-

浸没式膜生物反应器(submerged membrane bioreactor,SMBR)在食品、皮革或矿山等高浓度氨氮废水处理中有较广泛的应用,但高浓度盐分及钙离子带来的工艺问题仍未得到有效解决[1]。高盐环境使细胞发生质壁分离、抑制细胞活性,进而降低生物硝化-反硝化能力[2];高钙废水中钙离子沉积会改变膜运行特征,导致膜污染加剧,从而影响SMBR运行稳定性[3]。

现有研究结果表明,进水预处理、通过稀释降低进水高盐量、接种嗜盐微生物和改变水力停留时间(hydraulic retention time,HRT)等方法可缓解盐对硝化-反硝化主要功能微生物的抑制作用[4],其中,HRT是影响氨氮和总氮去除率的重要因素之一[5]。LIU等[6]和EL-FADEL等[7]分别利用SMBR处理垃圾渗滤液,进水

${\rm{NH}}_4^ + $ -N浓度为2 200.02~3 035.00 mg·L−1,当HRT由4.17 d延长至7.00 d时,出水浓度由1 630.81 mg·L−1降至20.00 mg·L−1以下,去除率由37.70%增加至99.10%,随着HRT延长,${\rm{NH}}_4^ + $ -N处理能力得到显著提升。NUANSAWAN等[8]利用前置反硝化膜生物反应器处理垃圾渗滤液,平均进水TN浓度为3 391.70 mg·L−1,当HRT由2.50 d延长至5.00 d时,出水TN浓度由735.99 mg·L−1降低至461.27 mg·L−1,平均TN去除率由78.30%增加至86.40%,结果表明,延长HRT增加了硝化-反硝化时间,提高了氨氮和总氮的处理能力。高浓度钙离子沉积会增大滤饼层阻力,导致膜的无机污染,针对该问题,目前常采用的方法有进水预处理、更换膜材料、化学清洗和调整运行/间歇时间等[9],其中,调整运行/间歇时间为最典型的膜污染控制方法[10]。HABIB等[11]研究运行与间歇时间之比对膜污染特征的影响,当运行与间歇时间之比分别为32∶1、24∶1和16∶1(运行/间歇时间分别为960 s/30 s、720 s/30 s和480 s/30 s)时,平均膜污染速率分别为60.00、50.00和2.63 kPa·h−1,膜运行时长分别为0.42、0.50和9.50 h,膜污染速率随着运行与间歇时间比值的减小而减小,缩短两者比例有助于控制膜污染。TABRAIZ等[12]在运行与间歇时间的比例保持不变(10∶1)条件下,研究不同运行周期对膜污染特征的影响,运行/间歇时间分别为15 min/1.5 min、10 min/1 min和5 min/0.5 min时,膜污染速率逐渐减慢,由1.64、1.45 kPa·h−1降低至1.34 kPa·h−1,膜运行时长由21.50、25.00 h延长至27.00 h。上述结果表明,当运行时间与间歇时间之比一定时,缩短运行周期能有效控制膜污染。但在含盐量和钙离子均较高的选矿废水处理方面,通过改变膜的运行与间歇时间之比及运行周期等工艺参数,实现膜污染控制的相关研究较少。

本研究利用SMBR处理高盐高钙选矿废水,研究了水温对脱氮特征(硝化特征、总氮去除特征)的影响,通过调整HRT,实现高盐废水在不同水温条件下的高效脱氮;考察了高钙废水中膜运行与间歇时间之比和运行周期对膜污染特征的影响,并确定出膜稳定运行的最佳工艺条件,以期为SMBR在高盐高钙选矿废水中应用提供技术支持。

全文HTML

-

反应器有效容积60 L,其中缺氧区10 L、好氧区35 L、膜区15 L,混合液回流比为600%;好氧区通过微孔曝气维持溶解氧在2~4 mg·L−1。膜组件采用PVDF中空纤维膜(SUEZ,法国),平均孔径为0.04 μm,有效过滤面积为0.1 m2。SMBR示意图见图1。

本研究通过排放混合液的方法维持污泥浓度(mixed liquor suspended solid,MLSS;mixed liquor volatile suspended solid,MLVSS)和控制污泥龄(sludge retention time,SRT)。在不同水力停留时间下,活性污泥浓度、MLVSS与MLSS的比值及污泥龄见表1。

膜运行周期分别为12 min和6 min,运行与间歇时间之比分别为5∶1和2∶1。膜清洗方式分为维持性清洗和恢复性清洗:当跨膜压差小于35 kPa时,每个运行周期均启动维持性清洗。维持性清洗采用化学在线清洗+水反洗,历时4 min(膜运行周期12 min)或2 min(膜运行周期6 min)。以维持性清洗2 min为例,具体清洗方法及时间安排如下:(膜松弛5 s)柠檬酸(30 s)-(膜松弛5 s,水反洗5 s)次氯酸钠(30 s)-(膜松弛10 s)水反洗(30 s)(膜松弛5 s),其中柠檬酸浓度为2 000 mg·L−1,次氯酸钠浓度为200 mg·L−1;当跨膜压差达到35 kPa时,进行恢复性清洗,先用水冲洗膜表面滤饼层,再依次用2 000 mg·L−1柠檬酸和1 000 mg·L−1次氯酸钠浸泡(分别浸泡8 h和20 h),恢复性清洗后膜的清水通量可恢复至新膜清水通量的99.95%~99.99%,跨膜压差为0.5~3.1 kPa。

-

本实验进水为某企业选矿废水二级处理系统(活性污泥-接触氧化组合工艺)出水,原水水质见表2。

-

文献中的TCOD、SCOD、

${\rm{NH}}_4^ + $ -N、${\rm{NO}}_2^ - $ -N、${\rm{NO}}_3^ - $ -N、Ca2+和总溶解性固体(total dissolved solids,TDS)均按《水和废水监测分析方法(第4版)》方法[13]测定。 -

当HRT分别为1.25、2.34、2.50和4.50 d时,取膜区活性污泥进行高通量测序,细菌16S rDNA的PCR扩增区域为V3~V4,扩增引物为341F和805R[4]。

1.1. 实验装置与运行条件

1.2. 原水水质

1.3. 水质分析方法

1.4. 高通量测序

-

1)不同HRT条件下

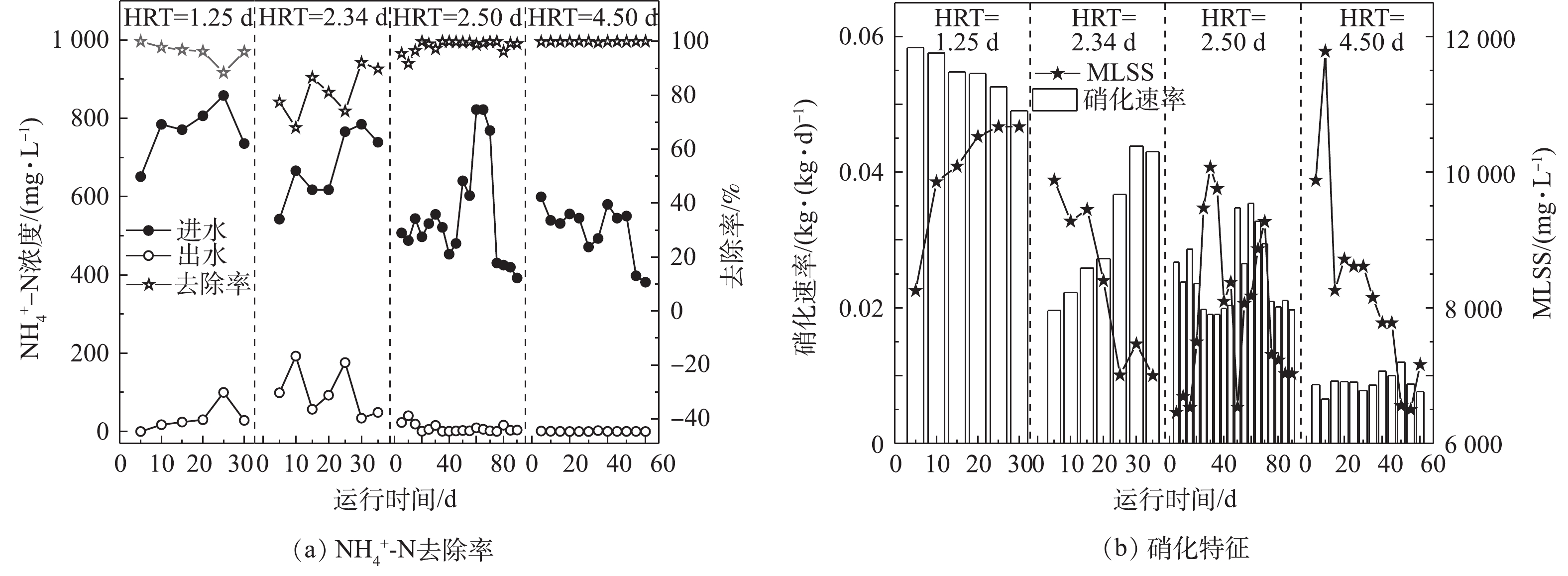

${\rm{NH}}_4^ + $ -N去除特征。不同HRT(水温≥15 ℃,TDS为11 057~14 321 mg·L−1,样本数n=53)条件下,${\rm{NH}}_4^ + $ -N的去除特征见图2。由图2(a)可知,与HRT为1.25、2.34和2.50 d相比,在HRT为4.50 d的条件下,氨氮去除效率分别提高了4.01%、18.61%和1.53%。实验结果表明,在高盐废水中,SMBR对

${\rm{NH}}_4^ + $ -N处理能力处于较高水平,且随着HRT延长,硝化时间更为充足,${\rm{NH}}_4^ + $ -N去除率有所提高;根据氨氮去除率及出水水质,确定最佳HRT为4.50 d。CHIEMCHAISRI等[14]和PUSZCZAłO等[15]分别利用SMBR处理氨氮浓度为950.00~1 750.00 mg·L−1的垃圾渗滤液,当HRT由0.50 d延长至1~1.50 d时,氨氮出水浓度由11.00~305.00 mg·L−1降至3.00~6.50 mg·L−1,去除率由80%提高到95%以上,氨氮处理能力随HRT延长得到显著的提升。HRT影响反应器在高盐废水中的氨氮去除效果,当HRT过短时,微生物降解不充分,出水水质差;延长HRT,当硝化时间充足时,有利于氨氮去除,出水水质得到明显改善[16]。由图2(b)可知,在HRT为1.25、2.34、2.50和4.50 d的条件下,MLSS平均浓度分别为(10 012±843)、(8 355±1 123)、(7 912±1 146)和(8 315 ±1 389) mg·L−1。RONALD等[17]的研究表明,当MLSS>10 000 mg·L−1、供氧不足、耗氧量相对较高的条件下,污泥浓度过高且黏度增加,氧传质阻力增大,从而导致好氧区DO降低,抑制硝化作用。RAJESH等[18]的研究表明,当MLSS为7 500~10 500 mg·L−1时,对硝化效果无显著影响。在本研究中,当污泥浓度为6 498~10 527 mg·L−1时,氨氮去除率为77.49%~99.99%,说明污泥浓度波动未显著影响硝化效果。

由图2可知,当HRT为1.25 d时,进水

${\rm{NH}}_4^ + $ -N浓度增加了8.99%(10~25 d),硝化速率增加了5.48%,去除率下降了8.29%;当HRT为2.34 d时,${\rm{NH}}_4^ + $ -N浓度增加了22.92%(15~25 d),硝化速率增加了27.64%,去除率降低了9.71%;当HRT为2.50 d时,进水${\rm{NH}}_4^ + $ -N增加了61.69%(5~65 d),硝化速率增加了34.55%,去除率稳定在98.84%;当HRT为4.50 d时,进水${\rm{NH}}_4^ + $ -N增加了15.82%(30~50 d),硝化速率增加了20.48%,去除率仍稳定在99.56%以上。上述结果表明,随着HRT的延长,反应器在高盐废水中的运行更加稳定,抗冲击负荷能力更强;根据氨氮去除的稳定性,确定最佳HRT应为2.50 d或4.50 d。同时,当HRT分别为2.50 d和4.50 d、进水${\rm{NH}}_4^ + $ -N平均浓度为508.48 mg·L−1和558.42 mg·L−1时,出水浓度分别为11.87 mg·L−1 (25~45 d)和0.35 mg·L−1 (10~25 d),表明当HRT为4.50 d时,SMBR出水水质更好。KAEWMANEE等[19]利用A/O-SMBR对垃圾渗滤液进行后处理的过程中发现,当HRT为1 d时,进水${\rm{NH}}_4^ + $ -N浓度为180.00 mg·L−1,去除率为44.44%,当进水氨氮浓度增加为219.96 mg·L−1(即氨氮浓度增加了22.22%),氨氮去除率减小了25.81%;当HRT延长至1.67 d时,进水${\rm{NH}}_4^ + $ -N浓度为100.00 mg·L−1,去除率高于95.00%,进水浓度增加为200.00 mg·L−1(即氨氮浓度增加了100%)时,去除率仍不低于95.00%,以上结果表明,HRT延长增强了反应器的运行稳定性。2)不同HRT条件下

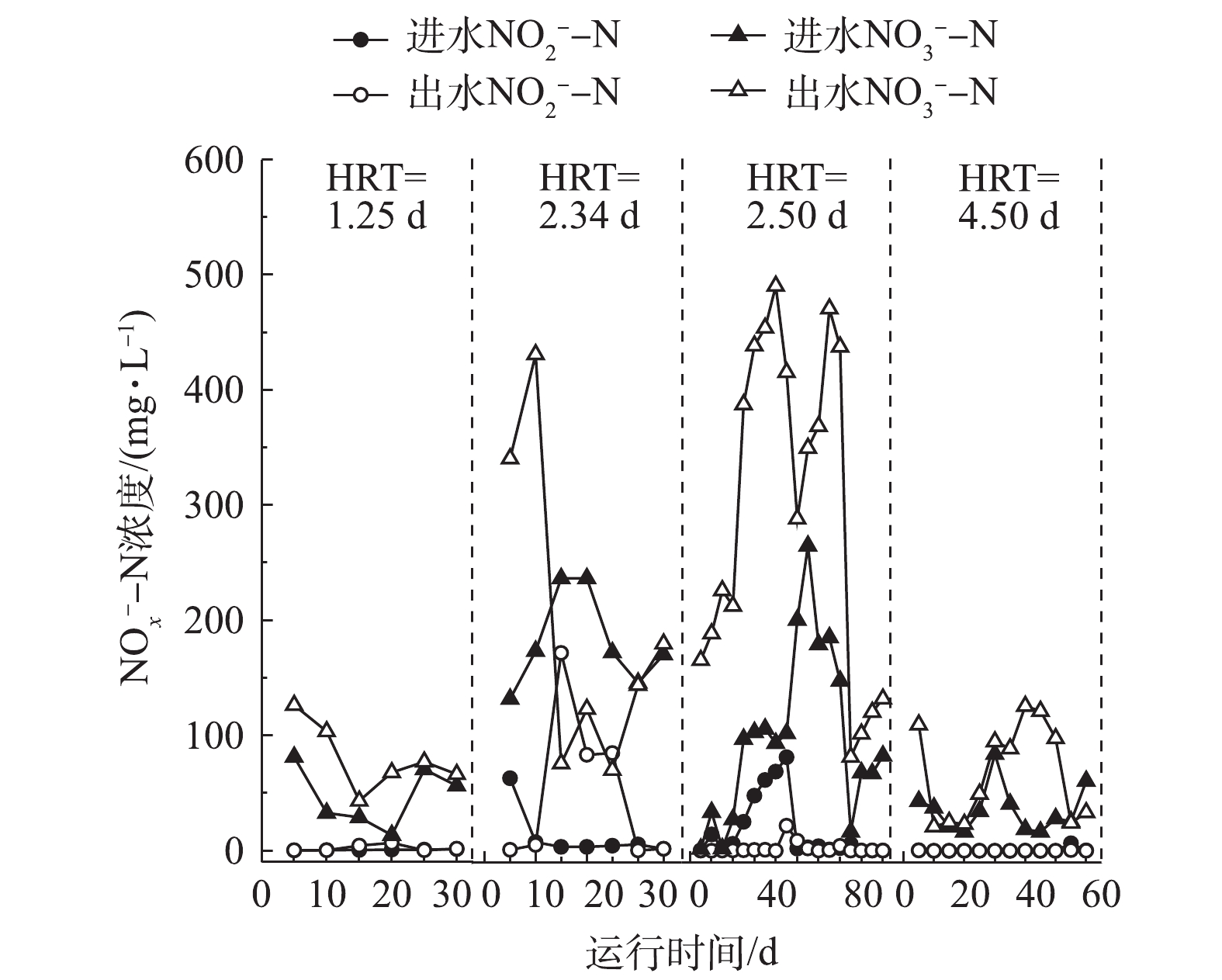

${\rm{NO}}_2^ - $ -N和${\rm{NO}}_3^ - $ -N生成特征。不同HRT条件下${\rm{NO}}_2^ - $ -N和${\rm{NO}}_3^ - $ -N生成特征见图3。由图3可知,与HRT为1.25、2.34和2.50 d相比,HRT为4.50 d的条件下出水${\rm{NO}}_2^ - $ -N分别降低了1.98、49.53和2.01 mg·L−1,出水${\rm{NO}}_3^ - $ -N浓度降低了12.67、130.14和228.61 mg·L−1。以上结果表明,HRT 为4.50 d时,出水${\rm{NO}}_2^ - $ -N、${\rm{NO}}_3^ - $ -N浓度最低。不同HRT条件下,出水氮的构成占比见表3。由表3可知,出水中的氮元素主要以硝态氮的形式存在,出水硝态氮的占比随HRT延长而增大,此时反应器内硝化作用良好。HASAR等[20]研究了HRT对出水硝态氮占比的影响,利用SMBR处理氨氮浓度为200~1 000 mg·L−1的垃圾渗滤液,当HRT分别为0.15 d和0.68 d时,出水

${\rm{NO}}_3^ - $ -N占比分别为26.67%和75.00%,结果表明,随着HRT延长,出水硝氮占比增加。SVOJITKA等[21]也发现了HRT对出水${\rm{NO}}_3^ - $ -N占比存在一定的影响。3)不同HRT条件下TN去除特征。不同HRT(水温≥15 ℃,COD/TN为0.89~4.30,混合液回流比为600%,样本数n=53)条件下,TN去除特征见图4。由图4(a)可知,HRT为1.25、2.34、2.50和4.50 d时,反硝化速率分别为0.33、0.16、0.11和0.08 kg·(kg·d)−1。与HRT为1.25 d相比,HRT为4.50 d时,污泥浓度降低20.41%,但总氮去除率提高2.09%,结果表明,污泥浓度不是限制反硝化脱氮效果的关键因素;HRT是影响反硝化脱氮速率的关键速率控制步,延长HRT,增加了硝化-反硝化时间,有效提高总氮的去除率,并减少了因反硝化不足引起的NOx−-N累积,有效缓解了高盐对脱氮的抑制作用;根据总氮去除效果和出水水质,确定最佳HRT为4.50 d。与HRT为1.25 d相比,当HRT为2.34 d和2.50 d时,污泥浓度分别降低了19.84%和26.54%,相应的总氮平均去除率分别降低了28.87%和31.38%。实验结果表明,脱氮效率的降低可能与水温、碳源、未知抑制和污泥浓度等因素有关,其中污泥浓度降低与脱氮效率下降之间的联系值得进一步研究。顾升波等[22]研究发现,利用A/O-MBR处理低碳氮比市政废水,当HRT由0.08 d增至0.30 d时,平均TN去除率由26.60%增至35.10%,表明TN去除率随着HRT延长而增加。

由图4可知,在HRT为1.25 d的条件下,进水TN浓度为732.44~929.32(5~30 d) mg·L−1,COD/TN为1.31~2.44,出水TN浓度为96.29~176.96 mg·L−1。按传统硝化反硝化途径分析氮平衡,去除1 g硝态氮需消耗3.05 g COD(考虑生物合成),TN减少量为605.75~728.55 mg·L−1。假设COD全用于反硝化细菌代谢,通过反硝化作用能去除的TN量为313.77~634.69 mg·L−1。因此,在SMBR中存在不同于传统硝化反硝化的脱氮途径,可额外去除61.95~291.98 mg·L−1的总氮,脱氮途径和机理值得进一步研究。在HRT为2.50 d的条件下,进水TN浓度为615.12~705.41 mg·L−1(25~45 d),COD/TN为1.97~3.20时,TN去除了122.97~259.35 mg·L−1,理论上通过反硝化可实现TN去除量为455.24~644.48 mg·L−1,总氮去除率减小了44.87%~80.92%。分析原因在于选矿废水成分复杂,存在未知抑制物质,对脱氮效果有显著影响。

由图4可知,HRT为1.25 d时,进水TN浓度增加了14.34%(10~25 d),反硝化速率无显著变化,总氮去除率降低了6.88%,这表明进水总氮浓度不是限制反硝化脱氮效果的控制因素;当HRT为2.34 d时,尽管进水TN浓度增加了8.35%(10~35 d),但反硝化速率增加了26.00%,TN去除率为61.82%~78.10%(平均值为67.40%);当HRT为2.50 d时,进水TN浓度增加了33.94%(25~70 d),反硝化速率增加了62.02%,TN去除率为19.99%~64.39%(平均值为44.15%);HRT为4.50 d时,进水TN浓度增加了19.80%(5~25 d),反硝化速率增加了22.16%,TN去除率均稳定在82.68%~96.20%(平均值为92.56%)。结果表明,延长HRT可显著提高总氮去除率和出水水质稳定性,HRT为控制反硝化脱氮的关键工艺条件。

不同HRT条件下,主要功能微生物的群落分布特征见图5。由图5可知,当HRT分别为1.25、2.34、2.50和4.50 d时,氨氧化菌(ammonia oxidizing bacteria,AOB)的主要菌属为Nitrosomonas(亚硝化单胞菌属),占比分别为1.57%、37.21%、2.89%和1.21%,亚硝酸盐氧化菌(nitrite oxidizing bacteria,NOB)的主要菌属为Nitrospira(硝化螺旋菌属),占比分别为0.14%、0.06%、0.59%和0.73%。在不同的HRT条件下,AOB/NOB分别为11.49、571.67、4.89和1.66,这表明反应器内硝化进程正常。随着反应器运行及HRT延长,AOB与NOB达到一定数量,维持硝化作用高效稳定进行,SMBR的处理能力和运行稳定性逐渐增强。当HRT为2.34 d时,TDS为13 139 mg·L−1,AOB占比远高于NOB,出水TN中

${\rm{NO}}_2^ - $ -N占比达13.40%,反应器内出现亚硝酸盐积累的现象。其原因在于:含盐量较高(TDS高于4 120 mg·L−1)时,易导致细胞壁破裂,细菌死亡,反应器处理性能降低[23];与AOB相比,NOB对盐的适应能力弱,对高浓度盐的抑制作用更为敏感,当含盐量过高时,NOB占比减小,亚硝酸盐氧化过程将被抑制,易出现亚硝酸盐的积累[24]。结合图5可知,当HRT由2.34 d延长至4.50 d时,出水${\rm{NO}}_2^ - $ -N占比由13.40%降低至0.71%,表明延长HRT增加了硝化细菌的作用时间,有效缓解亚硝酸盐积累。由图5可知,SMBR的活性污泥中反硝化菌属主要为Denitratisoma、Pseudomonas、Thauera、Comamonas、Azoarcus、Acidovorax、Rhizobium、Rhodobacter、Hydrogenophaga、Arcobacter、Thiobacillus、Sulfurimonas和Paracoccus属等,不仅包含传统缺氧反硝化菌,而且存在典型的异养硝化-好氧反硝化菌[25](如Paracoccus、Comamonas、Azoarcus和Thauera属),因此,SMBR既可在缺氧区实现传统异养反硝化,又可以在好氧区同步进行硝化及反硝化[26]。在HRT为1.25、2.34、2.50和4.50 d时,反硝化菌属占比之和分别为32.37%、7.82%、32.92%和34.48%,表明自反应器启动完成后,尽管HRT变化,但反应器内主要脱氮功能微生物种类相似,并始终维持一定数量,保证了反应器的脱氮能力与运行稳定性。

-

在HRT为2.50 d条件下,水温对硝化-反硝化速率的影响见图6。由图6可知,当平均水温分别为26.30、23.95、20.00和10.40 ℃时,硝化速率分别为0.032 1、0.029 5、0.022 9和0.013 1 kg·(kg·d)−1。上述实验结果表明,随着水温降低,硝化速率减慢。根据阿伦尼乌斯公式[27],计算可得硝化速率的温度修正系数(θ)为1.05±0.01;9 ℃(实验期间最低水温)的硝化速率为(0.012 9±0.001 7) kg·(kg·d)−1。根据以上结果计算可得,为确保最不利水温(9 ℃)时,出水氨氮不超过15 mg·L−1,好氧区(含膜区)HRT应不低于4.50 d。

由图6可知,当平均水温分别为26.30、23.55、20.00和10.40 ℃时,反硝化速率分别为0.111 4、0.106 7、0.090 7和0.064 6 kg·(kg·d)−1。结果表明,水温降低,反硝化速率减缓。根据阿伦尼乌斯公式,反硝化速率的温度修正系数(θ')为1.03±0.01;9 ℃(最不利水温)的反硝化速率为(0.064 2±0.009 0) kg·(kg·d)−1。为保证高盐废水在最低水温(9 ℃)条件下良好的反硝化效果,缺氧区HRT最短为0.90 d;为获得良好硝化-反硝化效果,总HRT应不低于5.40 d。若在低温且含盐量高的水质条件下,可通过增加水力停留时间、降低负荷等措施,保证良好的脱氮能力与运行稳定性。当低温时间较短时,可减少混合液排放并补充微生物所必需的营养,延长污泥龄,增加污泥浓度,保证在低温条件下HRT为4.50 d仍具有良好的脱氮能力。

-

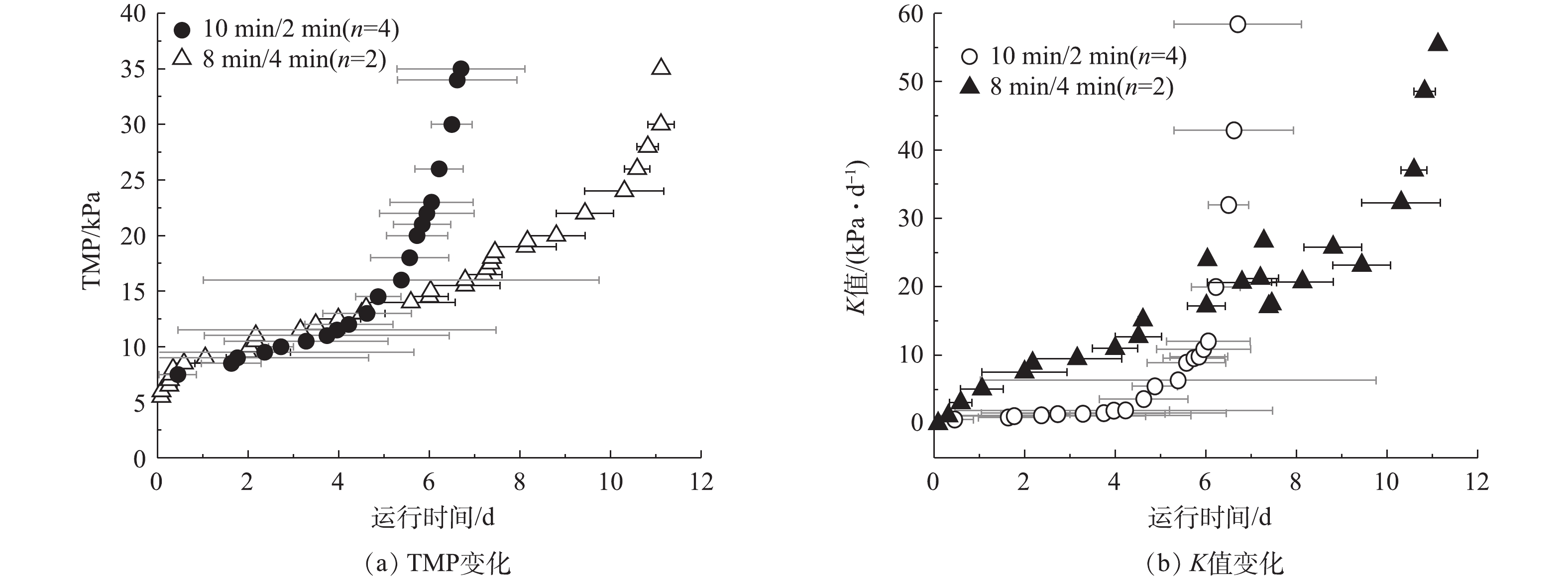

1)运行与间歇时间之比对膜污染特征的影响。运行与间歇时间之比对膜污染特征的影响见图7。由图7(a)可知,在运行周期固定为12 min、运行与间歇时间之比分别为5∶1和2∶1条件下,即运行/间歇时间分别为10 min/2 min和8 min/4 min,膜运行时长分别为(6.70±1.51) d和(11.14±3.14) d,延长约2倍。由图7(b)可知,跨膜压差变化率(K)直观反映了膜污染的速度,运行/间歇时间为10 min/2 min时,平均跨膜压差(transmembrane pressure,TMP)增长速率为5.07 kPa·d−1,K值增至10 kPa·d−1需历时5.49 d,而由10 kPa·d−1增至58.39 kPa·d−1仅需1.21 d;运行/间歇时间为8 min/4 min时,平均TMP增长速率为3.09 kPa·d−1,K值增至10 kPa·d−1需历时4.11 d,而由10 kPa·d−1增至55.42 kPa·d−1经历7.03 d,K值增长减缓。结果表明,随着运行与间歇时间之比减小,膜运行时长增加,K值增长显著降低;根据膜运行特征,确定运行与间歇时间之比为2∶1。计根良等[28]研究不同运行与间歇时间之比与膜污染的关系,设置运行/间歇时间分别为15 min /0、14 min/1 min、13 min/2 min、12 min/3 min、11 min/4 min和10 min/5 min,TMP平均增长速率分别为5.25、3.5、2.75、1.75、1.75和1.5 kPa·d−1,结果表明,通过减小运行与间歇时间之比,可使得膜污染速率有所减缓,膜污染可得到有效控制。程国玲等[29]在研究运行与间歇时间之比对膜污染的影响时发现,设置运行/间歇时间为12/3、9/3和6 min/3 min(比例依次为4∶1、3∶1和2∶1),膜污染速率分别为7.58、5.87和5.42 kPa·d−1,这表明随着运行与间歇时间之比的减小,膜污染速率有所降低。

本研究中的钙离子浓度为480.00~550.00 mg·L−1。已有研究[30]表明,在高浓度钙离子存在时,约55%的膜污染来源于滤饼层阻力,膜滤饼层阻力主要由无机污染物(钙离子沉积)引起[31]。当膜运行时,无机固体颗粒、污泥颗粒和胞外聚合物等膜污染物质会沉积至膜表面;当膜停止运行时,通过曝气在膜表面形成错流清洗,并同步进行维持性清洗(化学清洗+水反洗,并辅以4次膜松弛),从而将污染物从膜表面洗脱,进而减缓钙离子沉积引起的膜污染[32]。当运行与间歇时间之比较小时,膜的表面冲刷和清洗可有效完成;反之,间歇时间不足,膜表面的污染物无法完全去除,可加剧膜污染[33]。此外,靖大为等[34]研究含盐量对膜通量的影响时发现,含盐量是膜稳定运行的重要影响因素,当含盐量增加时,通量稳定性变差。本研究在研究膜污染特征和机理时,针对含盐量为11 057.00~14 321.00 mg·L−1的废水,其含盐量的变化对膜污染机理的影响仍需进一步研究。

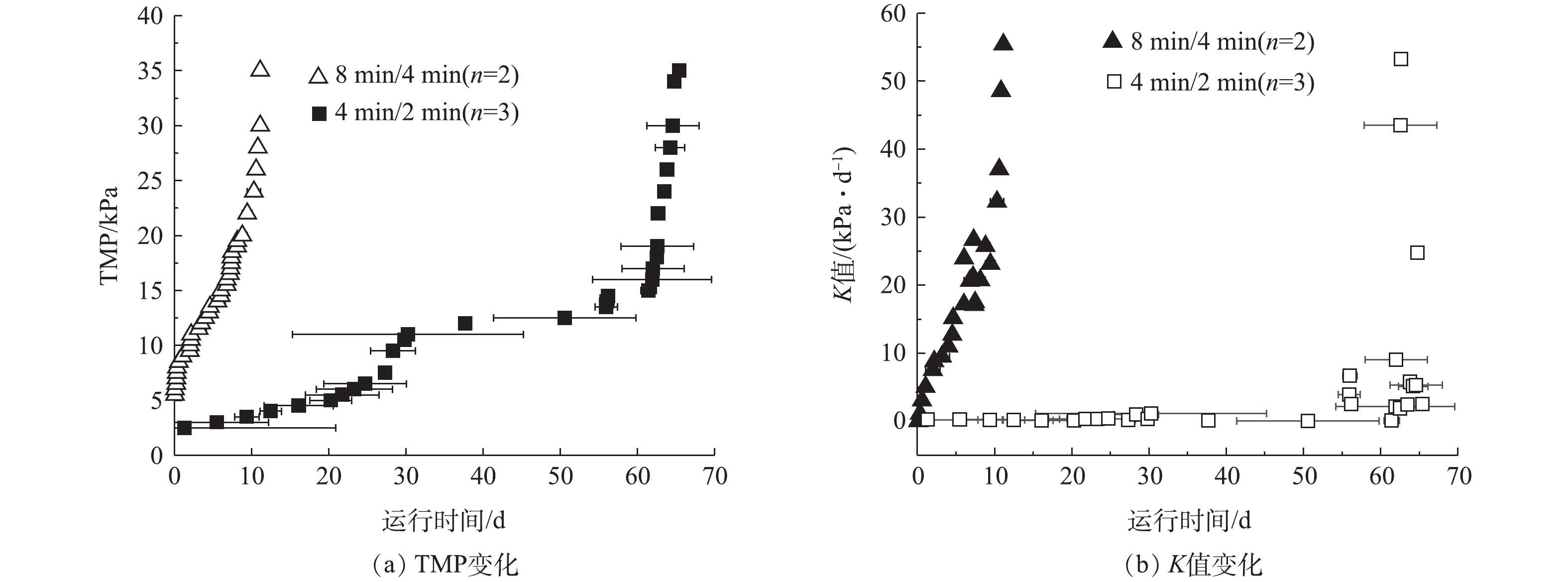

2)运行周期对膜污染特征的影响。运行周期对膜污染特征的影响见图8。由图8(a)可知,在保持运行与间歇时间之比固定为2∶1,运行周期分别为12 min和6 min条件下,即运行/间歇时间分别为8 min/4 min和4 min/2 min,膜运行时长分别为(11.14±3.14) d和(65.42±1.79) d,延长约6倍。由图8(b)可知,在运行/间歇时间为4 min/2 min时,平均TMP增长速率为0.60 kPa·d−1,K值增至10 kPa·d−1历时62.64 d,而由10 kPa·d−1增至53.27 kPa·d−1经历2.79 d,与运行/间歇时间为8 min/4 min相比,K值增长显著减慢,表明膜污染得到有效控制。实验结果表明,运行与间歇时间比例固定时,缩短运行周期,膜污染速率减小;根据膜污染特征,确定运行周期为6 min。MAQBOOL等[35]考察了运行与间歇时间之比不变(4∶1)的情况下,不同运行周期对浸没式膜生物反应器的膜污染特征影响,研究发现,当运行周期为16 min和10 min时,膜运行时长分别为7 d和12 d。本研究的结果表明,当运行与间歇时间比例不变时,缩短运行周期,可增加维持性清洗频率,从而有效减缓膜污染速率,可作为应对高盐高钙废水引起膜污染的有效方法。

结果表明,根据膜在高钙废水中的运行特征,在本研究采用的维持性清洗条件下,确定最佳运行与间歇时间之比为2:1,运行周期为6 min,即最佳运行/间歇时间为4 min/2 min。

2.1. 不同HRT条件下硝化-反硝化特征和功能微生物变化特征

2.2. 水温对硝化-反硝化速率的影响

2.3. 膜污染特征及膜污染控制

-

1)为确保高盐高钙废水深度处理的脱氮效果,根据

${\rm{NH}}_4^ + $ -N和TN去除特征及出水水质的稳定性,SMBR的最佳HRT为4.50 d,其中缺氧区HRT为0.75 d,好氧区HRT为3.75 d。2) 20 ℃的硝化速率为0.0229 kg·(kg·d)−1,硝化速率的温度修正系数为1.05;20 ℃的反硝化速率为0.090 7 kg·(kg·d)−1,反硝化速率的温度修正系数为1.03;根据硝化-反硝化速率和温度修正系数,确定最不利水温(9 ℃)条件下硝化速率为0.012 9 kg·(kg·d)−1,反硝化速率为0.064 2 kg·(kg·d)−1。根据最不利水温(9 ℃)条件下硝化-反硝化速率(污泥浓度为10 000 mg·L−1),SMBR的总HRT应不小于5.40 d(缺氧区HRT为0.90 d,好氧区HRT为4.50 d)。鉴于本研究所涉及企业的最不利水温(9 ℃)每年仅出现4~12 d(出现在每年12月下旬至1月上旬),建议在运行期间,从每年10月初开始,可通过减少剩余污泥排放,并补充微生物所必须的营养,延长污泥龄、提高污泥浓度(将污泥浓度由10 000 mg·L−1提高至12 000 mg·L−1以上),从而确保氨氮和总氮出水达标,SMBR的总HRT采用4.50 d。

3)当运行周期保持不变,降低运行与间歇时间之比,K值增长减慢,膜平均运行时长可显著延长;当运行与间歇时间之比不变,缩短膜运行周期时,膜污染速率减缓,膜污染得到有效控制。根据高盐高钙条件下的膜污染特征,确定SMBR的最佳运行/间歇时间为4 min/2 min。

下载:

下载: