-

据不完全统计,我国染料相关产业废水排放量约为6×109~8×109 t,占全国工业废水总排放量的30%~40%[1]。染料废水严重威胁到人体健康和其他生物生存。染料废水因具有化学成分复杂、难以自然降解、浓度高、废水量大及色度高等特点,成为国内外最难处理的工业废水之一。国内外常用物理法、化学法和生物法处理染料废水。但是,这些方法各自具有不同的优缺点。物理法适用于去除大颗粒物和浊度,但对于溶解性有机物和色度等问题无法有效解决;化学法可有效去除一些有机污染物,但需要使用昂贵的试剂并产生二次污染;生物法则受到生物耐受性和生长环境的限制。染料废水因其具有生物毒性,难以用常规的生物法进行处理[2]。

膜分离技术是21世纪应用最广泛的技术而膜材料是膜分离技术的核心,直接影响着分离过程中物质的传递效率和分离效果。聚酰胺复合膜(polyamide thin-film composite membrane, PATFC膜)是目前应用最广泛的无孔膜之一。PATFC选择透过性较好,且膜通量较高,比较容易调控,因而应用范围广[3]。在反渗透(RO)、纳滤 (NF)及正渗透(FO)等常见的膜分离技术领域的应用均占据主导地位。然而,由于PATFC膜耐氯性能差、易污染和Trade-off效应,在膜滤过程中易受到污染,且清洗效率低。为此,研究人员通过膜材料结构和性质的改变来提高其抗污染性能。

目前,PATFC膜的改性方法主要有:传统的前改性、后处理改性及新兴的中间层调控改性。前改性方法通过对PATFC膜亲水性改性,可以改善膜表面抗污染性能。YOU等[4]将制备好的乙二醇官能化的低聚半硅氧烷纳米颗粒(PEG-POSS)添加到水相溶液中,通过界面聚合反应合成改性PATFC膜,改性膜纯水通量是普通PATFC膜的2倍。然而,前处理改性可以显著提高其抗污染性能,但亲水性聚合物分子的引入,可能会破坏聚酰胺(PA)活性层的整体性,使改性膜的通量和截留性能受到影响。后处理改性主要包括表面接枝和表面涂覆,而且其操作简单,不会破坏膜的整体性,具备一定的实用价值,如刘彩虹[5]将纳米SiO2通过表面涂覆修饰到PATFC膜表面,得到具有亲水性的TMAC-SiNP-TFC和ARTMS-SiNP-TFC 2种新型复合膜,抗有机污染性能提升。虽然表面涂覆可将密度较高的改性涂层覆盖在PATFC膜表面,但由于连接涂层与PA活性层之间的官能团非相互作用较弱,涂层容易剥落;而表面接枝可克服这一缺陷,但随着接枝密度的增加,改性膜的渗透性会降低。中间层调控改性方法较难控制 PA 活性层的结构。近年来,研究人员在多孔支撑基底和PA活性层之间引入高分子、纳米材料等中间过渡层,调控PA活性层的微观结构,从而改善PATFC膜的分离性能[6]。如YU等[7]在膜上引入GO和CNT的联合过渡层,通过MWCNT调控GO层间距和结构,实现界面聚合反应有效调控。结果表明,与改性前的膜比较,改性后PA活性层厚度降低了60%。在3种改性方式中,通过前改性方法获得的改性膜,其抗污染性能显著。

但是,如何保持活性层的整体性,是该领域研究人员关注的重点方向。而传统的非金属光催化剂g-C3N4表面无孔隙结构、褶皱严重、结晶度低且缺陷较多。虽然g-C3N4能在可见光条件下激发,但能带宽度仍然较大,因而光生电子与光生空穴对具有较低的分离效率,导致其可见光催化活性不强。为提高非金属光催化剂g-C3N4的光催化活性及其在膜表面的附着强度、PATFC膜表面的抗污染性能与自清洁特性,本研究首先通过调控g-C3N4形貌,制备成二维超薄g-C3N4(UCN);然后通过超声及化学沉淀法将UCN与具有强导电性的GO及强光催化活性的AgI进行复合反应,构建异质结,得到具有较高光催化活性的AgI@GO@UCN(AGU)异质结光催化剂。随后,使用前改性方法将可见光响应AGU用于PATFC膜改性,获得具有光催化活性的AGU改性膜。通过对比PATFC膜及AGU改性膜的纯水通量、刚果红(CR)截留率和光照抗污染实验、可逆污染率与不可逆污染率、光催化自清洁实验及重复利用实验,评价了PATFC膜改性前后的选择透过性、抗污染性能、稳定性、通量恢复率以及自清洁特性。

-

尿素(CH4N2O)、氯化铵(NH4Cl)、三聚氰胺(C3H6N6)、石墨粉(C)、碘化钾(KI)、十二烷基苯磺酸钠(C18H29NaO3S)均购于上海阿拉丁生化科技股份有限公司;98% 浓硫酸(H2SO4)、硝酸钠(NaNO3)、30%过氧化氢(H2O2) 、盐酸(HCl)均购于广州化学试剂厂;高锰酸钾(KMnO4)、刚果红(C32H22N6Na2O6S2)、无水乙醇(C2H6O)均购于天津大茂化学试剂厂;硝酸银(AgNO3)购于国药集团化学试剂有限公司; 间苯二胺(C6H8N2)、均苯三甲酰氯(C9H3Cl3O3)、正己烷(CH3(CH2)4CH3)、对苯醌(C6H4O2)购于上海麦克林生化科技有限公司;氮气(N2)购于广州市英莱气体有限公司;PES聚砜膜购于迈纳德膜技术(厦门)有限公司。以上所有试剂均为分析纯,实验用水为自制去离子水。

-

1)可见光响应AgI@GO@UCN(AGU)异质结光催化剂的制备。首先是超薄g-C3N4(UCN)的制备:在100 mL烧杯中,放入三聚氰胺(3 g)、尿素(3 g)和氯化铵(10 g),随后加入超纯水(15 mL),搅拌、溶解;紧接着,将该烧杯放在加热搅拌器(75 ℃)上至水分蒸干,烧杯中留下的混合物移入坩埚(50 mL)中,并置入马弗炉,以一定的温度梯度(2.7 ℃·min−1)升温热至550 ℃,并保持3 h。将坩埚取出、冷却,研磨所得固体,制备得到UCN粉末。然后是GO的制备:采用邹正光等制备方法与流程获得GO[8]。紧接着是采用超声法制备GO@UCN 复合光催化剂:称取100 mg UCN粉末分散于超纯水中,加入4 mL GO分散液,超声1 h后通过抽滤收集样品。随后置于50 ℃烘箱中烘干,得到GO@UCN复合光催化剂。最后是通过化学沉淀法制备AGU异质结光催化剂:首先,将装有GO@UCN悬浊液的烧杯置于暗箱中的搅拌器上,逐滴滴入AgNO3溶液(0.1 mol·L−1)。搅拌0.5 h,均匀分散Ag+;然后,逐滴滴入KI溶液(0.1 mol·L−1)搅拌2 h,使Ag+反应完全;最后,通过抽滤收集AGU,用无水乙醇和纯水洗涤数次后置入烘箱中(50 ℃)干燥12 h,得到AGU异质结光催化剂。

2) AGU改性PATFC膜的制备。主要分为氮气压滤和界面聚合2个步骤。第一步氮气压滤。将PATFC膜平整固定于超滤杯底座上进行气密性测试。然后,通过加料口注入AGU异质结分散液(超声30 min)。紧接着通入氮气加压(0.10 MPa),缓缓滤出水分,使AGU异质结均匀分布于PATFC膜表面。第二步界面聚合。将表面均匀分布的AGU改性支撑膜转移到玻璃皿中,倒入间苯二胺(MPD)水相溶液,浸泡1~4 min后倒出水溶液,并用吹风机将膜表面多余水分吹干;随后倒入均苯三甲酰氯(TMC)有机相溶液使之进行界面聚合反应后倒出有机溶液,并将经过溶液处理的膜转移到80 ℃烘箱中热处理10 min。最后,使用无水乙醇和纯水洗涤数次,将得到的AGU改性膜置于去离子水中保存备用。

-

采用美国Nicolet IS50型傅立叶变换红外光谱仪分析测试膜样品表面带有的化学官能团;采用Escalab 250Xi型X射线光电子能谱仪分析测试原膜与改性膜材料的元素组成和价态;采用LYRA 3 XMU型场发射扫描电子显微镜表征原膜与光催化材料改性膜表面的微观形貌,并结合利用能谱仪(Energy Dispersive Spectrometer,EDS)对膜材料扫描,得到表面元素分布特征;采用UV-3600 (DRS)型紫外可见近红外分光光度计分析测试原膜与改性膜材料的可见光吸收性能;采用德国LSA-100型视频光学接触角测量仪测试膜样品的水接触角,以表征膜材料表面的亲水性能;采用德国Inspekt Table Blue 5KN型电子万能实验机测定膜样品的抗拉强度及断裂伸长率,以表征膜样品在实际使用过程中的机械强度。

-

1) AGU改性膜的纯水通量。将AGU改性膜置于自组装错流过滤膜池(有效过滤面积为38.5 cm2)中预压30 min(0.3 MPa),待膜通量稳定后将压力保持在0.2 MPa,通过式(1)计算膜样品的纯水通量。

式中:Jw是AGU膜通量,L·(m2·h)−1;V是为膜滤出水量,L;A是有效的膜滤面积,m2;t是膜滤时间,h。

2) AGU改性膜的截留性能。以20 mg·L−1的CR染料作为进料溶液,在0.2 MPa的操作压力下进行错流过滤截留实验。实验结束后,取5 mL滤液,以纯水作为参比,用紫外分光光度计(在496 nm处)测定膜滤液的波长,通过CR的溶度吸光度标准曲线计算滤液中CR浓度。通过式(2)计算截留率。

式中:R是膜对CR的截留率,%;Cp、Cf分别表示膜滤出水和进水中CR的浓度,mg·L−1。

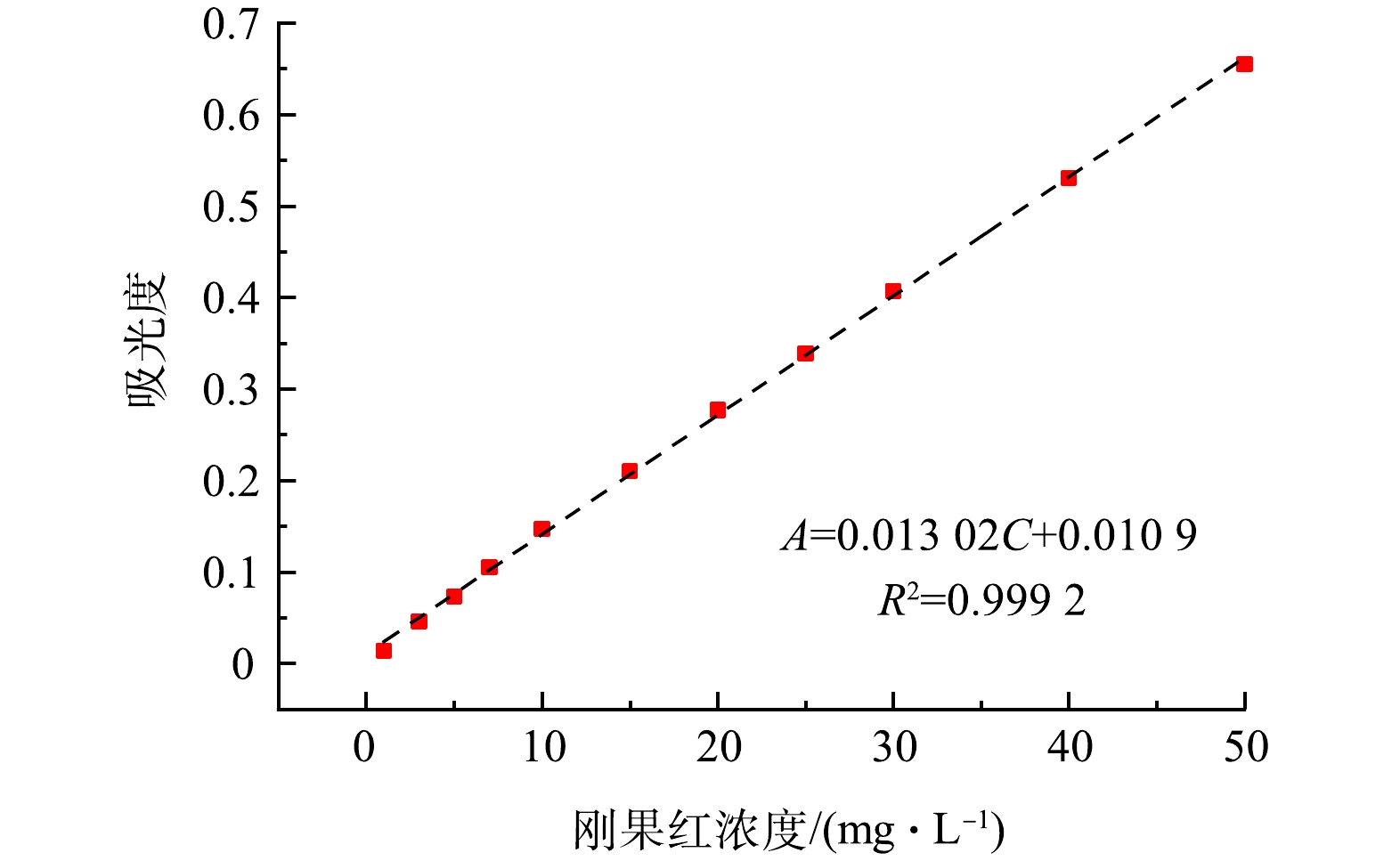

3) CR的定量测定方法。实验采用紫外-可见分光光度法定量测定模拟废水中不同CR溶液浓度对应的吸光度。图1为CR溶液浓度-吸光度标准拟合曲线,并获得CR溶液浓度与吸光度的关系式(式(3))。

式中:A为CR溶液的吸光度;C为CR溶液的浓度,mg·L−1

-

以300 W氙灯光源模拟太阳光。在光射和暗态条件下,对改性膜进行CR连续截留过滤实验。在实验过程中,每隔10 min记录滤过液体积。利用式(4)计算出不同时间段改性膜的比通量

$ {R}_{\mathrm{f}} $ 。通过计算比通量可获得膜通量衰减特性,并以此评价改性膜在光照条件下的截留特性与抗污染性能。式中:

$ {R}_{\mathrm{f}} $ 为比通量值;Jp为膜通量值,L·(m2·h)−1;Jw为膜的纯水通量值,L·(m2·h)−1。 -

在暗态条件下,对改性前后的PATFC膜连续进行CR截留过滤实验;随后,转移至 25 ℃的恒温水浴中,使用模拟太阳光照射60 min,测定恢复清洁后改性膜的纯水通量。通过通量恢复率衡量膜样品的光催化自清洁性能。

膜的抗污染性能可以用通量恢复率(

$ {F}_{\mathrm{r}} $ )和污染率(Rt)进行衡量。其中,污染率分为可逆污染率(Rr)和不可逆污染率(Rir)。通过式(5)~式(8)计算$ {F}_{\mathrm{r}} $ 、Rt、Rr及Rir。重复以上过程5~6次,根据通量恢复率及膜滤过程中的通量衰减速率变化规律,评估膜的重复利用性能与稳定性。式中:JP1为初始纯水通量,L·(m2·h)−1;JP2为暗态条件下膜滤实验最后10 min的平均通量,L·(m2·h)−1;JP3为清洗后改性膜的纯水通量,L·(m2·h)−1。

-

通过正交实验来确定AGU改性膜最佳制备工艺条件(表1)。本实验选取了5个因素:AGU光催化剂的投加量(M)、MPD水相溶液浓度(CMPD)、MPD水相溶液浸泡时间(TMPD)、TMC有机相溶液浓度(CTMC)和TMC有机相溶液浸泡时间(TTMC)。对于每个因素,均设置4个水平,以截留率η和纯水通量Jw作为AGU改性膜基本性能指标表征参数,分别计算出各因素各水平结果的平均值K(水平效应值),以此确定各因素的最佳水平。随后,根据水平效应值Ki,计算出各因素的极差值R。极差R值越大,则表示该因素对实验结果影响越大,以此确定各因素的主次顺序。

对于因素E(TMC 有机相液浸泡时间),根据正交实验结果极差值(表2),其对改性膜纯水通量(Jw)和CR染料截留率(η)的影响最大。当 TMC 浸泡时间由45 s上升到90 s 时,截留率由86.27%上升到93.73%,增幅仅为7.46%;但纯水通量却由35.97 L·(m2·h)−1降至18.22 L·(m2·h)−1,降幅约为50%。因此,因素E对Jw的影响比对η的影响更为显著。根据正交实验表中K值(水平效应值)的计算结果,对于因素E,选择影响纯水通量Jw程度最大的第一个水平作为最优条件(表2中的E1),即TMC有机相溶液最佳浸泡时间为45 s。

同理,可以推导其它因素对改性膜纯水通量 (Jw)和CR染料截留率(η)的影响程度及其最佳制备条件。对因素D ,TMC有机相溶液最佳浓度为0.25‰;因素C,MPD水相溶液最佳浸泡时间为2 min;因素B, MPD水相溶液最佳浓度为B2,即1.0%。对于因素A,AGU光催化剂最佳投加量为A3,即30 mg。

由表2中极值R可知,各因素对改性膜纯水通量(Jw)影响程度的主次顺序为:TMC有机相溶液浸泡时间>TMC有机相溶液浓度>MPD水相溶液浓度>AGU光催化剂投加量>MPD水相溶液浸泡时间。各因素对CR染料截留率(η)影响程度的主次顺序为:TMC有机相溶液浸泡时间> MPD水相溶液浓度> TMC有机相溶液浓度>光催化剂投加量> MPD水相溶液浸泡时间。基于正交实验表中各个因素条件下Jw和η对应的极差值R和水平效应值K值结果分析,得到AGU改性膜的最优制备条件为:AGU光催化剂投加量30 mg;MPD水相溶液浓度1.0%;MPD水相溶液浸泡时间2 min;TMC有机相溶液浓度0.25‰;TMC有机相溶液浸泡时间45 s。

-

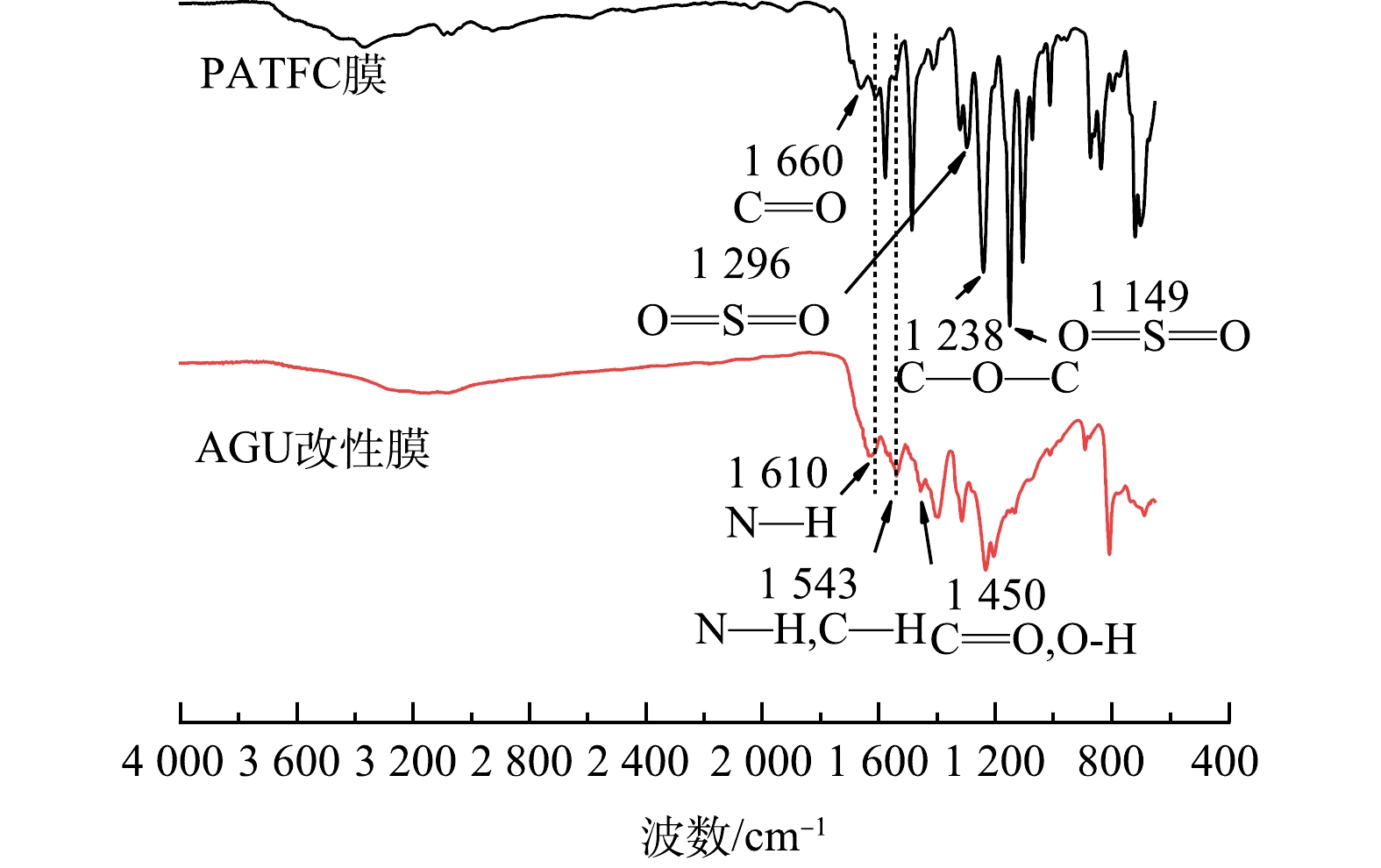

1)膜表面化学官能团。根据PATFC膜和AGU改性膜的傅里叶红外光谱图(ATR-FTIR)(图2),可以看到AGU改性膜在PATFC原膜的基础上,出现了新的官能团。对于PATFC原膜,在1 238和1 296 cm−1处的特征峰,分别呈现PES中C—O—C的不对称伸缩振动和O=S=O的拉伸振动,在1 149 cm−1处也出现了O=S=O的拉伸振动[9]。在1 543 cm−1(N—H弯曲振动,C—H拉伸振动,酰胺Ⅱ)、1 610 cm−1(N—H拉伸振动,酰胺Ⅰ)和1 660 cm−1(C=O拉伸振动,酰胺Ⅰ)处均出现聚酰胺振动峰[10]。这说明,MPD与TMC的界面聚合反应,在PES支撑膜表面生成了聚酰胺活性层,PATFC膜成功合成。在此基础上,利用AGU异质结对PATFC膜进行改性,改性PATFC膜在与原膜对应相同的特征峰处1 610、1 543和1 450 cm−1呈现相同的聚酰胺振动峰[11],但改性膜中未能明显看到原膜的O=S=O键。此外,在改性PATFC膜的ATR-FTIR谱图中,发现UCN和GO改性剂带来了新的特征峰。在803 cm−1处的特征峰与g-C3N4三嗪单元C-N的弯曲振动峰对应[12],1 200~1 640 cm−1处的系列吸收峰是g-C3N4芳香杂环C-N和C=N 的伸缩振动[13],而对于3 300 cm−1处的宽峰,则与GO上O-H基团的拉伸振动对应[14]。由ATR-FTIR表征结果可知,AGU改性膜成功合成。

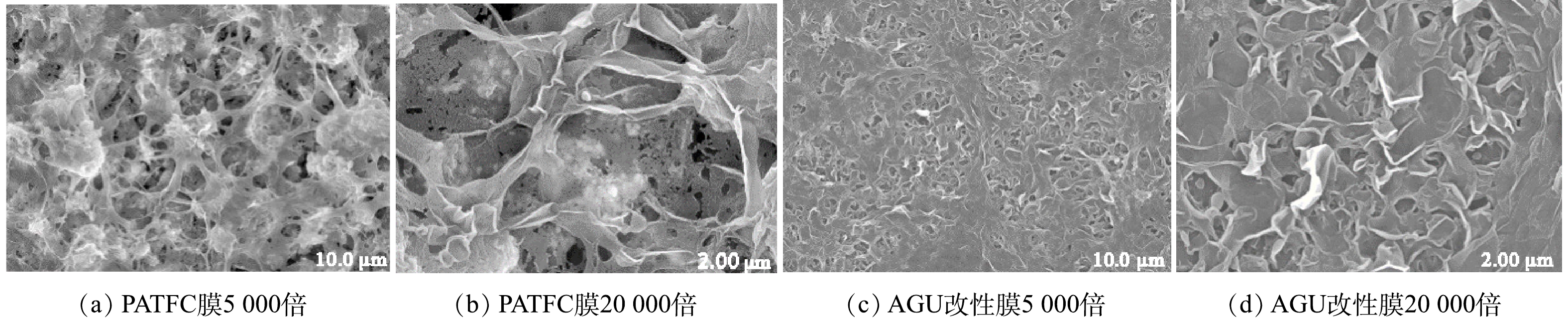

2)形貌结构。PATFC原膜和AGU改性膜的SEM照片见图3。由图3(a)、图3(b)可知,PATFC膜表面展现出了聚酰胺活性层特有的“山脊和山谷”形态[15],与文献报道一致。由图3(c)、图3(d)可知,加入AGU改性剂后,聚酰胺活性层“山谷和山脊”形貌特征变得相对平缓,且出现了颗粒状的结节结构。这可能是由于较小的纳米粒子填充了其“山谷”结构,而较大的纳米颗粒则覆盖于聚酰胺皮层之下,形成颗粒状结节结构。改性膜表面相对平滑,可以有效减少膜滤过程有机污染物的附着和积累,从而具有更好的抗有机污染性能[16]。由图3可知,AGU 异质结牢固地包裹在聚酰胺活性层与支撑基底之间,在膜滤和膜清洁的过程中AGU异质结不会从膜表面脱落,能保证改性膜过滤性能的稳定性。

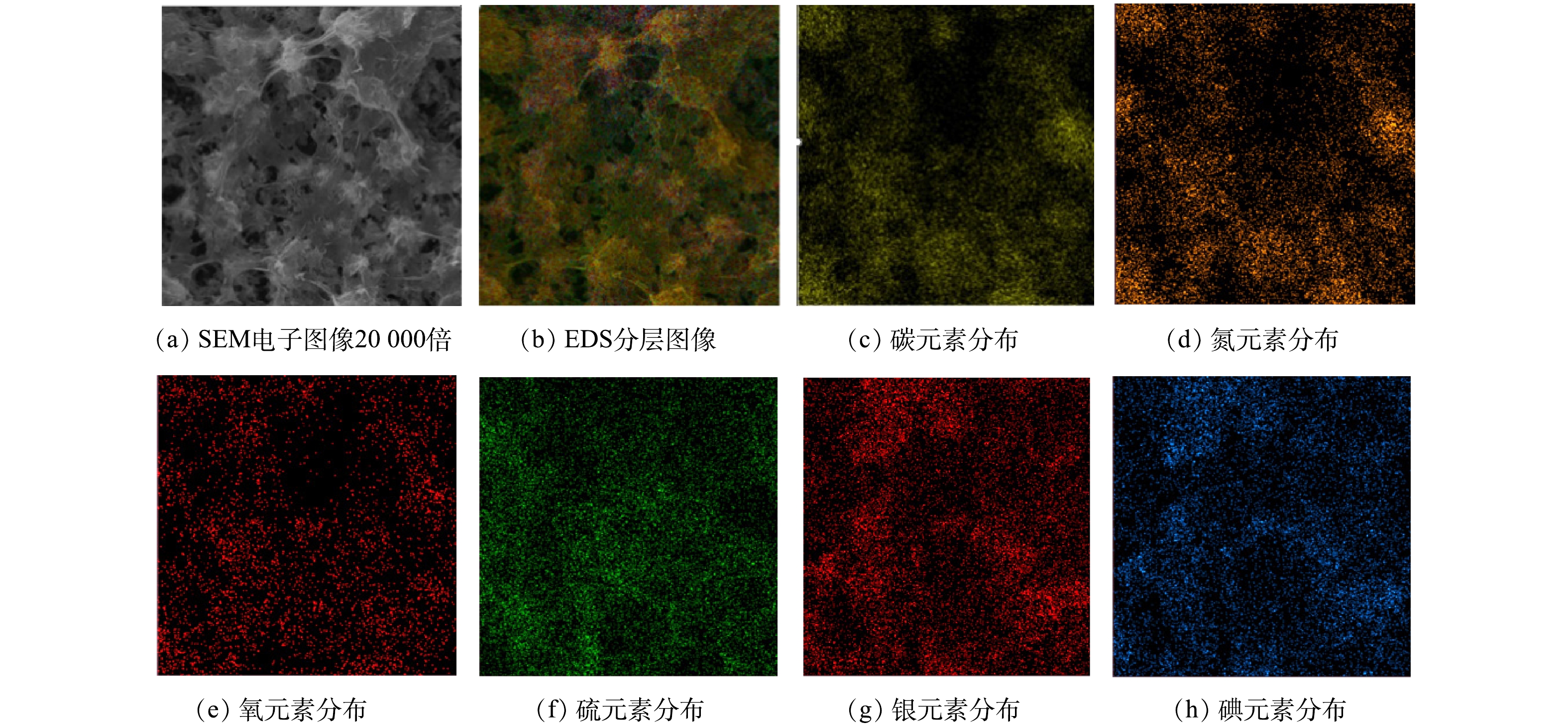

为进一步分析改性膜中元素组成以及分布状态,利用SEM结合EDS能谱面扫得到改性膜的元素组成与分布 (图4)。通过SEM-EDS可知改性膜表面元素组成: AGU 改性膜表面有C、N、O、S、Ag和I元素,对应的质量百分比分别为43.33%、40.03%、4.62%、2.40%、4.93%和 4.70%。由EDS谱图(图4)可知,C、N、O、S、Ag和I元素均匀分布。这表明氮气压滤能使AGU 异质结光催化剂均匀分布于支撑基底表面。

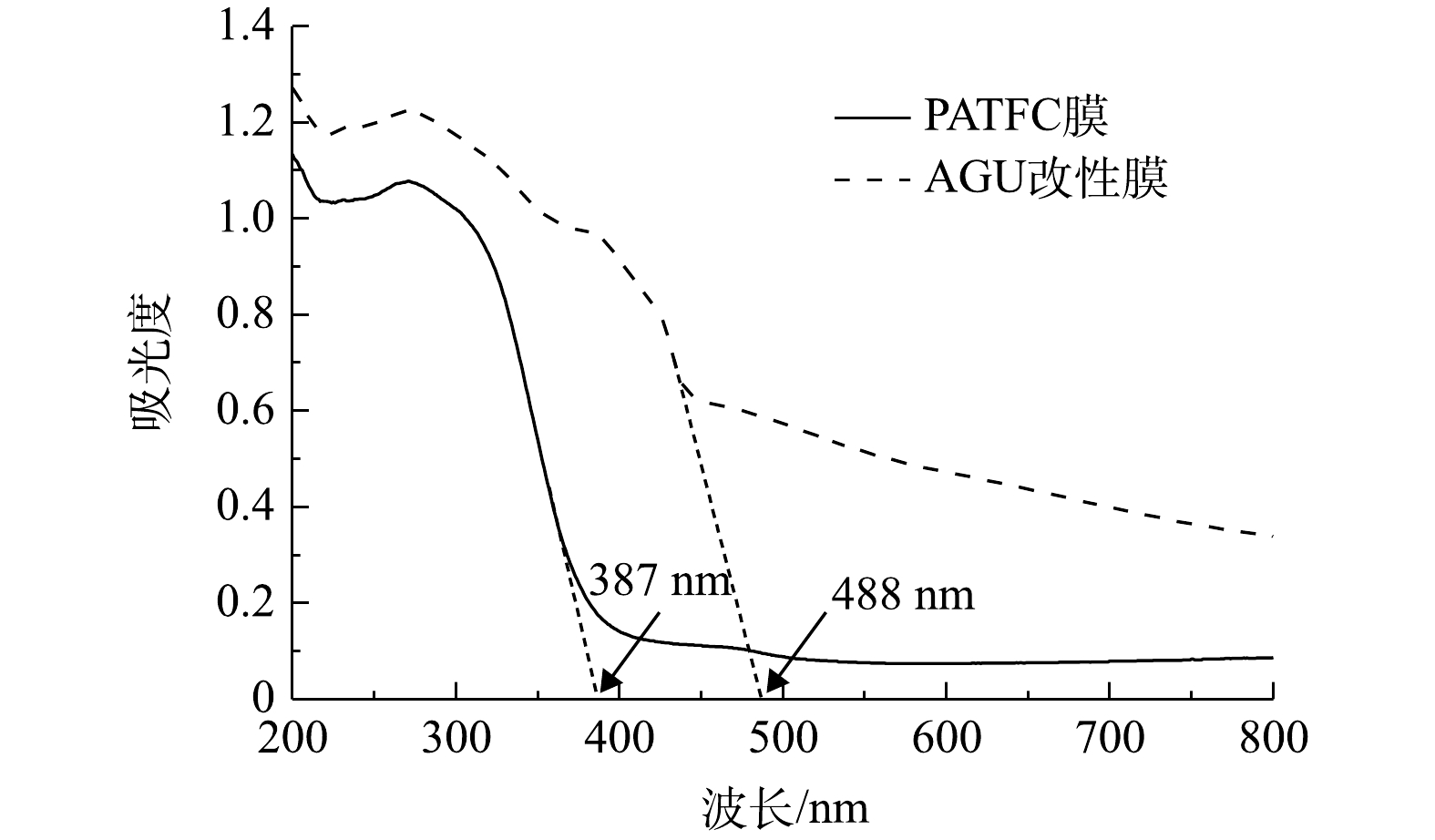

3)光吸收性能。由PATFC膜和AGU改性膜的UV-Vis谱图(图5)可见,PATFC膜的最大光吸收带边为387 nm,接近可见光吸收范围。这是由于聚酰胺分子结构中含有苯环和酰胺基,苯环中含有的π电子能够吸收紫外光,而酰胺基中N原子上的弧对电子能够吸收可见光的缘故[17]。而AGU改性膜的最大光吸收带边红移至 488 nm,已属于可见光(λ>400 nm)范围。这可能是异质结和聚酰胺活性层共同作用的结果。同时,相比PATFC复合膜,AGU改性膜在可见光范围内的光吸收能力更强。

4)表面亲水性能。根据PATFC原膜与AGU改性膜的水接触角(WCAs)测试结果,后者(40.7°)比前者(57.1°)降低了28.72%。这可能是由于AGU异质结和聚酰胺共同作用的结果:一方面,AGU可降低MPD和TMC的交联度,使聚合物链段的亲水基团(—NH2、CO—NH)打开[18];另一方面,AGU异质结中的 GO具备较好的亲水性能,有利于改善膜材料的亲水性,可有效减少膜表面有机污染物的附着和累积,进而提高改性膜的抗污染性能[19]。

5)机械强度。根据PATFC膜与AGU改性膜的抗拉强度和断裂伸长率(表3),由于改性层的存在,AGU改性膜相对于PATFC原膜,厚度与横截面的面积均略有增加。PATFC原膜的抗拉强度为22.68 MPa,改性膜的抗拉强度略微下降(20.67 MPa)。可能的原因是,改性膜表面粗糙度增加导致膜材料的局部应力集中,从而降低了最大负荷和抗拉强度[20]。但是,改性膜的断裂伸长率由PATFC膜的12.78%提高至15.09%,这表明,改性膜的延展性得到增强。

-

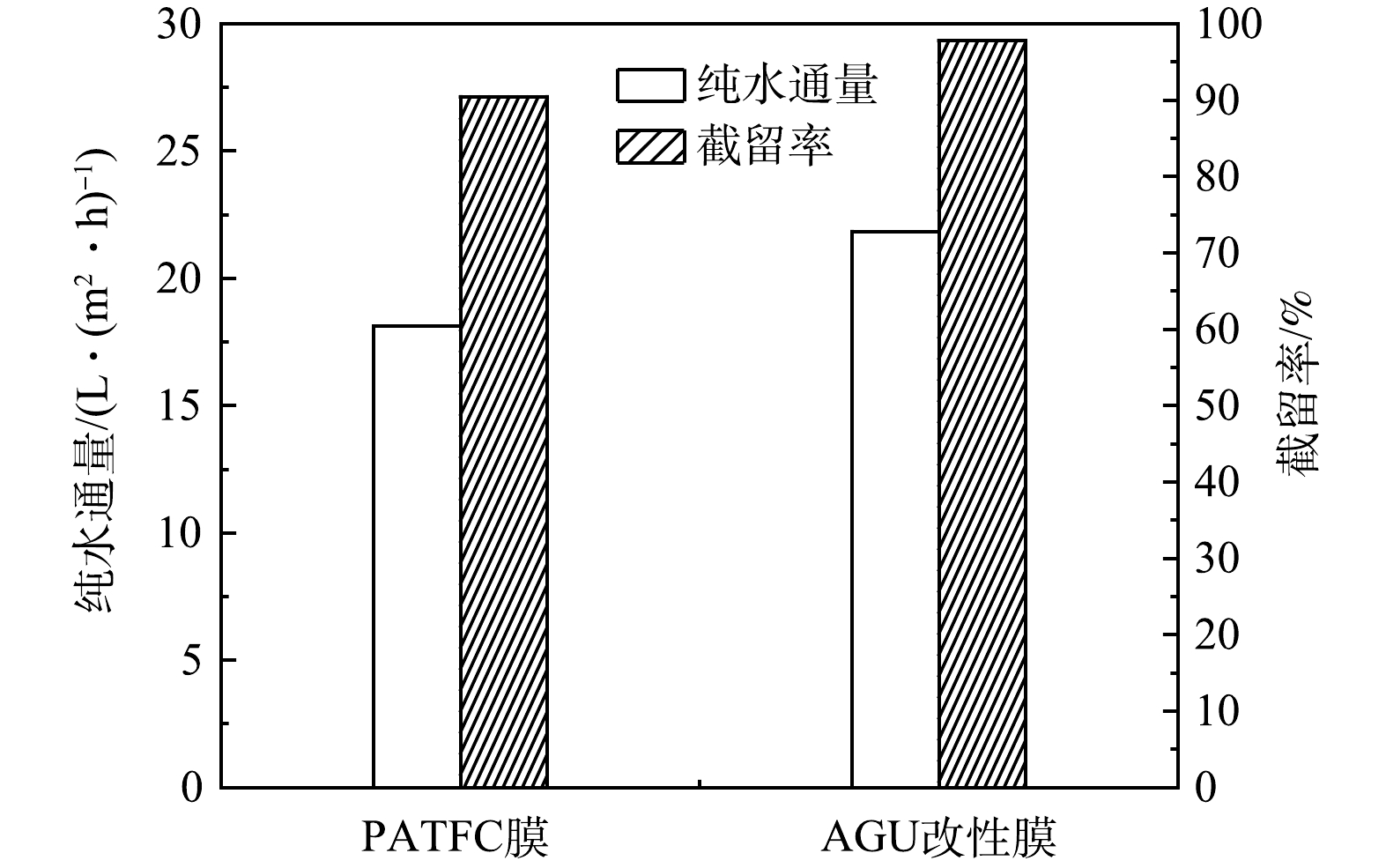

根据PATFC膜、AGU改性膜的纯水通量及CR截留率测试结果(图6),预压30 min后,PATFC膜和AGU改性膜的纯水通量分别为18.11 L·(m2·h)−1和 21.84 L·(m2·h)−1,比改性前的PATFC膜通量提高了20.60%。这可能是由于AGU异质结能够使聚酰胺皮层形成纳米级孔洞和凸起,由此提供了更多的水流通道而使通量增加[21]。PATFC膜和AGU改性膜对CR 的截留率分别为90.45%和97.80%。这表明,使用AGU异质结对PATFC膜改性,能够在一定程度上克服Trade-off效应的缺陷[22]。

-

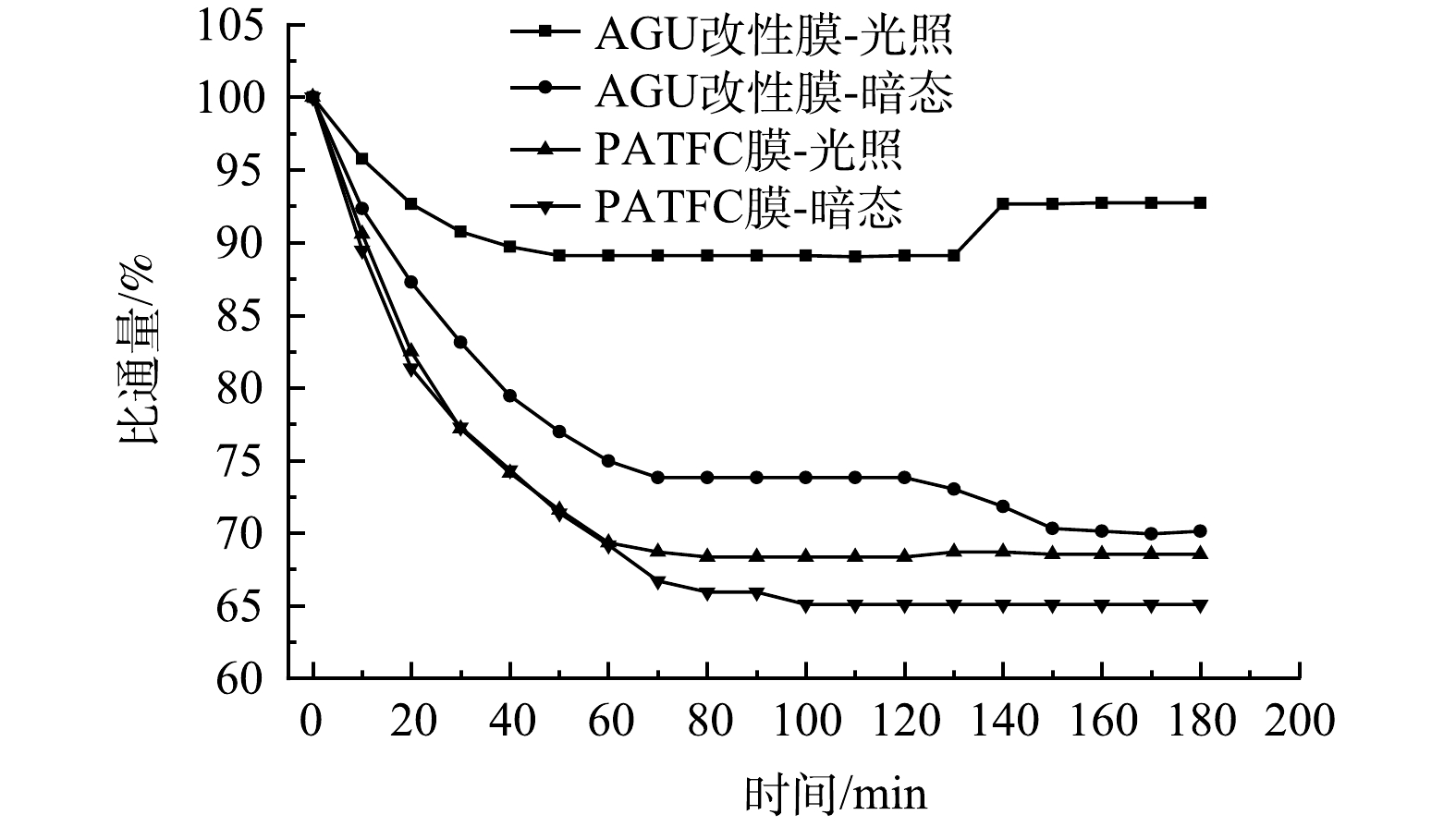

在模拟太阳光照和暗态条件下对PATFC膜和AGU改性膜通量随膜滤时间的衰减曲线(图7)。从图7可以看出,刚开始60 min的膜过滤过程,PATFC原膜RF值随时间显著下降,随后趋于稳定。这说明CR在短时间内即可污染堵塞PATFC原膜,使膜较早进入污染物吸附-脱附平衡期。这表明,PATFC膜对CR的缓冲能力差。在暗态与光照条件下连续运行180 min后,PATFC膜RF分别为65.10%和69.54%,变化不明显。而对于AGU改性膜,在暗态条件下过滤的前60 min内,其RF衰减速度明显减缓,这表明改性膜对CR的缓冲性能提升。过滤进行以180 min后, RF为70.13%,比PATFC膜RF值(65.10%)有所提高。这是由于:①异质结颗粒使聚酰胺出现了纳米级的孔洞和凸起,从而提高了改性膜的表面积和水流通道,增强了其抗污染性能;②AGU改性后PATFC膜的亲水性提高,水化层在改性膜表面更易形成,使传质阻力明显下降,不仅使水分子更易透过膜,同时还能减弱疏水性污染物对膜的粘附[23]。在模拟太阳光照条件下连续运行180 min后,AGU改性膜RF (92.75%) ,比其清洁状态下膜的RF仅下降7.25%。这说明,AGU改性膜抗有机污染性能显著增强。由图7可知,改性膜的通量衰减分为3个阶段:第1阶段(0~40 min),膜通量快速下降阶段,比通量RF由100%下降至89.11%;第2阶段(40~130 min),膜通量稳定阶段,RF稳定在89.11%;第3阶段(130~180 min),膜通量恢复阶段,RF从89.11%逐渐恢复至92.75%,膜污染程度下降。这主要与CR 在膜表面的吸附速度和光催化降解速度的相对大小有关:第1阶段,膜表面CR浓度较低,光催化反应速率较慢,CR在膜表面的吸附速率远远大于光催化降解速率,因而表现为膜通量快速下降;第2阶段,光催化速率逐渐加快,直至与CR在膜表面的吸附速率相等,膜通量保持稳定;第3阶段,光催化降解速率大于CR在膜表面的吸附速率,膜表面吸附的CR分子逐渐降解,此时膜通量得到部分恢复。这表明,AGU 异质结可使PATFC膜具备一定的光催化性能,提高了膜的抗污染性能。

-

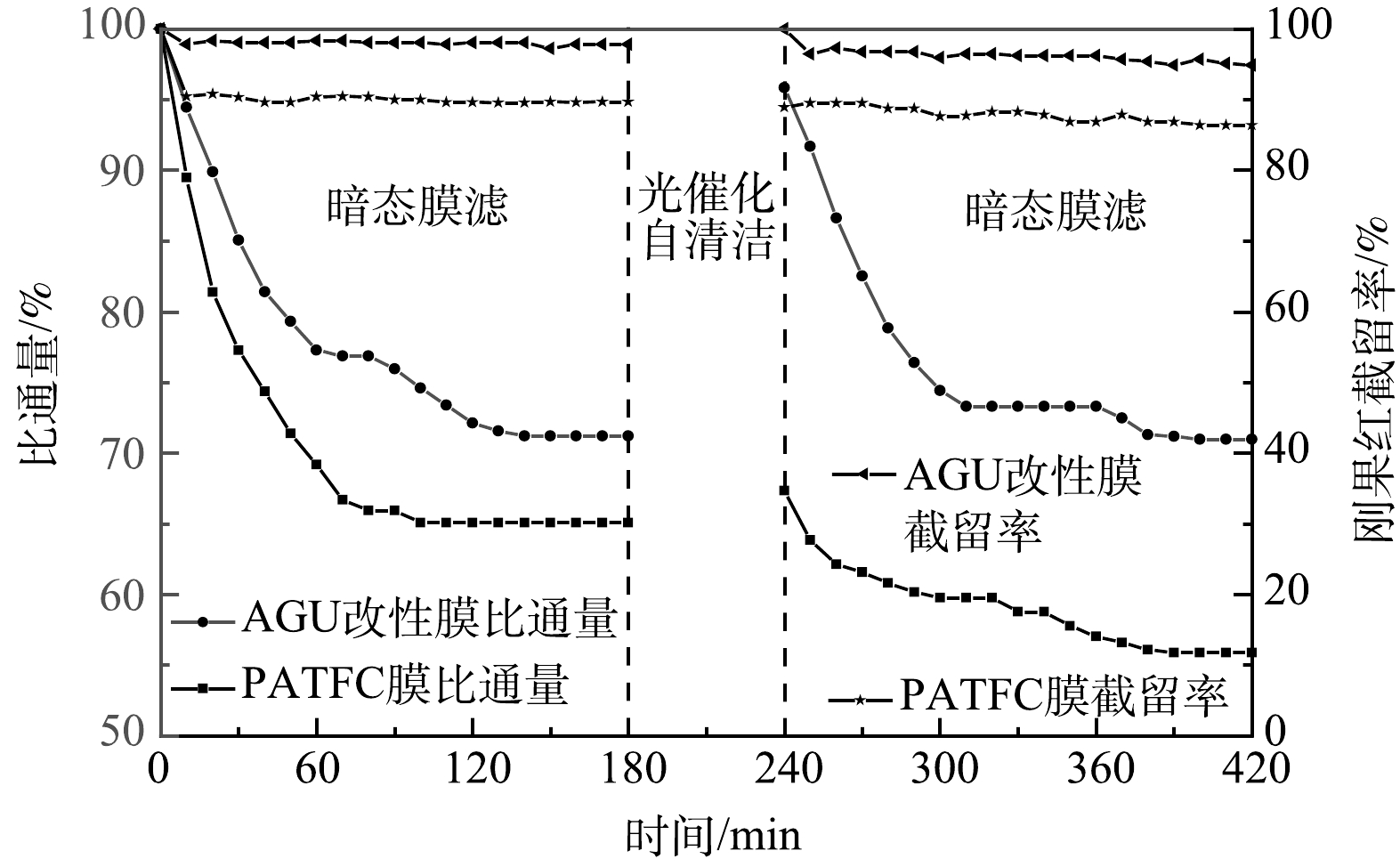

AGU改性膜光催化自清洁实验包括“暗态膜滤—光照清洁—暗态膜滤”3个步骤,测试结果如图8所示。由图8可知,在暗态条件下运行180 min后,PATFC膜和AGU改性膜的通量分别下降至初始的65.10%和71.20%。在经过60 min光催化自清洁后,PATFC原膜与AGU改性膜的通量恢复率分别为67.35%和95.83%。这是由于PATFC原膜无光催化活性,不能实现膜的自清洁;而AGU改性膜在光照条件下具有光催化能力,AGU 改性层使截留的污染物被光降解氧化,使膜通量得到显著恢复。这种光催化抗污染可能的机理是,PATFC膜表面改性剂AGU异质结,合成材料AgI与超薄g-C3N4(UCN)具有可见光催化协同作用。Ag+不仅可抑制微生物生长,而且在光照过程中微量单质纳米银析出的等离子效应,促进了可见光响应催化剂UCN的光催化效果。这种协同作用显著提升了膜表面的抗细菌污染、抗有机物污染等性能,膜通量恢复率高。进行光照自清洁实验后进行第2次膜滤实验(仍然是暗态条件),两者的通量分别下降至55.89%和70.39%。这两次膜滤后的通量变化以及对CR的截留率无明显变化,这说明光催化自清洁不会破坏改性膜的结构,从而保证了改性膜性能的稳定性。

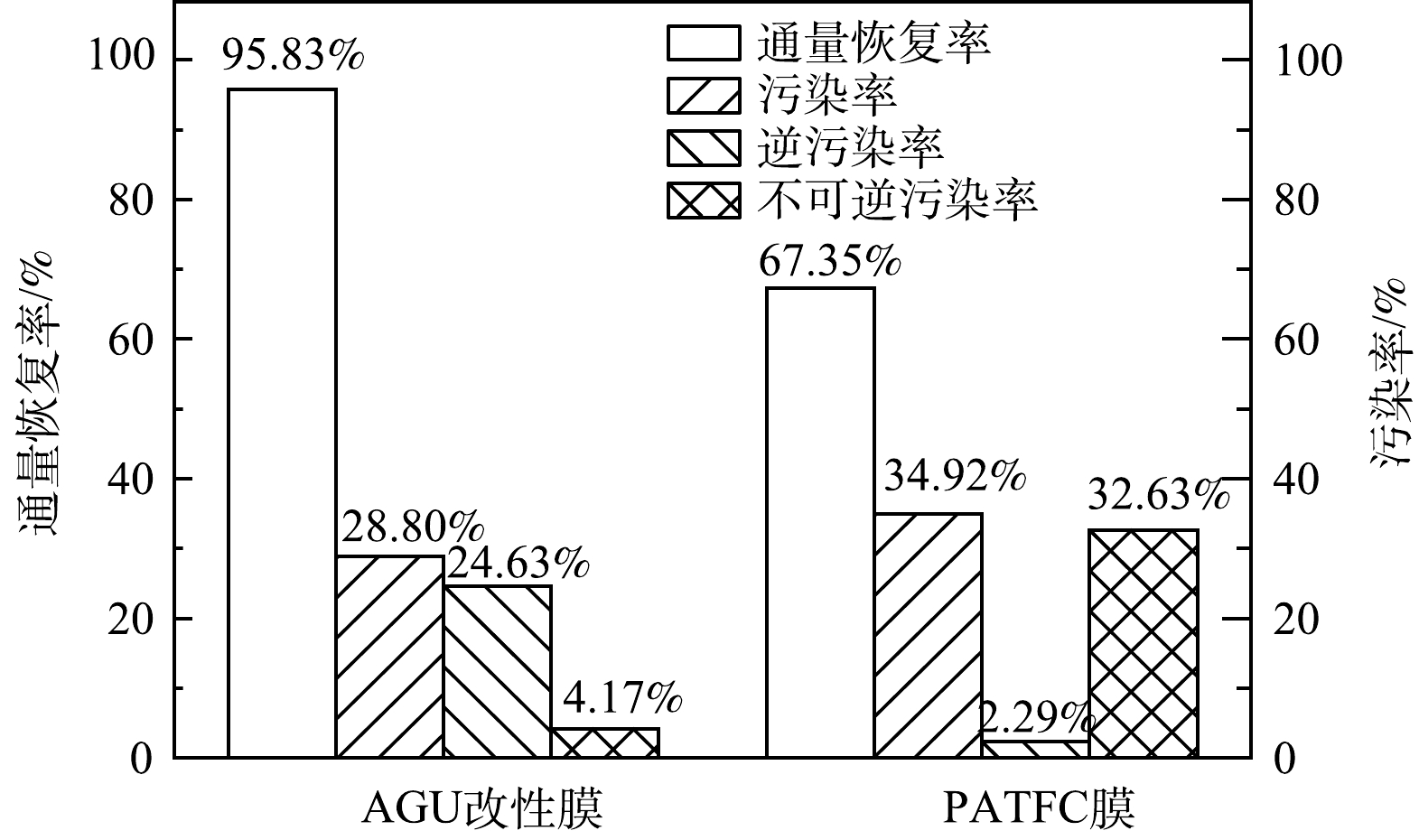

通量恢复率和膜污染是衡量膜抗污染性能的关键指标:通量恢复率越高,抗污染性能越强;在膜污染中,可逆污染可以通过简单的清洗或化学处理方式去除,而不可逆污染则只能通过更复杂的清洗或者更换膜组件解决。由PATFC膜与AGU改性膜的膜污染指数变化可知(图9),PATFC膜和改性膜的通量恢复率分别为67.35%和 95.83%,改性后膜通量恢复率提高了28.48%。PATFC膜的总污染率为34.92%,其中不可逆污染高达32.63%,可逆污染仅占2.29%。而改性膜总污染率为28. 80%,比PATFC膜降低了6.12%。此外,改性膜可逆污染率为24.63%,不可逆污染仅占 4.17%。AGU改性膜的不可逆污染率在PATFC原膜的基础上降低了87.2%,在光照条件下,AGU改性膜污染后膜通量易于恢复。因此,AGU异质结作为改性剂,可有效提高膜的抗污染性能。

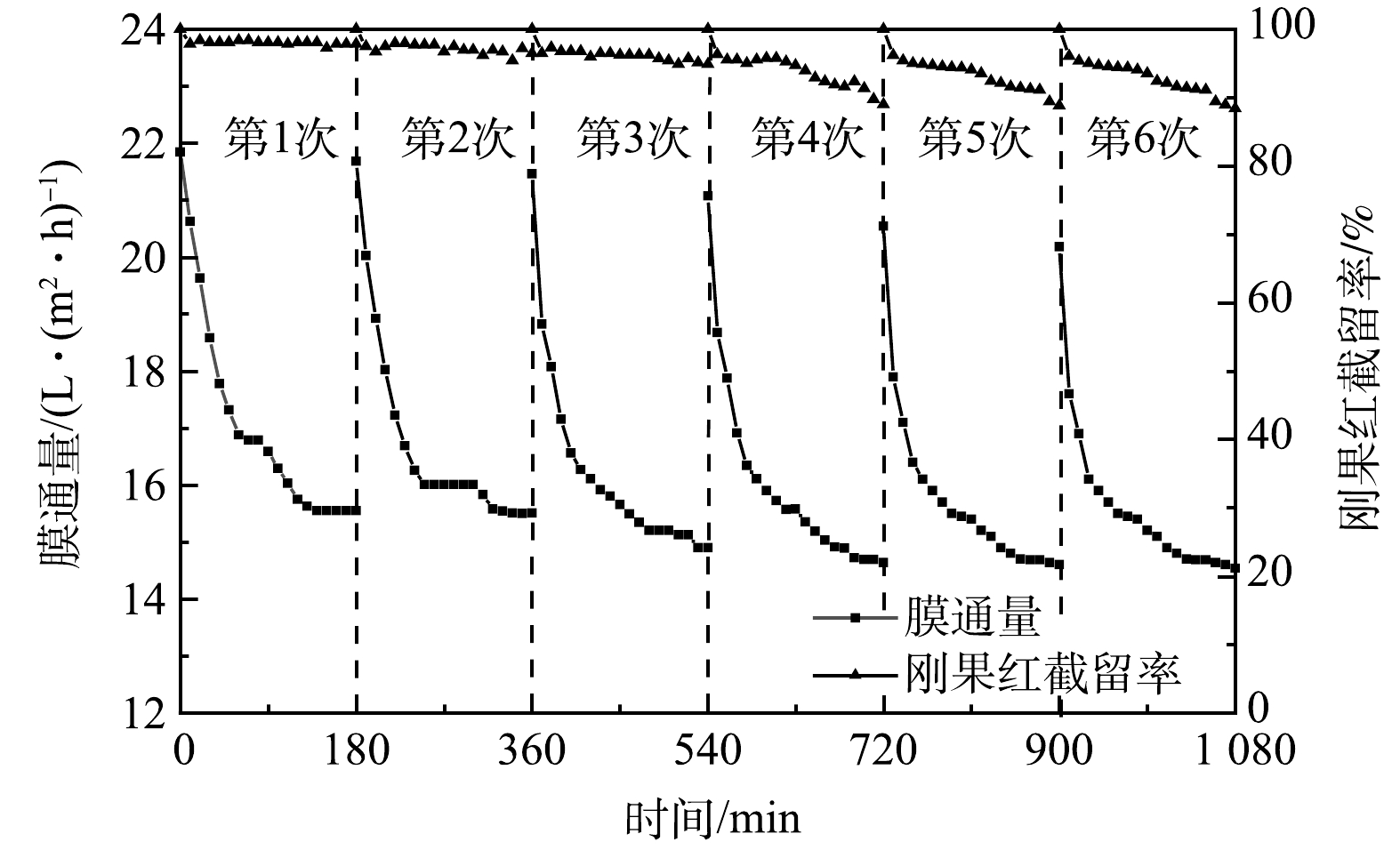

图10为改性膜的循环实验结果。在经过6次循环利用后,改性膜的通量仅下降了1.67 L·(m2·h)−1,通量恢复率可达89.86%。同时,改性膜对CR的截留率相对初始值(97.80%)仅下降了0.68%。以上结果进一步说明,AGU改性膜具有良好的纳滤稳定性和可重复利用性。

-

1) AGU改性膜的最优制备条件为:AGU光催化剂投加量30 mg;MPD水相溶液浓度1.0%;MPD水相溶液浸泡时间2 min;TMC有机相溶液浓度0.25 ‰;TMC有机相溶液浸泡时间45 s。AGU改性膜的纯水通量和CR截留率分别为21.84 L·(m2 ·h)−1和97.80% ,在PATFC膜的基础上得到明显改善。

2) AGU异质结使改性膜表面粗糙度增加,膜通量提升。同时,AGU改性膜的水接触角由 PATFC膜的57.1°下降至40.7°,亲水性增强,污染物的附着和积累显著下降。

3) AGU改性膜最大光吸收带边由387 nm 红移至488 nm,光吸收性能显著提升。改性膜通过60 min光催化自清洁后,其通量恢复率可达95.83%,而PATFC膜对应的恢复率仅为67.35%;经过6次循环利用后,改性膜通量恢复率可达89.86%,对CR截留率高达97.80%,具有良好的稳定性。

4)改性膜的抗污染性能显著提升,PATFC原膜的不可逆污染高达32.63%,约为AGU改性膜(仅为4.17%)的8倍;而AGU改性膜的可逆污染率为24.63%,约为原膜(仅为2.29%)的12倍。且在连续进行180 min的光照膜滤实验后,膜通量仅下降了7.25%,相较于PATFC膜的通量提升了23.21%。

一种新型可见光响应催化剂改性PATFC膜的制备及其抗污染性能

Preparation of a modified PATFC membrane coated with a novel visible light response catalyst and its anti-pollution properties

-

摘要: 以AgI、氧化石墨烯(GO)和超薄g-C3N4(UCN)为前驱体,通过超声结合化学沉淀法合成可见光响应AgI@GO@UCN(AGU)光催化剂,然后采用氮气压滤与界面聚合结合,将AGU负载于支撑基底聚酰胺膜(PATFC膜)表面,得到AGU改性PATFC膜,并对其制备条件及其抗污染性能进行研究。结果表明:改性膜最佳制备条件为:AGU投加量30 mg,间二胺(MPD)水相溶液质量分数1.0‰,MPD浸泡时间2 min,均苯三甲酰氯(TMC)有机相溶液质量分数0.25‰,TMC浸泡时间45 s;在最佳制备条件下,改性膜纯水通量为21.84 L·(m2·h)−1(抽吸压力0.2 MPa),对刚果红(CR)截留率可达97.80%;亲水性能显著改善,水接触角由57.1°(PATFC原膜)降至40.7°(AGU改性膜);可见光吸收性能提高显著,改性膜最大光吸收边带由原膜的387 nm红移至488 nm;改性膜抗污染性能很好,其比通量由PATFC膜的69.54%提升至92.75%;改性膜具有良好的光催化自清洁特性,光照60 min后膜通量恢复率可达95.83%;改性膜稳定性较高,重复利用6次后其通量恢复率仍可达92.35%,对CR截留率为97.29%。

-

关键词:

- AgI@GO@UCN可见光催化剂 /

- PATFC膜 /

- 抗污染性能 /

- 光催化自清洁特性

Abstract: In this study, AgI, graphene oxide (GO) and ultra-thin g-C3N4(UCN) were used as precursors, a type of visible light responsive AgI@GO@UCN(AGU) photocatalyst was synthesized through ultrasonic and chemical precipitation. Then, nitrogen press filtration combined with interfacial polymerization was used to load AGU on the surface of supporting polyamide membrane (PATFC), and AGU modified PATFC membrane was obtained. The preparation process conditions and anti-pollution properties of the modified membrane were studied. The results showed that the optimum preparation conditions were as follows: AGU dosage of 30 mg, MPD aqueous solution mass fraction of 1.0‰, MPD soaking time of 2 min, TMC organic phase solution mass fraction of 0.25‰, TMC soaking time of 45 s; Under the optimal preparation conditions, the pure water flux was 21.84 L·(m2·h)−1(suction pressure 0.2 MPa), and the retention rate of Congo red(CR) could reach 97.80%. The hydrophilicity was significantly improved, and the water contact angle decreased from 57.1°(PATFC) to 40.7°(AGU). The visible light absorption performance of the modified film increased significantly, and the red shift of its maximum absorption side band occurred from 387 nm to 488 nm. The modified membrane had a good anti-pollution performance, and its specific flux increased to 92.75% from 69.54% of PATFC membrane. The modified film had good photocatalytic self-cleaning properties, and the flux recovery rate could reach 95.83% after 60 min illumination. The modified film had a high stability, and its flux recovery rate could reach 92.35% and CR retention rate was still 97.29% after recycling for 6 times. -

-

表 1 正交实验结果

Table 1. Results of orthogonal test

因素 评价指标 M/

mgCMPD/

%TMPD/

minCTMC/

‰TTMC/

s纯水通量/

(L·(m2·h)−1)截留率/

%10 0.5 1 0.25 45 30.33 90.79 10 1.0 2 0.50 60 35.77 91.68 10 1.5 3 0.75 75 15.55 93.86 10 2.0 4 1.00 90 3.89 95.56 20 0.5 2 0.75 90 7.78 95.08 20 1.0 1 1.00 75 6.22 96.11 20 1.5 4 0.25 60 43.55 76.62 20 2.0 3 0.50 45 39.66 83.57 30 0.5 3 1.00 60 23.11 91.40 30 1.0 4 0.75 45 34.99 89.54 30 1.5 1 0.50 90 31.05 91.23 30 2.0 2 0.25 75 35.61 85.96 40 0.5 4 0.50 75 24.88 92.05 40 1.0 3 0.25 90 30.19 93.03 40 1.5 2 1.00 45 38.88 81.17 40 2.0 4 0.75 60 26.73 90.70 表 2 正交实验结果分析

Table 2. Analysis of orthogonal test results

项目 M(A)/

mgCMPD(B)/

%TMPD(C)/

minCTMC(D)/

‰TTMC(E)/

minK1(Jw) 21.385 21.525 23.582 34.920 35.965 K2(Jw) 24.302 26.793 29.510 32.840 32.290 K3(Jw) 31.190 32.258 27.127 21.263 20.565 K4(Jw) 30.170 26.473 26.828 18.025 18.227 R(Jw) 9.805 10.733 5.928 16.895 17.738 K1(η) 92.973 92.330 92.207 86.600 86.268 K2(η) 87.845 92.590 88.472 89.633 87.600 K3(η) 89.532 85.720 90.465 92.285 91.995 K4(η) 89.237 88.947 88.443 91.060 93.725 R(η) 5.128 6.870 3.764 5.695 7.457 表 3 PATFC膜和AGU改性膜的机械强度对比

Table 3. Comparison of tensile strength between PATFC membrane and AGU modified membrane

样品 样品尺寸

(长×宽×厚)/mm横截面积/

mm2最大负荷/

N抗拉强度/

MPa断裂伸长率/

%PATFC膜 90×15×0.225 3.375 76.55 22.68 12.78 AGU改性膜 90×15×0.238 3.570 73.78 20.67 15.09 -

[1] 周鑫, 唐勇. 2018~2022年中国染料行业发展趋势[J]. 染料与染色, 2018, 55(1): 11-23. [2] 谢艳新, 刘海娟, 尚磊, 等. 染料废水处理最新研究进展[J]. 印染助剂, 2020, 37(7): 11-16. doi: 10.3969/j.issn.1004-0439.2020.07.003 [3] 朱晓, 朱军勇, 张亚涛. 金属有机骨架/聚酰胺薄层纳米复合膜的研究进展[J]. 化工进展, 2022, 41(8): 4314-4326. [4] YOU X, MA T, SU Y, et al. Enhancing the permeation flux and antifouling performance of polyamide nanofiltration membrane by incorporation of PEG-POSS nanoparticles[J]. Journal of Membrane Science, 2017, 540: 454-463. doi: 10.1016/j.memsci.2017.06.084 [5] 刘彩虹. 聚酰胺复合膜功能层抗污染调控机制研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. [6] YANG Z, SUN P, LI X, et al. A critical review on thin membrane nanocomposite membranes with interlayered structure: Mechanisms, recent developments, and environmental applications[J]. Environmental Science & Technology, 2020, 54: 15563-15583. [7] YU F, SHI H, SHI J, et al. High-performance forward osmosis membrane with ultra-fast water transport channel and ultra-thin polyamide layer[J]. Journal of Membrane Science, 2020, 616: 118611. doi: 10.1016/j.memsci.2020.118611 [8] 邹正光, 俞惠江, 龙飞, 等. 超声辅助 Hummers 法制备氧化石墨烯[J]. 无机化学学报, 2011, 27(9): 1753-1757. [9] MA S, ZHAN S, JIA Y, et al. Enhanced disinfection application of Ag-modified g-C3N4 composite under visible light[J]. Applied Catalysis B:Environmental, 2016, 186: 77-87. doi: 10.1016/j.apcatb.2015.12.051 [10] 李馗. 类石墨相氮化碳共轭结构的调控及其光催化制氢性能的研究[D]. 广州: 华南理工大学, 2018. [11] 宋明顺, 黄佳, 张士朋, 等. 多指标正交试验设计去量纲准则及方法研究[J]. 工业工程与管, 2014, 19(1): 41-46. [12] 黄婕颖, 刘建军, 左胜利, 等. Ag3PO4量子点/石墨相氮化碳纳米片复合光催化剂的制备及其对苯甲醇选择性氧化活性[J]. 应用化学, 2020, 37(9): 1030-1037. doi: 10.11944/j.issn.1000-0518.2020.09.200047 [13] 张绍虎. 不同功能纳米材料共混改性聚醚砜膜及其超滤性能研究[D]. 兰州: 兰州理工大学, 2020. [14] ZHANG Z, QIN Y, KANG G, et al. Tailoring the internal void structure of polyamide films to achieve highly permeable reverse osmosis membranes for water desalination[J]. Journal of Membrane Science, 2020, 595: 117518. doi: 10.1016/j.memsci.2019.117518 [15] 付一菲. 基于ZIF-8的聚酰胺反渗透复合膜的制备与性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. [16] JAYALAKSHMI A, RAJESH S, KIM I C, et al. Poly(isophthalamide) based graft copolymer for the modification of cellulose acetate ultrafiltration membranes and a fouling study by AFM imaging[J]. Journal of Membrane Science, 2014, 465: 117-128. doi: 10.1016/j.memsci.2014.04.020 [17] ZHANG W, GUO J, REN Y. Synthesis, characterization, and properties of UV-absorbing polyimides based on alicyclic diamine with various linking positions[J]. Journal of Polymer Research, 2019, 26(6): 1-8. [18] 李晓峰. 聚吡咯中空微球改性聚哌嗪酰胺复合纳滤膜的制备及性能研究[D]. 天津: 天津工业大学, 2019. [19] YIN J, ZHU G, DENG B. Graphene oxide (GO) enhanced polyamide (PA) thin-film nanocomposite (TFN) membrane for water purification[J]. Desalination, 2016, 379: 93-101. doi: 10.1016/j.desal.2015.11.001 [20] OROOJI Y, FAGHIH M, RAZMJOU A, et al. Nanostructured mesoporous carbon polyethersulfone composite ultrafiltration membrane with significantly low protein adsorption and bacterial adhesion[J]. Carbon, 2017, 111: 689-704. doi: 10.1016/j.carbon.2016.10.055 [21] WANG C, ZHANG L, ZHANG Y, et al. Influence of surface roughness on the mechanical behavior of modified polypropylene films[J]. Polymer Engineering & Science, 2019, 59(9): 1844-1851. [22] SUN F , ZENG H , TAO S , et al. Nanofiltration membrane fabrication by the introduction of polyhedral oligomeric silsesquioxane nanoparticles: Feasibility evaluation and the mechanisms for breaking "trade-off" effect[J]. Desalination, 2022, 527: 115515. [23] CHEN S, LI L, ZHAO C, et al. Surface hydration: Principles and applications tow ard low-fouling/nonfouling biomaterials-ScienceDirect[J]. Polymer, 2010, 51(23): 5 283-5293. -

下载:

下载: