的5%。实际废水中油份以C9~C18的烷烃为主,并包含少量的烯烃和苯系物;油份密度为0.9~0.95 kg·m−3,20 oC时油泥混合物的粘度平均为柴油的23.7倍。

-

利用改性石英砂构建异质结颗粒群,并依托沸腾床分离结构设计异质结微通道分离器。如图1(b)所示,将异质结颗粒床层装填进分离器,且保证床层体积约占分离器有效体积的50%。异质结微通道分离器的柱段高度为直径的2倍,上部锥段锥角为45°;锥段上部柱段直径与高度相同,均为下部柱段的0.6倍; 设备上下部均采用椭球形封头,并在下部封头内置水帽,以防止介质颗粒跑损;此外,异质结微通分离器内置旋流再生部件的锥段锥角为90°,以确保颗粒介质充分再生脱附。

在实际分离实验过程中,来水带压从异质结微通道分离器的顶端进入,经过异质结颗粒床层的分离阶段,从分离器底部出口排出,分离过程中床层截滤的浮油通过排油口连续或间歇外排。待分离器分离时长或分离压降达到阈值,分离器随即切换至反洗再生阶段(图1(c));此时反洗水从分离器底部带压进入,充分流化颗粒床层并适当带走床层颗粒上层截滤的滤饼层(图1(d));反洗水夹带异质结颗粒继续进入顶部的旋流自转分离器,进一步脱附床层颗粒表面及孔道附着的油份及悬浮物,以确保介质充分再生(图1(e))。

如图2(a)所示,在模拟废水分离实验过程中,将均匀混合的异质结颗粒群装填进有机玻璃管内,实验过程中仅考察异质结颗粒群对模拟乳化废水的实际破乳效果。模拟实验所用的异质结微通道分离器由直径为50 mm、高度为200 mm的有机玻璃管简易构建,异质结颗粒群装填总高为50 mm,并按25 L·h−1的规模处理用四氯乙烯配置的模拟乳化废水。现场直径为1 000 mm、处理规模为10 m3·h−1的侧线异质结微通道分离器装置,主要用于实施脱固除油破乳目标(图2(b)),以取代现有隔油池、涡凹气浮(CAF)和溶气气浮(DAF)的组合处理工艺(图2(c)),重点保障出水油分质量浓度不超过20 mg·L−1[9-10],而异质结微通道分离器产生的污油和油泥则排入为现有工艺设施规划的污油罐和油泥罐。用于模拟乳化废水和实际废水处理的异质结微通道分离器运行过程中的过滤速度均设定在7~15 m·h−1。

-

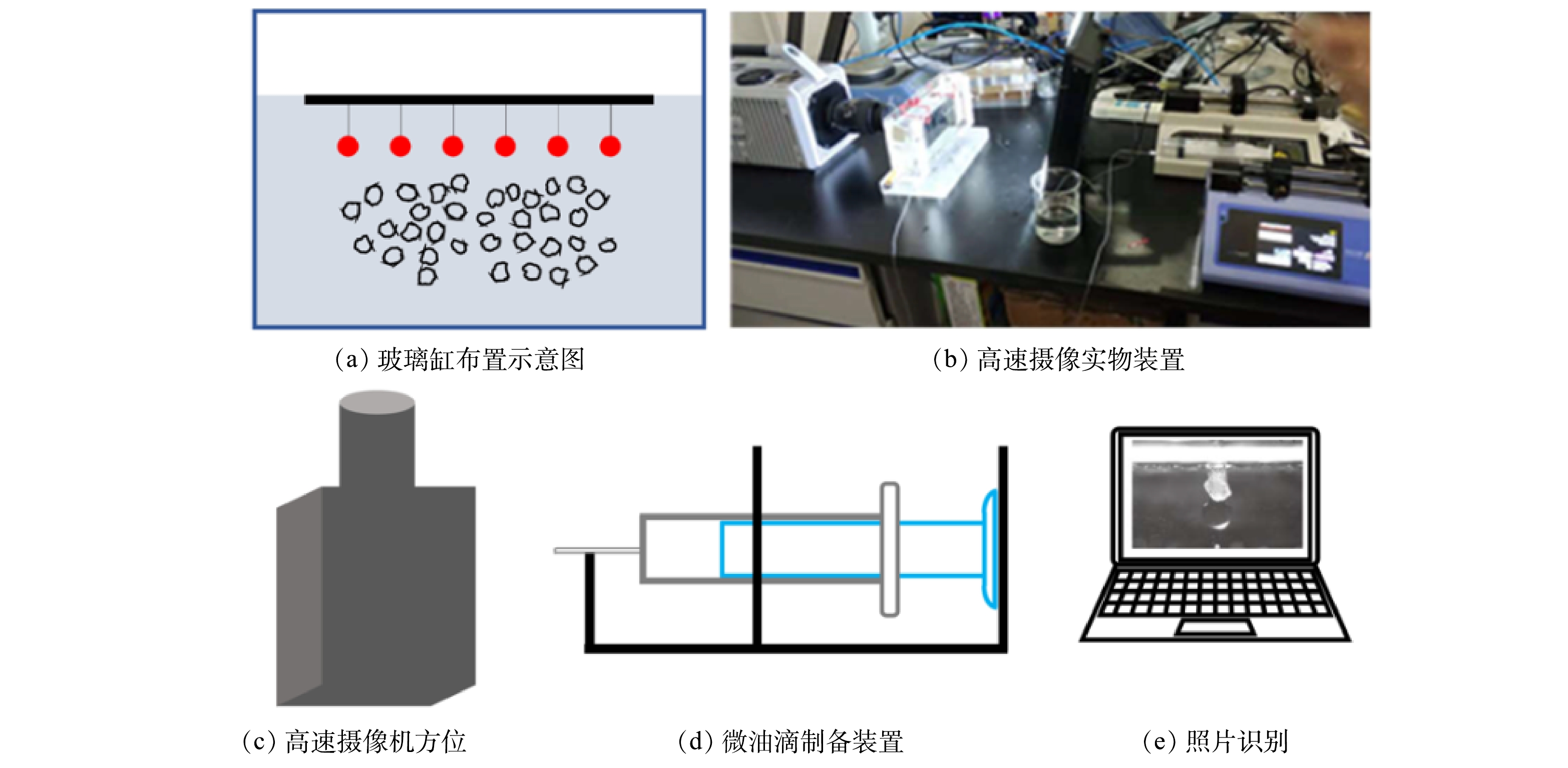

为精确识别改性前后石英砂颗粒与油滴接触过程的界面属性差别,如图3所示,首先将单一石英砂颗粒与针尖粘黏,并置于玻璃缸内;然后采用水平拉针仪制作具有收缩角度且出口锥尖尺寸合适的毛细玻璃管,通过控制注射泵流量,制备尺寸约为40~200 μm、单分散性突出的油滴,并通过控制颗粒与油滴的位置,在油滴上升时形成油滴与石英砂颗粒的界面接触过程[19]。采用美国TSI公司的高速摄像机(型号FASTCAM SA-X2)记录油滴与石英砂颗粒的接触过程,相机帧数设定为1 000 fps;实验用到的透镜包括普通单反镜头、5倍及以下普通放大镜头和显微镜头,并根据拍摄所需的放大倍数和视野范围适当选择[20]。实验背景光源为大功率的LED灯,发白色冷光;成套装置采用2个三维移动平台分别承载着高速摄像机和玻璃缸进行对焦。此外,本研究中还使用扫描电子显微镜(SEM)测定了石英砂改性前后的表面微观属性。

-

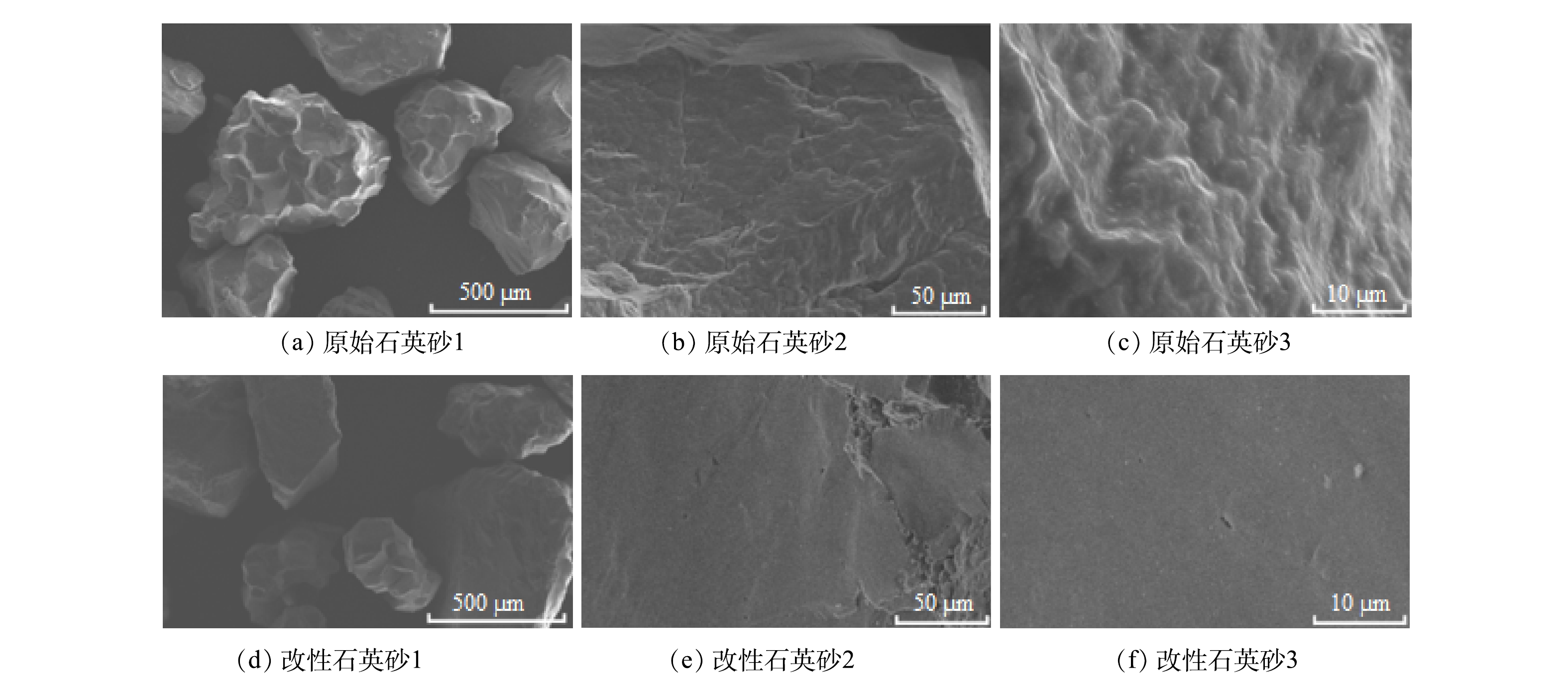

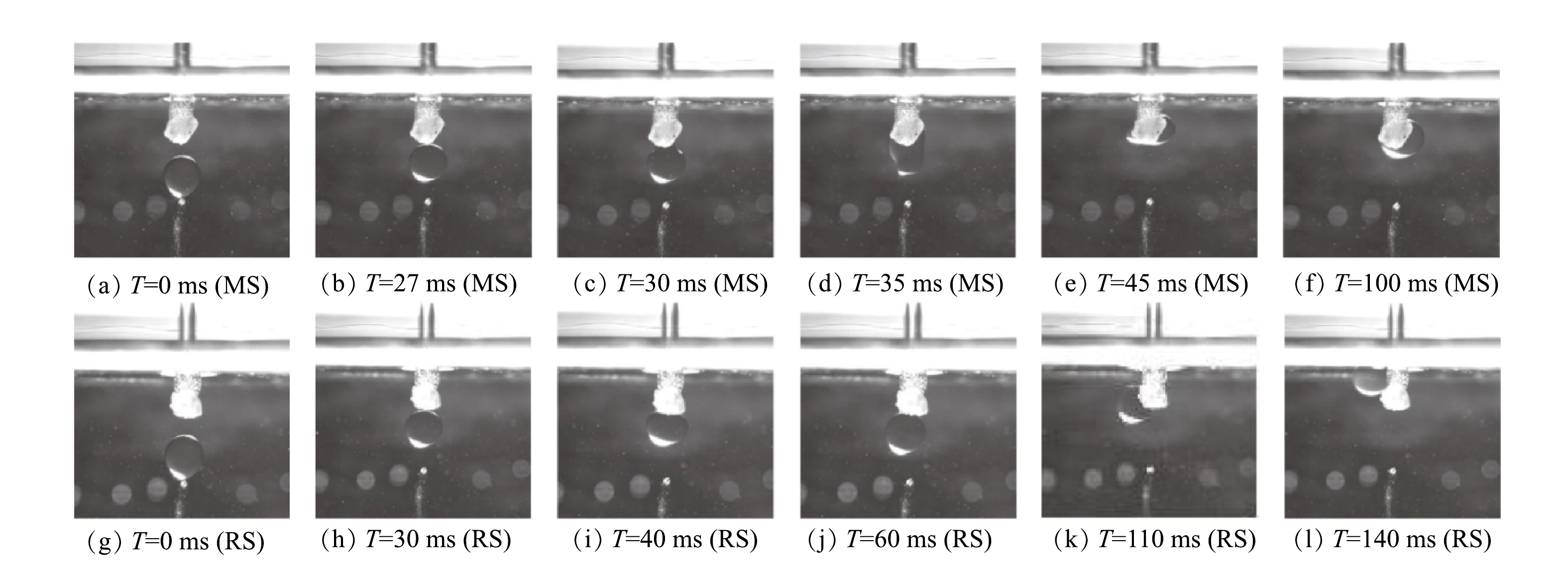

石英砂颗粒表面改性的首要目的是改变颗粒表面的疏水性。如图4所示,相较原始石英砂颗粒,改性石英砂颗粒表面呈现更为粗糙且均匀的微观结构;与此同时,改性石英砂颗粒在空气中与水接触角可达到135°,改性颗粒表面属性明显改变。进一步通过高速摄像识别了原始石英砂与改性石英砂接触油滴的动态过程。如图5所示,水中的模拟油滴上浮并接触颗粒的过程中,油滴与改性石英砂接触后,在100 ms内油滴快速形成对颗粒的包覆,且覆盖油滴在改性石英砂颗粒表面覆盖均匀,尤其颗粒底部的油膜与左右两侧类似而无明显的脱附趋势;原始石英砂颗粒与油滴的接触过程则差异明显,颗粒与油滴碰撞后出现变形并随后恢复球形,进一步沿石英砂壁面向上迁移并脱离石英砂颗粒,改性前后石英砂颗粒的疏油性差异极为显著。

-

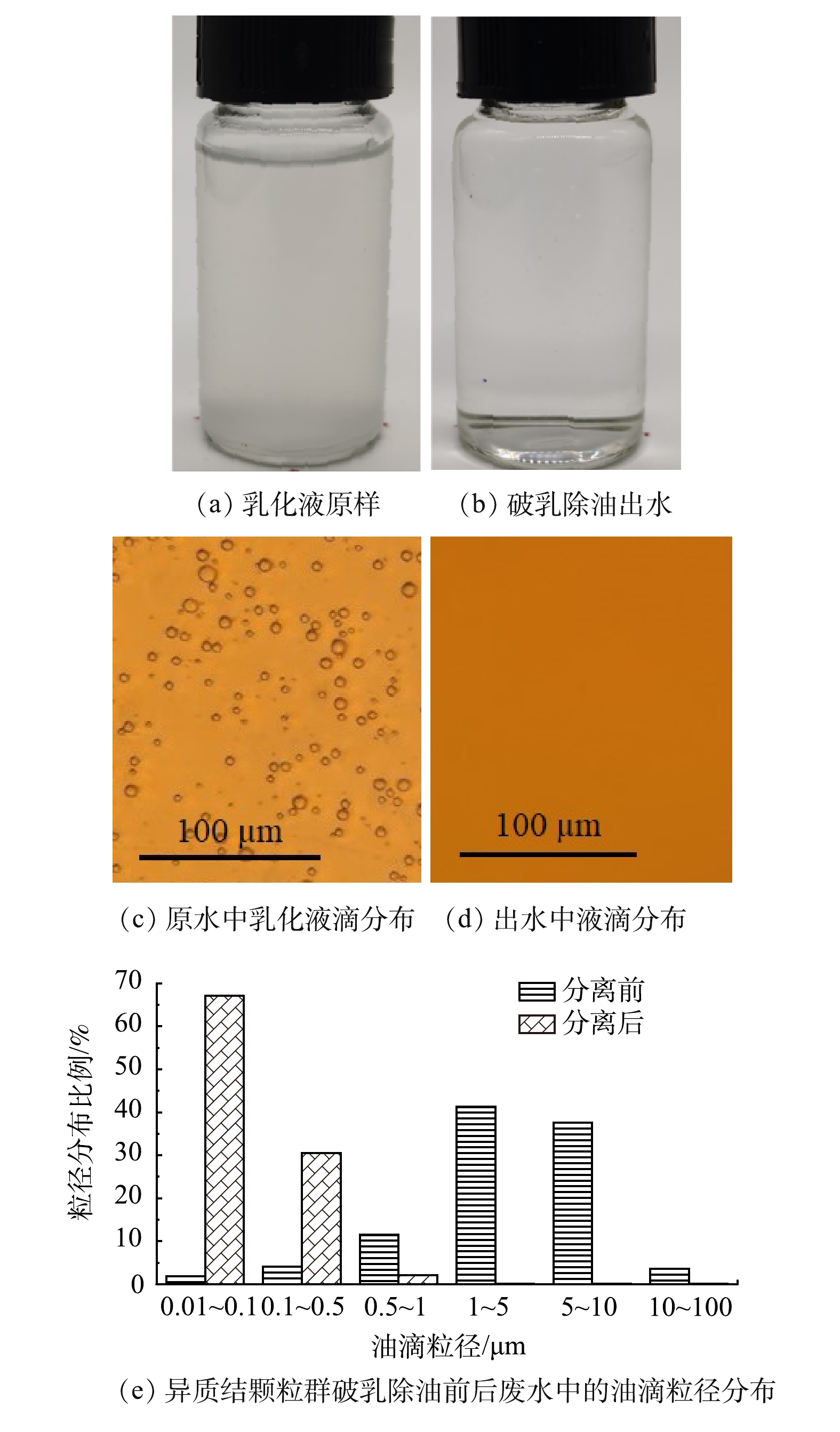

如图6(a)和图6 (b)所示(为保证微油滴识别视觉效果,电镜拍摄过程中乳化废水载玻片涂敷底色为黄色),油分质量浓度为1 000 mg·L−1的模拟乳化废水浑浊且透光率较差。同时,参考原始颗粒与改性颗粒在空气中与水的接触角,为确保改性石英砂颗粒与常规石英砂颗粒作为床层介质浸润在废水中时能形成致密的孔道截滤结构,将改性石英砂颗粒与常规石英砂颗粒的掺混比例设置为2:1,充分混合构建异质结颗粒群。经过异质结颗粒群过滤分离后,出水清澈程度和透光率显著改善,出水中的油分质量浓度显著降低至71 mg·L−1。对比图6(c)和图6(d)可见,进水中广泛散布的微小油滴在出水中近乎消失,两者视觉效果对比差异显著。进一步采用ImageJ软件定量识别对比进出水中特定区域内油滴的粒径分布范围。如图6(e)所示,来水中78.9%的油滴粒径为1~10 μm,呈典型乳化状且与实物对应;而出水中则既无可视浮油油滴,也基本观测不到1~10 μm的乳化油滴,其中99.7%以上的油滴粒径不足1 μm,即出水中仅剩的油分均大多数为溶解性油分。上述结果体现了异质结颗粒群的破乳效果和以异质结颗粒群为床层的截滤过程的显著除油效率。

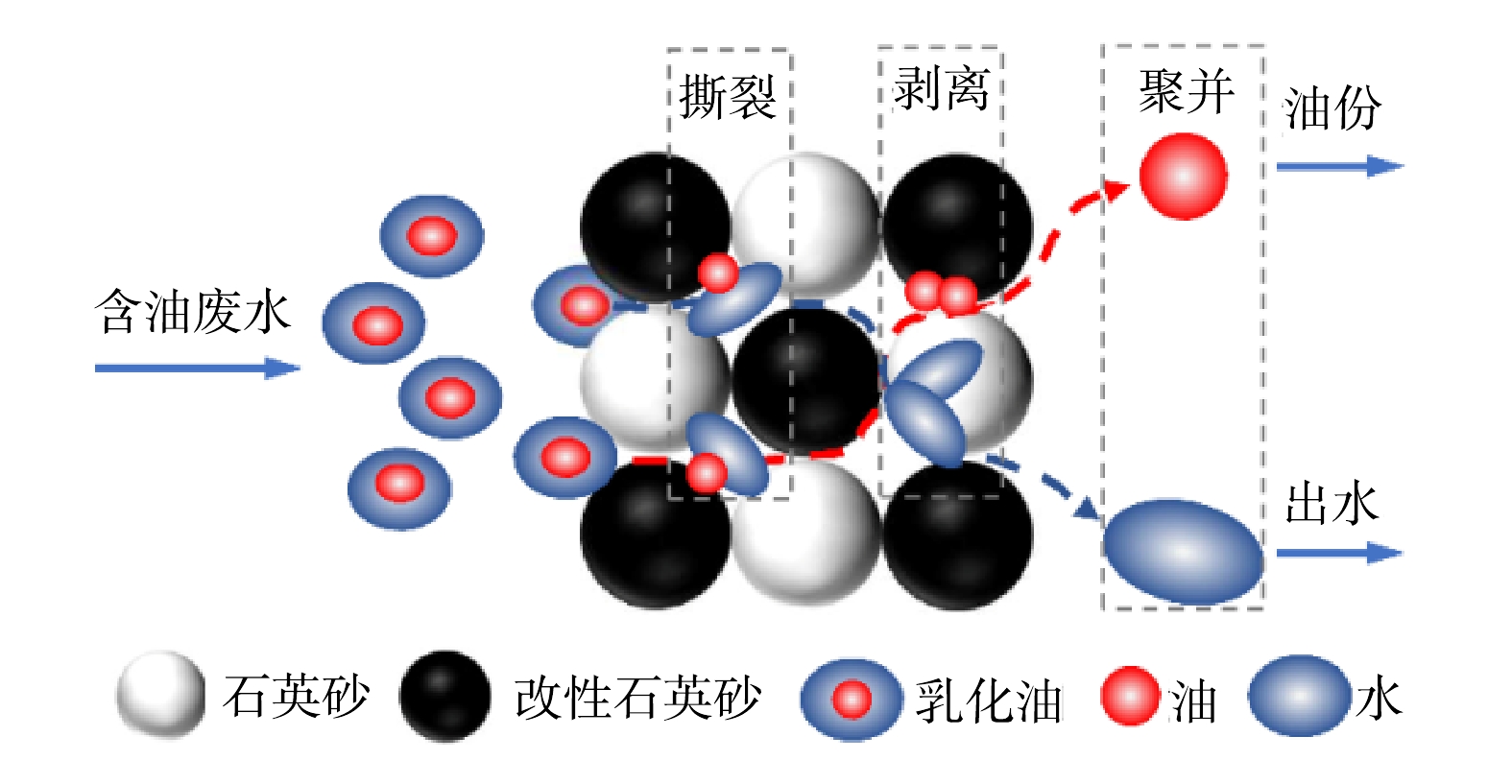

异质结颗粒群对模拟乳化废水先后实现了破乳和除油。如图7所示,在含油乳化废水经过异质结颗粒群的过程中,以水包油乳化液滴为例,在乳化液滴经过石英砂与改性石英砂接触界面的过程中,石英砂颗粒对水分的粘附首先引起对乳化液滴的撕裂趋势,异质结颗粒群中大量的异质颗粒接触界面形成对乳化液的整体撕裂效果。撕裂乳化液滴在继续前行的过程中,原始石英砂和改性石英砂分别粘附于水相和油相中,从而加剧对撕裂乳化液滴中水相与油相的剥离,且疏油改性石英砂还因对油滴的粘附捕集效果而实现微小油滴的聚并,从而改变油相和水相的迁移路径,油包水型的乳化液滴破乳过程与之相同。随着过滤过程沿床层向下深入,疏油改性石英砂最终形成对聚并油滴的截滤效果,直至实现油水分离。

-

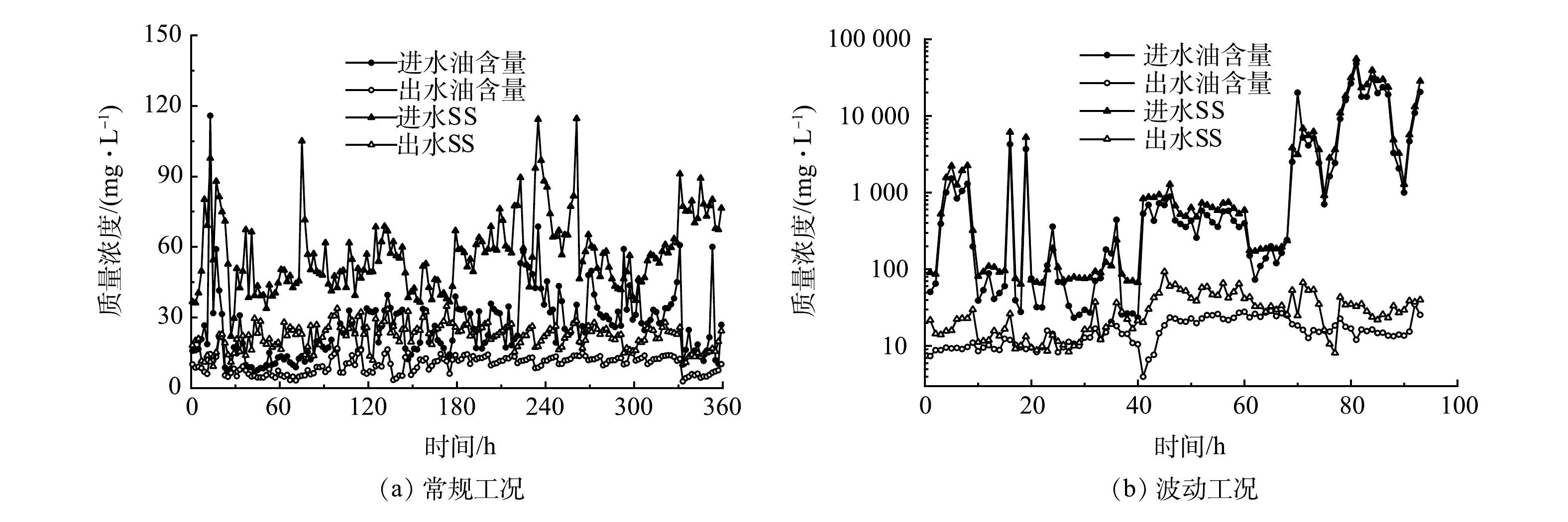

与模拟含油废水不同,实际石化废水中包含浮油、乳化油和悬浮物等复合污染物,因此,其微通道分离过程涉及悬浮物截滤、乳化液滴破乳和油分粘附截滤等综合分离需求。依托现场的异质结微通道沸腾床分离侧线实验装置,对现场实际含油废水先后开展了460 h的连续处理实验,其中来水稳定的工况持续360 h,且稳定工况下实验装置每72 h开展1次15 min的反洗;来水波动工况持续100 h,且波动工况下实验装置每12 h开展1次15 min的反洗。如图8(a)所示,针对油份和悬浮物质量浓度分别为6.4~115.8 mg·L−1和21.9~197.7 mg·L−1的来水,其出水平均油分和悬浮物质量浓度分别降至11.4 mg·L−1和21.3 mg·L−1;同时,所有出水的油分质量浓度均低于20 mg·L−1,且93.9%的出水的油分质量浓度低于15 mg·L−1。如图8(b)所示,针对油份和悬浮物最高质量浓度接近47 600 mg·L−1和55 200 mg·L−1的波动工况,出水平均油分和悬浮物质量浓度分别降至18.2 mg·L−1和29.1 mg·L−1;同时,所有出水的油分质量浓度均低于30 mg·L−1,且71.3%的出水的油分质量浓度低于20 mg·L−1。

采用异质结颗粒构建具有特定界面的颗粒群床层,不仅要实现来水中油份(含乳化油)和悬浮物的同步分离,还要在颗粒床层反洗过程中快速实现颗粒界面粘附悬浮物与油份的快速分离。在实际废水处理过程中,当沸腾床分离器介质床层纳污饱和后,利用沸腾床分离器出水反洗床层,颗粒群先充分流化,使床层表层截滤的悬浮物和部分油份从颗粒表面脱落,再进入沸腾床分离器顶部的旋流单元,利用流场剪切和颗粒的自转运动过程充分更新颗粒表面,实现床层介质净化。如图9所示,在常规工况水质条件下,在反洗流量为额定进水流量的140%时,床层介质再生经济性最高;经过20 min的反洗,出水油分和悬浮物质量浓度分别降至30 mg·L−1和50 mg·L−1以下,且截滤油分和悬浮物占进水的排除比例均超过90%,可确保满足设备长周期稳定运行要求。

-

1)采用PDMS、四氢呋喃、PMMA、固化剂等配制的涂敷剂改性石英砂颗粒,相较原始石英砂颗粒,改性石英砂颗粒在空气中与水的接触角增大至约135°,且在动态条件下与微油滴的接触过程中表现出明显的疏油特性;将其与原始石英砂颗粒混合构建异质结改性颗粒群,以此可开发异质结颗粒群微通道沸腾床分离器。

2)基于异质结颗粒群中颗粒间的界面属性差异,乳化液经过颗粒介质通道时相继发生撕裂、剥离和聚并过程,对乳化液中10 μm以下的细小油滴聚结效果显著,可确保含油废水中的油分去除率超过92%。

3)针对含悬浮物和油分且水质剧烈波动的实际含油乳化废水,常规工况和波动工况下的出水平均油分质量浓度可分别降至11.4 mg·L−1和18.2 mg·L−1,悬浮物质量浓度可分别降至21.3 mg·L−1和29.1 mg·L−1,且经过20 min反洗后沸腾床分离器满足长期稳定运行要求。

含油废水异质结微通道分离机理及实验

Mechanism and experiment of micro-channel filtration by heterostructure media particles for oily wastewater treatment

-

摘要: 石油炼制废水等石化行业含油废水普遍存在油分与悬浮物高度复合、油分乳化且水质剧烈波动等特征,其达标处理成为关乎企业绿色发展与产能拓展的关键因素。针对含油废水分离资源化需求,采用聚二甲基硅氧烷(PDMS)、四氢呋喃(THF)、聚甲基丙烯酸甲酯(PMMA)、固化剂等配制涂敷剂,通过喷涂石英砂制备了改性颗粒,并混合常规石英砂构建了异质结颗粒群,由此开发出异质结微通道沸腾床分离实验装置,考察了其对复合污染乳化废水中污染物的分离效果。结果表明:涂覆改性颗粒的接触角明显增加,且改性颗粒与油滴接触的微界面动态识别过程表明其较原始石英砂的疏油性显著增加;异质结颗粒群经过撕裂、剥离和聚并过程,将乳化液中10 μm以下的细小油滴有效聚结并确保废水油分去除率超过92%。针对油分和悬浮物质量浓度不超过50 000 mg·L−1的实际石化废水,现场10 m3·h−1规模的异质结微通道沸腾床侧线实验结果表明,在常规工况和波动工况条件下,其出水平均油分质量浓度分别为11.4 mg·L−1和18.2 mg·L−1,悬浮物质量浓度则分别降至21.3 mg·L−1和29.1 mg·L−1,且经过20 min反洗后沸腾床分离器满足长期稳定运行要求。Abstract: The petroleum refinery wastewater and other oily wastewater were characterized as the mixture of oil and suspended solids (SS), oil emulsification, and severe water quality fluctuations. Its compliance treatment has become a key factor related to the green development of enterprises and the expansion of production capacity. In response to the resource utilization of oily wastewater, polydimethylsiloxane (PDMS), tetrahydrofuran (THF), polymethylmethacrylate (PMMA) and curing agent were used to configure the coating agents for sand modification. The raw and modified sands were mixed as heterostructure media particles (HMPs) and filled in the fluidized bed for micro-channel filtration of oily wastewater. The results showed that the contact angle of the modified sand increased significantly as well as its oleophobicity through dynamic recognition of the micro-interface in contact. After tearing, peeling and coalescence of emulsified oil in heterostructure media particles, the fine oil droplets below 10 μm in the emulsion were effectively coalesced and the oil removal efficiency exceeded 92%. A 10 m3·h−−1 pilot-scale microchannel fluidized bed separator with heterostructure media particles was set up to treat the actual petroleum refinery wastewater with oil and SS contents over 50 000 mg·L−1. Under the normal and fluctuating conditions, the average effluent oil contents decreased to 11.4 mg·L-1 and 18.2 mg·L−1, as well as the SS contents decreased to 21.3 mg·L−1 and 29.1 mg·L−1, respectively. The fluidized bed separator can also satisfy the long-term stable operation requirements after 20 min backwashing.

-

-

-

[1] ANI I J, AKPAN U G, OLUTOYE M A, et al. Photocatalytic degradation of pollutants in petroleum refinery wastewater by TiO2- and ZnO-based photocatalysts: Recent development[J]. Journal of Cleaner Production, 2018, 205: 930-954. doi: 10.1016/j.jclepro.2018.08.189 [2] JAFARINEJAD S, JIANG S C. Current technologies and future directions for treating petroleum refineries and petrochemical plants (PRPP) wastewaters[J]. Journal of Environmental Chemical Engineering, 2019, 7: 103326. doi: 10.1016/j.jece.2019.103326 [3] TIAN X, SONG Y, SHEN Z, et al. A comprehensive review on toxic petrochemical wastewater pretreatment and advanced treatment[J]. Journal of Cleaner Production, 2020, 245: 118692. doi: 10.1016/j.jclepro.2019.118692 [4] HAN G, WIT J S, CHUNG J S. Water reclamation from emulsified oily wastewater via effective forward osmosis hollow fiber membranes under the PRO mode[J]. Water Research, 2015, 81: 54-63. doi: 10.1016/j.watres.2015.05.048 [5] COELHO A, CASTRO A V, DEZOTTI M, et al. Treatment of petroleum refinery sourwater by advanced oxidation processes[J]. Journal of Hazardous Materials, 2006, 137: 178-184. doi: 10.1016/j.jhazmat.2006.01.051 [6] ALIFF RADZUAN M R, ABIA-BITEO BELOPE M A, THORPE R B. Removal of fine oil droplets from oil-in-water mixtures by dissolved air flotation[J]. Chemical Engineering Research Design, 2016, 115: 19-33. doi: 10.1016/j.cherd.2016.09.013 [7] MOOSAI R, DAWE R A. Gas attachment of oil droplets for gas flotation for oily wastewater cleanup[J]. Separation Purification Technology, 2003, 33: 303-314. doi: 10.1016/S1383-5866(03)00091-1 [8] SANTO C E, VILAR V J P, BOTELHO C M S, et al. Optimization of coagulation–flocculation and flotation parameters for the treatment of a petroleum refinery effluent from a Portuguese plant[J]. Chemical Engineering Journal, 2012, 183: 117-123. doi: 10.1016/j.cej.2011.12.041 [9] SUN Y X, LIU Y, XU B W, et al. Simultaneously achieving high-effective oil-water separation and filter media regeneration by facile and highly hydrophobic sand coating[J]. Science of the Total Environment, 2021, 800: 149488. doi: 10.1016/j.scitotenv.2021.149488 [10] SUN Y X, LIU Y, CHEN J Q, et al. Physical pretreatment of petroleum refinery wastewater instead of chemicals addition for collaborative removal of oil and suspended solids[J]. Journal of Cleaner Production, 2021, 278: 123821. doi: 10.1016/j.jclepro.2020.123821 [11] SATHTHASIVAM J, LOGANATHAN K, SARP S. An overview of oilewater separation using gas flotation systems[J]. Chemosphere, 2016, 144: 671-680. doi: 10.1016/j.chemosphere.2015.08.087 [12] 王赫名, 桂程, 王刚, 等. 单室空气阴极微生物燃料电池处理含油废水[J]. 环境科学与技术, 2020, 43(11): 148-153. [13] 何少林, 陈辉, 于景琦, 等. 石化废水挥发性有机物逸散量的估算方法[J]. 化工环保, 2015, 35(6): 620-624. doi: 10.3969/j.issn.1006-1878.2015.06.013 [14] CAMBIELLA Á, ORTEA E, RíOS G, et al. Treatment of oil-in- water emulsions: Performance of a sawdust bed filter[J]. Journal of Hazardous Materials, 2006, 131: 195-199. doi: 10.1016/j.jhazmat.2005.09.023 [15] KNAPIK E, STOPA J. Fibrous deep-bed filtration for oil/water separation using sun-flower pith as filter media[J]. Journal of Ecological Engineering, 2018, 121: 44-52. doi: 10.1016/j.ecoleng.2017.07.021 [16] LIU H, HUANG J, CHEN Z, et al. Robust trans-lucent superhydrophobic PDMS/PMMA film by facile one-step spray for self-cleaning and efficient emulsion separation[J]. Chemical Engineering Journal, 2017, 330: 26-35. doi: 10.1016/j.cej.2017.07.114 [17] SRIRAM S, KUMAR A. Separation of oil-water via porous PMMA/SiO2 nanoparticles superhydrophobic surface[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2019, 563: 271-279. [18] CAO C, CHENG J. Fabrication of robust surfaces with special wettability on porous copper substrates for various oil/water separations[J]. Chemical Engineering Journal, 2018, 347: 585-594. doi: 10.1016/j.cej.2018.04.146 [19] LU H, XU X, XIE L S, et al. Deformation and crawling of oil drop on solid substrates by shearing liquid[J]. Chemical Engineering Science, 2019, 195: 720-729. doi: 10.1016/j.ces.2018.10.017 [20] HUANG Y, LI J P, ZHANG Y H, et al. High-speed particle rotation for coating oil removal by hydrocyclone[J]. Separation and Purification Technology, 2017, 177: 263-271. doi: 10.1016/j.seppur.2016.12.001 -

下载:

下载: