-

为实现“碳中和”目标,低碳脱氮新技术的开发及其工程化应用成为污水处理领域的研究热点。污水生物脱氮的主要途径为传统的硝化反硝化反应,但其工程应用仍存在能耗高且难实现低碳化的问题。厌氧氨氧化(anaerobic ammonium oxidation,anammox)可在厌氧条件下,以氨氮为电子供体、亚硝氮为电子受体,实现氨氮和亚硝氮的同步脱除并生成氮气。与传统硝化反硝化工艺相比,基于厌氧氨氧化的新工艺可有效降低曝气成本、减少污泥产量及有机碳源需求量,是未来污水生物脱氮的重要发展方向。为更好地宣传该领域最新成果,《环境工程学报》编辑部邀请李玉友、刘思彤、陈荣3位教授组织了“厌氧氨氧化生物脱氮理论与技术发展”专题。本文梳理和总结厌氧氨氧化的发现过程、理论研究、工艺发展、工程应用及其新动态,并作为该专题的代序言。

-

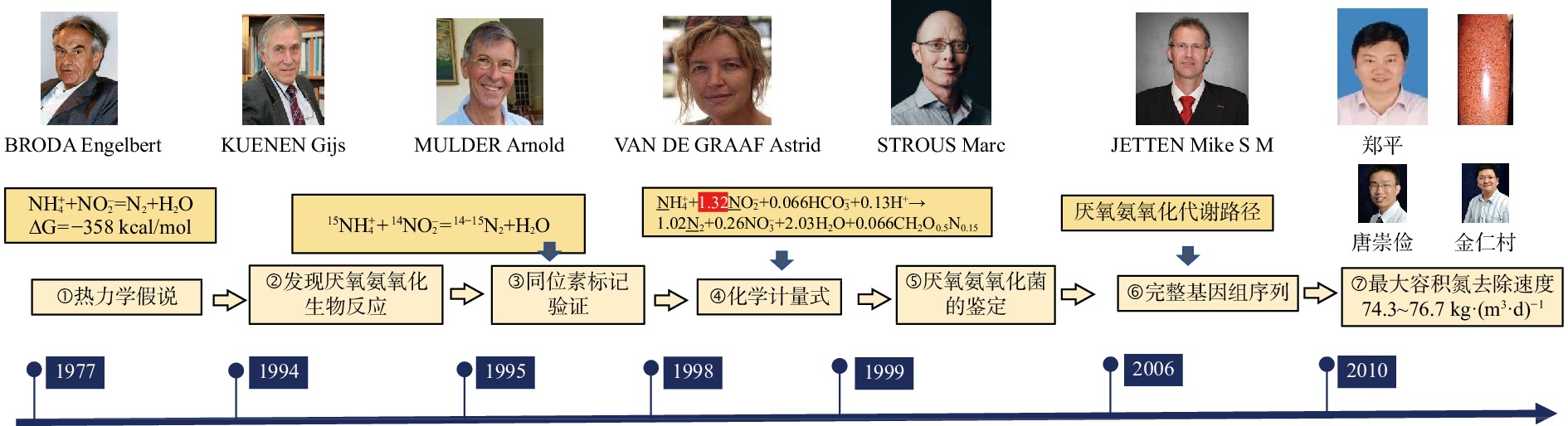

1977年,奥地利理论化学家BRODA Engelbert运用热力学理论推断并提出存在一种生物反应,可利用氨氮和亚硝氮生成氮气(式1)[1]。然而,传统学者认为:由于氨氮具有化学惰性,要氧化氨氮需要氧气和混合功能的加氧酶[2],故厌氧氨氧化是不可行的[2]。

20世纪90年代,荷兰Gist Brocades公司的MULDER Arnold发现该公司的反硝化中试流化床装置中存在一个有趣的现象:在厌氧条件下,当污水中含有硝氮时,反应器中氨氮明显减少并伴有氮气的产出。该现象被命名为厌氧氨氧化(anaerobic ammonium oxidation)[3]。MULDER Arnold将此现象介绍给了荷兰代尔夫特理工大学的KUENEN Gijs教授。1995年,KUENEN Gijs的学生VAN DE GRAAF Astrid通过向基质中加入N15标记

${\rm{NH}}_4^{+} $ -N和N14${\rm{NO}}_2^{-} $ -N生产14-15N2,直接证明了厌氧氨氧化生物反应的存在[4]。同年,奈梅亨拉德伯德大学的JETTEN Mike S M加入KUENEN Gijs团队,他致力于厌氧氨氧化微生物代谢组学的研究,取得了丰硕成果。 -

KUENEN Gijs团队从1997年开始对anammox展开系统性的基础研究。首先,STROUS Marc利用序批式反应器将厌氧氨氧化菌纯化至70%以上,确定了anammox菌隶属于浮霉菌门(Planctomycete),将实验株命名为Candidatus Brocadia anammoxidans,并提出了厌氧氨氧化反应的化学计量式(式(2))[5-6]。由式(2)可看出,anammox菌的增殖系数非常低,消耗每摩尔

${\rm{NH}}_4^{+} $ 生产出的anammox生物质含有(0.066±0.01)mol碳,即anammox菌每消耗1 g N会生成0.0486 g anammox生物质[8],相当于0.164 g COD[7],其倍增时间更长达11 d[5-6]。随后,KUENEN Gijs团队与澳大利亚昆士兰大学FUERST John A团队合作,基于电子显微镜对厌氧氨氧化细胞结构的观察,发现其独特的隔膜结构,并将其命名为厌氧氨氧化体(Anammoxosome)[9]。STROUS Marc和JETTEN Mike S M对神秘的厌氧氨氧化菌进行了宏基因分析,确认了潜在的中间代谢产物羟氨(NH2OH)和肼(N2H4)及潜在的代谢路径[10]。基于宏基因分析结果,JETTEN Mike S M的学生DE ALMEIDA Naomi M进一步确定了关键的厌氧氨氧化酶在不同细胞结构中的位置,并提出厌氧氨氧化体是厌氧氨氧化生物反应的关键细胞结构[11]。

-

现有厌氧氨氧化菌的培养和富集技术有5种:1) KUENEN Gijs和JETTEN Mike S M团队利用序批式反应器富集絮状anammox污泥[5-6];2)荷兰代尔夫特理工大学VAN LOOSDRECHT Mark培育厌氧氨氧化菌时形成了厌氧氨氧化颗粒污泥[12];3)美国马里兰大学生物技术研究所SCHREIER Harold J团队利用移动床反应器形成厌氧氨氧化菌附着在移动床反应器(moving bed biofilm reactor,MBBR)载体上[13];4)日本熊本大学的古川憲治团队使用固定载体富集厌氧氨氧化菌[14];5)VAN LOOSDRECHT Mark团队通过膜生物反应器培养菌种时形成了厌氧氨氧化游离细胞悬浮液,并修正了厌氧氨氧化反应的化学计量式(即式(3))[15]。2010年,浙江大学郑平教授团队的唐崇俭(现就职于中南大学)利用升流式厌氧污泥床反应器(up-flow anaerobic sludge bed/blanket,UASB)富集出高污泥浓度厌氧氨氧化颗粒污泥,最大容积氮去除速率达到74.3~76.7 kg·(m3·d)−1[16]。郑平教授的另一个学生金仁村(现就职于杭州师范大学)对多种anammox抑制物(包括重金属、抗生素等)的作用进行了机理研究,为厌氧氨氧化反应应用于光伏行业、制药行业以及农牧业废水的处理提供了参考[17]。

式中:CH1.72O0.31N0.2为厌氧氨氧化菌生物质的化学式。

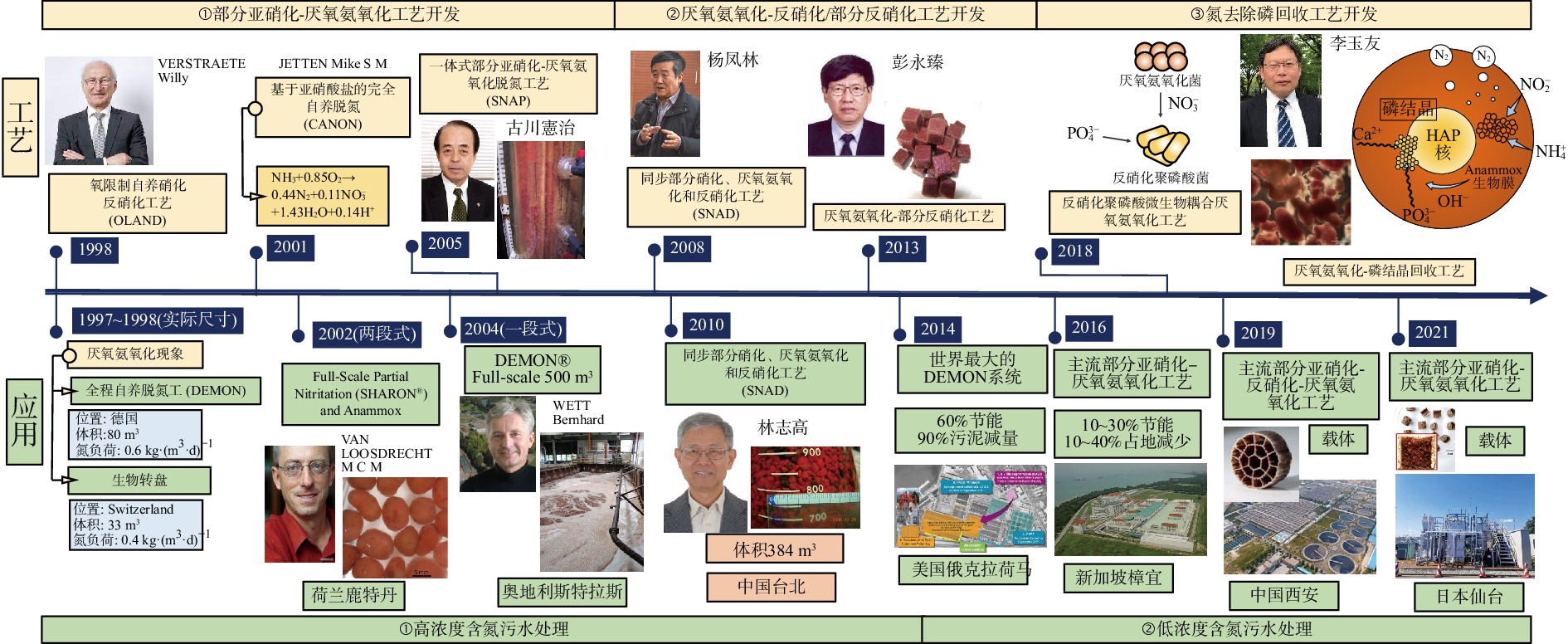

图1概述了厌氧氨氧化生物反应的发现、探索,以及厌氧氨氧化菌的富集技术研究,为该研究的初步阶段。

-

1)一段式工艺的演进。1998年,比利时根特大学的VERSTRAETE Willy团队采用序批式反应器率先提出氧限制型自养硝化反硝化工艺(oxygen-limited autotrophic nitrification-denitrification,OLAND) [18]。2001年,JETTEN Mike S M团队以氧气为限制条件控制部分亚硝化过程,利用序批式反应器提出了基于亚硝酸盐的完全自养脱氮CANON(Completely Autotrophic Nitrogen removal Over Nitrite)的一段式工艺。该工艺的反应式为式(4)[19]。

2005年,古川憲治团队使用固定床生物膜培养富集厌氧氨氧化菌,并提出一段式部分亚硝化-厌氧氨氧化脱氮工艺(single-stage nitrogen removal using anammox and partial nitritation,SNAP)[20]。由于厌氧氨氧化反应会产生硝氮,其比例达进水总氮的7.5%~11.2%,故需要进一步去除。2008年,大连理工大学杨凤林团队结合反硝化工艺提出了同步部分亚硝化、厌氧氨氧化和反硝化工艺(simultaneous partial nitrification, anammox and denitrification,SNAD),以去除剩余的硝氮[21]。

2)针对高浓度含氮污水的改进工艺。1997—1998年,德国的80 m3的全程自养脱氮(Deammonification,DEMON)工艺[22]和瑞士的33 m3生物转盘反应器在处理高浓度氨氮的垃圾渗滤液时均发生厌氧氨氧化反应[23]。2001—2006年,VAN LOOSDRECHT Mark及其同事与帕克公司合作,用两年时间在荷兰鹿特丹市启动了第1个两段式SHARON®-Anammox®脱氮示范工程,用以处理污泥消化回流液[12,24]。该工艺的前段SHARON(Single reactor system for High-rate Ammonium Removal Over Nitrite)是采用1 800 m3完全混合式的部分亚硝化工艺(partial nitrification,PN),而PN出水进入70 m3内循环(internal circulation,IC)厌氧反应器,并通过厌氧氨氧化颗粒污泥转化为氮气[12,25]。2004年,WETT Bernhard和HELL Martin在奥地利Strass污水处理厂采用500 m3序批式反应器用两年半时间成功启动一段式厌氧氨氧化悬浮污泥脱氮工艺(DEMON®)(反应式为式(5))[26]。该工艺基于硝化反应产H+原理,通过检测pH调节曝气实现部分亚硝化,并采用旋流分离器和微筛选择器截留污泥,以控制污泥停留时间、减少厌氧氨氧化菌流失[27]。

2010年,为进一步去除厌氧氨氧化反应产生的硝氮,台湾省交通大学林志高团队在台北市成功启动同步部分亚硝化、厌氧氨氧化和反硝化(SNAD)工艺(384 m3),用以处理垃圾渗滤液[28]。2014年,美国俄克拉荷马市蓝色平原污水处理厂建立全球最大的侧流全程自养脱氮工艺(DEMON®)。该污水处理厂的氮处理能力为11 800 kg·d−1,并且节省了60%的能耗、减少了90%的污泥[29]。

截止2014年,全球范围内采用厌氧氨氧化工艺建成的商用污水处理厂已超过100座,但这些污水处理厂主要用于处理高氨氮浓度的污水[30]。

3)针对低浓度含氮污水(市政污水)的改进工艺。2016年,新加坡公用事业局的曹业始及其同事在樟宜再生水厂的市政污水处理单元(处理量为20×104t·d−1)中实现了部分厌氧氨氧化工艺(处理贡献率>30%)[31]。该工艺较传统脱氮工艺降低了10%~30%能耗,减少了10%~40%池容[31]。2019年,北京工业大学彭永臻院士团队利用移动床生物膜反应器(MBBR)改造西安第四污水厂(处理量为25×104t·d−1),实现了部分厌氧氨氧化工艺(处理贡献率>16%)[32]。2021年,日本东北大学李玉友教授团队在市政污水处理厂的厌氧膜生物反应器出水后实现了中试规模一段式流动载体型的部分亚硝化-厌氧氨氧化工艺(处理贡献率>89%),并开发了中试规模一段式部分亚硝化-厌氧氨氧化-羟基磷酸钙型的脱氮磷回收工艺(partial nitritation/anammox-hydroxyapatite,PNA-HAP)[33–35]。

-

1)利用甲烷型反硝化耦合厌氧氨氧化工艺。2013年,澳大利亚昆士兰大学袁志国团队提出利用甲烷型反硝化耦合厌氧氨氧化的工艺[36]。该工艺中,厌氧甲烷氧化反硝化(denitrifying anaerobic methane oxidation,DAMO)菌可利用厌氧氨氧化反应产出的硝氮及发酵液中的溶解性甲烷,进而生成亚硝氮或者氮气(反应见式(6)和(7))。之后,亚硝氮还可继续被厌氧氨氧化菌利用。该工艺有3个优势:提高脱氮效率;去除厌氧出水中溶解性甲烷,防止温室气体甲烷释放至大气中;无需额外补充有机物就能去除硝氮。

2)部分反硝化耦合厌氧氨氧化工艺。2013年,北京工业大学彭永臻院士团队提出了部分反硝化(

${\rm{NO}}_3^{-} $ -${\rm{NO}}_2^{-} $ )耦合厌氧氨氧化的工艺[37]。部分反硝化(partial denitrification,PD)将厌氧氨氧化产生的硝氮(${\rm{NO}}_3^{-} $ )转化成亚硝氮(${\rm{NO}}_2^{-} $ )(反应式(8))被厌氧氨氧化菌利用,从而有效减少系统对有机物的需求[37]。更重要的是,由于在低浓度氨氮环境中,亚硝酸盐氧化菌更容易将亚硝氮氧化成硝氮,故制约了厌氧氨氧化技术应用。针对此问题,该团队将产生的硝氮通过部分反硝化菌还原成亚硝氮作为厌氧氨氧化的基质,为厌氧氨氧化在市政污水中的稳定运行提出了新思路[38]。3)同步脱氮回收磷型颗粒污泥工艺。2018年,李玉友团队利用膨胀颗粒污泥床(expanded granular sludge bed,EGSB),在厌氧氨氧化颗粒污泥的基础上耦合化学结晶法,实现了磷的回收(反应式为式(9))。该工艺中形成的新型anammox-HAP颗粒污泥外层为厌氧氨氧化生物膜,可实现脱氮,其内核为碱式磷酸钙结晶[39]。这种颗粒污泥的沉降速度可达到300 m·h−1,使得系统污泥流失率大大减小[40]。该工艺已发展出一段式和两段式2种类型,在温度为7~35 ℃、进水总氮浓度为200~1 500 mg·L−1条件下,已长期运行并高效地实现了氮的去除和磷的回收[41-42]。

式中:CH1.72O0.31N0.2为厌氧氨氧化菌生物质的化学式。

4)反硝化聚磷酸微生物耦合厌氧氨氧化工艺。2018年,阿里格尔穆斯林大学BASHEE Farrukh团队和北京工业大学彭永臻院士团队先后提出利用反硝化聚磷酸菌回收污水中磷的耦合厌氧氨氧化工艺。该工艺既可减少厌氧氨氧化产出硝氮,又能高效地实现磷的回收[43-44]。利用该工艺处理市政污水时,出水的平均TN为5.0 mg·L−1、平均

${\rm{NH}}_4^{+} $ -N为1.5 mg·L−1、平均TP为0.2 mg·L−1,氮去除率和磷去除率可分别达到90%和70%[43-44]。 -

如图2所示,历经多年的发展,厌氧氨氧化工艺开发已取得诸多新进展新突破,但是,在厌氧氨氧化的实际工程应用中仍存在菌种倍增时间长、亚硝氮来源受限、易发生抑制、运行不稳定等诸多问题。如何高效富集anammox细菌、快速启动反应器,以及如何优化调控

${\rm{NO}}_2^{-} $ /${\rm{NH}}_4^{+} $ 比和${\rm{NO}}_3^{-} $ ·生成以达到高效稳定的脱氮效果,实现anammox在含氮污水处理中的大规模工程应用和普及,需要开展以下2方面的研究:从理论上进一步阐明anammox菌的生理代谢特征,探讨相关微生物群落结构(生物膜和颗粒)和互利共生的调控机制;从技术上合理利用一段法和两段法,探索anammox菌高效持留、互利菌群种间高效协同等技术策略,提升该相关工艺控制和运营技术,提高最大处理能力和抗环境冲击能力,开发适用于不同类型污水的快速启动、稳定高效运行新技术。

厌氧氨氧化:理论和工艺发展概述(代序言)

An overview of theoretical and technological development of anammox

-

-

-

[1] BRODA E. Two kinds of lithotrophs missing in nature[J/OL]. Zeitschrift für allgemeine Mikrobiologie, 1977, 17(6): 491–493 [2021–08–09]. https://onlinelibrary.wiley.com/doi/full/10.1002/jobm.19770170611. [2] KUENEN J G. Anammox bacteria: From discovery to application [J/OL]. Nature Reviews Microbiology, 2008, 6(4): 320–326 [2019–02–22]. http://www.nature.com/articles/nrmicro1857. [3] MULDER A, VAN DE GRAAF A A, ROBERTSON L A, et al. Anaerobic ammonium oxidation discovered in a denitrifying fluidized bed reactor[J/OL]. FEMS Microbiology Ecology, 1995, 16(3): 177–183[2021–08–09]. https://academic.oup.com/femsec/article/16/3/177/523781. [4] VAN DE GRAAF A A, MULDER A, DE BRUIJN P, et al. Anaerobic oxidation of ammonium is a biologically mediated process[J]. Applied and Environmental Microbiology, 1995, 61(4): 1246-1251. doi: 10.1128/AEM.61.4.1246-1251.1995 [5] STROUS M, HEIJNEN J J, KUENEN J G, et al. The sequencing batch reactor as a powerful tool for the study of slowly growing anaerobic ammonium-oxidizing microorganisms[J/OL]. Applied Microbiology and Biotechnology 1998 50: 5, 1998, 50(5): 589–596[2021–08–10]. https://link.springer.com/article/10.1007/s002530051340. [6] STROUS M, FUERST J A, KRAMER E H M, et al. Missing lithotroph identified as new planctomycete[J/OL]. Nature, 1999, 400(6743): 446–449[2018–02–09]. http://www.nature.com/articles/22749. [7] NI B J, CHEN Y P, LIU S Y, et al. Modeling a granule-based anaerobic ammonium oxidizing (ANAMMOX) process[J]. Biotechnology and Bioengineering, 2009, 103(3): 490-499. doi: 10.1002/bit.22279 [8] ZHANG Y, MA H, CHEN R, et al. Stoichiometric variation and loading capacity of a high-loading anammox attached film expanded bed (AAEEB) reactor[J]. Bioresource Technology, 2018, 253: 130-140. doi: 10.1016/j.biortech.2018.01.043 [9] LINDSAY M R, WEBB R I, STROUS M, et al. Cell compartmentalisation in planctomycetes: Novel types of structural organisation for the bacterial cell[J]. Archives of Microbiology, 2001, 175(6): 413-429. doi: 10.1007/s002030100280 [10] STROUS M, PELLETIER E, MANGENOT S, et al. Deciphering the evolution and metabolism of an anammox bacterium from a community genome[J/OL]. Nature 2006 440: 7085, 2006, 440(7085): 790–794 [2021–08–10]. https://www.nature.com/articles/nature04647. [11] ALMEIDA N M de, NEUMANN S, MESMAN R J, et al. Immunogold Localization of Key Metabolic Enzymes in the Anammoxosome and on the Tubule-Like Structures of Kuenenia stuttgartiensis[J/OL]. Journal of Bacteriology, 2015, 197(14): 2432–2441[2021–11–05]. https://journals.asm.org/doi/abs/10.1128/JB.00186-15. [12] VAN DONGEN U, JETTEN M S M, VAN LOOSDRECHT M C M. The SHARON®-Anammox® process for treatment of ammonium rich wastewater[J]. Water Science and Technology, 2001, 44(1): 153-160. doi: 10.2166/WST.2001.0037 [13] TAL Y, WATTS J E M, SCHREIER S B, et al. Characterization of the microbial community and nitrogen transformation processes associated with moving bed bioreactors in a closed recirculated mariculture system[J]. Aquaculture, 2003, 215(1-4): 187-202. doi: 10.1016/S0044-8486(02)00372-1 [14] FUJII T, SUGINO H, ROUSE J D, et al. Characterization of the microbial community in an anaerobic ammonium-oxidizing biofilm cultured on a nonwoven biomass carrier[J]. Journal of Bioscience and Bioengineering, 2002, 94(5): 412-418. doi: 10.1016/S1389-1723(02)80218-3 [15] LOTTI T, KLEEREBEZEM R, LUBELLO C, et al. Physiological and kinetic characterization of a suspended cell anammox culture[J]. Water Research, 2014, 60: 1-14. doi: 10.1016/j.watres.2014.04.017 [16] TANG C J, ZHENG P, WANG C H, et al. Performance of high-loaded ANAMMOX UASB reactors containing granular sludge[J]. Water Research, 2011, 45(1): 135-144. doi: 10.1016/j.watres.2010.08.018 [17] JIN R C, YANG G F, YU J J, et al. The inhibition of the Anammox process: A review[Z/OL]. Elsevier, 2012: 67–79(2012–07–15)[2019–05–19]. https://www.sciencedirect.com/science/article/pii/S1385894712005864. [18] KUAI L, VERSTRAETE W. Ammonium removal by the oxygen-limited autotrophic nitrification- denitrification system[J/OL]. Applied and Environmental Microbiology, 1998, 64(11): 4500–4506 [2021–11–05]. https://journals.asm.org/doi/abs/10.1128/AEM.64.11.4500-4506.1998. [19] SLIEKERS A O, DERWORT N, GOMEZ J L C, et al. Completely autotrophic nitrogen removal over nitrite in one single reactor[J]. Water Research, 2002, 36(10): 2475-2482. doi: 10.1016/S0043-1354(01)00476-6 [20] LIEU P K, HATOZAKI R, HOMAN H, et al. Single-Stage Nitrogen Removal Using Anammox and Partial Nitritation (SNAP) for Treatment of Synthetic Landfill Leachate[J]. Japanese Journal of Water Treatment Biology, 2005, 41(2): 103-112. doi: 10.2521/JSWTB.41.103 [21] CHEN H, LIU S, YANG F, et al. The development of simultaneous partial nitrification, ANAMMOX and denitrification (SNAD) process in a single reactor for nitrogen removal[J]. Bioresource Technology, 2009, 100(4): 1548-1554. doi: 10.1016/j.biortech.2008.09.003 [22] HIPPEN A, ROSENWINKEL K H, BAUMGARTEN G, et al. Aerobic deammonification: A new experience in the treatment of waste waters[J]. Water Science and Technology, 1997, 35(10): 111-120. doi: 10.1016/S0273-1223(97)00211-4 [23] SIEGRIST H, REITHAAR S, LAIS P. Nitrogen loss in a nitrifying rotating contactor treating ammonium rich leachate without organic carbon[J]. Water Science and Technology, 1998, 37(4-5): 589-591. doi: 10.1016/S0273-1223(98)00164-4 [24] MULDER J W, VAN LOOSDRECHT M C M, HELLINGA C, et al. Full-scale application of the SHARON process for treatment of rejection water of digested sludge dewatering[J]. Water Science and Technology, 2001, 43(11): 127-134. doi: 10.2166/WST.2001.0675 [25] VAN DER STAR W R L, ABMA W R, BLOMMERS D, et al. Startup of reactors for anoxic ammonium oxidation: Experiences from the first full-scale anammox reactor in Rotterdam[J]. Water Research, 2007, 41(18): 4149-4163. doi: 10.1016/j.watres.2007.03.044 [26] FIGDORE BRYCE, NEETHLING J B, STENSEL D. Deammonification [EB/OL](2019)[2022–01–03]. https://www.waterrf.org/sites/default/files/file/2021-07/Deammonification.pdf. [27] WETT B. Solved upscaling problems for implementing deammonification of rejection water[J]. Water Science and Technology, 2006, 53(12): 121-128. doi: 10.2166/WST.2006.413 [28] WANG C C, LEE P H, KUMAR M, et al. Simultaneous partial nitrification, anaerobic ammonium oxidation and denitrification (SNAD) in a full-scale landfill-leachate treatment plant[J/OL]. Journal of Hazardous Materials, 2010, 175(1–3): 622–628[2019–01–24]. https://www.sciencedirect.com/science/article/pii/S0304389409017038. [29] DC Water to house world’s largest deammonification system for advanced nitrogen removal | WaterWorld [EB/OL][2021–11–06]. https://www.waterworld.com/technologies/article/16215013/dc-water-to-house-worlds-largest-deammonification-system-for-advanced-nitrogen-removal. [30] LACKNER S, GILBERT E M, VLAEMINCK S E, et al. Full-scale partial nitritation/anammox experiences - An application survey[J]. Water Research, 2014, 55: 292-303. doi: 10.1016/j.watres.2014.02.032 [31] YESHI C, HONG K B, VAN LOOSDRECHT M C M, et al. Mainstream partial nitritation and anammox in a 200, 000 m3/day activated sludge process in Singapore: scale-down by using laboratory fed-batch reactor[J]. Water Science and Technology, 2016, 74(1): 48-56. doi: 10.2166/WST.2016.116 [32] LI J, PENG Y, ZHANG L, et al. Quantify the contribution of anammox for enhanced nitrogen removal through metagenomic analysis and mass balance in an anoxic moving bed biofilm reactor[J/OL]. Water Research, 2019, 160: 178–187[2019–06–24].https://www.sciencedirect.com/science/article/pii/S0043135419304580. DOI:10.1016/j.watres.2019.05.070. [33] RONG C, LUO Z, WANG T, et al. Chemical oxygen demand and nitrogen transformation in a large pilot-scale plant with a combined submerged anaerobic membrane bioreactor and one-stage partial nitritation-anammox for treating mainstream wastewater at 25 °C[J]. Bioresource Technology, 2021, 341: 125840. doi: 10.1016/j.biortech.2021.125840 [34] WU J, KONG Z, LUO Z, et al. A successful start-up of an anaerobic membrane bioreactor (AnMBR) coupled mainstream partial nitritation-anammox (PN/A) system: A pilot-scale study on in-situ NOB elimination, AnAOB growth kinetics, and mainstream treatment performance[J]. Water Research, 2021, 207: 117783. doi: 10.1016/J.WATRES.2021.117783 [35] GUO Y, LUO Z, RONG C, et al. The first pilot-scale demonstration of the partial nitritation/anammox-hydroxyapatite process to treat the effluent of the anaerobic membrane bioreactor fed with the actual municipal wastewater[J]. Science of The Total Environment, 2022, 807: 151063. doi: 10.1016/J.SCITOTENV.2021.151063 [36] SHI Y, HU S, LOU J, et al. Nitrogen removal from wastewater by coupling anammox and methane-dependent denitrification in a membrane biofilm reactor[J/OL]. Environmental Science and Technology, 2013, 47(20): 11577–11583[2021–11–16]. https://pubs.acs.org/doi/full/10.1021/es402775z. [37] CAO S, WANG S, PENG Y, et al. Achieving partial denitrification with sludge fermentation liquid as carbon source: The effect of seeding sludge[J]. Bioresource Technology, 2013, 149: 570-574. doi: 10.1016/j.biortech.2013.09.072 [38] MA B, QIAN W, YUAN C, et al. Achieving Mainstream Nitrogen Removal through Coupling Anammox with Denitratation[J/OL]. Environmental Science and Technology, 2017, 51(15): 8405–8413 [2021–11–16]. https://pubs.acs.org/doi/full/10.1021/acs.est.7b01866. [39] MA H, ZHANG Y, XUE Y, et al. A new process for simultaneous nitrogen removal and phosphorus recovery using an anammox expanded bed reactor[J/OL]. Bioresource Technology, 2018, 267: 201–208 [2018–07–25]. https://www.sciencedirect.com/science/article/pii/S0960852418309416#f0010. [40] XUE Y, MA H, KONG Z, et al. Bulking and floatation of the anammox-HAP granule caused by low phosphate concentration in the anammox reactor of expanded granular sludge bed (EGSB)[J/OL]. Bioresource Technology, 2020, 310: 123421 [2020–05–01]. https://linkinghub.elsevier.com/retrieve/pii/S0960852420306933. [41] MA H, XUE Y, ZHANG Y, et al. Simultaneous nitrogen removal and phosphorus recovery using an anammox expanded reactor operated at 25 °C[J/OL]. Water Research, 2020, 172: 115510[2020–02–18]. https://linkinghub.elsevier.com/retrieve/pii/S0043135420300464. [42] GUO Y, LI Y Y. Hydroxyapatite crystallization-based phosphorus recovery coupling with the nitrogen removal through partial nitritation/anammox in a single reactor[J]. Water Research, 2020, 187: 116444. doi: 10.1016/j.watres.2020.116444 [43] SENGAR A, AZIZ A, FAROOQI I H, et al. Development of denitrifying phosphate accumulating and anammox micro-organisms in anaerobic hybrid reactor for removal of nutrients from low strength domestic sewage[J]. Bioresource Technology, 2018, 267: 149-157. doi: 10.1016/J.BIORTECH.2018.07.023 [44] ZHAO J, WANG X, LI X, et al. Advanced nutrient removal from ammonia and domestic wastewaters by a novel process based on simultaneous partial nitrification-anammox and modified denitrifying phosphorus removal[J]. Chemical Engineering Journal, 2018, 354: 589-598. doi: 10.1016/j.cej.2018.07.211 -

下载:

下载: