-

制浆造纸行业产生的废水对生态环境和人体健康产生威胁[1]。制浆造纸废水中有机污染物种类复杂,主要包括直链烷烃类、醇类、酮类、醛类、酯类、脂肪酸类、芳香族等[2],其中,醇类、酯类、醛类、酮类和脂肪酸类可以在物化、生化处理过程中可得到有效降解,但主要来源于制浆造纸过程中木素的脱除物及添加的涂料、废纸油墨等的芳香族有机污染物具有很好的化学稳定性[3],难以在物化、生化处理过程中被彻底去除[4],在造纸废水二级生化出水中占难降解污染物的80%以上。随着造纸行业污染物排放新标准的颁布和实施,污水排放标准日益严格,造纸废水深度处理刻不容缓。

目前,工程应用的制浆造纸废水深度处理工艺主要有以羟基自由基(OH∙)为主要活性物种的Fe2+活化双氧水(H2O2)的Fenton氧化技术以其高效的降解能力,得到了广泛的关注和重视,但调酸步骤繁琐,所用的氧化剂运输及储存过程存在安全隐患,在工程应用中饱受诟病[5]。过二硫酸盐(PS,persulfate)作为新型高级氧化技术,近年来逐步成为研究热点,PS具有常温下性质稳定、适用pH广泛(2.5~11)、易于储存、易溶于水、价格低廉、反应产物温和等应用优势,可在Fe2+活化作用下产生硫酸根自由基(

$ {\rm{SO}}_4^{ \cdot - }$ ),从而降解污染物[6],其具有氧化还原电位(E0=+2.5~3.1 V)高于羟基自由基(E0=+2.3~2.8 V)[7]、氧化活性更好、寿命更长的特点,在近中性至碱性条件下降解污染物方面具有更好的优越性[8]。另外,$ {\rm{SO}}_4^{ \cdot - }$ 不仅可与有机物发生C—H键的抽氢和C=C键的加成反应外,作为强的电子受体在通过电子转移夺得苯环上的电子使其开环断链并矿化为CO2和H2O,这使得PS高级氧化法应用于处理分子中含苯环类的难降解废水方面具有更鲜明的优势[9]。而过二硫酸盐室温下呈固体状态,易于储存和输送、稳定性高,在水溶液中比过氧化氢具有更高的溶解度,这一特征也有利于PS高级氧化法深度处理废水的工程应用。本研究以本团队设计完成的广东东莞某造纸厂废水PS无酸高级氧化处理工程为例,着重分析了该处理工艺发技术特征及PS无酸高级氧化工艺在深度处理制浆造纸废水的工程应用状况,对各处理工段水质进行系统检测,分析有机物、氮、磷等污染物的变化规律和水质特征,评估PS无酸高级氧化工艺深度处理造纸废水体系。探讨PS无酸高级氧化工艺深度处理造纸废水过程中的溶解性有机物的去除特性,分析深度处理进出水中的有机物组成,为类似废水提供理论依据;探讨了该工艺的实际运行状况,以期对造纸废水深度处理提供借鉴经验。

-

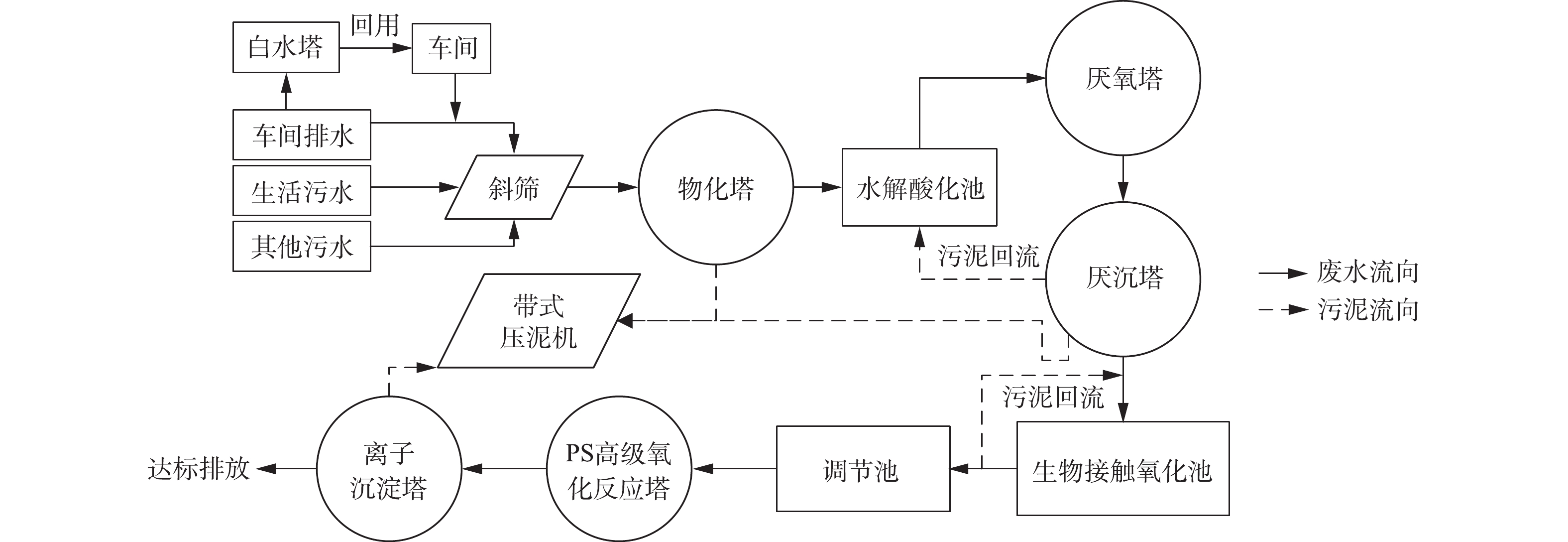

某造纸厂以废纸为原料,主要生产高强度瓦楞纸以及包装纸等,生产能力为1.9×105 t·a−1。废水来源主要是车间排水、生活污水以及其他污水组成。目前,已经建成4 000 m3·d−1规模的生化处理设施,造纸废水生化出水指标如表1所示,生化出水BOD5/COD值为0.038~0.089,远低于可生化性废水要求所需的0.5以上。这是由于废水经厌氧-好氧处理工段后,废水中的悬浮物和大分子易降解的有机污染物得以去除,而木质素降解碎片以及芳香烃难降解污染物通过累积效应大量存在于生化出水中,导致废水可生化性极差[2],生化出水COD、SS以及色度等指标无法达到《制浆造纸工业水污染物排放标准》(GB 3544-2008)制浆和造纸联合生产企业所规定的水污染物特别排放限值。因此,造纸废水的深度处理势在必行。废水的处理流程如图1所示,本工程创新性地利用亚铁活化PS体系在中性条件下对难降解有机污染物进一步降解,离子沉淀工段则通过去除SS,以进一步提高水质,可以高效稳定实现对制浆造纸废水的深度处理。

-

PS无酸高级氧化工艺流程见图2。可以看出,生化出水进入调节池混合均质化后,在进水泵前加入过二硫酸盐药液,与废水充分混合后,泵入高级氧化塔内。硫酸亚铁药液从高级氧化塔顶部加入,催化活化PS产生

$ {\rm{SO}}_4^{ \cdot - }$ 等自由基,以进攻难降解有机污染物,将其降解为CO2和H2O等小分子物质后,经溢流堰进入离子沉淀塔,泵入氢氧化钠药液以保证铁离子的沉淀。而形成的氢氧化铁胶体可起到絮凝作用,从而将水中小分子悬浮物聚集,加入聚合氯化铝药液辅助絮凝沉淀,所产生的铁泥与物化排泥混合后压滤脱水后处理,借助氢氧化铁胶体与PAC相互作用,可进一步去除废水中的SS,从而提高水质经溢流堰达标排放。PS无酸高级氧化工艺深度处理制浆造纸构筑物为塔式结构,占地面积小、空间利用率高、基建设备投资费用低。主要构筑物为PS高级氧化塔和一/二级离子沉淀塔如图2(b)所示。PS高级氧化塔为不锈钢塔结构、圆柱体、圆锥底,锥度为0.75°,直径φ=9 m、高度H=12 m、有效容积为575 m3、设计水量为150 m3·h−1,水力停留时间为3.8 h,上升流速为1.58 m·h−1;一/二级离子沉淀塔为不锈钢塔结构、圆柱体,圆锥底,锥度为0.8°,直径φ=12 m,高度H=10 m,有效容积为905 m3,设计水量为150 m3·h−1,水力停留时间为6.0 h。

-

1)水质指标分析和废水分子质量分级。pH采用SLIM48工业用pH计HP-480测定;COD采用HJ 828-2017中的重铬酸钾法测定;分子质量采用1260型凝胶色谱仪(Agilent,美国) 测定;UV-vis 光谱采用UV-2600分光光度计(Shimadzu,日本) 测定。

2)三维荧光分析。采用RF-5301型荧光光度计(Shimadzu,日本) 测定。本实验以10 nm为增量,激发波长为200~600 nm,发射波长为200~600 nm,扫面速度为12 000 nm·min−1,最后使用Origin软件对三维荧光光谱数据进行处理。

3) GC-MS分析。将475 mL水样加入1 000 mL分液漏斗中,测定pH为6.5~7.0,加入50 mL二氯甲烷,振荡萃取5 min,静置10 min,将有机层收集到烧瓶中。分别用硫酸和10 mol·L−1氢氧化钠溶液调节水样pH为1.5和10,使用50 mL二氯甲烷依次进行酸性和碱性条件下的萃取,振荡5 min,静置10 min,合并所有萃取液,经无水Na2SO4除水后,取1 mL加入进样瓶中上机进样分析。

-

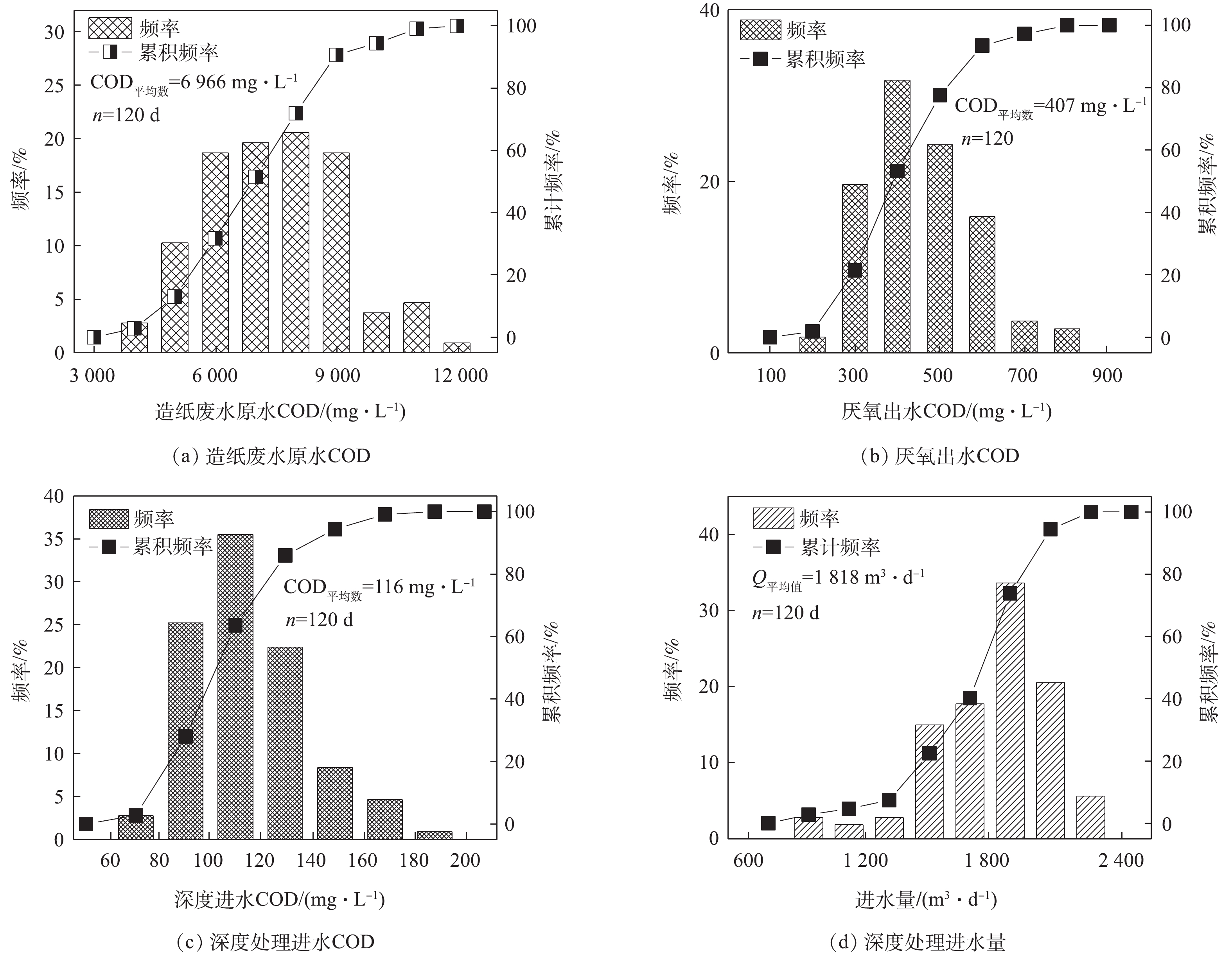

对PS高级氧化结合离子沉淀深度处理工艺自启动后连续运行120 d的数据进行水质水量状况分析。图3为制浆造纸废水质水量频率分布直方图以及累积频率分布曲线。由图3(a)可知,制浆造纸废水原水COD为3 000~12 000 mg·L−1,其中原水COD在5 000~9 000 mg·L−1范围内的累积频率达到了87.85%。其波动范围较广,这也对后续处理单元的抗有机负荷冲击能力提出新的挑战。经物化-厌氧生物处理后,有机污染物中容易被降解的大分子得到有效去除,厌氧出水的COD值也主要集中在300~500 mg·L−1,造纸废水的COD平均值也由原水的6 966 mg·L−1降低到407 mg·L−1,COD去除率达到94.15%。厌氧出水经好氧生物处理后,COD平均值由407 mg·L−1下降至116 mg·L−1,COD去除率由厌氧生物处理的94.15%下降至71.50%。这主要是由于难降解有机污染物的累积降低了废水的可生化性,从而导致生物处理效率有所下降,COD无法通过生化进一步降低。而深度处理进水的COD为100~180 mg·L−1,累积频率达到96.26%,COD平均值为116 mg·L−1,远远超过排放标准所规定的限值(COD<60 mg·L−1),为保证废水的稳定达标排放,深度处理也已迫在眉睫。而对深度处理的水量进行分析,结果如图3(d)所示,水量主要集中在1 600~2 200 m3·d−1,累积分布频率达到92.53%。进行深度处理的水量平均值为1 818 m3·d−1,满足深度处理的设计水量要求3 600 m3·d−1。

-

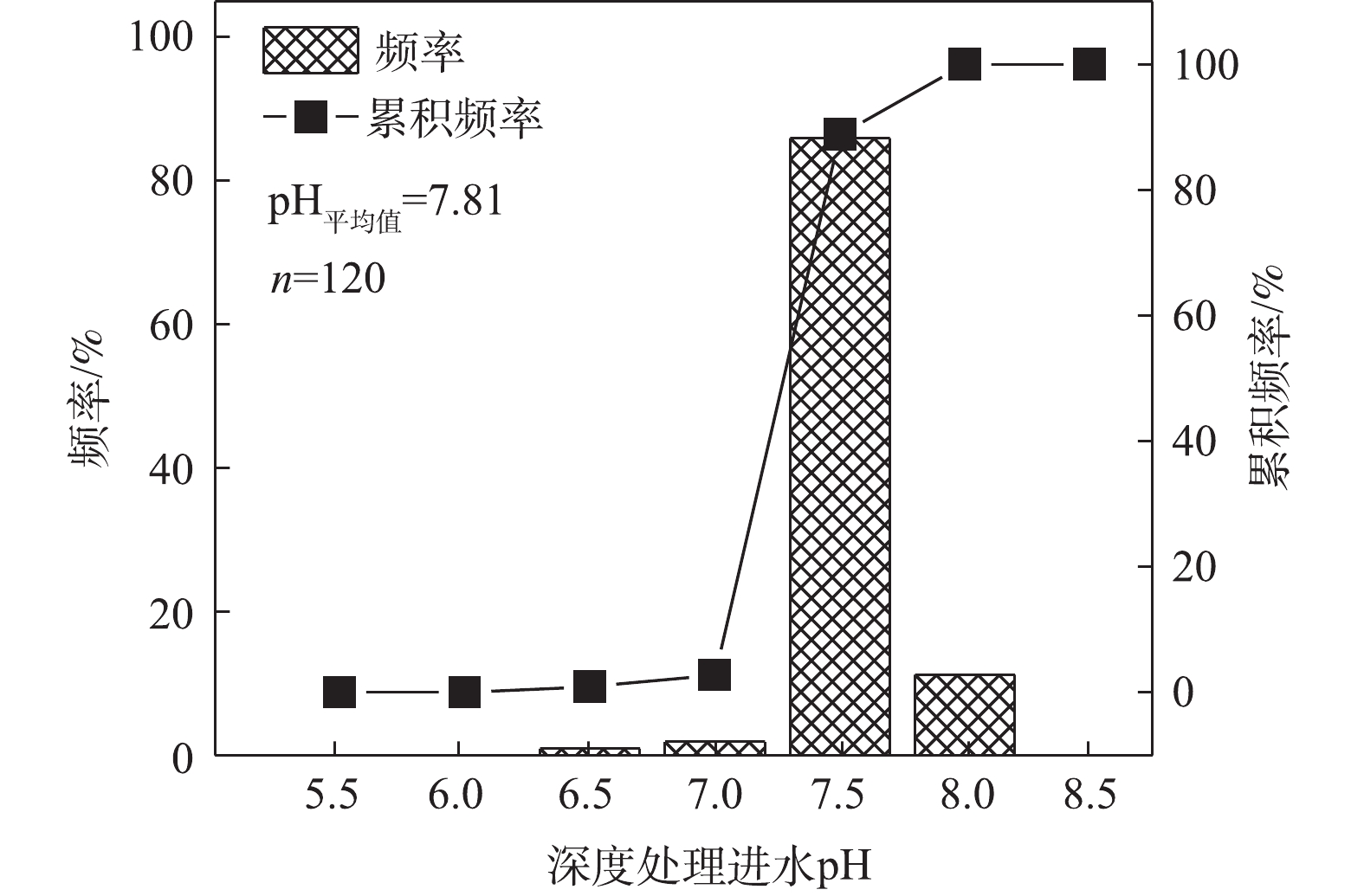

1)深度处理效率状况。为研究深度处理进水酸碱性,对进水pH进行连续监测分析,图4为深度处理进水的pH分布状况。当pH为8.0~8.5时,累积频率达到97.20%,可见造纸废水经生化处理后明显呈碱性,这主要与生化过程中的生物新陈代谢产物以及小分子纤维素分解产物的累积有关[10]。对于传统的Fenton高级氧化处理而言,深度处理进水的碱性特征对处理效果是极为不利的[11],因此,在工程应用中必须要加酸调节pH至4~5以下,这一过程不仅增大运行成本,而且所加入的酸腐蚀性极强,形成的酸雾对环境和人体危害较大,给废水处理带来新的安全隐患。而PS高级氧化技术由于pH适用范围广,无需对废水进行pH调控即可进行处理,极大地简化了处理流程,降低运行成本的同时也保证了废水的处理效果。

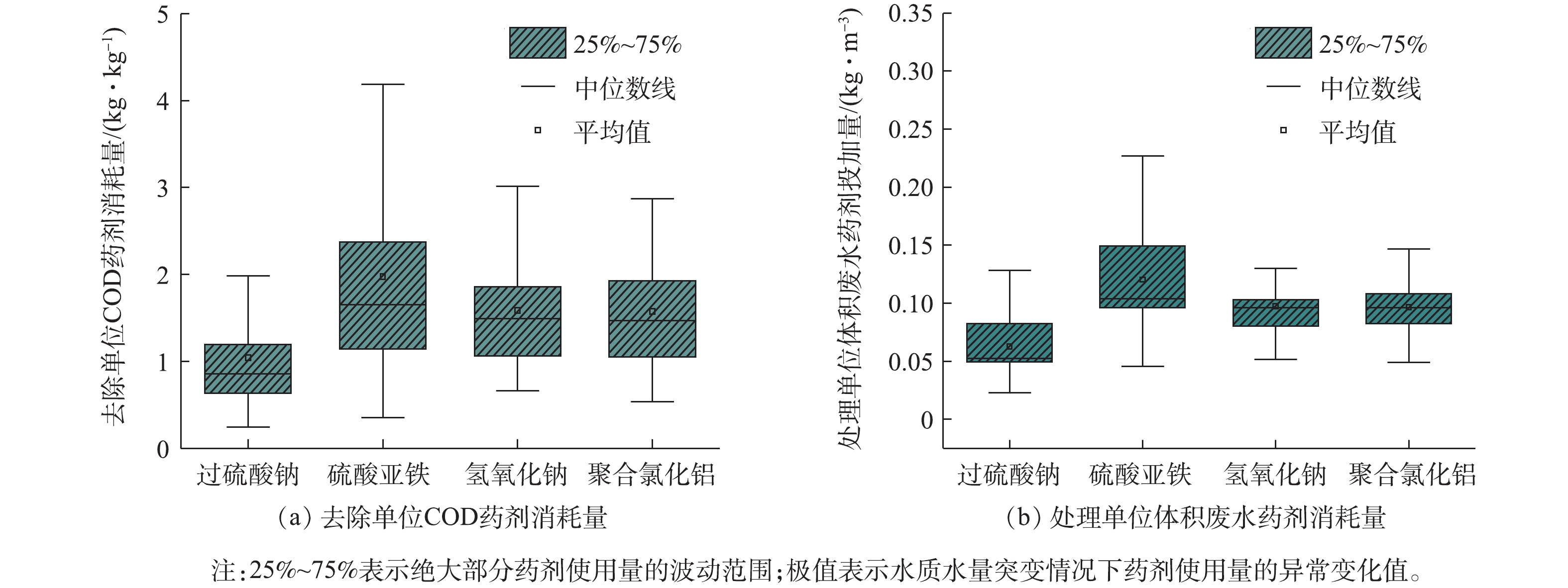

图5为深度处理出水COD分布状况。制浆造纸生化出水经PS无酸高级氧化工艺后,水中的难降解有机污染物得以降解,而水中的SS等物质在聚合氯化铝和氢氧化铁胶体的作用下也得到进一步去除。因此,深度处理出水COD稳步下降,为40~55 mg·L−1,累积分布频率达到80.43%,深度出水COD平均值为47 mg·L−1,远低于排放限值。在水质水量均出现波动情况下,PS无酸高级氧化工艺连续运行120 d内均可保证出水达标排放,也充分体现了这一新型深度处理工艺的高效稳定。

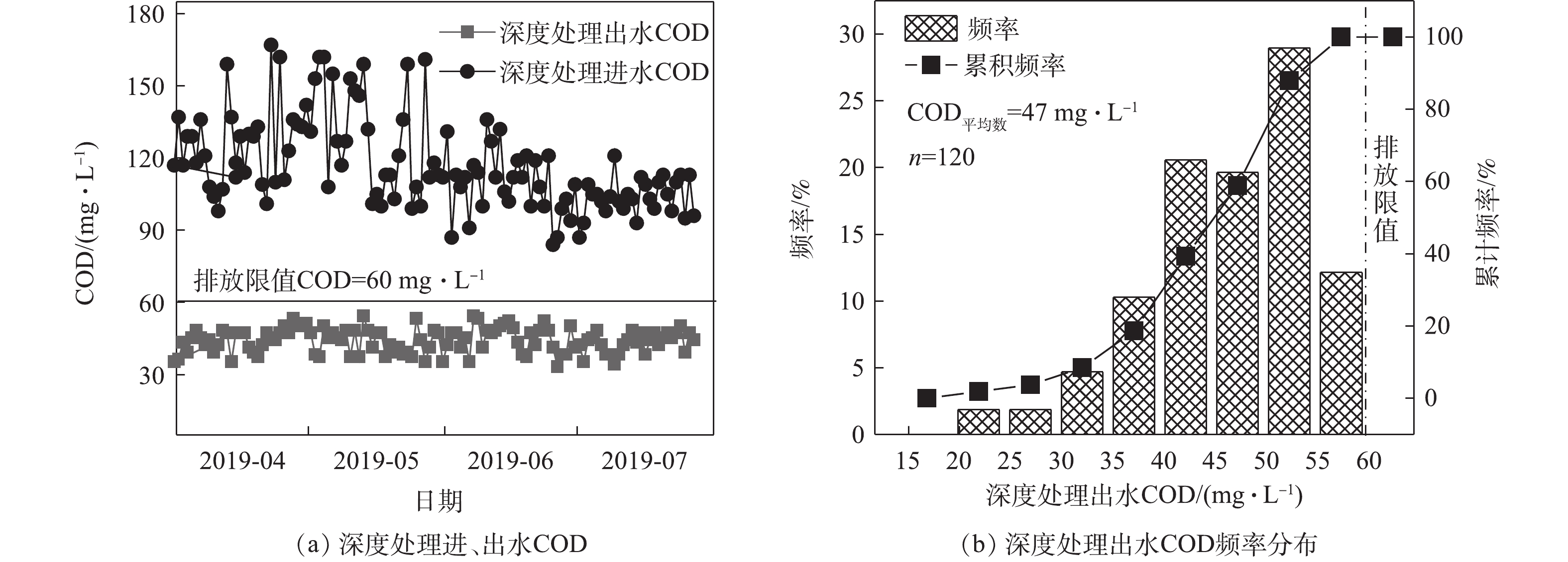

2) PS无酸高级氧化工艺药剂用量分析。为研究PS无酸高级氧化工艺中药剂用量对处理单位水量与去除单位COD的影响,深度处理连续运行过程中药剂量根据进出水COD及水量进行动态调控。PS无酸高级氧化工艺主要使用的药剂有过硫酸钠、硫酸亚铁、氢氧化钠以及聚合氯化铝。药剂均为固体粉剂,方便运输保存,且相较于双氧水而言,氧化剂过硫酸钠常温常压储存周期长,无易制爆风险。由于PS高级氧化pH适用范围广,无需酸液的加入,大幅降低成本和运行难度,所有药剂均现场配制药液后通过药液投配系统加入指定位点。对PS高级氧化结合离子沉淀深度处理工艺自启动后连续运行120 d的数据对其加药量进行分析,将加药量数据绘制成箱线图,反映药剂使用量的变化情况。去除单位COD药剂消耗量如图6(a)所示,过硫酸钠投加量为0.64~1.18 kg·kg−1,平均投加量为1.05 kg·kg−1 (以COD计)。而硫酸亚铁的投加量则主要分布在1.14~2.37 kg·kg−1,平均投加量为1.97 kg·kg−1。可以发现硫酸亚铁和过硫酸钠的药剂加入摩尔比接近3:1。这是由于在高级氧化塔内由于生化出水pH呈碱性,有部分硫酸亚铁形成氢氧化铁沉淀而无法催化活化PS。因此,需要保证硫酸亚铁足量加入,以可有效活化PS产生自由基。同时硫酸亚铁的水解作用可缓慢释放氢离子,从而形成酸性或弱酸性环境[12],当高级氧化塔内pH逐步下降至6~7左右时,也更利于自由基的降解作用。经PS高级氧化后进入离子沉淀工段,水中的Fe2+、Fe3+具有良好的混凝作用,氢氧根离子的引入,一方面可通过形成氢氧化铁絮体去除水中的铁离子,另一方面氢氧化铁絮体和加入的PAC通过电中和、压缩双电层等作用降低胶体的Zeta电位,使胶体脱稳,从而形成紧实的矾花沉淀去除[13],水中的SS和COD进一步降低。处理单位水量药剂消耗量如图6(b)所示,处理单位水量PS投加量平均值为0.06 kg·m−3,而硫酸亚铁投加量平均值为0.12 kg·m−3。氢氧化钠主要受到加入的硫酸亚铁量波动而变化,投加量平均值为0.09 kg·m−3。PAC的加入量则波动幅度不大,主要集中在0.08~0.10 kg·m−3。药剂的加入量可针对不同进水有机负荷进行变化,因此,PS无酸高级氧化工艺也保证了出水的稳定达标排放。

-

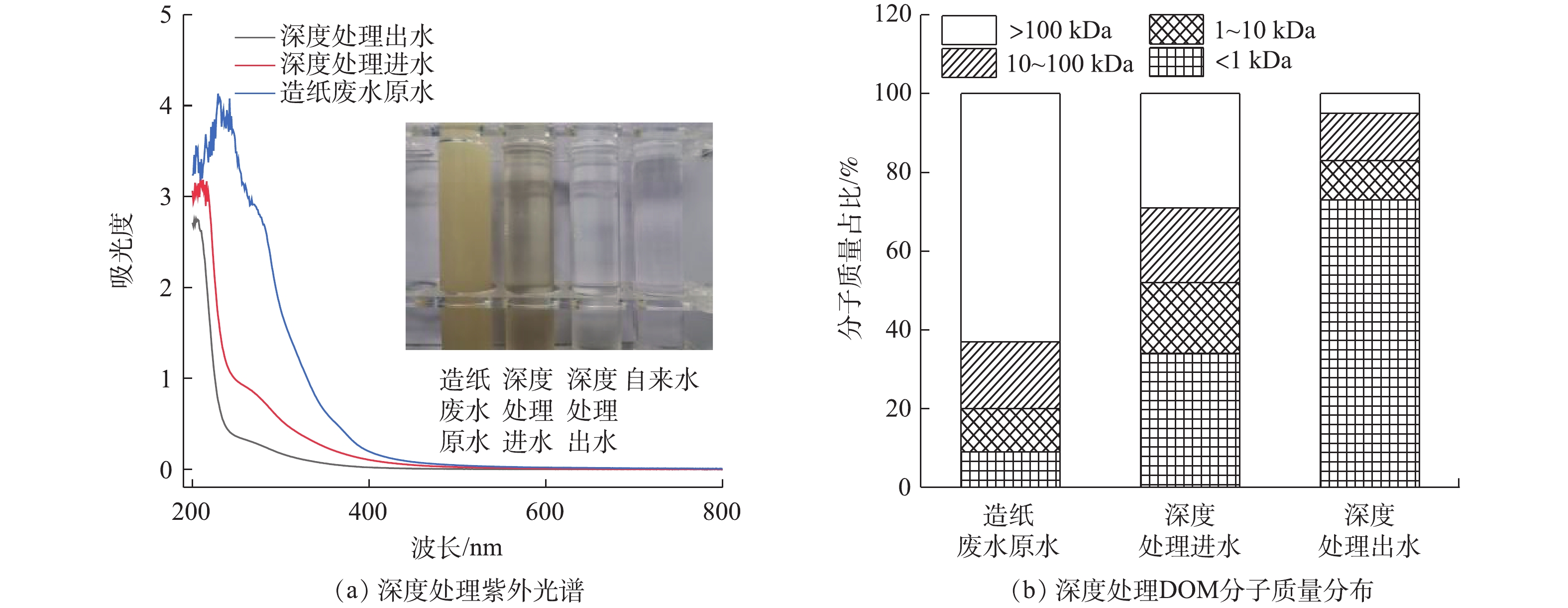

1)紫外全波长扫描及DOM分子质量分布。溶解性有机物(DOM)对于造纸废水各工段的COD值贡献率均较高,因此,对DOM的降解可大幅提高COD去除率。为研究深度处理对废水中的溶解性有机物(DOM)的降解影响,对造纸废水原水、深度处理进/出水进行紫外-可见光谱分析以及DOM分子质量分布研究。紫外-可见光谱(UV-vis)可以通过特定波长的吸光度变化表征废水的芳香性,也可表征分子结构的发色基团特征等[14]。由于含芳香环和双键共轭体系的有机化合物在对254 nm处的紫外光有较强吸收征,水样于254 nm处的吸光度(UV254)可反映样品的芳香性,UV254越高,说明样品芳香族化合物含量越高[15];一般用254 nm和356 nm处的吸光度之比(E254/E365)可反映DOM分子大小的比例,比值与水中小分子比例呈正相关,而300 nm和400 nm的吸光度比值(E300/E400)则可说明DOM的腐殖化程度和芳香性,比值越大,说明芳香性越低。275~295 nm与350~400 nm波段斜率之比(SR) 可用于表征DOM的结构变化,SR值越高,DOM分子质量越低,表明DOM被微生物降解的反应活性降低[16]。图7(a)为PS无酸高级氧化工艺不同工段水样的紫外全波长扫描图,造纸废水原水与深度处理进/出水的吸收波长曲线趋势一致,在220 nm附近出现明显的特征峰,这也说明水中含有苯环类有机污染物。UV-vis比值如表2所示,造纸废水经不同处理单元处理后,其UV254明显下降,说明PS无酸高级氧化工艺进一步去除了水中芳香族难降解有机污染物;而E254/E365则随着处理工段推进逐步升高,水中小分子物质比例提高,这也说明了深度处理后大分子难降解物质均已被降解为小分子物质,水质得以提高;E300/E400也逐步升高,说明在经深度处理后废水芳香性进一步降低;而SR则由造纸废水原水的3.70降低至深度处理进水的3.54,废水的可生化性降低,这是由于原水中的大量易降解有机污染物在经生化处理后均得到有效降解,而难降解的有机污染物则由于累积效应抑制了废水的可生化性。而经PS无酸高级氧化工艺后废水的SR由3.54升高至4.93,说明废水中的大量难降解有机污染物均得到有效去除,水体的可生化性得以大幅提高。图7(a)中的附图为不同工段水样,经PS无酸高级氧化工艺后废水的色度与浊度得以大幅降低,基本与自来水一致。

图7(b)为不同工段水样中DOM分子质量所占比例,通过不同孔径的超滤/纳滤膜分离水样的溶解性有机物[17],得到4种不同分子质量的DOM组分(>100 kDa、100~10 kDa、1~10 kDa、<1 kDa)[16-18]。经PS无酸高级氧化处理废水中分子质量<10 kDa的分子所占比例由原水的20%提高至83%,这是因为PS高级氧化可通过强氧化自由基破坏难降解污染物的苯环结构,从而导致其分子质量降低。因而水中的难降解有机污染物均得以有效去除,与紫外扫描所得的Uv254以及E254/E365结论一致,进一步证实了PS无酸高级氧化工艺的高效稳定。生化处理可将大分子有机物分解成小分子,腐殖化程度降低;PS高级氧化深度处理后小分子物质所占比例明显增加,水质也得到进一步改善。

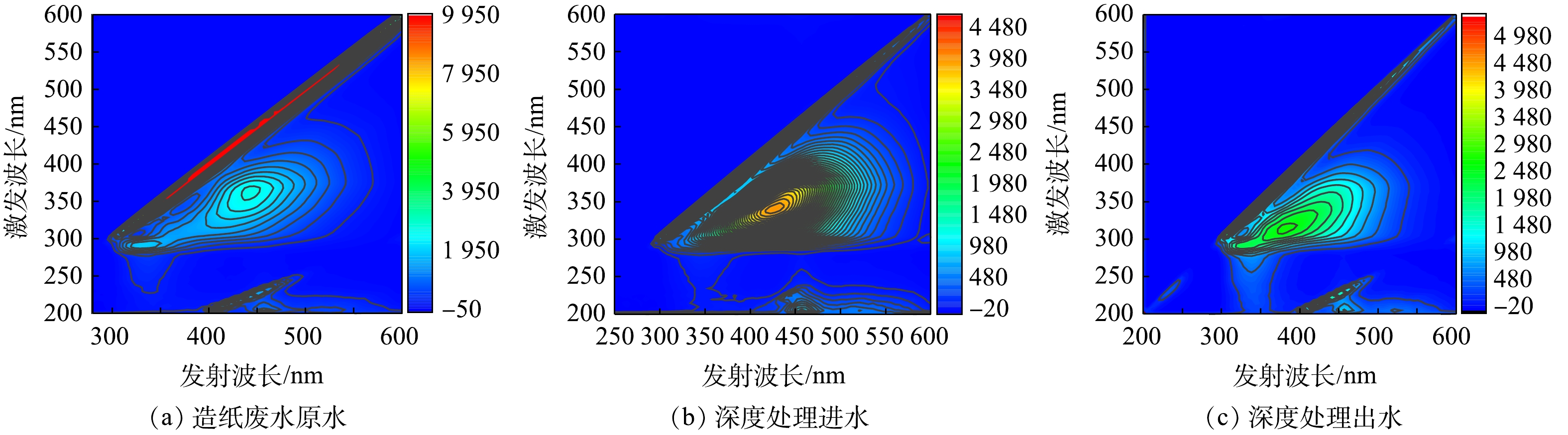

2)三维荧光分析。制浆造纸废水深度处理过程中三维荧光分析如图8所示,利用峰值法对各工段废水三维荧光谱图进行分峰。造纸废水原水出现3个比较明显的峰,峰中心分别为Ex/Em=360 nm/440 nm,属于可见光类腐殖酸类腐殖质荧光峰[19];Ex/Em=285 nm/325 nm,属于含苯环类蛋白质荧光峰;Ex/Em=205 nm/355 nm,属于低激发态色氨酸类蛋白质[20]。而造纸废水经厌氧-好氧生化处理后,色氨酸类蛋白质峰中心出现10~20 nm的蓝移,这是由于生化作用导致一些易降解大分子转化为难降解的小分子污染物,共轭基团数量也明显下降;腐殖酸类腐殖质类峰反而出现20~35 nm的红移,这一方面是由于微生物的新陈代谢作用产生了一些难降解的污染物,另一方面,则是在生化作用过程中为加强生物脱氮而进行的回流导致部分难降解物质出现富集现象;此外深度处理进水出现还新的特征荧光峰,峰中心为Ex/Em=220 nm/380 nm,属于可见光区内的富里酸类腐殖质,这主要是废水中的易于降解的大分子物质通过生物作用降解为难生物降解的富里酸类腐殖质[21]。而经PS无酸高级氧化深度处理后,各荧光峰峰强度(fluorescence intensity, FI)均有降低,这说明PS的强氧化作用结合PAC的絮凝作用对水中的难降解污染物有较好的去除效果,可明显改善水质。

表3为PS无酸高级氧化工艺不同工段荧光光谱的荧光强度(I)比值(A指色氨酸类蛋白质、B指芳香族类蛋白质、C指类腐殖酸类腐殖质)。其中IA/IB可反映水中DOM类蛋白质的构成,其值越大,说明难生物降解类蛋白质比例越低[22]。可以看出:经PS无酸高级氧化工艺处理后,IA/IB明显提高,说明水中的芳香族类蛋白质在PS高级氧化作用下得到有效降解,深度处理出水中芳香族类蛋白质比例迅速下降;IA/IC与废水的生物降解性能呈正相关,在经深度处理后废水的IA/IC由低于原水的0.85提高至1.02,这是由于大量难降解类腐殖酸类腐殖质得到有效降解,导致生物活性大幅提高,也进一步提高水体安全;此外IB/IC可指示DOM中难生物降解物质的比例以及腐殖化程度,其值越高,说明腐殖化程度越低,经PS无酸高级氧化处理后,废水的IB/IC有所降低,腐殖化程度提高,而腐殖化作用是一种有效的污染物脱毒方法[23],也进一步证明深度处理提高了废水生物稳定性。

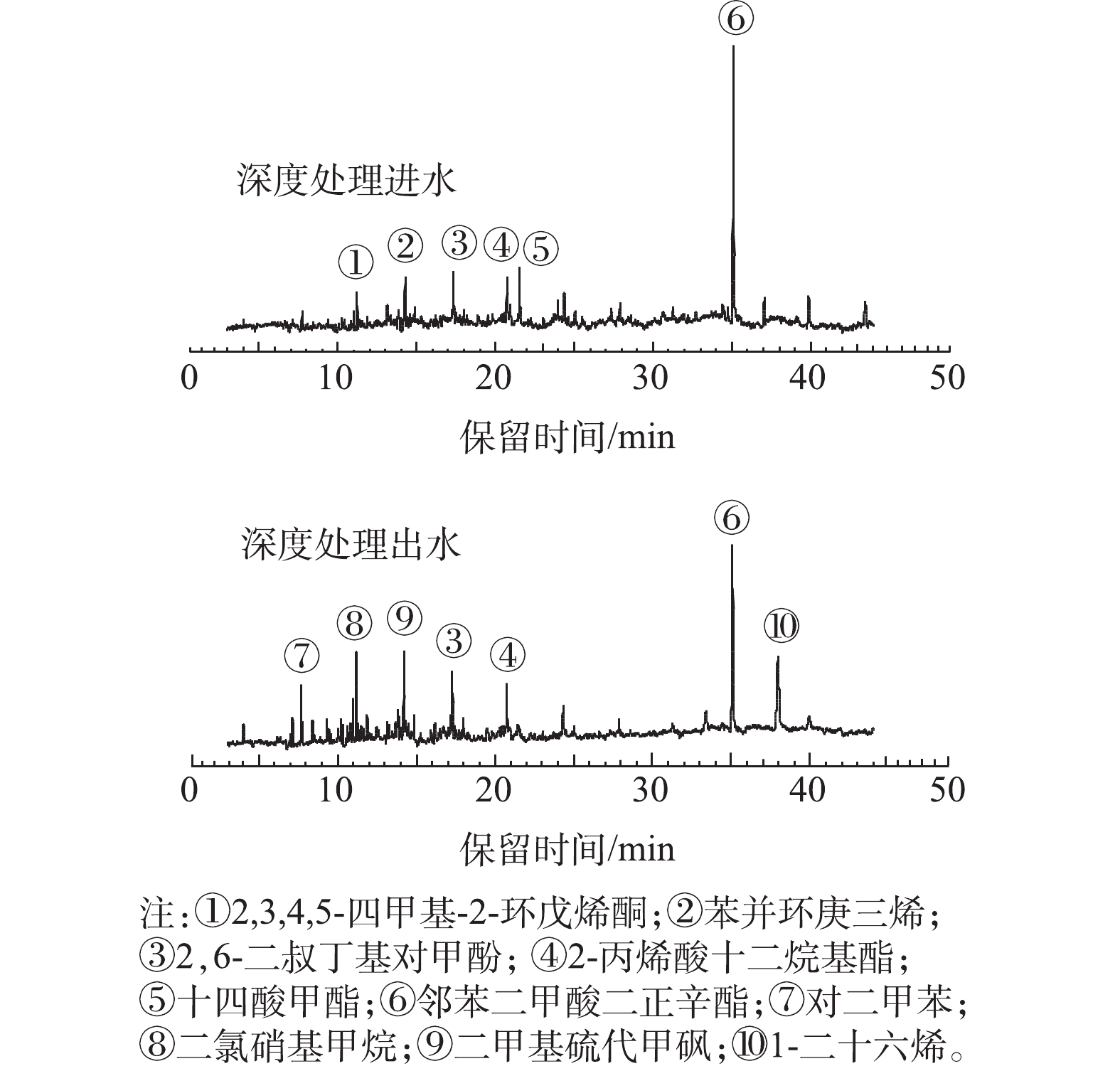

3)GC-MS分析。为了进一步揭示制浆造纸废水深度处理过程中有机物迁移转化,采用GC-MS分析方法对深度处理进水和出水成分进行了分析[24],结果见图9。由于波峰多而密,故只对水样全扫描谱图9中主要峰进行了分析。利用NISTO5a.L谱库进行检索[25],检测出的化合物及其匹配率具体信息见表4。由GC-MS可以看出,经过生化处理后的深度处理进水中共检测出酰胺类、酯类、酚类、酮类、芳香族化合物及大量脂肪烃类物质。其中含有大量的长链脂肪烃(长链脂肪烃、脂肪酸、烯烃、氯、碘及溴的卤代烃等物质)和长链脂肪酸酯类,这2类物质是水体常见的有机荧光物质,GC-MS检测结果与三维荧光的测定结果具有很好的一致性。由表4可知,经过深度处理后,长链脂肪烃、烯烃、长链脂肪酸酯、烯醇等物质被氧化生成短链脂肪烃,酰胺类和酚类物质的浓度明显降低,未检测出酮类物质。结果表明,PS无酸高级氧化处理工艺可以实现C—X(X—Cl、Br、I)键断裂、—OH、—CH3等支链从苯环上的分离及苯环和杂环化合物的开环,从而对造纸废水起到良好的深度处理作用。

-

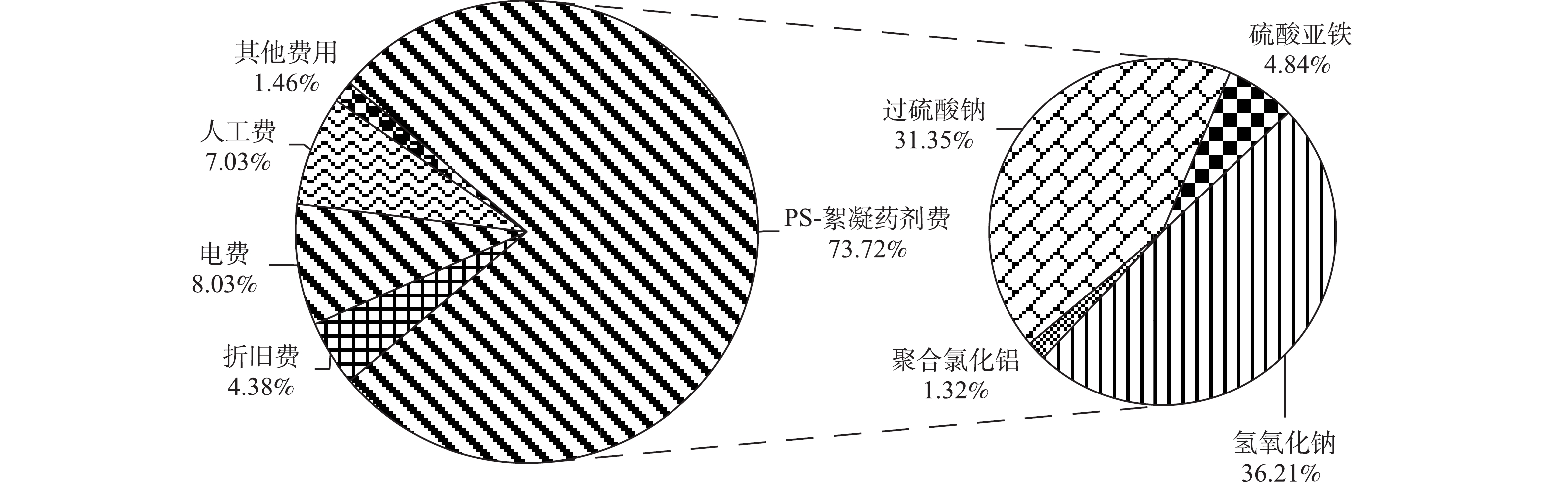

废水的深度处理费用一般由设备折旧、人员运行维护、电费、药剂费用以及电费等组成,传统的Fenton高级氧化深度处理工艺处理制浆造纸废水费用一般为1.7~5元·t−1,其中药剂成本为1.19~1.8元·t−1[26]。而PS无酸高级氧化工艺由于其处理流程简单,基建及设备投资费用较低,其中,药剂主要有过硫酸钠、硫酸亚铁、氢氧化钠以及聚合氯化铝,无需调酸步骤,大大简化日常运行工作量。结合工厂连续运行状况及市场药剂单价,采用PS无酸高级氧化工艺总费用成本仅为1.30元·t−1,各部分费用所占比例如图10所示,药剂费用所占比例为73.72%,药剂成本为0.96元·t−1。因此,运行成本较低、深度处理效果显著以及操作步骤简便等优势也让PS无酸高级氧化工艺有望成为制浆造纸废水深度处理的优选方案。

-

1)深度处理进水COD平均值为116 mg·L−1,处理单位水量所需的过硫酸钠、硫酸亚铁、氢氧化钠以及聚合氯化铝平均加入量分别为0.06、0.12、0.09和0.095 kg·m−3,去除单位COD时所需的过硫酸钠、硫酸亚铁、氢氧化钠以及聚合氯化铝平均加入量分别为1.05、1.97、1.59和1.57 kg·kg−1,硫酸亚铁和过硫酸钠的摩尔加入比例集中在3∶1。

2) UV-vis以及DOM分子质量分布结果表明,经PS无酸高级氧化工艺后出水DOM中分子质量明显下降,难降解有机污染物得以有效降解。

3)三维荧光光谱分析结果表明,深度处理后出水腐殖化程度有所提高,芳香族类蛋白质大幅降低,难生物降解的类腐殖酸和类富里酸也得以降解;GC-MS实验结果表明,造纸废水中生化出水中主要的污染物为长链脂肪烃和芳香族类物质。经过深度处理后,出水难生物降解的有机物均得到有效去除,酯类、酮类和酚类物质得到有效降解。经PS无酸高级氧化处理后出水生物性得以改善,水质得以进一步提高。

4)实际运行结果表明,PS无酸高级氧化可以高效稳定的对造纸废水进行深度处理,无需调酸步骤,简化操作,确保出水达到《制浆造纸工业水污染物排放标准》(GB 3544-2008)排放标准。运行成本为1.30元·t−1,其中药剂费用为0.96元·t−1,所占比例为73.72%。PS无酸高级氧化工艺可成为制浆造纸废水深度处理的优先方案。

PS无酸高级氧化工艺深度处理制浆造纸废水的工程应用

Engineering application of pulping and papermaking wastewater advanced treatment by PS acid-free advanced oxidation process

-

摘要: 相较于Fenton高级氧化深度处理造纸废水,PS无酸高级氧化技术具有无需调节进水pH,药剂稳定等优点。基于此,以某造纸厂废水PS无酸高级氧化处理工程为依托,系统分析了该技术的工艺特点,研究了过硫酸钠、硫酸亚铁、氢氧化钠、聚合氯化铝等处理药剂用量与水量、进水负荷、COD去除量之间的关系。连续运行数据表明,高级氧化深度处理进水COD平均值为116 mg·L−1,出水COD平均值为47 mg·L−1,可稳定保持在60 mg·L−1以下。过硫酸钠、硫酸亚铁、氢氧化钠及聚合氯化铝的平均投加量分别为0.06、0.12、0.09和0.095 kg·m−3(以单位水量计),硫酸亚铁和过硫酸钠的投加摩尔比例为2.0~3.0。采用UV-vis光谱、三维荧光和气相质谱等指纹图谱分析手段对深度处理水样中溶解性有机物(DOM)特性进行了分析,结果表明,中小分子质量的DOM物质比例有所提高,芳香族难生物降解污染物和类腐殖酸均得到了有效降解。此外,对PS无酸高级氧化技术进行了系统工艺分析。以上研究结果可为废水处理中新型高级氧化技术的应用提供参考。Abstract: Compared with Fenton advanced oxidation process for pulping and papermaking wastewater treatment, the PS acid-free advanced oxidation process has many advantages of stable reagents, no need to adjust initial pH and so on. Based on the operation data of PS acid-free advanced oxidation process treating the biochemical effluent from a pulp and paper factory, the relationships between the dosage of the chemicals (sodium persulfate, ferrous sulfate, sodium hydroxide and polyaluminium chloride) and water flow, influent load and COD removal amount were systematically analyzed. Continuous running data showed that the average COD of influent was 116 mg·L−1, while the average COD of effluent was 47 mg·L−1 which was stable below 60 mg·L−1. The average dosages of sodium persulfate, ferrous sulfate, sodium hydroxide and polyaluminum chloride were 0.06, 0.12, 0.09 and 0.095 kg·m−3 (as unit volume of wastewater), respectively. Besides, the molar ratio of ferrous sulfate to sodium persulfate was mainly between 2.0 and 3.0. The characteristics of dissolved organic matter (DOM) were characterized by fingerprinting methods such as UV-vis spectroscopy, three-dimensional fluorescence and GC-MS. The results showed that the proportions of substances with medium and small molecular weights in DOM increased. Persistent aromatic pollutants and humic acids were effectively degraded during the treatment. The water quality was greatly improved after the advanced treatment. With the reduced operating costs and simplified operation process, the PS acid-free advanced oxidation process can ensure that the effluent meets the discharge requirements. The systematic process analysis of PS acid-free advanced oxidation technology could provide technical support and theoretical reference for the application of advanced oxidation technology in wastewater treatment.

-

-

表 1 某制浆造纸厂废水生化出水水质指标

Table 1. Water quality index of wastewater from the pulp and paper mill

mg·L−1 实测值与标准 COD BOD5 SS NH3-N TN TP 实测值 90~130 5~8 30~65 4~7 8~12 0.32~0.42 国家标准 60 10 10 5 12 0.50 表 2 深度处理工艺各工段UV-vis吸收值

Table 2. UV-vis absorption values of each section during advanced treatment process

处理工段 UV254 E254/E365 E300/E400 SR 造纸废水原水 3.28 4.95 5.20 4.70 深度处理进水 1.02 6.83 8.09 3.70 深度处理出水 0.35 7.30 8.96 4.93 表 3 深度处理工艺不同工段荧光光谱FI比值

Table 3. FI ratio of different sections during advanced treatment process

水样 IA/IB IA/IC IB/IC 造纸废水原水 1.58 0.98 0.62 深度处理进水 1.43 0.85 0.59 深度处理出水 2.34 1.02 0.45 表 4 造纸废水深度处理前后GC-MS全扫描定性分析结果

Table 4. Analysis results of GC-MS complete scanning before and after advanced treatment

序号 污染物 匹配率/% 处理前 处理后 ① 2,3,4,5-四甲基-2-环戊烯酮 89 — ② 苯并环庚三烯 98 — ③ 2,6-二叔丁基对甲酚 94 — ④ 2-丙烯酸十二烷基酯 96 — ⑤ 十四酸甲酯 95 — ⑥ 邻苯二甲酸二正辛酯 97 92 ⑦ 对二甲苯 — 90 ⑧ 二氯硝基甲烷 — 89 ⑨ 二甲基硫代甲砜 — 93 ⑩ 1-二十六烯 — 87 -

[1] TOCZYŁOWSKA-MAMIŃSKA R. Limits and perspectives of pulp and paper industry wastewater treatment: A review[J]. Renewable and Sustainable Energy Reviews, 2017, 78: 764-772. doi: 10.1016/j.rser.2017.05.021 [2] CHANDRA R, SINGH R. Decolourisation and detoxification of rayon grade pulp paper mill effluent by mixed bacterial culture isolated from pulp paper mill effluent polluted site[J]. Biochemical Engineering Journal, 2012, 61: 49-58. doi: 10.1016/j.bej.2011.12.004 [3] SINGH A K, CHANDRA R. Pollutants released from the pulp paper industry: Aquatic toxicity and their health hazards[J]. Aquatic Toxicology, 2019, 211: 202-216. doi: 10.1016/j.aquatox.2019.04.007 [4] KAMALI M, GAMEIRO T, COSTA M E V, et al. Anaerobic digestion of pulp and paper mill wastes: An overview of the developments and improvement opportunities[J]. Chemical Engineering Journal, 2016, 298: 162-182. doi: 10.1016/j.cej.2016.03.119 [5] KLIDI N, PROIETTO F, VICARI F, et al. Electrochemical treatment of paper mill wastewater by electro-Fenton process[J]. Journal of Electroanalytical Chemistry, 2019, 841: 166-171. doi: 10.1016/j.jelechem.2019.04.022 [6] WACŁAWEK S, LUTZE H V, GRÜBEL K, et al. Chemistry of persulfates in water and wastewater treatment: A review[J]. Chemical Engineering Journal, 2017, 330: 44-62. doi: 10.1016/j.cej.2017.07.132 [7] 渠艳飞, 关泽宇, 马邕文, 等. 基于硫酸自由基氧化降解邻苯二甲酸二丁酯的密度泛函理论研究[J]. 环境化学, 2017, 36(9): 1896-1905. doi: 10.7524/j.issn.0254-6108.2016122002 [8] GHANBARI F, MORADI M. Application of peroxymonosulfate and its activation methods for degradation of environmental organic pollutants: Review[J]. Chemical Engineering Journal, 2017, 310: 41-62. doi: 10.1016/j.cej.2016.10.064 [9] CHI H, WAN J, MA Y, et al. Ferrous metal-organic frameworks with stronger coordinatively unsaturated metal sites for persulfate activation to effectively degrade dibutyl phthalate in wastewater[J]. Journal of Hazardous Materials, 2019, 377: 163-171. doi: 10.1016/j.jhazmat.2019.05.081 [10] MAZHAR S, DITTA A, BULGARIU L, et al. Sequential treatment of paper and pulp industrial wastewater: Prediction of water quality parameters by Mamdani fuzzy logic model and phytotoxicity assessment[J]. Chemosphere, 2019, 227: 256-268. doi: 10.1016/j.chemosphere.2019.04.022 [11] 冯素敏, 王浩, 宋振扬, 等. 芬顿氧化-混凝深度处理二级出水试验研究[J]. 河北科技大学学报, 2017, 38(1): 94-100. [12] LUO T, WAN J, MA Y, et al. Sulfamethoxazole degradation by an Fe(Ⅱ)-activated persulfate process: insight into the reactive sites, product identification and degradation pathways[J]. Environmental Science: Processes & Impacts, 2019, 21: 1560-1569. [13] MOSADDEGHI M R, SHARIATI F P, YAZDI S A V, et al. Application of response surface methodology (RSM) for optimizing coagulation process of paper recycling wastewater using Ocimum basilicum[J]. Environmental Technology, 2018, 41: 100-108. [14] 李璐璐, 江韬, 闫金龙, 等. 三峡库区典型消落带土壤及沉积物中溶解性有机质(DOM)的紫外-可见光谱特征[J]. 环境科学, 2014, 35(3): 933-941. [15] WEISHAAR J L, AIKEN G R, BERGAMASCHI B A, et al. Evaluation of specific ultraviolet absorbance as an indicator of the chemical composition and reactivity of dissolved organic carbon[J]. Environmental Science & Technology, 2003, 37(20): 4702-4708. [16] WANG K, LI W, GONG X, et al. Spectral study of dissolved organic matter in biosolid during the composting process using inorganic bulking agent: UV-vis, GPC, FTIR and EEM[J]. International Biodeterioration & Biodegradation, 2013, 85: 617-623. [17] NI B, FANG F, XIE W, et al. Characterization of extracellular polymeric substances produced by mixed microorganisms in activated sludge with gel-permeating chromatography, excitation-emission matrix fluorescence spectroscopy measurement and kinetic modeling[J]. Water Research, 2009, 43(5): 1350-1358. doi: 10.1016/j.watres.2008.12.004 [18] HE M, SHI Y, LIN C. Characterization of humic acids extracted from the sediments of the various rivers and lakes in China[J]. Journal of Environmental Sciences, 2008, 20(11): 1294-1299. doi: 10.1016/S1001-0742(08)62224-X [19] 姜浩, 章婷曦, 杨帆, 等. 生活污水处理过程荧光光谱及紫外光谱特征分析[J]. 环境科学与技术, 2019, 42(6): 151-156. [20] 赵紫凡, 孙欢, 苏雅玲. 基于紫外-可见光吸收光谱和三维荧光光谱的腐殖酸光降解组分特征分析[J]. 湖泊科学, 2019, 31(4): 1088-1098. doi: 10.18307/2019.0411 [21] 陈诗雨, 李燕, 李爱民. 溶解性有机物研究中三维荧光光谱分析的应用[J]. 环境科学与技术, 2015, 38(5): 64-68. [22] COBLE P G. Characterization of marine and terrestrial DOM in seawater using excitation-emission matrix spectroscopy[J]. Marine Chemistry, 1996, 51(4): 325-346. doi: 10.1016/0304-4203(95)00062-3 [23] 王大扬, 王明铭, 张学真, 等. 硫酸根自由基降解二级出水中有机物的研究[J]. 环境工程, 2017, 35(4): 20-25. [24] 周圆, 李怀波, 郑凯凯, 等. 微波强化Fenton 技术对焦化废水印染工业园区集中废水处理达标难点及特征DOM解析[J/OL].[2020-02-10]. https://kns8.cnki.net/KCMS/detail/detail.aspx?dbcode=CAPJ&dbname=CAPJLAST&filename=HJJZ20191219002&v=MjY1MTlNem1SbjZqNTdUM2ZscVdNMENMTDdSN3FkWitacUZpcmxWNy9CSVZZPUxTZkJkTEc0SDlqTnJZNU1aT3NOWXc5. [25] 宋晓乔, 刘罡, 李天昕, 等. 麦草浆制浆造纸废水难降解有机物成分鉴定[J]. 中国造纸学报, 2018, 33(4): 12-16. doi: 10.11981/j.issn.1000-6842.2018.04.12 [26] 时孝磊, 朱琳, 刘晋恺, 等. Fenton/絮凝工艺深度处理制浆造纸废水的工程应用分析[J]. 环境工程学报, 2013, 7(9): 3415-3420. -

下载:

下载: