-

厌氧发酵技术是目前有机固体废弃物资源化利用最为常用的处理工艺,其中,干法厌氧发酵工艺因具有原料利用范围广、占地小、池容产气率高以及无沼液产生等优点[1],在国内外农业废弃物处置、餐厨垃圾处理等领域得到了广泛应用[2]。目前,我国已开展大量关于玉米、水稻等秸秆干法厌氧发酵小试实验研究,并在黑龙江、上海、江苏等地实现了工程应用[3]。除预处理、物料配比、温度、停留时间等主要控制参数外,搅拌也会对厌氧发酵效率产生重要影响[4]。沼气工程运行过程中搅拌工艺的选择十分重要,适当的搅拌可促进传质传热、提高有机物的降解转化效率以及沼气逸出,同时也是直接影响工程产气效率和优化能源产出消耗的重要手段之一[5]。

干法厌氧发酵工程中常用的搅拌方式有机械搅拌、气动搅拌和水力搅拌,因各具优缺点,故这几种搅拌方式适用的领域不尽相同。针对搅拌对干法厌氧发酵过程的影响,RICO等[6]进行了水力搅拌下牛粪厌氧发酵的中试实验,结果表明,在较长的水力停留时间下,水力搅拌对反应器几乎不产生影响;LATHA等[7]研究了不同搅拌方式对餐厨垃圾与污泥共发酵的性能影响,结果表明,沼气搅拌方式下的产气量较机械搅拌上升了31%;NANDI等[8]研究了机械搅拌对牛粪厌氧发酵的影响,发现与不搅拌的反应器相比,沼气产量和甲烷体积分数仅提高了2%和3%。搅拌方式对厌氧发酵效率影响受制于不同类型底物、反应器性能、运行条件等[9]。目前大多数研究集中于对餐厨垃圾、畜禽粪便等匀质度高的物料,但关于搅拌对秸秆类废弃物为主的发酵物料影响研究却鲜有报道。秸秆类农业废弃物密度小、流动性差,厌氧发酵过程中会造成物料分层和表面结垢等现象[10],且传统发酵罐内存在“死角”,易使局部区域中间代谢产物过度积累,降低发酵效率[11]。因此,有必要探索如何通过优化搅拌方式来克服上述问题。

考虑到搅拌方式的改进优化对提高秸秆类农业废弃物干法厌氧发酵效率具有的直接影响,本研究基于长三角地区开展的稻秸干法厌氧发酵的最佳工艺参数 [12-13],并借鉴常见的横卧推流式中试厌氧反应器,通过改进框型叶片机械搅拌及增加前后端气动搅拌组件,设置机械搅拌、全程气动搅拌和前端气动搅拌3种搅拌方式,考察连续进出料条件下单一搅拌方式对稻秸干法厌氧发酵产气规律、底物降解特性及系统稳定性的影响,并据此进一步优化搅拌组合工艺,综合考察发酵效率和能源消耗情况,以期为稻秸轻质纤维类农业废弃物干法厌氧发酵工程中的搅拌方式改进提供技术参考。

-

以水稻秸秆作为主发酵原料,于2020年10月在上海市练塘镇双菱村(30°58′38″N,121°1′39″E)一次性采收后,运至平铺1.2 mm厚的HDPE防渗膜的存放区,将稻秸破碎至长度≤5 cm后,边堆垛压实边喷洒氢氧化钠溶液(氢氧化钠用量约为10 g·kg−1),调节含水率为35%后进行黄贮预处理[14]。堆垛高度控制在4 m左右,单垛占地面积在20 m2左右,堆垛用PE防水雨布密闭覆盖、四周沙袋垫高压实,存放时间不少于60 d,以确保黄贮预处理效果。氮源选用新鲜猪粪,分多次取自上海松江区新浜镇某家庭农场。在中试装置启动阶段,接种物取自位于上海市青浦现代农业园区农业废弃物处理中心(30°58′4″N,121°1′33″E)干法厌氧发酵固液分离后的新鲜沼液。实验材料物理化学性质如表1所示。

-

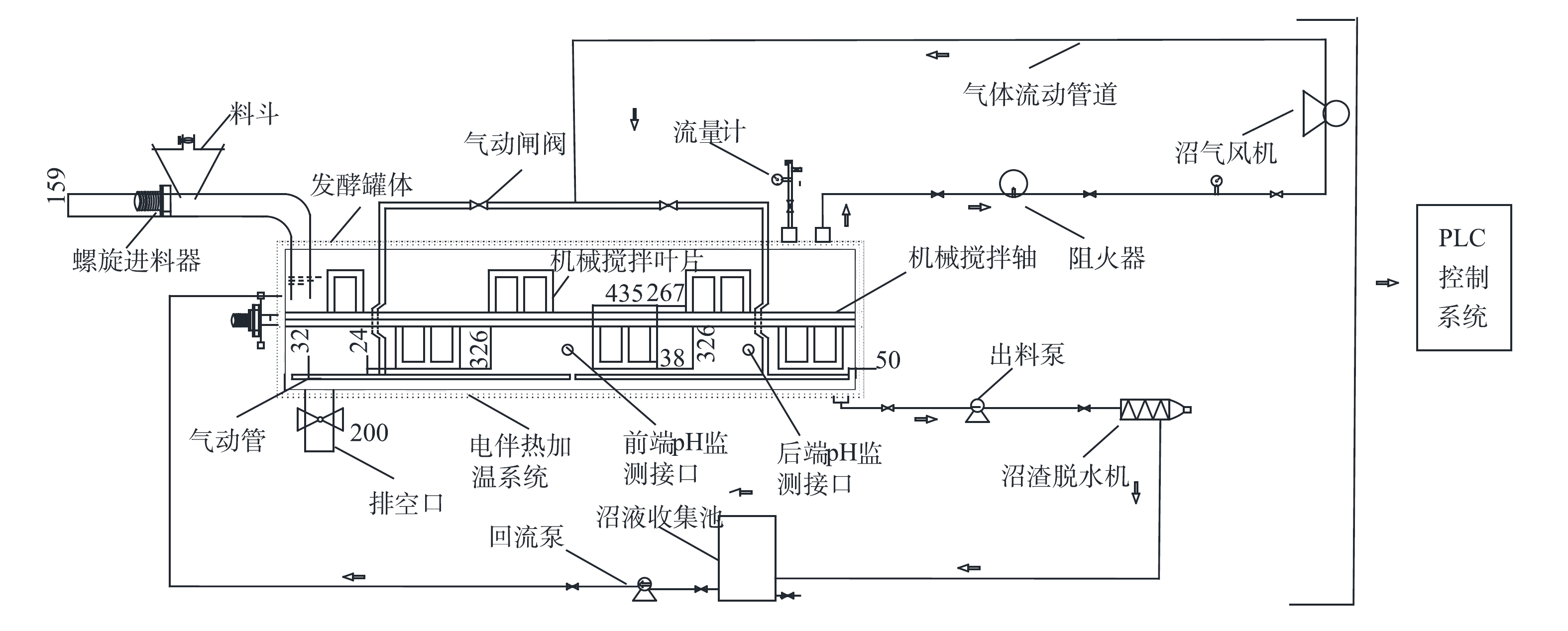

本研究采用横卧推流式中试装置,结构如图1所示。该装置长4 m、高1 m,罐体容积3.14 m3,最大日处理能力15 kg·d−1(停留时间为30~40 d),由进出料组件、机械和气动搅拌组件、电伴热控温组件、沼渣脱水机等系统组成,并配置有pH在线监测仪(型号U-PH6-ZXCN2,深圳伊斯达仪表有限公司)、温度在线监测仪、气体流量监测仪(型号LWQ-40A/S/A,江苏华成自动化仪表有限公司),以及上位机控制系统,可对沼气日产量、物料pH和温度进行实时监测。其中,进料系统设置在罐体前端顶部,处理量为5 kg·h−1,通过螺旋进料器将物料送至发酵罐液面以下,料斗高1.2 m,料斗下方与进料螺旋外径焊接相连。出料系统包括出料器和沼渣脱水机,出料沼渣由出料器输送至沼渣脱水机内,将其含固率(TS)由10%~15%脱水至40%后进行好氧堆肥处理;液体部分通过回流泵全部送至发酵罐前端,通过定期投加TS<3%的稀释鲜猪粪,控制发酵体系TS为10%左右。

-

每个中试实验周期设置为3个阶段,分别为启动调试阶段(阶段Ⅰ)、稳定运行单一搅拌阶段(阶段Ⅱ)和稳定运行组合搅拌阶段(阶段Ⅲ)。其中,阶段Ⅰ运行期间,按照4∶1(TS∶TS)的比例在发酵罐中一次性投入黄贮后的稻秸(200 kg)和鲜猪粪(45 kg),调节TS至10%±1%,接种20%的沼液,设置发酵温度为(35±5) ℃,待产气基本结束后,以5 kg·d−1(TS)的运行负荷连续运行至稳定产气后启动阶段Ⅱ。阶段Ⅱ运行期间,探索机械搅拌(阶段Ⅱ.1)、全程气动搅拌(阶段Ⅱ.2)和前端气动搅拌(阶段Ⅱ.3)等3种单一搅拌方式下的产沼规律及系统稳定性。基于阶段Ⅱ的运行结果,通过设置不同机械搅拌和前端气动搅拌优化组合模式,进一步优化搅拌频次(阶段Ⅲ.1、Ⅲ.2和Ⅲ.3),开展阶段Ⅲ的中试实验,综合考察优化组合搅拌方式下的稻秸发酵效率和能源消耗情况。

根据稻秸干法厌氧发酵产气特征和传质要求,设定阶段Ⅰ实验周期为50~60 d,阶段Ⅱ和阶段Ⅲ每种搅拌方式以40 d为1个观测期,机械搅拌转速设为1.5 r·min−1,全程气动搅拌流量为2.37~3.16 m3·s−1,前端气动搅拌流量为4.74~6.32 m3·s−1。

-

TS在(105±5) ℃烘箱中烘干至恒重测定;挥发性固体(VS)则在550~600 ℃马弗炉中灼烧至恒重测定;纤维素、半纤维素质量分数采用酸碱醇醚-分光光度法进行测定[15];总碳(C)和总氮(N)分别采用重铬酸钾-稀释热法和半微量开氏法进行测定[16];甲烷体积分数使用便携式甲烷测定仪(型号GDWC-600,深圳市万安迪科技有限公司)测定,并用NY/T 1700-2009《沼气中甲烷和二氧化碳的测定 气相色谱法》标准方法验证[17];乙酸、丙酸以及其他挥发性有机酸(VFAs)采用气相色谱(型号Agilent-7809B,杭州瑞析科技有限公司)进行测定。

-

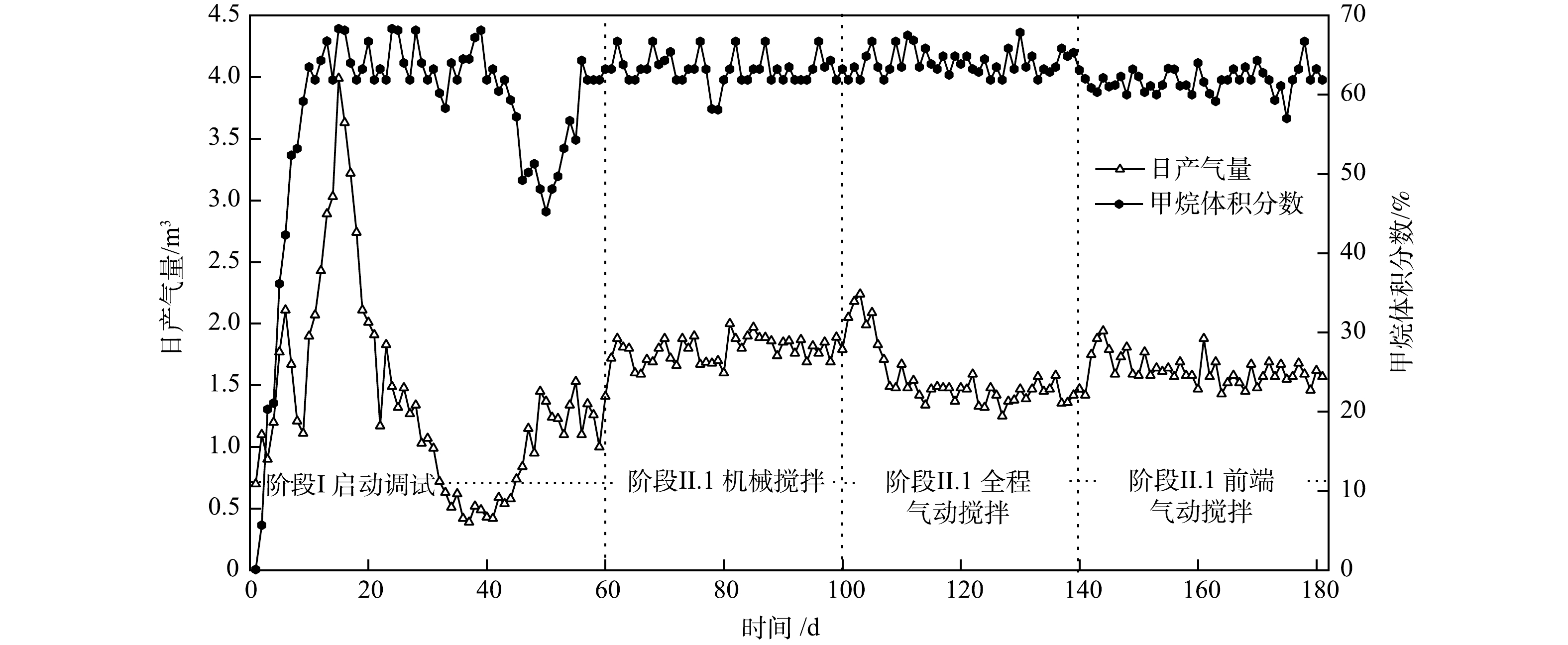

1)沼气产量和甲烷体积分数变化特征分析。在启动阶段和稳定运行阶段,不同搅拌方式下稻秸干法厌氧发酵的沼气日产量变化及甲烷体积分数如图2所示。在前40 d的启动调试期内,总产气量达到了61.4 m3,单位VS产气率为364.2 L·kg−1;从第10 d起,甲烷体积分数可持续达到60%以上,当产气几乎停止时,可认为反应器内已具有适宜厌氧微生物生长的环境[18]。在以5 kg·d−1(TS)的运行负荷连续进出料模式下,待产气稳定后(60 d),正式开启不同搅拌方式下的连续式实验。搅拌方式对沼气总产量有一定影响,不同搅拌方式下的总产气量呈现出“Ⅱ.1>Ⅱ.3>Ⅱ.2”的规律,40 d产气量分别为75.5、66.5和61.9 m3,单位VS产气量分别为441.9、389.3和362.3 L· kg−1,甲烷体积分数均稳定在60%以上,与杨立等[19]报道的“秸秆单位VS产气潜力为342.5 L· kg−1 以上”基本一致。

阶段Ⅱ.1,在机械搅拌模式下,运行初期日产气量稳定到1.8 m3·d−1并保持在同一水平至机械搅拌运行阶段结束。在进入阶段Ⅱ.2后,单日产气连续5 d处于高位值,最高可达2.2 m3·d−1,较Ⅱ.1高了22%,这主要是由于沉积于罐底的物料“死角”被扰动,提高了罐体的有效容积,致使产气量上升。而后,产气于第5 d后开始缓慢下降,稳定在1.5 m3·d−1,与Ⅱ.1相比降低了16%,但甲烷体积分数达到了64.80%,高于Ⅱ.1的62.68%。这可能是因为,二氧化碳在水中的溶解度是甲烷的40倍,沼气循环曝气增大了发酵液中的二氧化碳体积分数,进而促进了甲烷的产生[20]。在阶段Ⅱ.3运行初期,日产气变化亦表现出了相似的上升趋势,运行中后期日产气量下降并稳定至1.7 m3·d−1左右,与Ⅱ.3相比增加了13%。这可能是因为,Ⅱ.3中前端气动搅拌的强度约为Ⅱ.2全程气动搅拌强度的2倍,新鲜物料剧烈搅动加速了水解酸化进程[21]。

KARIM等[22]提出了不同的研究结论,认为在TS为10%的牛粪厌氧发酵系统中,气动搅拌的产气效果优于机械搅拌。造成两者差异的主要原因可能是,厌氧发酵底物性质不同,畜禽粪便等反应基质在反应器内能够均匀分布,而以稻秸为主原料的厌氧反应器中,物料分层形成结壳层、清液层和沉渣层3层[23]。气动搅拌通过防爆鼓风机将产生的沼气分散成气泡压回反应器内,气泡上升过程中增大了气-液-固三相的接触面积,但这种径向的搅拌作用不利于打破物料的分层。相较于气动搅拌,Ⅱ.1机械搅拌通过改进型框型叶片的转动可有效翻动上层物料到下层与发酵液充分接触,从而提高传热传质效率。

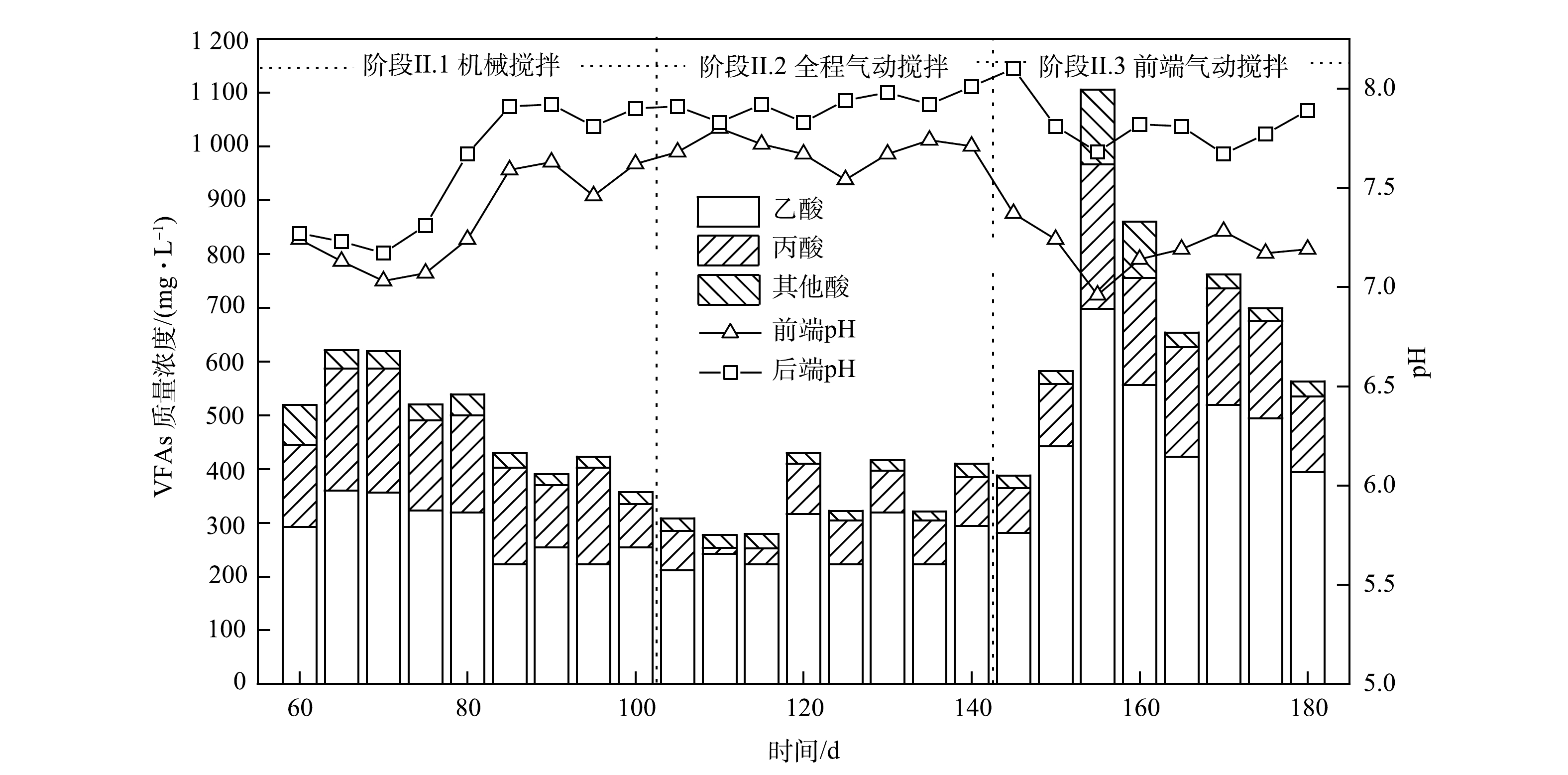

2)物料pH和VFAs变化特征分析。pH和VFAs可作为厌氧发酵过程中的重要指标,可反映系统运行的稳定性[24]。本研究对阶段Ⅱ中不同搅拌方式下稻秸厌氧发酵系统中pH和VFAs变化情况做了连续监测,结果见图3。在运行阶段Ⅱ.1和Ⅱ.2中,乙酸的质量浓度分别为254~360和223~319 mg·L−1,略高于BJORNSSON等[25]的研究结果。这是由于,厌氧发酵系统运行过程中碳氮比高于最佳范围(20~30)。但在Ⅱ.1和Ⅱ.2运行过程中,并未观察到VFAs的累积,这说明,厌氧发酵过程的中间产物VFAs降解较为完全,发酵系统运行稳定。阶段Ⅱ.3运行前期VFAs逐渐累积并于第10 d累积至最高值1 106 mg·L−1,但之后5 d迅速降低并维持在700 mg·L−1左右。这与PATINVOH等[26]的研究结果类似,可认为VFAs累积后快速消耗同样可作为系统稳定和正常运行的依据。

由图3可看出,VFAs高峰期时系统pH通常为发酵过程中最低值,但pH 波动范围较小,机械搅拌、全程气动搅拌和前端气动搅拌组的发酵罐前后端pH值基本处于6.6与7.8之间,均在厌氧发酵系统的适宜范围(6.0~8.5)内[27]。这可能是因为猪粪起到了一定的缓冲作用[28]。此外,阶段Ⅱ.1和Ⅱ.2中前后端pH较为接近,而阶段Ⅱ.3运行过程中,前后两端pH有明显的差距。这是因为,发酵罐前端多为新鲜物料,水解产酸程度提高,形成了前端低后端高的pH梯度,更利于产酸菌和产甲烷菌的分段生长繁殖[29]。

3)有机组分降解特征分析。不同搅拌方式下的有机组分降解效率见表2。经过40 d的厌氧发酵,运行阶段Ⅱ.1、Ⅱ.2和Ⅱ.3中的VS降解率分别为37.3%、30.6%和32.7%。可见,与气动搅拌相比,机械搅拌能够明显提高稻秸厌氧发酵系统中VS的降解率。这表明机械搅拌传质效果优于气动搅拌[30]。阶段Ⅱ.1、Ⅱ.2和Ⅱ.3运行所产生的沼渣中纤维素和半纤维素质量分数明显降低,可达12.7%~14.7%和10.1%~14.1%。这说明,厌氧发酵后的物料中易降解部分被分解,沼渣的生物稳定性较高,可作为良好的肥料制备原料[31]。厌氧发酵后Ⅱ.1、Ⅱ.2和Ⅱ.3的沼渣中总养分(N、P2O5和K2O)质量分数分别为3.5%、3.2%和3.5%,而根据NY/T 525-2021《有机肥料》[16],总养分的质量分数要达到≥4%,因此,作为秸秆沼渣有机肥料的主要限制标准,搅拌方式对沼渣肥料的影响可忽略不计。

-

基于阶段Ⅱ的单一搅拌方式下稻秸干法厌氧发酵的产气规律和有机组分降解情况,为进一步探索搅拌方式优化对提高发酵效率的影响,本研究探索了机械搅拌和前端气动搅拌2种组合模式下系统运行效果(阶段Ⅲ),搅拌方式对应的发酵效率如表3所示。实验结果显示,与单一机械搅拌模式相比,3种组合搅拌方式下稻秸干法厌氧发酵40 d总产气量相近,但甲烷体积分数均有所升高。其中,阶段Ⅲ.1中单位VS产气量和有机组分降解率均最高,单位VS产气量达到了447.2 L·kg−1,纤维素和半纤维素降解率分别可达14.9%和15.1%,产气效率比Ⅲ.2和Ⅲ.3高了2.3%和6.1%。综上可知,在优化组合搅拌模式下,机械搅拌对提高沼气生成和有机物水解的贡献大于气动搅拌。这可能是因为,在以稻秸为主的干法厌氧发酵系统内,机械搅拌的传质效果优于气动搅拌,但前端气动可弥补单一机械搅拌方式下发酵罐内存在的“死角”问题;同时,这种组合搅拌方式有利于两段式厌氧发酵系统的形成,最大限度地发挥了搅拌的作用。因此,从厌氧发酵效率来看,以机械搅拌为主、前端气动搅拌为辅的组合搅拌工艺效果较好。

-

根据中试运行过程中的产气效率和能源损耗测算,不同搅拌方式下年产气量及运行耗能如表4所示。在阶段Ⅲ中,3种组合搅拌的方式运行耗能均高于Ⅱ.1机械搅拌,其可节省能源9%~20%。其中,在Ⅲ.3运行过程中搅拌耗能所占总能耗的比例最低,仅为31%;与KARIYAMA等[32]报道的大中型沼气工程中搅拌耗能占比可达29%~54%相比,本研究的能耗较低。根据MAO等[33]和KIM等[34]的研究,充足的搅拌可为微生物提供均质的生长环境,但优化搅拌不仅要提高沼气产量,更要考虑能源利用效率。因此,综合考虑产气效率和能源消耗,以气动搅拌为主、机械搅拌为辅的组合搅拌模式可作为工程运行上的首选搅拌方式。

-

1)在单一搅拌工艺条件下,稻秸干法厌氧发酵40 d总产气量大小排序为:机械搅拌>前端气动搅拌>全程气动搅拌。这说明,机械搅拌通过改进型框型叶片的转动更能够有效翻动物料促进与发酵液的充分接触。

2)在机械搅拌和前端气动搅拌组合优化模式下,“机械搅拌(每天4次)+前端气动搅拌(每天4次)”组合搅拌方式的厌氧发酵效率最高,单位VS产气量达447.2 L·kg−1,纤维素和半纤维素降解率分别可达14.9%和15.1%。

3)3种“机械+气动”组合搅拌模式耗能均低于单一机械搅拌模式,尤其是“机械搅拌(每天2次)+前端气动搅拌(每天4次)”的组合搅拌方式能耗仅为单一机械搅拌方式能耗的约40%。这说明,以前端气动搅拌为主、机械搅拌为辅的组合模式在能源节省方面具有优势。

中试条件下稻秸干法厌氧发酵搅拌方式的优化

Optimization of stirring methods for rice straw dry anaerobic digestion under pilot test

-

摘要: 针对秸秆类农业废弃物干法厌氧发酵过程中易产生物料分层、表面结垢以及存在“死角”等问题,通过改进横卧推流式中试厌氧反应器搅拌工艺,探索了连续运行条件下机械搅拌、前端气动搅拌和全程气动搅拌等3种单一搅拌方式对稻秸干法厌氧发酵产气规律、底物降解特性及系统稳定性的影响,并通过进一步设置不同的搅拌频次优化了机械搅拌和前端气动搅拌组合工艺,综合考察了发酵效率和能源消耗情况。结果表明,在单一搅拌工艺条件下,稻秸干法厌氧发酵40 d总产气量呈现出“机械搅拌>前端气动搅拌>全程气动搅拌”的规律,分别为75.5、66.5和61.9 m3,对应的单位VS产气量分别为441.9、389.3和362.3 L·kg−1,这说明采用改进型框型叶片的机械搅拌可有效翻动物料,以促进其与发酵液的充分接触。在进一步优化“机械+前端气动”的组合搅拌工艺后发现,稻秸40 d产气量与单一机械搅拌模式较为接近,尤其是“机械搅拌(每天4次)+前端气动搅拌(每天4次)”的组合搅拌方式,单位VS产气量高达447.2 L·kg −1,纤维素和半纤维素降解率分别可达14.9%和15.1%;但从能源损耗角度来看,“机械搅拌(每天2次)+前端气动搅拌(每天4次)”的组合搅拌方式中能耗最低,仅为单一机械搅拌方式能耗的约40%。在稻秸干法厌氧发酵工程实际运行过程中,可根据厌氧发酵效率和能耗节省需求,因地制宜地选择合适的组合搅拌工艺。本研究结果可为木质纤维素类废弃物干法厌氧发酵工程中的搅拌方式改进提供参考。Abstract: To solve the problems of stratification, surface scaling and “dead corners” of lignocellulosic wastes during the dry anaerobic digestion process, the stirring device was improved and the continuous operation was conducted on a horizontal push-flow pilot reactor in this study. Through setting three different stirring methods such as mechanical stirring, front-end pneumatic stirring and whole-process pneumatic stirring, the characteristics of gas production and substrate degradation were explored. The combined process of mechanical stirring and front-end pneumatic stirring was optimized, and the fermentation efficiency and energy consumption were comprehensively investigated. Results showed that the total biogas production of rice straw anaerobic fermentation for 40 days under different stirring methods showed the rule of impeller stirring> front pneumatic stirring> full pneumatic stirring. The yield was 75.5、66.5 and 61.9 m3 and the corresponding unit volatile solids biogas production volume was 441.9、389.3 and 362.3 L·kg−1, respectively. It indicated that impeller stirring with improved frame-shaped blades can effectively stir materials and make that contact with the fermentation broth fully. After further optimizing the stirring time of the mechanical and front pneumatic combined-stirring, the biogas production of rice straw anaerobic fermentation for 40 days under these stirring methods was near to the single-stirring. Especially the combined stirring method of mechanical stirring (4 times every day) and front-end pneumatic stirring (4 times every day), the gas production volume of unit volatile solid was 447.2 L·kg−1, cellulose and the degradation rate of hemicellulose could reach 14.88% and 15.06%. However, as far as concerning energy consumption, the combined stirring method of mechanical stirring (2 times every day) and front-end pneumatic stirring (4 times every day) had the lowest energy consumption, which was only 40% of the energy consumption of a single mechanical stirring method. Therefore, during the actual operation of the rice straw dry anaerobic fermentation project, a suitable combined-stirring method could be selected according to the anaerobic fermentation biogas efficiency and energy-saving requirements. The above results can provide a reference for the improvement of stirring methods in lignocellulosic wastes dry anaerobic digestion.

-

Key words:

- rice straw /

- dry anaerobic digestion /

- pilot test /

- mechanical stirring /

- pneumatic stirring /

- fermentation efficiency

-

表 1 供试材料理化性质

Table 1. Physical and chemical properties of raw materials

供试材料 总固体质量分数/% 挥发性固体质量分数/% 纤维素质量分数/% 半纤维素质量分数/% pH C/N 水稻秸秆 90.5 87.6 37.5 22.0 − 64 猪粪 22.7 86.6 − − 8.1 9 沼液 4.0 86.0 − − 7.2 − 表 2 不同搅拌方式下的有机组分去除效率

Table 2. Removal efficiency of organic components under different stirring methods

运行阶段 VS去除率/% 纤维素降解率/% 半纤维素降解率/% Ⅱ.1 37.3±2.1 14.7±1.1 14.1±1.2 Ⅱ.2 30.6±2.1 12.9±0.6 10.3±0.9 Ⅱ.3 32.5±3.1 12.7±0.8 13.1±0.8 表 3 组合搅拌方式下的产气效率及有机组分降解效率

Table 3. Gas production efficiency and organic component degradation efficiency under combined stirring methods

运行阶段 产气情况 有机组分降解情况 单位VS产气量/(L·kg−1) 甲烷体积分数/% 总产气量/m3 VS去除率/% 纤维素降解率/% 半纤维素降解率/% Ⅲ.1 447.2 63.7±3.7 76.4 41.4±1.2 14.9±0.9 15.1±1.6 Ⅲ.2 437.3 63.8±1.2 74.7 38.2±1.9 13.7±1.5 15.3±1.3 Ⅲ.3 421.5 64.5±1.8 72.0 35.3±1.4 12.3±1.3 15.9±2.1 表 4 不同搅拌工艺条件下年耗能对比测算

Table 4. Comparison and estimation table of annual energy consumption under different stirring methods

运行阶段 运行耗能/ kwh 搅拌耗能/kwh 搅拌耗能占比/% Ⅱ.1 6570 3351 51 Ⅲ.1 5475 2311 42 Ⅲ.2 4927 1825 37 Ⅲ.3 4380 1388 31 注:搅拌能耗占比指搅拌能耗占中试装置运行过程中总耗能的比例。 -

[1] SUN M X, XU X B, WANG C D, et al. Environmental burdens of the comprehensive utilization of straw: Wheat straw utilization from a life-cycle perspective[J]. Journal of Cleaner Production, 2020, 259: 120702. doi: 10.1016/j.jclepro.2020.120702 [2] 李欣, 周知戬, 谭祎琦. 农业废弃物资源化利用现状及对策分析——以秸秆、稻壳、畜禽粪便为例[J]. 现代农业研究, 2020, 26(5): 125-126. doi: 10.3969/j.issn.1674-0653.2020.05.055 [3] 李冰峰, 张大雷. 干式厌氧发酵技术现状与国内应用项目简介[J]. 可再生能源, 2021, 39(3): 294-299. doi: 10.3969/j.issn.1671-5292.2021.03.002 [4] DAI X H, HUA Y, DAI L L, et al. Particle size reduction of rice straw enhances methane production under anaerobic digestion[J]. Bioresource Technology, 2019, 293: 122043. doi: 10.1016/j.biortech.2019.122043 [5] LINDMARK J, THORIN E, BEL FDHILA R, et al. Effects of mixing on the result of anaerobic digestion: Review[J]. Renewable and Sustainable Energy Reviews, 2014, 40: 1030-1047. doi: 10.1016/j.rser.2014.07.182 [6] RICO C, RICO J L, MUNOZ N, et al. Effect of mixing on biogas production during mesophilic anaerobic digestion of screened dairy manure in a pilot plant[J]. Engineering in Life Sciences, 2011, 11(5): 476-481. doi: 10.1002/elsc.201100010 [7] LATHA K, VELRAJ R, SHANMUGAM P, et al. Mixing strategies of high solids anaerobic co-digestion using food waste with sewage sludge for enhanced biogas production[J]. Journal of Cleaner Production, 2019, 210: 388-400. doi: 10.1016/j.jclepro.2018.10.219 [8] NANDI R, SAHA C K, HUDA M S, et al. Effect of mixing on biogas production from cow dung[J]. Eco-friendly Agril J 2017, 10(02): 07-13. [9] ROCAMORA I, WAGLAND S T, VILLA R, et al. Dry anaerobic digestion of organic waste: A review of operational parameters and their impact on process performance[J]. Bioresource Technology, 2020, 299: 122681. doi: 10.1016/j.biortech.2019.122681 [10] YANG H N, DENG L W. Using air instead of biogas for mixing and its effect on anaerobic digestion of animal wastewater with high suspended solids[J]. Bioresource Technology, 2020, 318: 124047. doi: 10.1016/j.biortech.2020.124047 [11] MUHAYODIN F, FRITZE A, ROTTER V S. A Review on the Fate of Nutrients and Enhancement of Energy Recovery from Rice Straw through Anaerobic Digestion[J]. Applied Sciences, 2020, 10(6): 2047. doi: 10.3390/app10062047 [12] 张敏, 王振旗, 沈根祥, 等. 基于连续运行条件下的稻秸干法厌氧发酵中试研究[J]. 农业环境科学学报, 2019, 38(12): 2852-2859. doi: 10.11654/jaes.2019-1059 [13] 王振旗, 张敏, 沈根祥, 等. 不同黄贮预处理对水稻秸秆干法厌氧发酵特性的影响[J]. 农业环境科学学报, 2021, 40(4): 894-901. doi: 10.11654/jaes.2020-1100 [14] LIN Y Q, WANG D H, WU S Q, et al. Alkali pretreatment enhances biogas production in the anaerobic digestion of pulp and paper sludge[J]. Journal of Hazardous Materials, 2009, 170(1): 366-73. doi: 10.1016/j.jhazmat.2009.04.086 [15] 薛惠琴, 杭怡琼, 陈谊. 稻草秸秆中木质素、纤维素测定方法的研讨[J]. 上海畜牧兽医通讯, 2001(2): 15. doi: 10.3969/j.issn.1000-7725.2001.02.005 [16] 中华人民共和国农业农村部. 有机肥料: NY/T 525-2021[S]. 北京: 中国农业出版社, 2021. [17] 中华人民共和国农业农村部. 沼气中甲烷和二氧化碳的测定气相色谱法: NY/T 1700-2009[S]. 北京: 中国农业出版社, 2009. [18] 白晓凤, 李子富, 尹福斌, 等. 鸡粪与玉米秸秆混合“干-湿两相”厌氧发酵启动研究[J]. 中国沼气, 2014, 32(2): 22-25. doi: 10.3969/j.issn.1000-1166.2014.02.006 [19] 杨立, 张婷, 王永泽, 等. 不同秸秆厌氧发酵产沼气效果的比较[J]. 可再生能源, 2008, 26(5): 46-52. doi: 10.3969/j.issn.1671-5292.2008.05.014 [20] MCMAHON K D, STROOT P G, MACKIE R I, et al. Anaerobic codigestion of municipal solid waste and biosolids under various mixing conditions II: microbial population dynamics[J]. Water Resource, 2001, 35(7): 1817-1827. [21] SHEN J, ZHENG Q, ZHANG R H, et al. Co-pretreatment of wheat straw by potassium hydroxide and calcium hydroxide: Methane production, economics, and energy potential analysis[J]. Journal of Environmental Management, 2019, 236: 720-726. doi: 10.1016/j.jenvman.2019.01.046 [22] KARIM K, HOFFMANN R, THOMAS KLASSON K, et al. Anaerobic digestion of animal waste: effect of mode of mixing[J]. Water Resource, 2005, 39(15): 3597-606. [23] KAINTHOLA J, KALAMDHAD A S, Goud V V. Optimization of process parameters for accelerated methane yield from anaerobic co-digestion of rice straw and food waste[J]. Renewable Energy, 2020, 149: 1352-1359. doi: 10.1016/j.renene.2019.10.124 [24] ABRAHAM A, MATHEW A K, PARK H, et al. Pretreatment strategies for enhanced biogas production from lignocellulosic biomass[J]. Bioresource Technology, 2020, 301: 122725. doi: 10.1016/j.biortech.2019.122725 [25] BJORNSSON L, MATTIASSON B, HENRYSSON T. Effects of support material on the pattern of volatile fatty acid accumulation at overload in anaerobic digestion of semi-solid waste[J]. Applied Microbiology and Biotechnology, 1997, 47(6): 640-644. doi: 10.1007/s002530050988 [26] PATINVOH R J, KALANTAR MEHRJERDI A, SARVARI HORVATH I, et al. Dry fermentation of manure with straw in continuous plug flow reactor: Reactor development and process stability at different loading rates[J]. Bioresource Technology, 2017, 224: 197-205. doi: 10.1016/j.biortech.2016.11.011 [27] LI Y, HUA D L, XU H P, et al. Acidogenic and methanogenic properties of corn straw silage: Regulation and microbial analysis of two-phase anaerobic digestion[J]. Bioresource Technology, 2020, 307: 123180. doi: 10.1016/j.biortech.2020.123180 [28] SHEN F, LI H D, WU X Y, et al. Effect of organic loading rate on anaerobic co-digestion of rice straw and pig manure with or without biological pretreatment[J]. Bioresource Technology, 2018, 250: 155-162. doi: 10.1016/j.biortech.2017.11.037 [29] WARD A J, HOBBS P J, HOLLIMAN P J, et al. Optimisation of the anaerobic digestion of agricultural resources[J]. Bioresource Technology, 2008, 99(17): 7928-40. doi: 10.1016/j.biortech.2008.02.044 [30] KAPARAJU P, BUENDIA I, ELLEGAARD L, et al. Effects of mixing on methane production during thermophilic anaerobic digestion of manure: lab-scale and pilot-scale studies[J]. Bioresource Technology, 2008, 99(11): 4919-28. doi: 10.1016/j.biortech.2007.09.015 [31] ZHU Q H, LI X G, LI G W, et al. Enhanced bioenergy production in rural areas: Synthetic urine as a pre-treatment for dry anaerobic fermentation of wheat straw[J]. Journal of Cleaner Production, 2020, 260: 121164. doi: 10.1016/j.jclepro.2020.121164 [32] KARIYAMA I D, ZHAI X D, WU B X. Influence of mixing on anaerobic digestion efficiency in stirred tank digesters: A review[J]. Water Resource, 2018, 143: 503-517. [33] MAO L W, ZHANG J X, DAI Y J, et al. Effects of mixing time on methane production from anaerobic co-digestion of food waste and chicken manure: Experimental studies and CFD analysis[J]. Bioresource Technology, 2019, 294: 122177. doi: 10.1016/j.biortech.2019.122177 [34] KIM M, KIM B C, CHOI Y, et al. Minimizing mixing intensity to improve the performance of rice straw anaerobic digestion via enhanced development of microbe-substrate aggregates[J]. Bioresource Technology, 2017, 245: 590-597. doi: 10.1016/j.biortech.2017.09.006 -

下载:

下载: