-

油田落地油泥是在油田生产过程中,井口溢流、作业落地以及集输过程中跑冒滴漏等造成的含油物质[1-2]。落地油泥的成分比较复杂,一般含有石油烃、水、矿物质和泥砂等物质。目前,落地油泥主要采用焚烧、热解和热水洗等工艺处置,但这些处置方法均存在处理成本高、工艺复杂或处理不彻底等问题[3-5]。因此,开发出经济、高效、环保的落地油泥无害化处置技术有利于油田企业的绿色和可持续发展。

落地油泥的生物降解处置对环境影响小、处理后不会改变泥砂的性质,是油泥无害处置中较为环保的技术之一[6-7]。在处置过程中,利用生物材料,就可以实现油泥的无害化处理,与其他技术相比经济、生态优势明显。然而,生物降解处置适用于含油率低的油泥[8],含油率一般需低于50 mg·g−1。这是因为,在含油率高于50 mg·g−1的条件下,一方面需要更长的生物处理周期;另一方面含油率过高会影响微生物的生长代谢。为解决这一问题,国外有学者提出采用掺土的办法降低含油率,但这种方法又会大幅度增加处理总量,存在一定局限性[1, 9]。从减量化的角度来看,热水洗法与生物降解处置具有良好的兼容性,在有效控制处理成本的前提下,可实现高含油落地油泥的经济、快速处置。

本研究以油田高含油落地油泥为供试材料,拟建立一种热水洗辅助微生物修复高含油落地油泥组合工艺。通过清洗剂类型及清洗温度的优化,以去除大部分的石油烃,使水洗后的含油残砂适用于进一步生物处理。在生物降解过程,探究了填料和烃降解菌对生物降解速率的影响,以期为油田石油污染土壤的治理提供参考。

全文HTML

-

落地油泥样品取自某采油厂油泥缓存站,参照《污染场地环境监测技术导则》(HJ 25.2-2014)[10]和《工业固体废物采样制样技术规范》(HJ/T 20-1998)[11]设计了6个采样点取样。采用红外光谱法测定油泥含油率,方法依据《危险废物鉴别标准-毒性物质含量鉴别》(GB 5085.6-2007)[12]中附录O的要求,结果见表1。本实验将6个不同取样点的样品混合均匀后使用,混合后的油泥含油率为107 mg·g−1。利用索氏抽提器,以氯仿为溶剂,提取落地油泥中的石油烃,用于嗜烃微生物的筛选及界面张力测试。清洗剂分别由鼠李糖脂或脂肽发酵液与OP10(辛基酚聚氧乙烯醚)配制而成。填料秸秆和沼渣均取自东营某农产品公司,使用前经过粉碎处理,长度小于3 cm。客土取自东营市黄河口文化园,填料的化学成分见表2。实验用水为落地油泥缓存站临近联合站注入水,其离子组成及性质见表3。石油醚、尿素、磷酸氢二钾(K2HPO4)均为分析纯。

-

实验中使用的主要仪器包括:红外测油仪(OIL450,北京华夏科创仪器股份有限公司);恒温振荡器(Climo-shaker 1SF1-X,瑞士阿道夫科耐公司);机械搅拌器(Eurostar 20,德国伊卡公司);高速冷冻离心机(J26SXPI,美国贝克曼公司);荧光显微镜(BX53,日本奥林巴斯公司);高通量测序仪(X5/XL,美国赛默飞世尔科技公司);界面张力仪(TX500C,美国CNG公司);总N/P分析仪(Multi C/N 2100,德国耶拿仪器股份有限公司);pH计(FE28,梅特勒-托利多公司);电热恒温鼓风干燥箱(DHG-9023A,上海林频仪器股份有限公司)。

-

由于落地油泥含油量高(含油率107 mg·g−1),不适于直接生物修复,因此有必要采用水洗预处理工艺降低含油率[13]。使用配注水配制质量浓度为0.5%的鼠李糖脂/OP10溶液和脂肽/OP10溶液,调节溶液pH为7。利用界面张力仪测试上述清洗剂与从落地油泥中提取的原油间的界面张力,测试条件为50 ℃、6 000 r·min−1。在250 mL锥形瓶内分别加入25 g落地油泥和75 mL清洗剂,在控制转速800 r·min−1和50 ℃水浴条件下,考察清洗剂的洗油效率;同时,考察水洗温度对洗油效率的影响;随后,将水洗后的残砂加入无菌水,质量体积比(m/V)为1∶5,分析水洗后残砂浸出液pH、总N、总P、微生物菌浓、细微粒组分(粒径小于50 μm)含量。

-

将100 g落地油泥、200 mL无菌生理盐水和50 mL石油醚混合,经机械振荡清洗、离心(12 000 r·min−1、15 min)后收集水相中的微生物菌体。提取油泥中土著菌群的DNA及进行微生物群落高通量测序分析,具体步骤参考胡婧等[14]报道的方法。利用涂布平板法从油泥中分离出烃降解菌,将适量油泥用无菌生理盐水分散后,移取菌悬液涂布在原油平板上,在37 ℃下恒温培养2 d,观察以原油为碳源的菌落生长及产生排油圈情况。将平板上形成排油圈的菌落再次培养后,挑取单菌落保存于LB斜面培养基中;将单菌落接种于原油平板上恒温培养2 d,挑取出排油圈与菌落直径差大的菌株接种于原油液体培养基中作进一步驯化处理,从而获得油泥中的土著烃降解菌;随后,使用普通培养基培养上述分离出的烃降解菌。该培养基组成为葡萄糖3 g·L−1、蛋白胨3 g·L−1、酵母粉3 g·L−1、磷酸氢二钾2.7 g·L−1、氯化钠5 g·L−1。培养条件,37 ℃、180 r·min−1。

-

有效提升生物处置过程的好氧降解是加速生物修复速率的关键[15],而通过添加填料提升土壤溶氧量是其中一种有效的方式[16-17]。在本研究中,选择秸秆、客土、沼渣等填料作为研究对象,将上述物质与油泥混合拌匀,使混合物中填料质量分数分别为3%、5%、8%和10%,并转移至1 L烧杯后在室内环境下静置7 d。随后,利用环刀法测定混合物最大持水量和土壤容重指标[18]。

-

对水洗处理后的残砂进行生物降解性能评价,考察投加烃降解菌及填料对生物降解效率的影响。实验设置空白组、生物强化组和生物投加组。前述3个处理组的区别在于,空白实验过程不投加任何营养元素,生物强化组加入填料和无机盐,生物投加组加入嗜烃菌、填料和无机盐。实验中,将残砂、填料及适宜比例营养元素(尿素和K2HPO4,用量按C∶N∶P=100∶10∶1加入)拌匀后装入塑料盆内。对于生物投加组,按其质量3%比例平均喷洒上述2株烃降解菌发酵液。对上述所有实验对象补充自来水,使含水保持在35%~50%。将塑料盆置于室外(实验在5—11月之间进行),定期检测含水率、含油率、总N/P含量,并根据需要补充水或总N/P。

以上每组实验均设置3个平行实验,实验结果取平均值。

1.1. 供试原料及检测方法

1.2. 实验仪器

1.3. 油泥水洗预处理

1.4. 油泥中微生物菌群分析与烃降解菌分离

1.5. 生物降解用填料优选

1.6. 生物降解性能评价

-

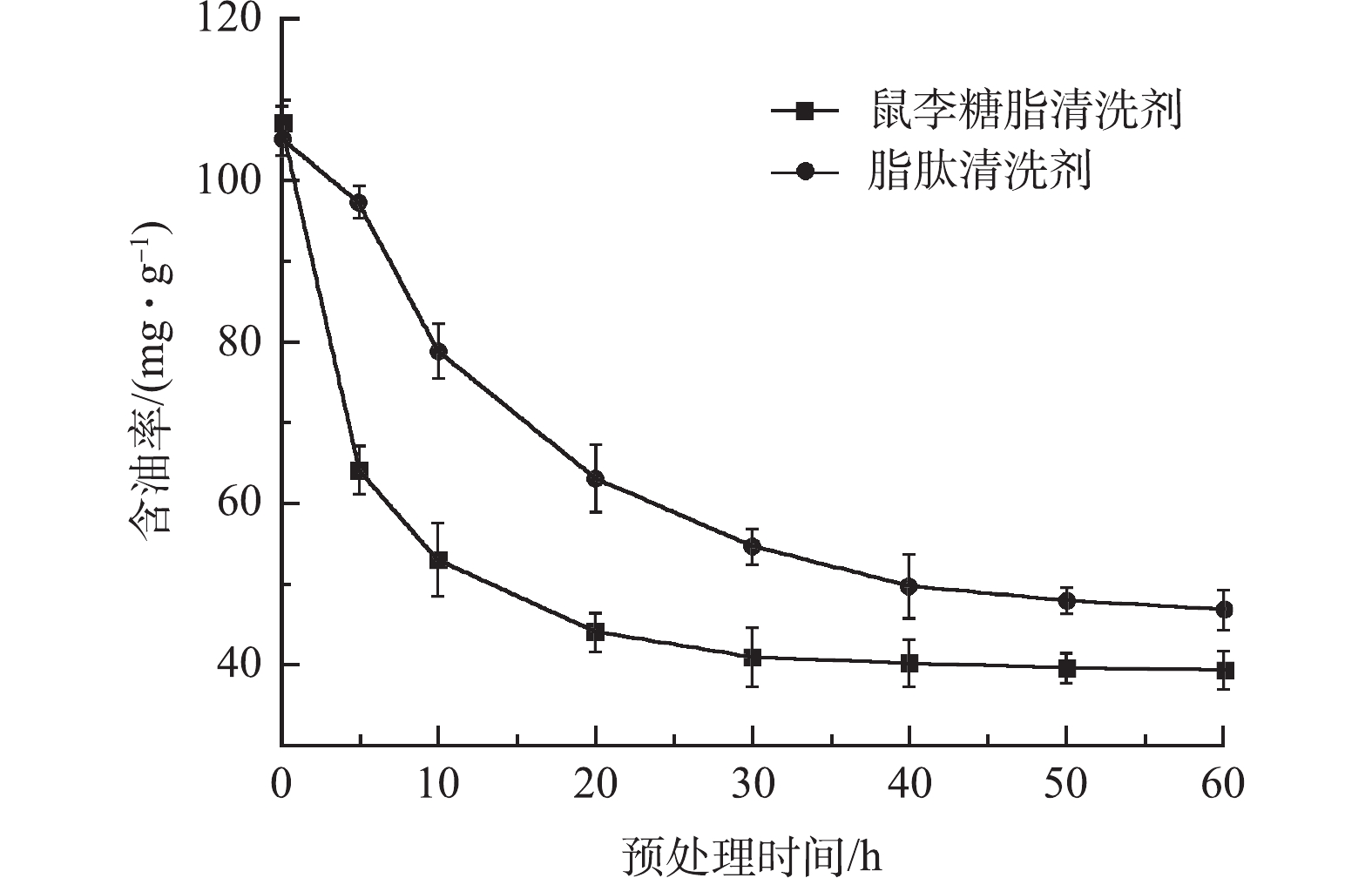

在生物降解前,对落地油泥进行水洗处理,来降低其含油率,以有利于提升后续的生物修复效率。实验考察了鼠李糖脂清洗剂(配方1)和脂肽清洗剂(配方2)的水洗效果,测试结果见图1。从图1中可见,相比于脂肽清洗剂,鼠李糖脂清洗剂具有更好的清洗效率,水洗后残砂的含油率最低可降至35.4 mg·g−1。这是因为,配方1与原油(从落地油泥中提取的原油)的油水界面张力为0.21 mN·m−1,低于配方2与原油间的界面张力(0.89 mN·m−1),因此能更有效地降低原油从固体颗粒表面剥离所要克服的粘附功。此外,从图1中可见,水洗效率随水洗时间呈逐渐下降趋势,30 min后基本趋于平缓。因此,从能耗和日处理量考虑,水洗时间以30 min为宜,此时水洗后残砂的含油率为39.3 mg·g−1。

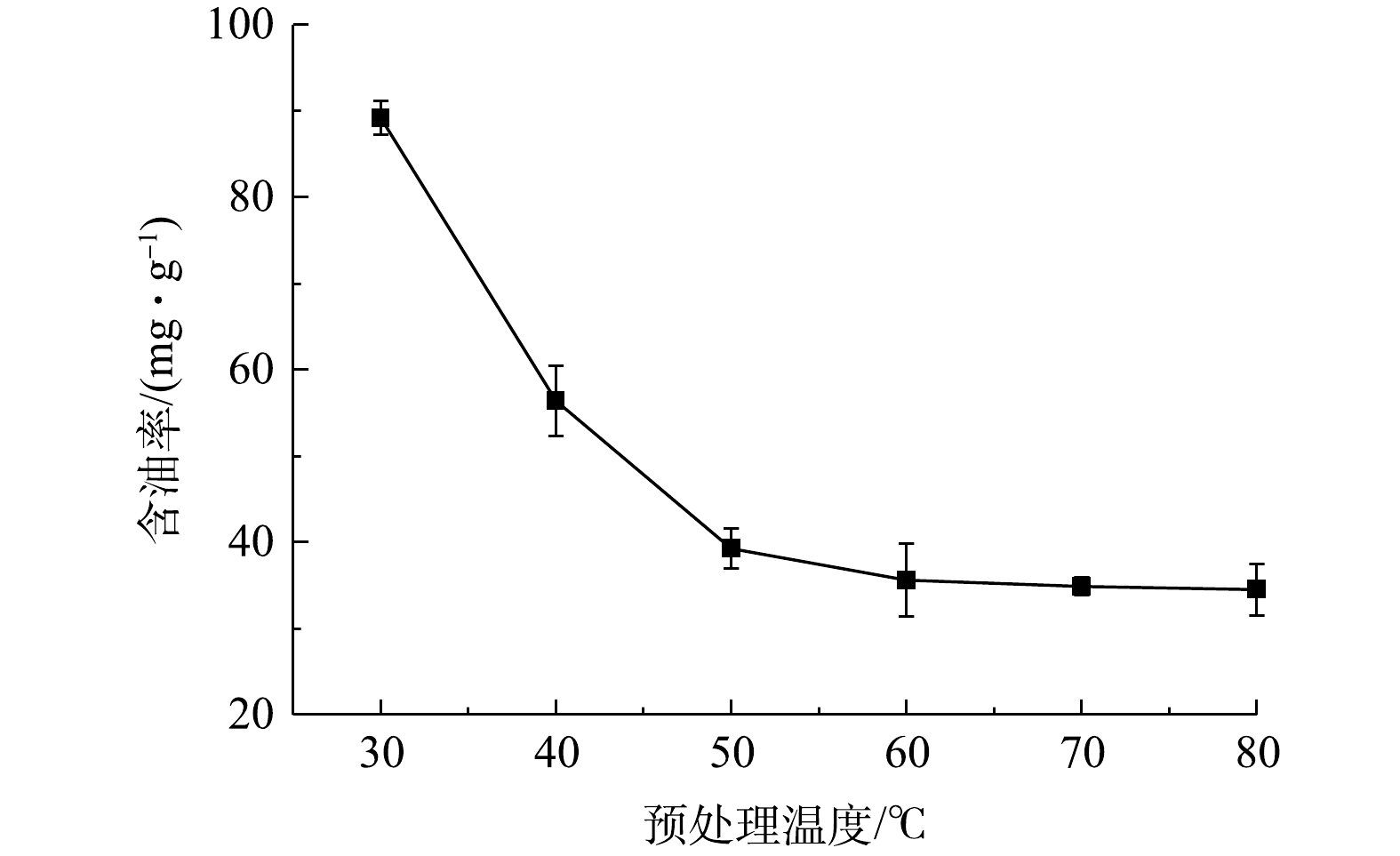

考察了配方1条件下水温对落地油泥洗油效率的影响,结果见图2。从测试结果可知,随着水洗温度的升高,洗油效率亦大幅提升,在水洗温度为30 ℃时,残砂中含油率为89.2 mg·g−1;当水洗温度升至50 ℃时,含油率降至39.3 mg·g−1;随后,洗油效率提升缓慢,到80 ℃时含油率降至34.5 mg·g−1。水洗过程影响洗油效率的关键因素之一是石油烃的黏度,在水温由30 ℃升至50 ℃时,石油烃黏度大幅下降,流动性增强,其在搅拌剪切力作用下从固体颗粒表面剥离,此时洗油效率大幅提升。当温度升至50 ℃上后,黏度对洗油效率的影响作用减弱,因此洗油效率提升速率减慢[19]。综合考虑水洗的能耗和水洗效率,采用水温50 ℃即可以达到预期热水洗目标。

分析了水洗后残砂的理化性质,包括浸出液总N、总P、pH、细微粒组分含量及微生物菌含量,结果见表4。从表中可以看出,相比于水洗前的落地油泥,水洗后残砂中的总N、总P、细微粒组分含量及微生物菌含量均出现了不同程度的下降。这是因为,在水洗过程,加热和搅拌作用会致使大部分的水溶物质(包括无机盐、矿物质和微生物等)进入水相,并随固液分离而流失。而经过水洗后的残砂,从含油率、pH、细微粒组分含量等多个参数来看,能够满足生物修复的基本要求[13]。但由于残砂中总N、总P含量偏低,无法满足微生物的正常生长代谢。因此,需要在后续的生物处理过程补充外源菌剂、足够量的营养物质,以保障微生物的嗜烃代谢活动。

-

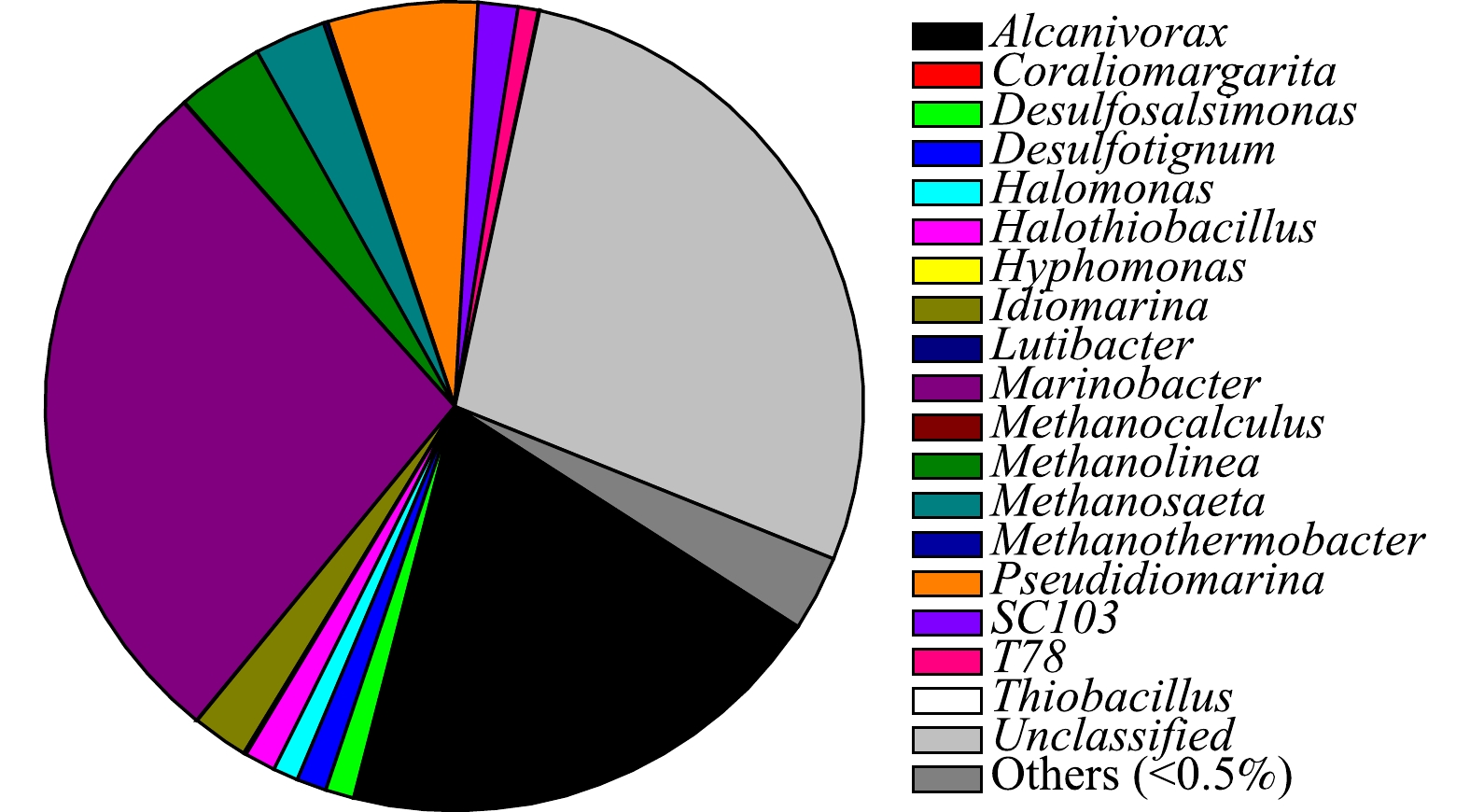

利用高通量测序分析了落地油泥中土著微生物的群落结构,结果见图3。从图中可以看到,土著微生物菌群以食烷菌属(Alcanivorax)、海杆菌属(Marinobacter)、假海源菌属(Pseudidiomarina)及假交替单胞菌属(Pseudoalteromonas)等为主。有报道称,食烷菌属能降解烷烃类有机物[20-21]。另外,有研究[22-24]结果表明,海杆菌属、假海源菌属和假交替单胞菌属均能降解多环芳烃类有机物。以上菌群出现在落地油泥中,说明落地油泥在其产生、转移及场地堆放过程能逐渐形成以烃降解微生物为主的群落结构。这是因为,油泥中的石油烃能为这些微生物的代谢生长提供必要的碳源和营养,只是由于油泥中氮、磷元素含量太低(见表4),难以满足微生物的正常代谢活动,故微生物的数量维持在较低水平,对石油烃的降解作用弱。同时,前人报道的烃降解菌多数来源于海洋环境,而本实验选取的落地油泥的产生地点位于黄河三角洲沿海滩涂地区,故其中的群落结构受海洋环境影响较大。因此,在其长期存放过程中,以石油烃为碳源的微生物逐渐形成优势菌群[25]。

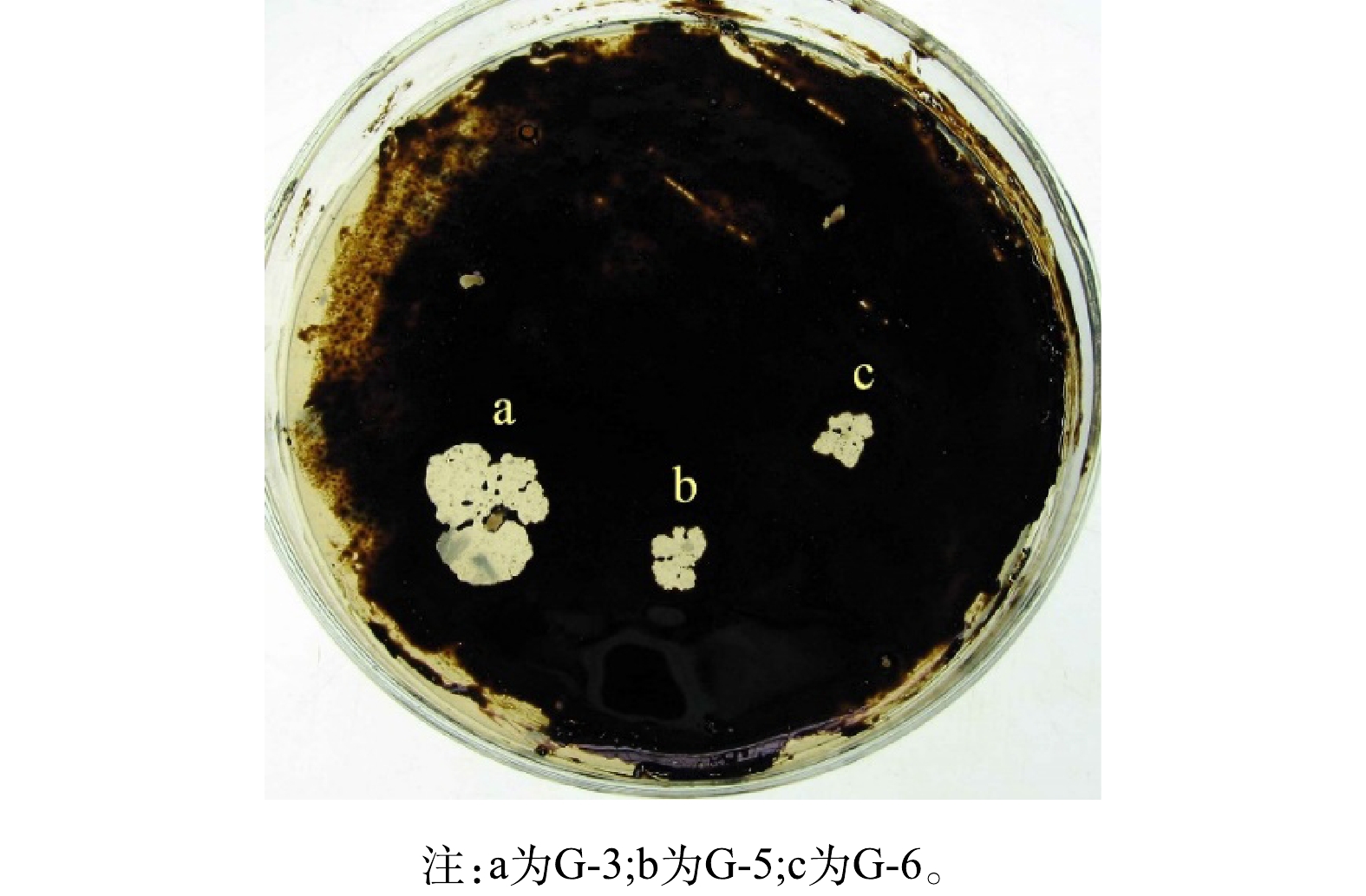

采用涂布平板法分离烃降解菌,原油平板上出现3个扩油圈,如图4所示。从图中可见,标记为“a”、“b”和“c”的菌株能够利用原油为碳源代谢生长,并产生表面活性物质,形成排油圈。出现排油圈则表明上述菌株能够利用平板内的原油为唯一碳源进行代谢生长,并代谢合成表面活性剂。而表面活性剂的产生,则能够进一步乳化原油,提升微生物利用效率[26-28]。进一步分离后,挑取出排油圈与菌落直径差大的2株嗜烃菌,命名为G-3和G-6。随后,使用培养基培养G-3和G-6,获得烃降解菌发酵液,经显微镜检测,发酵液中菌含量均能够达到2×108个·mL−1,表明这2株烃降解微生物具备现场应用的基本条件。

-

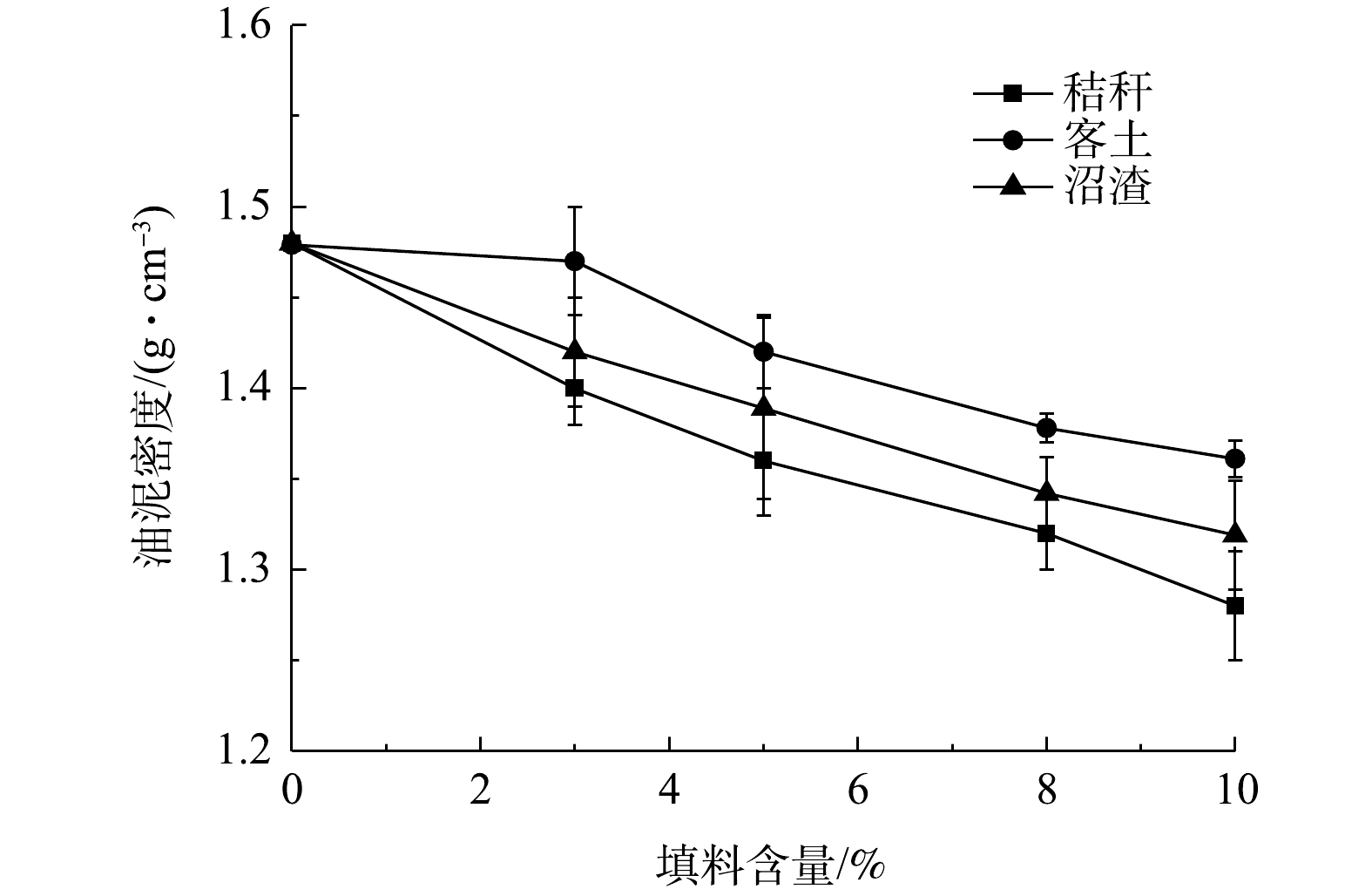

考察加入填料对提高油泥溶氧量的影响,评价的指标包括油泥密度和最大持水量,结果见图5和图6。从图5可以看出,残砂中加入秸秆、客土和沼渣后均能有效降低油泥密度;而且随着填料加入比例的增加,密度呈线性下降。与沼渣和客土相比,加入质量分数为10%的秸秆后,则密度下降13.5%,而加入相同质量分数的客土后,密度下降了7.97%。这是因为,在加入相同质量分数的填料中,秸秆体积最大,掺入残砂后最有利于提高油泥的蓬松度。而在土壤修复领域,特别是采用地耕法处置污染土壤过程,秸秆等廉价、疏松的填料常用于提高土壤通透性[29-30],以达到增加溶氧的目的。

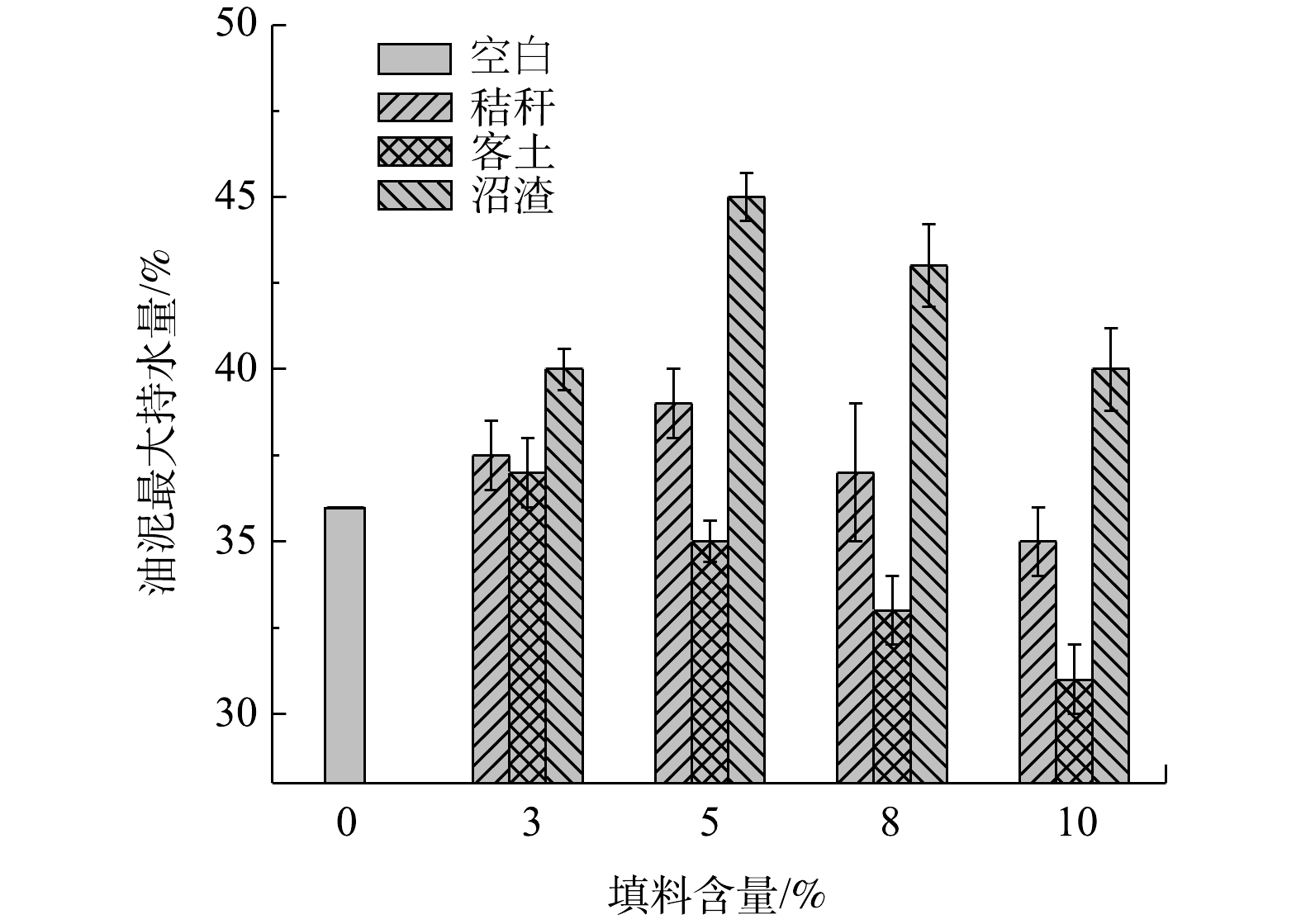

图6给出了添加不同填料后对油泥最大持水量的影响。从测试结果来看,添加秸秆和沼渣对提高最大持水量有一定的提高作用,而添加客土后最大持水量出现下降趋势。相比于秸秆,沼渣具有更好的持水能力,添加量为5%时,最大持水量由36%提升到45%;此后,继续增加沼渣含量时,油泥的最大持水量开始下降。对于秸秆,增加量在3%以内,有利于保水,随后出现下降趋势。这是因为,管状空心结构的秸秆能够增加油泥表层的水分流动通道,使水分蒸发加剧。而对于处理后的沼渣,能够有效改良油泥结构,提高其含水饱和度和持水能力,从而降低油泥脱水速度,最终提高油泥保水、抗旱性能。

此外,通过比较客土、秸秆和沼渣的化学性质来看(表2),沼渣具有丰富的N、P元素和有机物,能够为微生物的代谢生长提供营养物质。此外,沼渣中还含富含有腐殖质,而这类物质能作为电子受体参与有机物的厌氧生物降解过程,提升微生物对有机物的代谢速率[31]。而这一推论在大量的研究报道中已被证实,即在厌氧环境下,微生物以腐殖质为电子受体氧化石油类有机物[32-33]。因此,沼渣作为一种新型的填充物不仅能够有效提高油泥的通透性,同时其富含的腐殖质能够使厌氧区域发生更高速率的生物降解。因此,通过以上实验筛选出沼渣用量为5%并用于其后的生物降解实验。

-

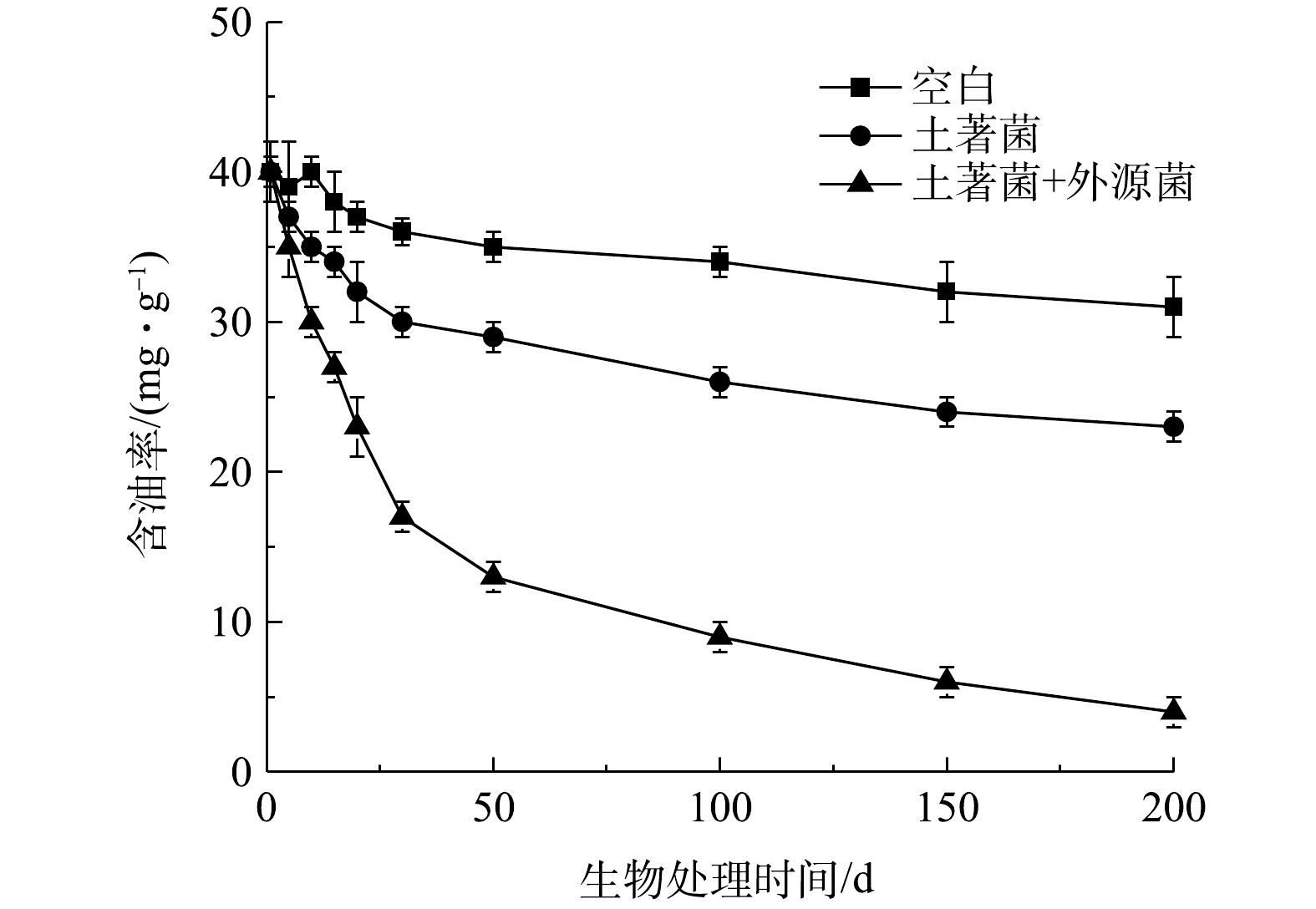

在生物降解性能评价过程中,考察了添加G-3和G-6外源烃降解菌对处理效果的影响,结果见图7。从图中看到,相比于空白组,单纯通过激活油泥中土著微生物进行生物修复时,效果较差,处理至200 d时残砂样品的含油率仍然达到26.3 mg·g−1。相反,投加烃降解菌组对石油烃有着较强的降解效果,处理87 d时残砂样品的含油率降至10.0 mg·g−1以下,处理200 d时则降至4.62 mg·g−1。由此可认为,在预处理水洗过程中,在水溶液环境下的搅拌剪切作用破坏了油泥的微生态环境,高温水洗、投加药剂造成大量的土著烃降解菌死亡或随水体流失(见表4),从而导致残砂中土著烃降解菌的数量和种类大幅降低,最终造成生物修复效果较差。而通过添加筛选的烃降解菌,补充和提升了残砂样品中烃降解菌的种类和数量,在营养元素富余的条件下,嗜烃微生物的生物量大幅提升,并能够有效降解残砂中的石油烃,因此取得了理想的处理效果。由此可得出,在选择水洗技术为预处理工艺时,在生物修复过程中,需要投加适量的烃降解外源菌,从而提高处置的效果。

测试了未处理时、处理第200 d时的对照组及投加菌剂组样品中含油率及各组分含量的变化,结果如表5所示。由表可知,在实验前,空白组和投加菌剂组含油率分别为39.3 mg·g−1和39.1 mg·g−1;经过200 d的生物处理后,空白组含油率下降至31.2 mg·g−1,而投加菌剂组含油率下降至4.62 mg·g−1。其中,不同石油烃组分经过生物处理后含量均下降,其中以饱和烃和芳香烃降解率最为显著,而胶质和沥青质则较难被降解。

2.1. 清洗剂与水洗温度的确定

2.2. 落地油泥的群落结构分析及烃降解菌分离

2.3. 填料的优选

2.4. 生物降解实验

-

1)从高含油落地油泥中分离获得2株烃降解菌,用于微生物修复实验。添加5%的沼渣能能够提升油泥的溶氧能力,最大持水量增加到45%。

2)在鼠李糖脂清洗剂总用量为0.5%、水洗时间30 min和50 ℃条件下,油泥含油率由107 mg·g−1降至39.3 mg·g−1。水洗后残砂中总N/P、细微粒组分(粒径≤50 μm)及土著微生物菌浓均不同程度下降,在随后的生物修复过程需要补充外源菌和营养物质。

3)生物修复过程投加沼渣和2株烃降解菌,生物降解速率得到提升;经过200 d的生物修复后,残砂含油率降至4.62 mg·g−1。在此过程中,微生物优先降解饱和烃和芳香烃,对胶质和沥青质的降解作用弱。

下载:

下载: