-

在我国北方地区,热电机组承担着民生供暖和工业供热任务,在满足正常热负荷需求的同时,还应关注机组运行的稳定性[1]。脉冲袋式除尘器作为机组烟气净化系统的一部分,保障其滤袋寿命是维持热电机组高效稳定运行的关键步骤[2-5]。空气动力学损伤是影响滤袋寿命的主要原因之一,包括含尘过滤气流冲刷和喷吹气流偏斜等因素,特别是清灰气流含尘浓度过高也会导致滤袋磨损甚至大范围破损[6-9]。然而,目前为止,关于滤袋磨损过程仍依靠实践经验来判断,缺乏精确系统的分析。

CFD数值模拟技术广泛应用于大型袋除尘器的内部气流组织特性分析。CANDIDO等[10]、PARK等[11]就气流分布不均问题,采用单相流数值模拟方法进行了袋式除尘器的结构和性能研究。ANDERSEN等[12]通过数值模拟发现,喷吹时采用直孔喷嘴会使脉冲射流严重偏离,加装喷嘴对气流具有一定矫正作用。上述研究为防止滤袋破损提供了研究基础,但采用的单相流模拟方法无法分析颗粒对滤袋磨损过程及其影响规律。而王以飞等[13]、潘伶等[14]、马洁等[15]在研究含尘过滤气流时,加入了拉格朗日离散颗粒模型(Discrete particle model,DPM),直观、准确地描述了颗粒在袋除尘器箱体内的运动轨迹和状态,但未涉及清灰过程中含尘气流对滤袋内表面磨损过程分析内容。脉冲清灰气流是由压缩空气诱导上箱体清洁气流形成的,压缩空气的含尘浓度应小于5 mg·m−3[4-5,16]。某燃煤热电厂在运行期间多次发生滤袋破损现象,反复检修更换滤袋后,滤袋破损问题并未得到根本解决。现场初步判断上箱体花板积灰是滤袋反复破损的主要原因之一。由于对颗粒在箱体净气侧的运动状态和磨损滤袋的过程及规律认识不足,无法确定滤袋破损的根本原因,严重影响了机组运行的稳定性。因此,采用气固两相流模拟方法分析清灰时含尘气流对滤袋的内磨损机制成为袋除尘器稳定运行的关键。

本研究以该燃煤热电厂为例,针对袋式除尘器滤袋短时间反复破损失效现象,采用DPM模型,对清灰气流含尘浓度过高导致滤袋破损失效的演变过程进行了分析,同时结合现场调研和破损滤袋检测结果,明确了产生此类故障的原因,并针对此类故障提出了处置建议,为燃煤电厂提高袋式除尘器运行维护水平和烟气净化系统稳定性提供参考。

-

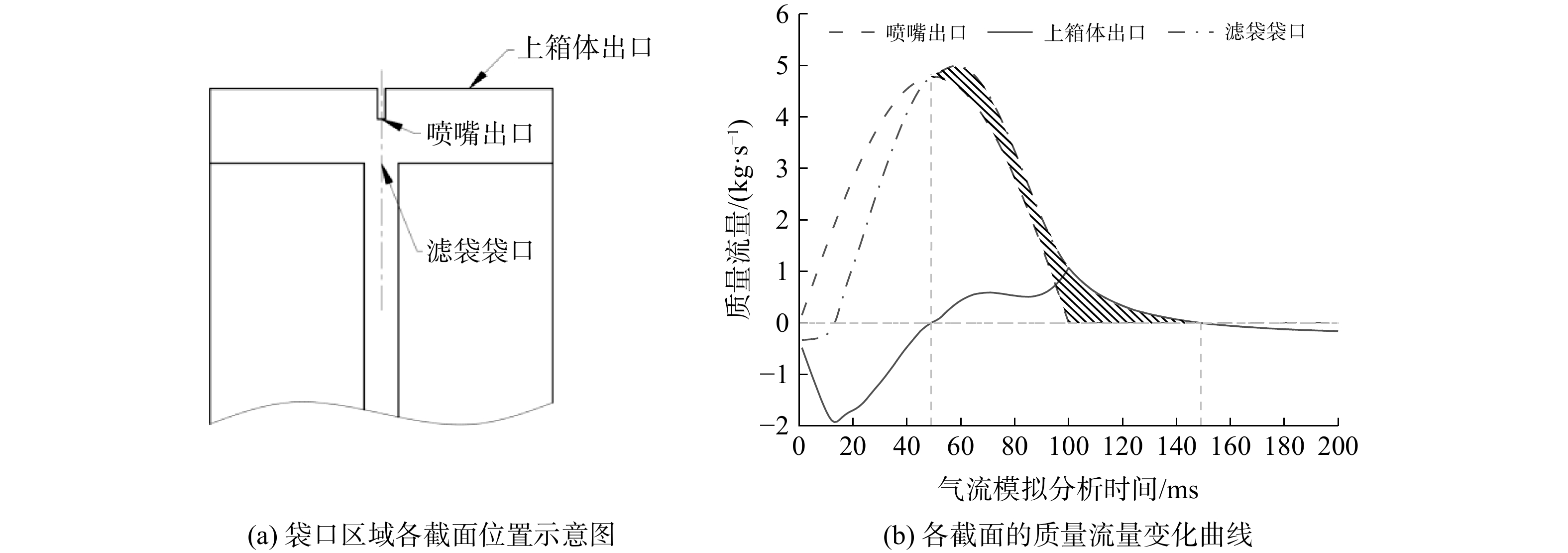

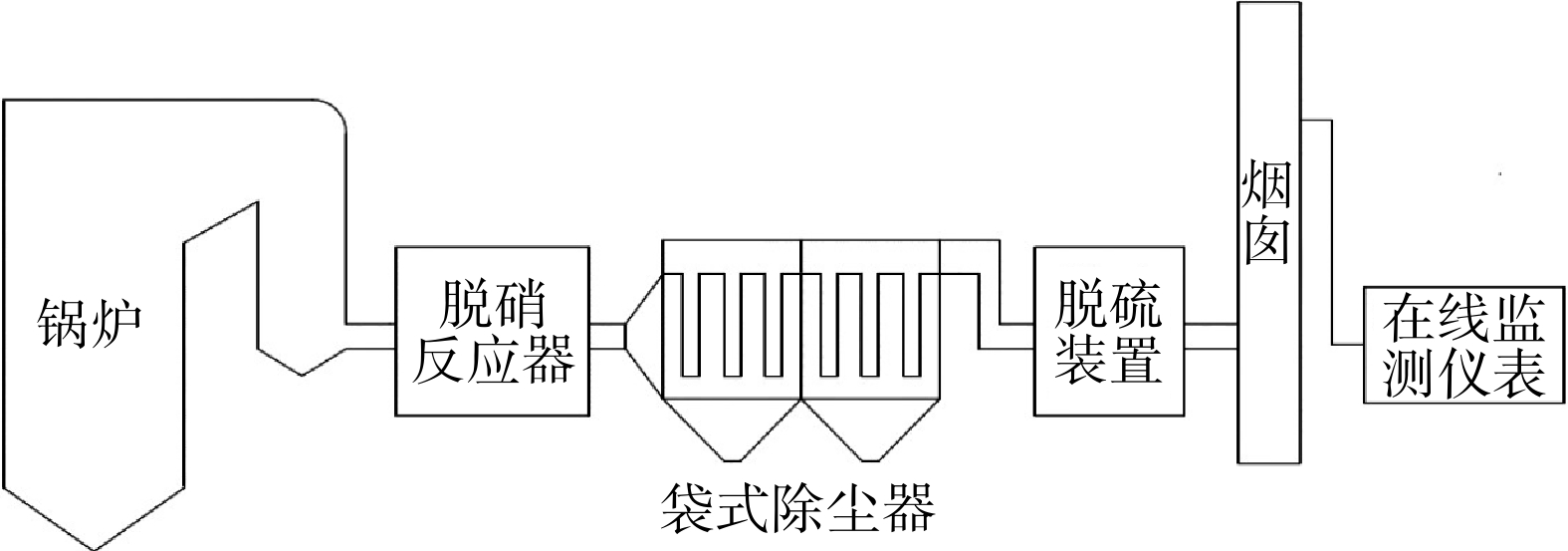

该热电厂煤粉炉锅炉烟气净化流程示意图如图1所示。正常投运1个月后,发现湿法脱硫石膏颜色逐渐加深,在线监测结果显示烟囱出口颗粒物排放浓度超出当地环保标准限值。据此可判断脉冲袋式除尘器中存在滤袋破损现象,并及时采取了检漏换袋等措施。但换袋检修2周后又出现同类故障,按电厂现有的袋式除尘器故障分析方法和维护检修方案,经多次检修仍达不到预期目的,导致维护成本大幅增加。

现场调研发现,除尘器检修时对积灰滤袋进行了紧急封堵,上箱体内的积灰严重,未进行清除,箱体净气侧粉尘浓度增加,滤袋内部有积灰破损现象。现场墙板附近、支架阻挡处等风速较小的区域积灰多,如图2 (a)所示。其中,图2 (b)~(d)表示滤袋出现缝线断裂,净气面滤料磨损;图2 (e)中底部强层净气面笼筋之间出现明显滤料缺损;图2 (f)~(h)表示滤袋内部积灰及中下部破损情况,滤袋竖筋之间存在净气面磨损甚至条形破损现象,破损痕迹环绕滤袋均匀分布,破损范围为现场积灰滤袋的粉尘堆积高度上方区域。为进一步明确滤袋破损的根本原因,采用数值模拟分析方法对滤袋的清灰过程进行了研究。

-

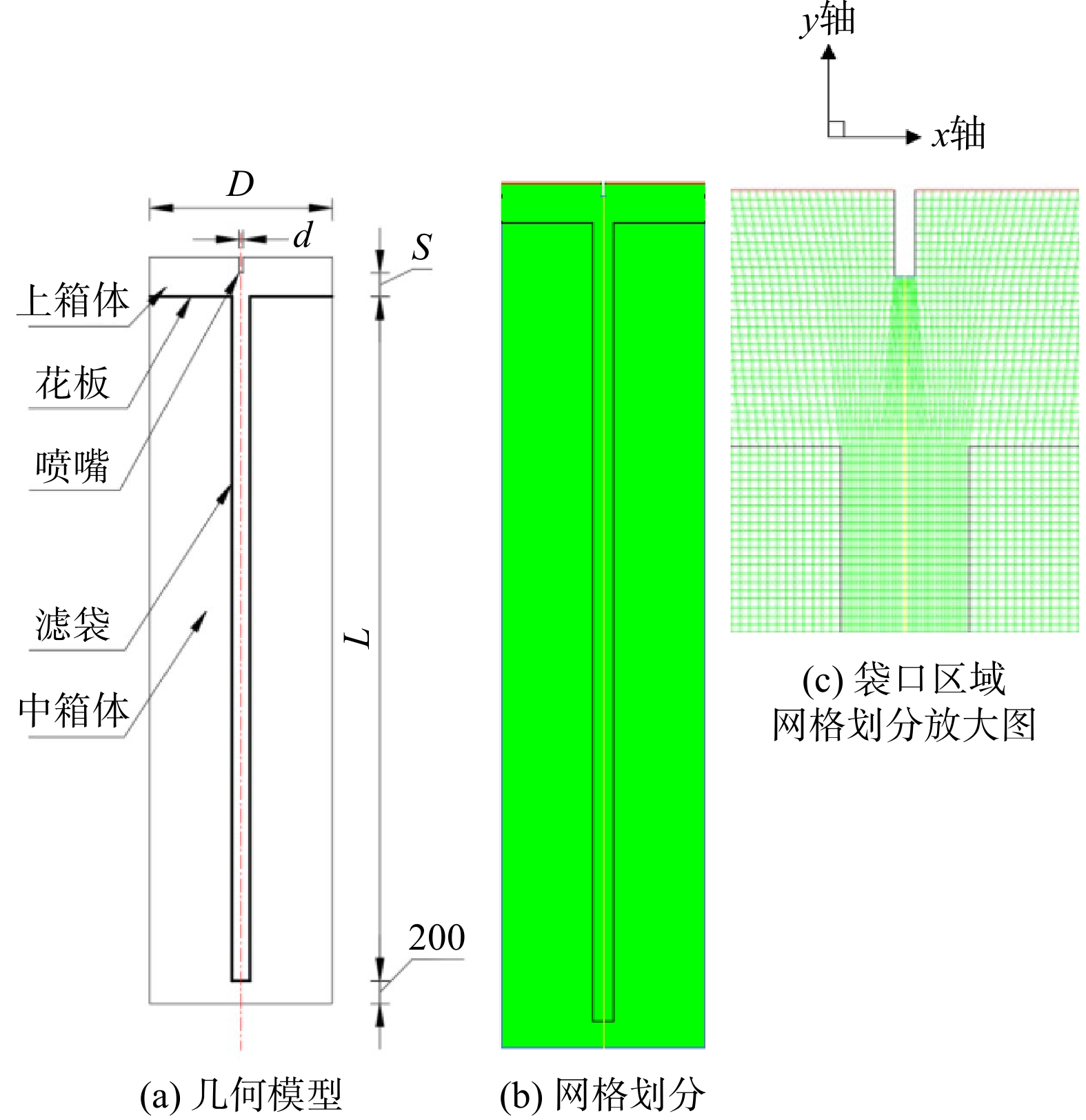

图3为清灰模拟的二维几何模型及网格划分图,S为喷吹距离,L为滤袋长度,d为喷嘴直径,D为计算区域宽度。利用Gambit软件进行结构化网格划分,尺度为水平x方向5 mm,垂直y方向10 mm,喷嘴出口区域进行了加密[17]。

-

CFD模拟计算时采用的控制方程包括连续性方程、动量方程和能量方程,湍流方程采用标准k−ε双方程模型[17-19]。喷吹清灰模拟采用二维轴对称非稳态流动数学模型。假定流体是等温不可压缩,喷吹气流轴向速度沿喷嘴径向均匀分布。

喷嘴采用速度进口边界条件,中箱体边界设为压力进口,上箱体边界设为压力出口,滤袋设为多孔跳跃,花板、滤袋底部设为固体壁面。中箱体采用恒压边界条件,依据压力的大小确定出滤袋的外表面过滤气速。参数设置为S=200 mm、L=6 m、d=26 mm、滤袋直径Φ=160 mm、喷吹压力P=0.25 MPa。Fluent模拟残差标准设为10−3,时间步长为0.001 s,SIMPLE算法求解,稳态迭代收敛后进行非稳态模拟计算。喷吹时间T=100 ms,清灰过程结束后进行过滤过程模拟,此时喷嘴速度为0,其余边界条件设置不变。

-

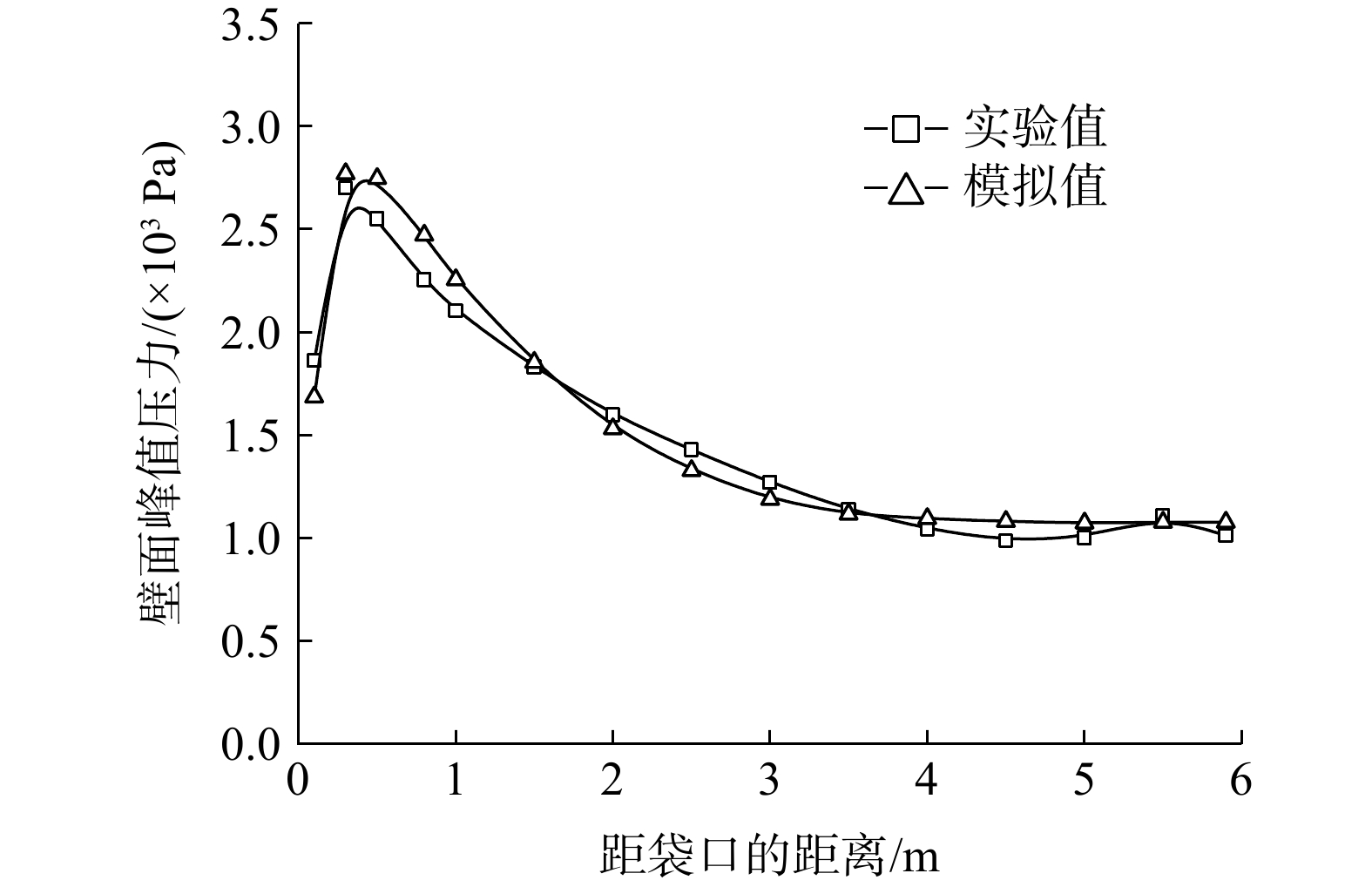

以参考文献[18]的设定条件进行数值模拟,物理模型实验采用清洁滤袋,模拟设置渗透率a=7×10−12 m2。以清灰时在滤袋壁面产生的最大静压值即壁面峰值压力为评价指标进行对比,结果如图4所示。模拟结果和实验测定结果基本吻合,壁面峰值压力各测点误差均小于10%,验证了模型的可靠性。偏差主要是受喷吹时间和滤袋的渗透系数取值等因素影响,故利用数值模拟的方法来分析滤袋内喷吹气流分布特性是可行的。

-

式中:u代表连续相的速度;up表示离散相的运动速度;ρ、ρp分别表示连续相和离散相的密度;FD(u-up)代表颗粒单位质量的曳力;Fx表示其他相间单位质量作用力。

模拟除尘器正常运行时的清灰状态,渗透率a=1.89×10−12 m2[20]。在验证的单相流数值模拟基础上,加入双向耦合的DPM模型。以温度为298.15 K,密度为1.225 kg·m−3、黏性系数为1.789 4×10−5 kg·(m·s)−1的空气作为连续相,以密度为2 100 kg·m−3[4]的粉煤灰球形颗粒作为离散相。考虑颗粒的重力、曳力及惯性力影响。滤袋壁面离散模型边界条件,分析对上箱体内颗粒影响时设为reflect;分析对袋内颗粒影响设为trap,颗粒在运动过程中撞到壁面即被捕集。

-

清灰过程对上箱体内颗粒的影响主要从气流特性和颗粒特性两方面分析。气流特性包括滤袋内部的压力分布、袋口区域的诱导气量和诱导气流速度大小。气流模拟分析时间为1 000 ms(在原喷吹时间T=100 ms基础上增加900 ms的过滤过程)。两相流模拟设置:气流模拟分析时间t=0时上箱体中颗粒为悬浮状态,按网格划分尺寸均匀投放颗粒;模拟煤粉炉粉煤灰的粒径为10~80 μm[21]。颗粒特性以距离袋底最近的颗粒为分析目标,以颗粒距袋口的距离、颗粒的垂直速度分量vy、进入滤袋颗粒占比(进入袋内的颗粒数量占上箱体内总投放数量的比值)、逃逸颗粒占比(逃逸出计算域的颗粒数量占总投放数量的比值)为评价指标分析气流对颗粒的输送能力、诱导程度和扰动程度。

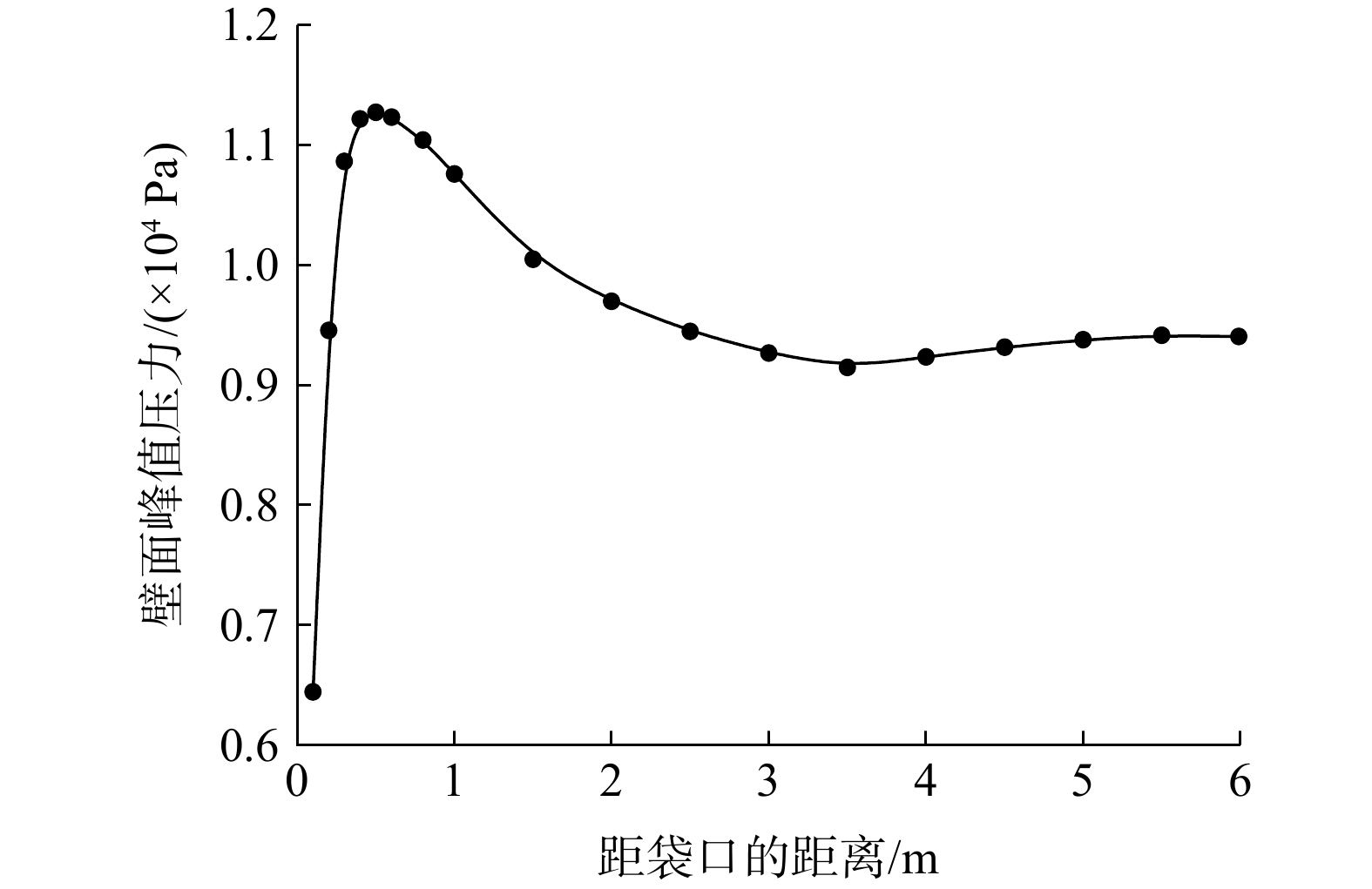

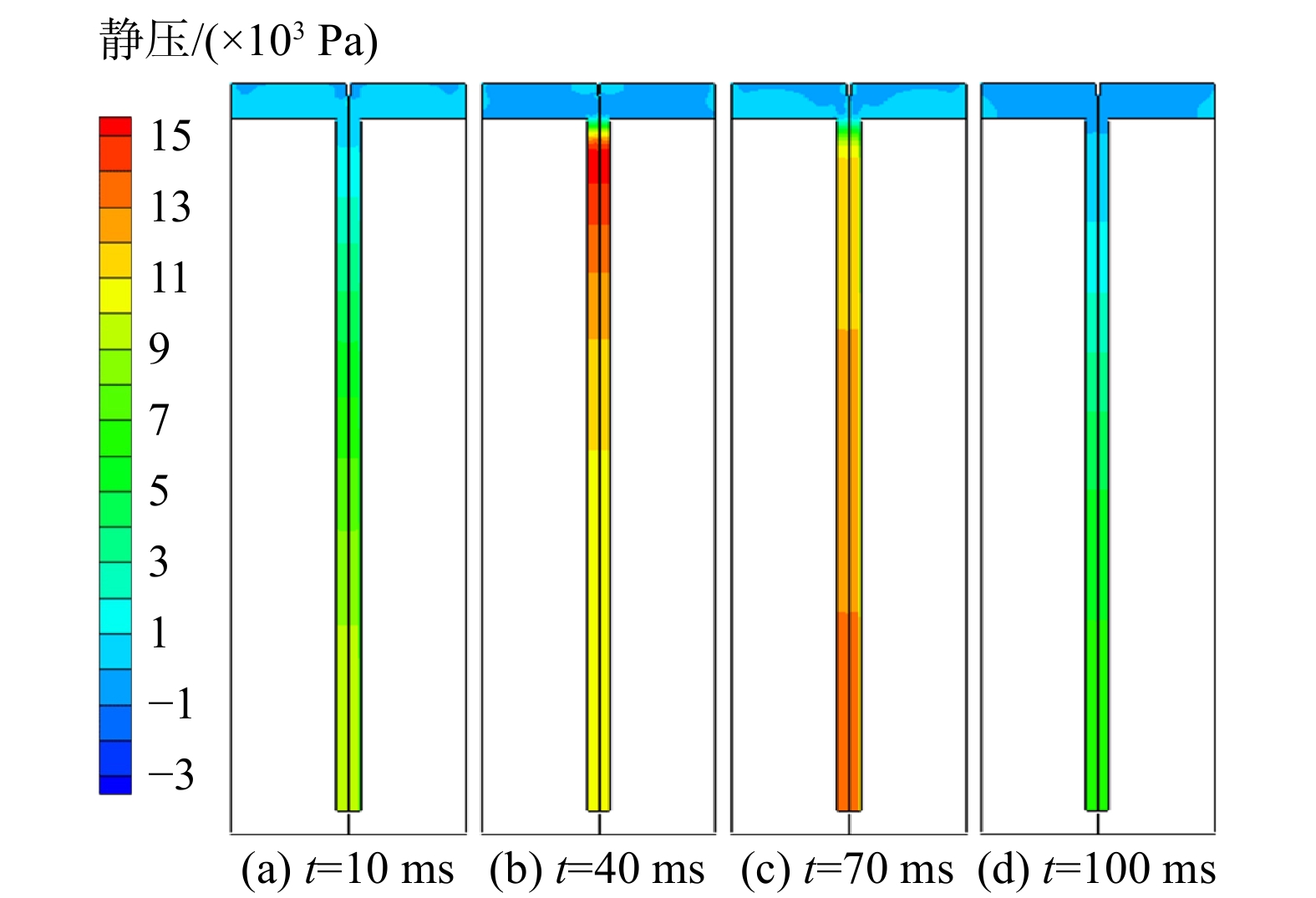

1)气流特性。清灰时滤袋的壁面峰值压力曲线见图5。距袋口0.5 m处壁面峰值压力最大,与图4中清洁滤袋的壁面峰值压力曲线趋势基本一致。对应不同喷吹时刻下滤袋的压力分布云图如图6所示。其中,40 ms时气流作用于袋口附近;70 ms时作用于滤袋底部,但压力值较袋口位置减少。这是由于滤袋为多孔介质,喷吹气流在从袋口流向袋底的过程中逐渐向袋外渗出。

清灰气流的诱导作用通过对比不同位置的气流质量流量和不同时刻袋口区域流线图进行分析。气流模拟分析时间t=0~200 ms的质量流量对比如图7所示(主气流方向向下为正,向上为负)。滤袋袋口气流质量流量0~50 ms时小于喷嘴的流量,50~150 ms时出现诱导气流,尤其100 ms时诱导气量最大;上箱体出口50 ms后气流向箱体内部流动,100~200 ms时与袋口流量重合。这是由于在清灰前期,喷吹气流用于阻碍过滤气流,出现射流逃逸,喷嘴出口中的气流无法直接进入袋内而从上箱体出口流出。诱导气流需要在喷吹气流于袋内积蓄一定程度后开始起作用,当进入袋内的喷吹气量最大时,诱导气量最大。气脉冲时间结束后,滤袋内部喷吹气流的诱导过程还未结束。袋内清灰气流消失后,诱导作用随之停止。

50~150 ms时积分所得诱导气流量(阴影区域)占该时间段总喷吹气流的22%,箱体净气侧粉尘浓度增加,上箱体花板积灰严重,引起喷吹气流含尘浓度增加,品质下降。根据圆柱形喷管的射流理论[22]可得出,诱导进入袋内的气流占总喷吹气流的77%。数值模拟得到的诱导气流量占比偏低,其主要原因为:理论分析结果是基于理想状态下的自由射流条件分析所得,而数值模拟受过滤气流、计算模型大小、喷吹参数、边界条件等因素的影响。

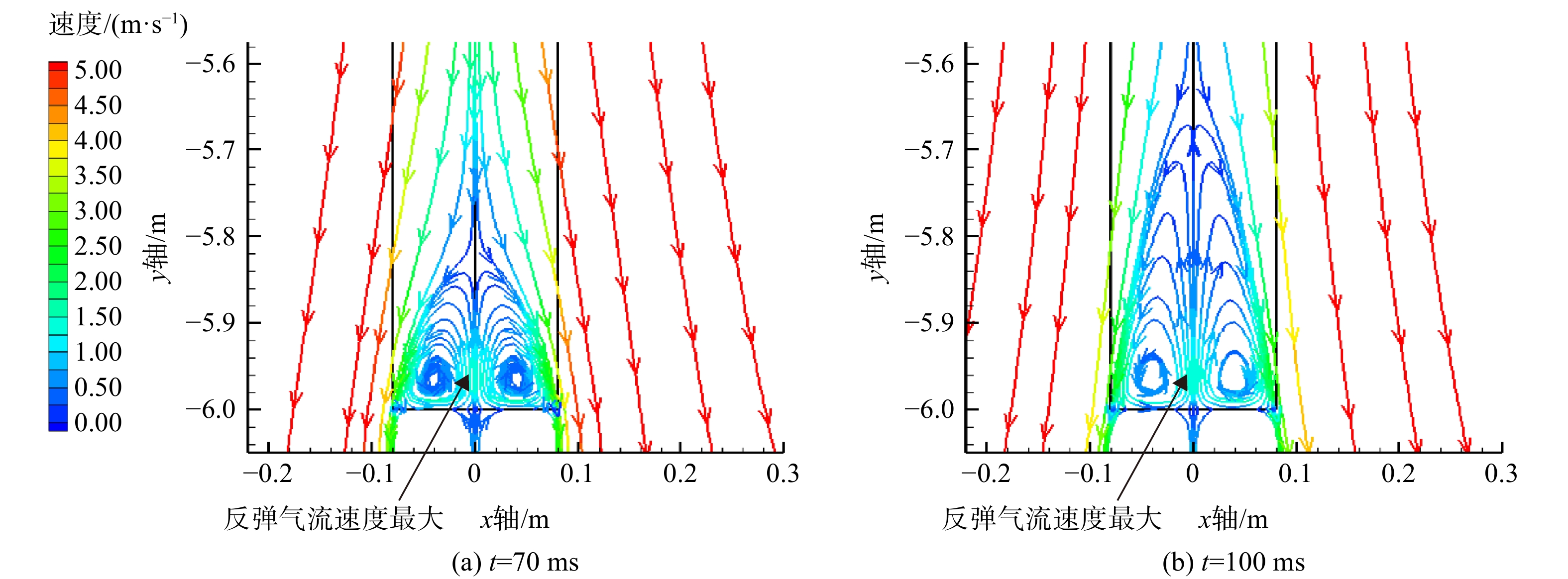

上箱体及袋口区域的局部流线如图8所示。70 ms时袋口附近有涡流存在,气流的诱导作用较弱;100 ms时,诱导作用显著。其原因在于,喷吹70 ms前脉冲气量较小,在线清灰过滤气流与脉冲气流方向相反,高压气流在喷入袋口时,受上升过滤气流冲击迅速膨胀绕流并改变其射流规律流向上箱体,从而在袋口位置形成涡流[23]。喷吹后期,脉冲气量作用增强,袋内过滤气流作用消失,上箱体中的气流被诱导流向滤袋内部。花板上方袋口周边20 mm处(x=100 mm),诱导气流沿y轴由上到下速度逐渐增加,最大可达6.84 m·s−1,该速度下袋笼环形头盖上方的积灰在喷吹气流的扰动作用下更易被扬起。

2)颗粒特性。不同粒径颗粒在不同气流分析模拟时间下的运动特性如图9所示。颗粒粒径越大,则进入袋内后被气流输送距袋口的距离逐渐增加;当t=100 ms、1 000 ms时,颗粒的垂直速度分量vy随着粒径的增大而增加,当t=150 ms时,粒径10、70、80 μm颗粒的vy明显高于其余粒径;进入袋内的颗粒数量占上箱体内总投放数量之比呈先增加后减少的趋势;逃逸出计算域的颗粒数量随粒径增加占比逐渐减少。导致上述现象的原因在于颗粒的粒径越大,受重力的影响越大,进入袋内后被输送的距离以及速度就越大。150 ms时为过滤状态,颗粒在到达滤袋中部时,受到向上气流的曳力作用速度发生减缓。袋口涡流将阻碍颗粒进入袋内,粒径越小,气流的跟随性越好,越易被袋口的涡流扰动由上箱体出口逃逸。粒径越大,则需要更大的诱导气流速度来克服曳力,将颗粒诱导进入袋内。

一次喷吹后,上箱体悬浮颗粒可达滤袋中部;80 μm颗粒在t=1 000 ms时距袋底0.5 m,vy为1 m·s−1。这说明,在喷吹气流的作用下颗粒可以到达袋底区域。过滤时,袋底区域的上升气流速度较小,以过滤气流速度1 m·min−1计算得出,在袋底区域的颗粒悬浮粒径为16.3 μm[24],表明粒径大于16.3 μm的颗粒会到达滤袋底部且无法返回上箱体。

当t=150 ms时,诱导进入袋内的颗粒占比最高,40 μm颗粒进入袋内占31% (t=0 时袋口上方−80 mm<x<80 mm且0<y<200 mm区域颗粒数目占总投放颗粒的12% );100 ms和1 000 ms时颗粒进入袋内的占比均近15%。这说明当诱导气流完全进入袋内时,对颗粒的诱导作用最大;1 000 ms时袋内部分颗粒返回至上箱体。这是由于在过滤时,向上过滤气流速度沿袋底至袋口逐渐增加,气流速度过大,部分袋口附近的颗粒被带回上箱体。另外,位于袋口射流核心区域附近的颗粒易进入袋内到达袋底,该区域速度梯度变化大,颗粒易受气流扰动作用。颗粒被诱导进入滤袋的比率偏低,主要受模型径向模拟范围偏大(滤袋直径的10倍)及袋口涡流影响,实际160 mm×6 000 mm的袋式除尘器花板孔间距为240 mm[4-5],故喷吹气流诱导粉尘进入滤袋的几率将进一步增加。

颗粒由滤袋破损处进入上箱体,部分随气流由出口排放,部分受箱体结构、壁面影响,于风速较小的区域悬浮或沉积。过滤和清灰交替进行,可导致已沉积的颗粒将因清灰气流作用再被卷起进入滤袋。上箱体内悬浮颗粒甚至袋口周边沉积的粉尘将在清灰气流的诱导作用下进入滤袋,并逐渐积累。现场靠近积灰的区域,滤袋内部积灰更多,这进一步验证了喷吹气流对上箱体粉尘的诱导作用。因此,上箱体花板积灰未及时清除是导致滤袋内部积灰和清灰气流含尘浓度过高的主要原因。

-

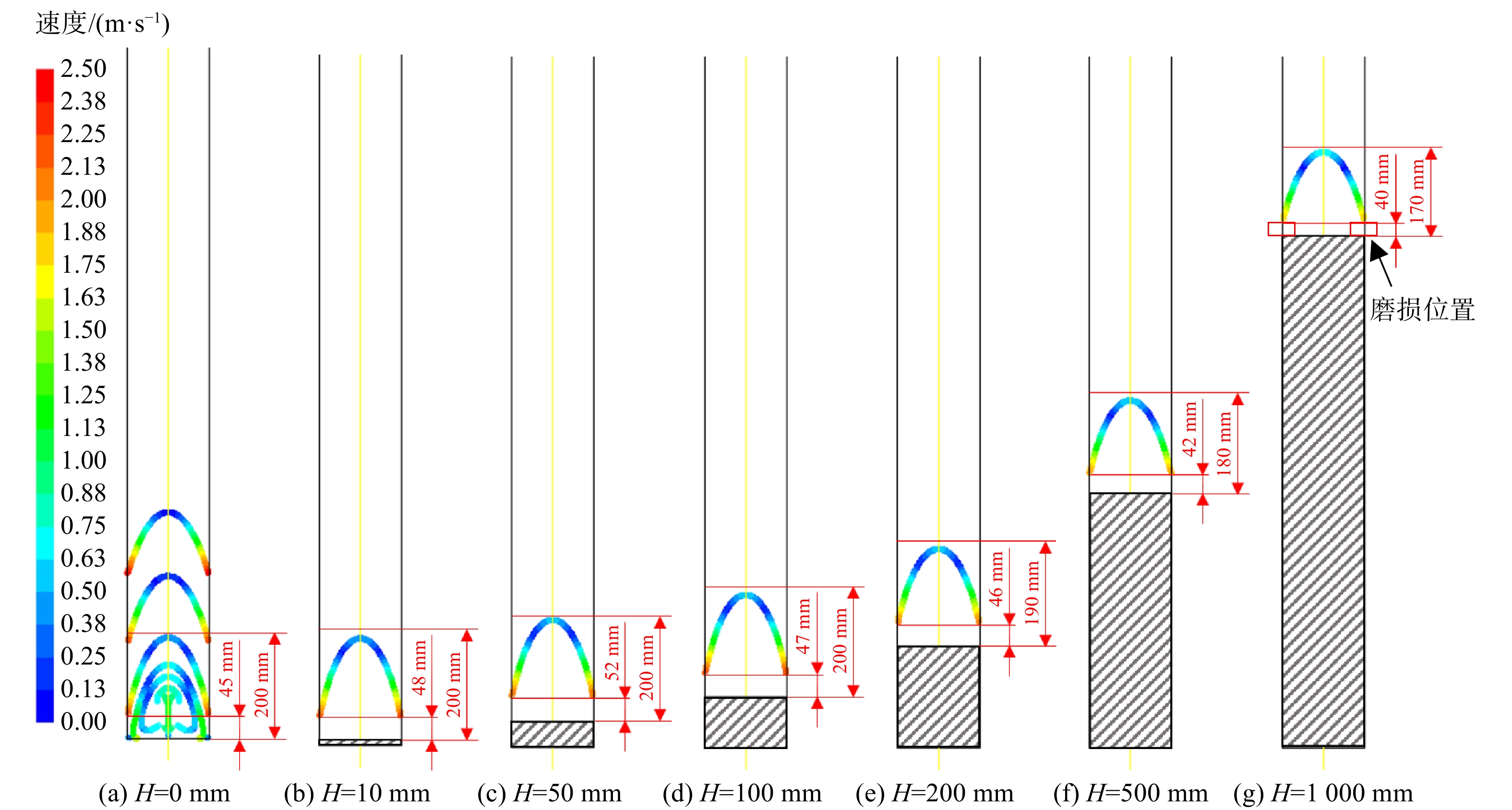

通过分析袋底的反弹气流特性和颗粒受反弹气流作用特性,可确定清灰过程对袋内颗粒的影响。反弹气流特性主要包括气流大小和运动轨迹。t=0时,在距灰柱沉积表面上方不同悬浮高度处投放粒径为20 μm的颗粒;设袋内积灰高度为H,H以下粉尘不会被气流吹起,模拟时设置灰柱沉积表面的边界条件为wall。不同灰柱沉积表面上颗粒特性以靠中心轴线处的颗粒为目标,以颗粒被气流输送的高度变化(Δh=|喷吹后距沉积面高度-喷吹前距沉积面高度|)、被滤袋捕集比率(不同高度下颗粒被滤袋捕集的数量占该高度总释放颗粒数的比值)为评价标准来分析颗粒受反弹气流的影响趋势及磨损滤袋规律。

1)气流特性。滤袋底部反弹气流速度大小如图10所示。中心轴线速度在70、100 ms时分别距袋底140、480 mm,出现反弹气流。反弹气流在距袋底30 mm时速度最大,接近1 m·s−1,远大于1 m·min−1的过滤速度。这说明在袋底区域,反弹气流对颗粒的影响大于过滤气流的作用,袋底颗粒易受反弹气流扰动影响滤袋内侧,喷吹气流是影响滤袋底部内侧磨损的主要因素。袋底区域气流的流线图如图11所示。在中心轴线两侧气流呈涡旋向滤袋壁面冲刷,70 ms较100 ms时反弹气流范围缩小。这是由于:喷吹气流到达滤袋底部,受壁面和喷吹气流阻碍,在有限区域内做旋转运动,70 ms时喷吹气量大于100 ms,对底部反弹气流冲击大。

2)颗粒特性。颗粒被气流输送的高度变化Δh曲线如图12(a)所示。投放颗粒高度随距灰柱沉积面高度的增加呈现先增加后降低再增加的趋势,这与中心轴线气流速度曲线趋势一致;当Δh=0时,中心轴线上颗粒发生悬浮,处于距沉积面的最大高度位置。颗粒被滤袋捕集比率大小如图12(b)所示。距灰柱沉积面0~110 mm时,颗粒被滤袋捕集的比率由5%增至35%;距灰柱沉积面110~200 mm时,颗粒被捕集率曲线出现峰值;距灰柱沉积面大于200 mm时,颗粒被捕集率基本保持不变。这是由于:距灰柱沉积面距离小于200 mm时,反弹气流速度大于0.44 m·s−1,此时颗粒在反弹气流作用下向上运动,而不被滤袋捕集;随着距沉积面距离的增加,颗粒虽受反弹气流影响,但受颗粒重力和曳力影响更大,颗粒在斜向下的清灰气流作用下,逐渐向滤袋壁面撞击,此范围颗粒对滤袋的磨损作用显著;当距离增加到一定程度时,喷吹短时间内不受反弹气流的影响,仅受斜向下清灰气流的作用而撞击滤袋壁面。

当积灰高度H不同时,随着距沉积表面距离的增大,颗粒被气流输送的高度变化Δh呈先增加后降低再增加,被滤袋捕集比率呈先增加后逐渐平缓降低。两组数据出现变化的位置基本一致。当H为0~100 mm时,Δh差值在2 mm以内;当H>100 mm时,Δh差值大于4 mm。可见,灰柱高度越高,Δh=0时距灰柱沉积表面距离越小。当H为200~1 000 mm时,被滤袋捕集率变化较为明显。当距沉积面的距离小于110 mm时,H为500、1 000 mm的被滤袋捕集颗粒的比率率先达到峰值;当距沉积面的距离大于110 mm时,H为500、1 000 mm的被滤袋捕集颗粒的比率小于H<200 mm时的比率。这是由于随着积灰高度增加、与袋口距离越近,反弹气流受清灰气流冲击越大,作用范围逐渐缩小。

H=0时,颗粒t=100 ms时的系统中颗粒运动状态如图13(a)所示。由上到下,初始释放位置依次距袋底600、400、200、100、50、10 mm。在气流推动下,喷吹前距袋底>200 mm时,颗粒随气流向滤袋壁面撞击;距袋底10~100 mm时,被反弹气流作用而向上运动;Δh=0时,颗粒最大高度位置距袋底200 mm。上述结果表明,清灰时存在“拱形”有限区域,最顶端距袋底200 mm,最底端距袋底45 mm;拱形外侧,受向下的清灰气流作用,诱导进入袋内的颗粒将首次对滤袋壁面产生磨损;拱形内部,已沉积的颗粒又因反弹气流作用向上运动,反复磨损滤袋壁面由袋底往上45 mm范围内。

H>0时,不同积灰高度下的颗粒在t=100 ms时亦形成“拱形”有限区域,结果如图13(b)~(g)所示(积灰高度H即为阴影区域高度)。与H=100 mm时相比,H=1 000 mm时颗粒磨损滤袋的区域范围缩小了7 mm;随H的增加,颗粒撞击滤袋壁面速度逐渐减小。这说明颗粒数量相同时,积灰高度愈高,颗粒因速度因素对滤袋磨损性减弱。但滤袋磨损范围缩小,在同一位置颗粒撞击滤袋内侧的几率增加;同时,积灰高度越高,含尘浓度愈高,颗粒数目增加,滤袋磨损范围和程度增加。因此,在不同积灰高度下,颗粒磨损滤袋的位置均处于粉尘堆积高度上方50 mm范围内;滤袋底部沉积粉尘受清灰气流扰动反复磨损滤袋内侧净气面,其磨损位置、程度和袋内积灰高度有关。

粉尘进入滤袋内部,上箱体花板积灰厚度分布不均匀,对应不同位置的滤袋内部积灰高度H不同。同一过滤单元内不同滤袋的净气面存在程度不同的磨损甚至破损失效现象。当进入袋内的积灰量小时,滤袋缝线被磨断、底部加强层出现破洞;当积灰量大时,在其积灰高度区域的滤袋内侧被磨损的范围及程度大,因而出现大面积的磨损和破洞现象。上述结果表明,清灰气流磨损滤袋内侧净气面规律数值模拟和现场检测结果基本一致,这验证了模拟方法的可靠性。

-

对机组不同检修阶段的破损滤袋样品进行外观检测、物理性能及扫描电镜分析,结果如图14所示。滤袋外侧无破损痕迹,受测滤袋拉伸断裂强度和伸长率无明显衰减,但净气面厚度降低,透气度偏低,滤袋迎尘面粉尘淤积,净气面和迎尘面与基布相比含有较多粉尘。这说明滤袋净气面受粉尘侵入磨损严重,出现了内侧磨损现象。滤料净气面纤维孔隙大于迎尘面,为粗纤维层,滤袋内侧滤料在喷吹时被含尘气流反复磨损,不仅会造成滤袋的过滤效率下降,还将使得细纤维层失去支撑,尤其在磨啄性较强的粉煤灰颗粒作用下,滤袋更易发生破损[25]。含尘过滤气流对滤袋的冲刷磨损一般为迎尘面产生局部磨损,滤袋破洞环绕滤袋均匀分布,净气面磨损严重。这说明滤袋破损受圆柱形均匀的清灰气流磨损造成。因此,清灰气流含尘浓度过高是导致滤袋磨损失效的根本原因。

-

袋式除尘器各过滤单元出口装配烟尘测试仪等在线检测设备,可实时监控除尘器的运行状态,确保除尘器出口排放浓度的达标且箱体净气侧的含尘浓度在规范限值范围内。然而,在线监测状态异常时,需进行人工诊断以排除除尘器发生故障的原因,这属于事故发生后的检修处理。而采用数值模拟分析方法进行故障特征分析,判断不同类型故障发生的原因、趋势及后果,则有助于对除尘器健康状况提前做出判断和警示,可在故障发生之前有针对性地进行预防和处理,缩短维修时间,降低维修成本。

除尘器发生故障,以及滤袋内侧发生磨损时,采用荧光粉等传统滤袋检漏技术,无法检测滤袋的内侧磨损状况。若按技术要求仅更换破损的滤袋,剩余没有明显破损但已经内部积灰的滤袋,在含尘的清灰气流持续磨损下,存在破袋隐患,会导致除尘设备的故障率的增加。尤其是在无隔板的直通式袋式除尘器中,破损滤袋的影响范围将扩展至整个除尘器内部的全部滤袋,从而影响工艺系统的高效稳定运行。因此,若滤袋发生破损,上箱体产生积灰,停机检修时应按要求及时更换破损滤袋,抽取具有代表性的破袋进行失效分析,并记录抽取位置及破损数量[26]。

除此之外,还需逐一清理上箱体及滤袋内部的积灰,保证清灰气流的品质。对同一个过滤单元内的所有滤袋均应进行检查,并根据其内侧磨损程度确定滤袋更换数量。应系统抽取未破损的滤袋样品进行寿命评估,着重检查滤料的内侧性能,并与新滤料寿命系数[26]作比较,判断其能否满足正常工艺系统的使用条件。若不满足正常使用周期要求,则建议更换滤袋单元内部甚至整个箱体内的全部滤袋。

根据本研究结果提出的针对性维修方案,经现场实施后,袋式除尘器运行2年来再未发生同类事故,且烟气净化系统出口颗粒物排放浓度低于当地环保排放限值10 mg·m−3。

-

1)喷吹总气量的22%为诱导气流,袋口上方的诱导气流速度接近7 m·s−1,上箱体内悬浮颗粒甚至袋口周边沉积的粉尘将在清灰气流的诱导作用下进入滤袋,并逐渐积累。袋内灰柱表面粉尘受清灰气流扰动,在沉积层上方反复磨损滤袋内侧净气面,磨损的位置与积灰高度相关,均位于积灰表面向上50 mm范围内。

2)模拟分析与现场检测结果一致。该电厂上箱体花板积灰未及时清除是造成滤袋内部积灰和清灰气流的含尘浓度过高的主要原因。清灰气流对袋底粉尘的扰动造成了滤袋磨损失效。

3)发生内磨损的滤袋处于一种亚健康状态,检修时不能只更换破损滤袋,而是应该逐一对同一个过滤单元内的所有滤袋健康状态进行检查,并根据其受损程度和设备使用要求确定滤袋更换数量。

基于CFD的滤袋内侧磨损失效过程分析

Analysis on the wear-out failure process of the inner surface of the filter bag based on CFD

-

摘要: 针对某燃煤热电厂袋式除尘器滤袋破损和多次换袋检修失效现象,采用气固两相流数值模拟方法,对清灰气流含尘浓度过高导致滤袋破损失效的演变过程进行了分析,并结合现场调研和破损滤袋检测结果,明确了产生此类故障的原因。结果表明:喷吹总气量的22%为诱导气流,袋口上方的诱导气流速度接近7 m·s−1,上箱体内悬浮颗粒甚至袋口周边沉积的粉尘将在清灰气流的诱导作用下进入滤袋,并逐渐积累;袋内灰柱表面的粉尘受清灰气流扰动在沉积层上方反复磨损滤袋内侧净气面,磨损位置与积灰高度相关,均位于积灰表面上方50 mm范围内。模拟分析结果与检测结果一致,上箱体花板和滤袋内部长期积灰是导致滤袋破损失效的根本原因。根据上述研究结果提出了有针对性的维修方案并经现场实施后,袋式除尘器运行2年时间内再未发生滤袋破损失效现象,且烟气净化系统出口颗粒物排放浓度低于当地环保排放限值10 mg·m−3。本研究结果可为判断滤袋健康状况及导致滤袋破损失效的直接原因提供参考。Abstract: Aiming at the phenomenon that the breakage of filter bags and the failure of repeated bag replacement in a coal-fired thermal power plant, the evolution process of the filter bag’s damage caused by the cleaning airflow with high dust concentration was analyzed by gas-solid two-phase flow numerical simulation method. The cause of the failure was clarified combined with field investigation and the tests of damaged filter bags. The results showed that the 22% of the total airflow is the induced airflow, and the velocity of the induced airflow above the bag mouth is close to 7 m·s-1. The suspended particles in the upper box and even particles deposited around the mouth of the bag were inducted into the filter bag by the airflow and gradually accumulated in the bag. Therefore, the particles above the surface of the dust column will be disturbed by the airflow and repeatedly wear out the inner surface of the filter bag above the deposition layer. The wear position of the inner surface was related to the height of the dust accumulation in the bag, which was located within 50 mm above the deposition surface of the ash column in the bag. The simulation analysis was basically consistent with the on-site test results, the fundamental cause of filter bag breakage and failure was the long-time dust accumulation in the upper box and inside filter bags. Based on the research results, a targeted maintenance plan was proposed and implemented on site. No filter bag breakage and failure occurred during the operation of bag filter for 2 years, and the emission concentration of particulate matter at the outlet of the flue gas purification system was lower than the local environmental protection emission value of 10 mg·m-3. The results of this study can provide reference for judging the health status of filter bags and the direct causes of filter bag damage and failure.

-

-

-

[1] 陶晖, 陶岚. 袋式除尘技术在我国燃煤电厂的推广应用[J]. 中国环保产业, 2015(1): 15-21. doi: 10.3969/j.issn.1006-5377.2015.01.003 [2] 姚群, 宋七棣, 陈志炜. 2019年袋式除尘行业发展评述及展望[J]. 中国环保产业, 2020(2): 19-22. [3] ZHENG C H, KANAOKA C. Recent advances in dust collection technology and ISO standardization in bag filtration[J]. Journal of Zhejiang University-Science A:Applied Physics & Engineering, 2018, 19(1): 21-33. [4] 张殿印, 王纯. 脉冲袋式除尘器手册[M]. 北京: 化学工业出版社, 2010. [5] 陈隆枢, 陶辉. 袋式除尘技术手册[M]. 北京: 机械工业出版社, 2010. [6] 王丹丹, 钱付平, 夏勇军, 等. 基于故障树分析法袋式除尘器滤袋失效的研究与应用[J]. 环境工程学报, 2016, 10(6): 3118-3124. doi: 10.12030/j.cjee.201501135 [7] 柳静献, 毛宁, 孙熙, 等. 预防袋除尘滤料失效的措施分析[J]. 中国环保产业, 2019(7): 26-28. doi: 10.3969/j.issn.1006-5377.2019.07.011 [8] 陈隆枢. 设备本体缺陷导致袋式除尘器失效因素探析[J]. 中国环保产业, 2012(3): 34-39. doi: 10.3969/j.issn.1006-5377.2012.03.012 [9] 雷新维, 唐勇. 电厂袋式除尘器滤袋故障分析及处理[J]. 中国环保产业, 2010(8): 38-40. doi: 10.3969/j.issn.1006-5377.2010.08.010 [10] CANDIDO T, BEZERRA F, RESSEL F, et al. The influence of the fabric filter layout of in a flow mass filtrate[J]. Journal of Cleaner Production, 2016, 111: 117-124. doi: 10.1016/j.jclepro.2015.09.070 [11] PARK S, JOE Y H, SHIM J, et al. Non-uniform filtration velocity of process gas passing through a long bagfilter[J]. Journal of Hazardous Materials, 2018, 42: 433-444. [12] ANDERSEN B O, NIELSEN N F, WALTHER J H. Numerical and experimental study of pulse-jet cleaning in fabric filters[J]. Powder Technology, 2016, 291: 284-298. [13] 王以飞, 沈恒根. 袋式除尘器在线清灰流场分布的研究[J]. 环境工程, 2010, 28(2): 72-77. [14] 潘伶, 刘菲, 杨沛山. 基于气固两相流场的袋式除尘器钢结构优化[J]. 机械设计与研究, 2013, 29(1): 104-106. doi: 10.3969/j.issn.1006-2343.2013.01.027 [15] 马洁, 王春波, 任育杰, 等. 柔性膜高温除尘器内气固两相流动数值模拟与优化设计[J]. 华北电力大学学报:自然科学版, 2019(1): 99-106. [16] 环境保护部. 袋式除尘工程通用技术规范: HJ 2020-2012[S]. 北京: 中国环境科学出版社, 2012. [17] 党小庆, 刘美玲, 马广大, 等. 脉冲袋式除尘器喷吹气流的数值模拟[J]. 西安建筑科技大学学报:自然科学版, 2008(3): 403-406. [18] 钟丽萍. 脉冲袋式除尘器喷吹清灰性能工艺参数优化试验研究[D]. 西安: 西安建筑科技大学, 2015. [19] 温正, 良臣, 毅如. FLUENT流体计算应用教程[M]. 北京: 清华大学出版社, 2009. [20] 郭星, 党小庆, 劳以诺, 等. 回转定位脉冲喷吹袋式除尘器滤袋长度可延长性分析[J]. 环境工程学报, 2017, 11(3): 1766-1770. doi: 10.12030/j.cjee.201511165 [21] 王辉. 流化床粉煤灰与煤粉炉粉煤灰理化性质研究[J]. 能源与节能, 2017, 144(9): 72-74. doi: 10.3969/j.issn.2095-0802.2017.09.037 [22] 马鑫. 袋式除尘器脉冲喷吹清灰机理研究[D]. 沈阳: 东北大学, 2009. [23] 娄可宾. 袋式除尘器脉冲清灰的数值模拟[D]. 上海: 东华大学, 2007. [24] 谢洪勇, 刘志军. 粉体力学与工程[J]. 2版. 北京:化学工业出版社, 2007: 9-18. [25] 柳静献, 毛宁, 孙熙, 等. 我国除尘滤料历史、现状与发展趋势综述[J]. 中国环保产业, 2020(11): 6-18. doi: 10.3969/j.issn.1006-5377.2020.11.001 [26] 中国电力企业联合会. 火力发电厂袋式除尘器用滤料寿命管理与评价方法: DL/T 1514-2016 [S]. 北京: 中国电力出版社, 2018. -

下载:

下载: