-

随着我国食品加工[1]、造纸[2]等行业的快速发展,含糖废水的排放负荷不断增加,仅在 2016 年,全国含糖废水排放量就达到了2.73×109 t[3]。含糖废水通常包含单糖、多糖、聚糖等物种,其在水体中呈现色度高、有机物浓度大、难降解等特征,如不经过处理直接排入水体,会对水环境和人体健康造成威胁。目前处理含糖废水的主要方法有吸附法[4]、生物法[5]、絮凝沉淀法[6]、化学氧化法[7]等。吸附法是使用吸附剂(活性炭等)利用其多孔结构吸附含糖废水中的糖类大分子,从而降低色度与化学需氧量(chemical oxygen demand, COD),然而富含浓缩污染物的吸附剂难以脱附再生,如处理不当会造成环境二次污染[8]。生物法对实际含糖废水中高浓度难生化降解有机污染物的处理效果极其有限,且生物法处理周期长,对环境温度要求高[9]。因此,高效、环境友好型水处理技术的探索对于实际含糖废水达标排放处理具有重要意义。

絮凝沉淀法是在含糖废水中加入絮凝剂以吸附架桥和电中和方式与糖类大分子等发生分子间作用形成大颗粒絮体从而使之沉降[10]。JABIN等[11]使用聚酰胺基阳离子聚电解质处理制糖工业中的废水,在表氯醇与二苯胺摩尔比为1.5∶1时,加入2 mg·L−1的PE-2(环氧氯丙烷与二苯胺的摩尔比为1.5∶1)后,对COD的去除率达94.8%。此外,LI等[12]采用聚合氯化铝絮凝方法作为预处理以降低焦化废水中40.1%的COD,减小后续膜蒸馏过程中膜污染发生的可能性。有研究表明,絮凝沉淀法可高效去除实际废水中的悬浮物、胶体以及大分子有机污染物,然而对一些小分子可溶性有机污染物(如脂类、酸类等)去除效果较差[13]。因此,为实现实际废水的达标排放,往往需要大幅度提高化学絮凝药剂的投加量,这无疑增加了处理成本,也为后续大量生成的化学污泥处理带来困难。

基于过硫酸盐的高级氧化技术起步较晚,但因具有以下特性而备受关注:过硫酸盐在外部能量作用下可将O—O键断裂,从而生成具有强氧化性的硫酸根自由基(

$ {\text{SO}}_{\text{4}}^{\text{-}} \cdot $ , E0=2.5~3.1 V),$ {\text{SO}}_{\text{4}}^{\text{-}} \cdot $ 相比较于Fenton反应生成的羟基自由基($ \cdot \rm{OH} $ )半衰期长达30~40 μs;过硫酸根离子与天然有机物反应较少,在实际废水中具有较好的稳定性,作用时效性更长[14]。秦文欣等[15]使用多巴胺和聚乙烯亚胺共沉积制备出PDA/PEI@PP材料能够协同Fe2+催化过硫酸盐,当Fe2+初始浓度为0.5 mmol·L−1时,在90 min内对酸性红B的降解率为98%。然而,单一过硫酸盐氧化过程中生成的含氧活性物种对于一些高浓度大分子有机污染物(聚合糖类等)去除效果较差[16],这一定程度上限制了其在处理复杂实际水体中的应用。基于上述单一絮凝沉淀法和过硫酸盐氧化法的技术局限性,构建絮凝耦合过硫酸盐氧化体系来处理实际、复杂废水是研究者们常用的方法。例如,LUO等[17]首先使用质量浓度均为500 mg·L−1的聚丙烯酰胺(polyacrylamide, PAM)与聚合氯化铝(polyaluminum chloride, PAC)处理提取油气时的返排和采出水,再添加质量浓度均为40 mg·L−1的Fe0与C以及30 mmol·L−1的过硫酸盐,在pH为3的条件下,使总有机物去除率达95.7%,悬浮固体去除率达92.4%,色度去除率达97.5%。目前关于絮凝耦合过硫酸盐氧化体系的研究,主要集中在单一絮凝或氧化过程中新型絮凝剂或催化剂的研发,污染物转化路径及降解机理的探究对于絮凝耦合过硫酸盐氧化体系的构建与优化非常关键,但相关的研究非常缺乏。

本研究以实际、复杂难降解废水为研究对象,首次构建出处理含糖废水的絮凝耦合过硫酸盐氧化体系,通过对单一絮凝体系和过硫酸盐氧化过程关键影响因子的探究,例如助凝剂、复合絮凝剂、氧化剂投加量等,构建出可同步高效去除实际、复杂含糖废水中COD和色度的耦合技术体系,基于紫外全波长扫描和GC-MS分析,揭示实际含糖废水在耦合体系中污染物转化路径,以期为实际、复杂含糖废水的达标排放提供现实可行的新方法,并为深入理解絮凝耦合过硫酸盐氧化体系中污染物转化机理提供参考。

-

实验所用药剂聚合氯化铝(PAC)纯度Al2O3>28%(1 600 元·t−1);聚丙烯酰胺(PAM)为非离子型,分子质量1 200万(6 000 元·t−1);七水合硫酸亚铁(FeSO4·7H2O)为分析纯(220 元·t−1);过硫酸盐(Na2S2O8)为分析纯(8 200 元·t−1)。以上药剂均购买于凯玛特(天津)化工科技有限公司。含糖废水取自天津市某糖厂,在糖厂废水出水管口处首先使废水放流10 min,之后使用玻璃制盛水器取水,之后将采集的水样保存到恒温20 ℃环境中,并立即展开实验。

-

1)复合絮凝剂配比在单一絮凝体系中对絮凝效果的影响。在250 mL烧杯中均加入100 mL废水样,3组实验中复合絮凝剂总投加量均为废水质量的0.5%,其中PAC的投加量分别为0.49、0.495、0.497 g,则PAM:PAC质量比分别为1∶50、1∶100、1∶150。投加复合絮凝剂后以50 r·min−1搅拌10 min,使废水中复合絮凝剂与污染物充分接触絮凝后,停止搅拌,静置30 min;再将溶液过滤,取滤液进行紫外全波长扫描并测试pH、色度及COD值。

2)复合絮凝剂投加量在单一絮凝体系中对絮凝的影响。在250 mL烧杯中均加入100 mL废水样,3组实验PAM∶PAC的质量比均为1:100,其中PAC的投加量分别为0.495、0.99、1.48 g,则所加复合絮凝剂总量分别为废水质量的0.5%、1%、1.5%。投加复合絮凝剂后以50 r·min−1搅拌10 min,使废水中复合絮凝剂与污染物充分接触絮凝后,停止搅拌,静置30 min;再将溶液过滤,取滤液进行紫外全波长扫描并测试pH、色度及COD值。

3) FeSO4·7H2O与Na2S2O8的摩尔比对氧化效果的影响。在250 mL烧杯中均加入100 mL废水样,直接投加FeSO4·7H2O和Na2S2O8,加入FeSO4·7H2O的量均为0.5 mmol·L−1,加入Na2S2O8的量分别为0.5、1、2.5、5 mmol·L−1(FeSO4·7H2O与Na2S2O8的摩尔比分别为1∶1、1∶2、1∶5和1∶10),之后以50 r·min−1搅拌反应3 h,实验完成后取样并测试pH、色度及COD。

4)絮凝后FeSO4·7H2O与Na2S2O8的摩尔比对实验结果的影响。为了研究絮凝耦合催化氧化体系对实验结果的影响,在选取最优絮凝条件下将废水样进行絮凝处理后,将絮凝后的滤液按照实验3)中催化剂FeSO4·7H2O和氧化剂Na2S2O8的投加方法进行实验并取样检测。实验过程中空白对照即为不添加任何药剂的糖厂废水原水。

-

色度的检测方法按照《水质色度的测定稀释倍数法》(HJ 1182—2021)进行,先将试样初级稀释并记录稀释次数为n,再按照自然倍数稀释并记录稀释倍数D1,最终样品色度

$ D={D}_{1}\times {10}^{(n-1)} $ 。COD使用紫外-可见智能型多参数水质测定仪(LH-3BA,兰州连华科技公司)测定。pH测试是使用便携式的多参数测量仪(Multi3630 IDS,德国WTW公司)测定。紫外全波扫描使用紫外-可见分光光度计 (UVP4,上海马帕达仪器有限公司) 测定,慢速扫描范围为190~1 100 nm,扫描速率250 nm·min−1。取原水与在最佳条件下絮凝耦合过硫酸盐处理后的废水水样进行气相色谱质谱(GC-MS)检测,GC-MS检测使用仪器型号为美国-安捷伦-7890,其中色谱柱为HP-5ms, 30 mm$\subseteq $ 0.25 mm$\subseteq $ 0.25 μm,进样量为1 μL,进样口温度280 ℃,分流比为20∶1,加热器280 ℃;色谱条件:在40 ℃下,保持5 min,以10 ℃·min−1 升温至220 ℃,再以15 ℃·min−1升温至280 ℃保持12 min。 -

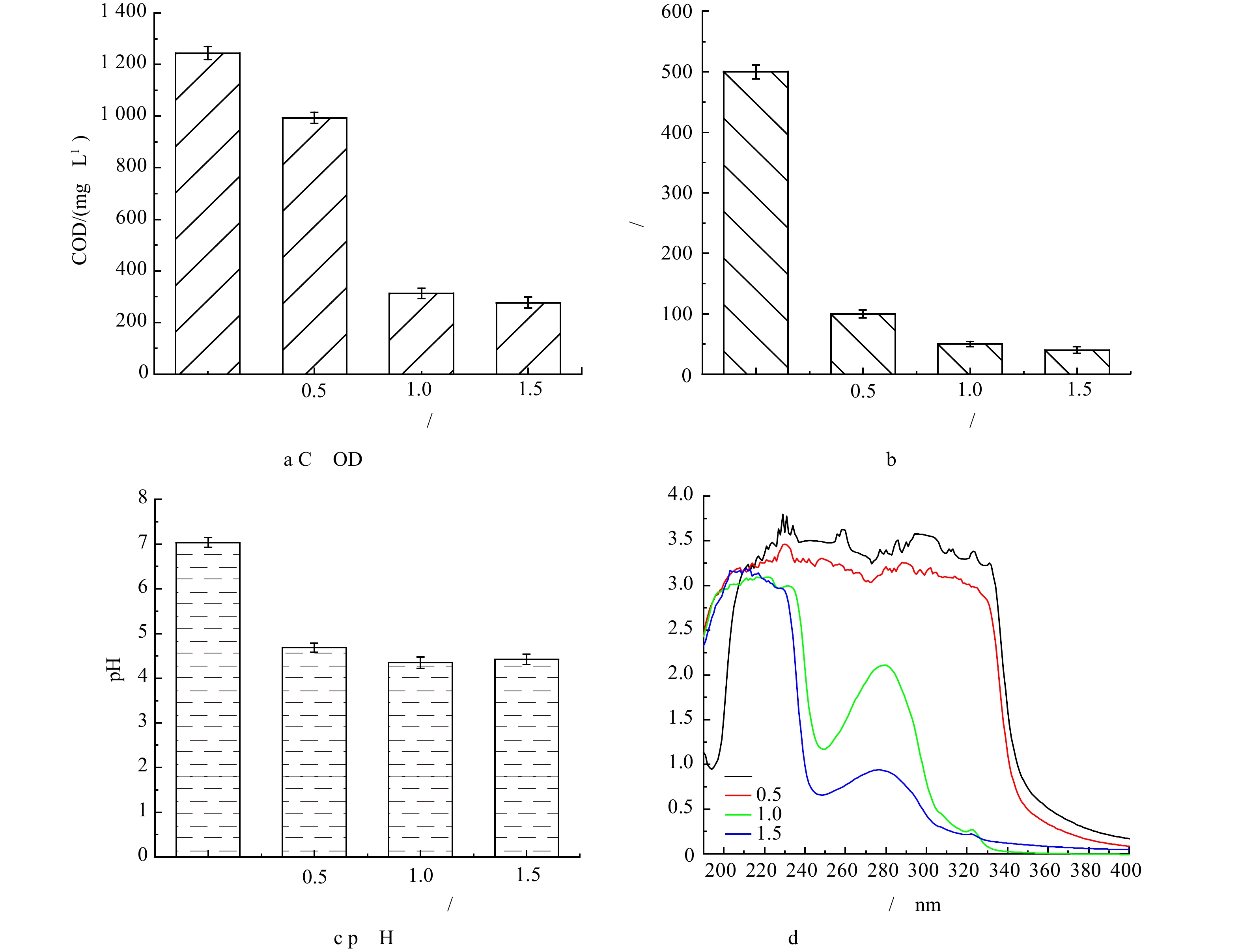

1) PAM与PAC比例对絮凝沉淀过程的影响。无机絮凝剂PAC主要使胶体颗粒脱稳从而发生絮凝沉淀,但反应过程中所产生的絮体分子链较短,不易沉降,而助凝剂PAM可以通过架桥等作用将无机絮凝剂所形成的短分子链絮体团聚成大絮团,从而增强絮体沉降能力[18]。本文探究了当PAM和PAC比例分别为1∶150、1∶100和1∶50时,絮凝沉淀对实际含糖废水的处理效果。如图1(a)和图1(b)所示,随着PAM与PAC比例的降低,絮凝沉淀对实际含糖废水中COD和色度的去除率持续升高。当PAM∶PAC比例为1∶50时,COD和色度的去除率分别为16.16%和60%;而当PAM∶PAC比例降低到1∶150时,实际含糖废水中COD和色度的去除率则分别增加到27.25%和80%。虽然助凝剂PAM的长链结构可通过架桥等作用强化絮凝沉淀且去除实际含糖废水中的COD和色度,但过高的PAM投加量并不会进一步提升实际废水的处理效果。这是由于过多的PAM高分子会覆盖胶体表面,使接近的胶体受到压缩变形而具有排斥势能[19]。实际含糖废水经絮凝沉淀处理后pH变化如图1(c)所示。PAC的水解作用会造成溶液pH的下降,而助凝剂PAM过多的投加会一定程度上抑制PAC水解过程,影响废水中COD的去除,这与废水COD和色度处理结果相一致。

原水和絮凝沉淀处理后废水的紫外全波长扫描结果如图1(d)所示。当复合絮凝剂投加量为0.5%时,通过调节PAM和PAC比例,实际含糖废水的COD最高可降低约339 mg·L−1,色度最高可降低约84%,然而值得注意的是相比于原水,絮凝沉淀处理后水样在190~400 nm内的吸光度并没有明显下降。根据实际含糖废水COD、色度去除率以及紫外全波长扫描结果,推断絮凝沉淀过程中优先去除一些不具有发光基团的大分子有机污染物,例如聚合物和长链烷烃(二十九烷烃、三十四烷烃等)等,这些物质同样也是构成实际含糖废水色度的重要组成部分。

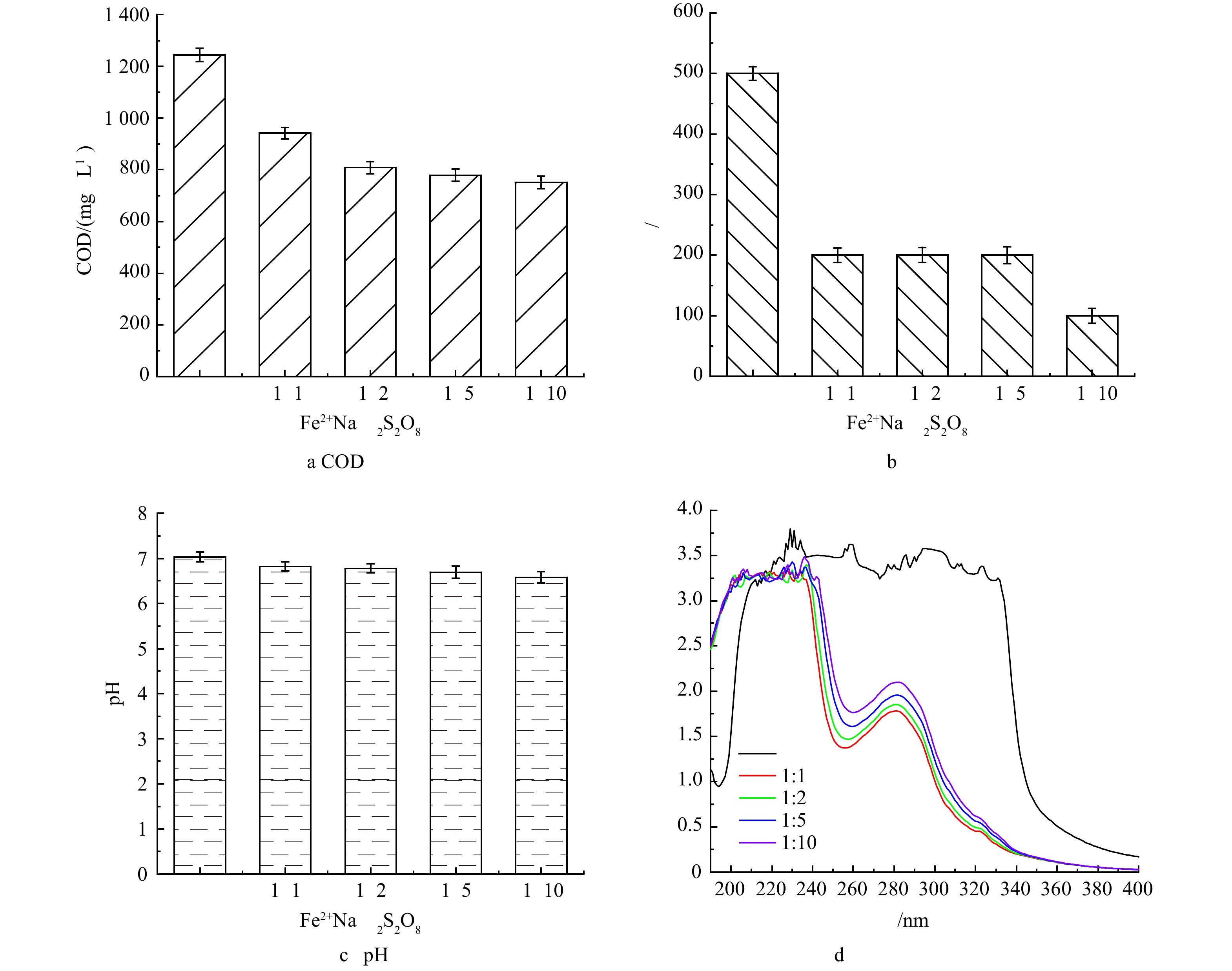

2)复合絮凝剂投加量对絮凝沉淀效果的影响。由图2(a)和图2(b)可见,当复合絮凝剂投加量由0.5%增加到1%时,实际废水中COD去除率由20.18%升至74.84%,色度也进一步由100 倍降低到50 倍。然而,当复合絮凝剂投加量增加到1.5%时,实际含糖废水中COD和色度的去除率几乎没有提升。这是由于增加絮凝剂有助于絮凝沉淀反应的充分进行,但过多的絮凝剂会改变胶体颗粒电性,使得脱稳胶体重新稳定,不利于废水中污染物的去除[20]。由于絮凝沉淀过程中氯化铝的水解作用,处理后废水的pH有所下降。如图2(c)所示。pH的降低有利于后续过硫酸盐氧化,因为二价铁在酸性环境下更倾向于以离子形式存在[21]。

原水和絮凝沉淀处理后废水的紫外扫描结果如图2(d)所示。紫外扫描结果表明,随着絮凝剂投加量的进一步增大,在240~300 nm内的吸光度显著下降,而在200~240 nm内的吸光度未下降。根据之前的研究[22-23]表明,推断随着絮凝剂投加量的增加,实际含糖废水中包含紫外或可见发光基团的大分子有机污染物(如芥酸酰胺、邻苯二甲酸丁酯等)逐渐被去除,而包含发光基团的小分子有机物(如乙酸丁酯等)的去除效果依旧很差。此外,紫外全波长扫描和色度去除结果表明,上述包含发光基团的大分子有机污染物同样也是构成实际含糖废水色度的物质。综合COD、色度去除以及絮凝剂投加成本综合分析,1%的复合絮凝剂投加量作为后续实验的最佳条件。

-

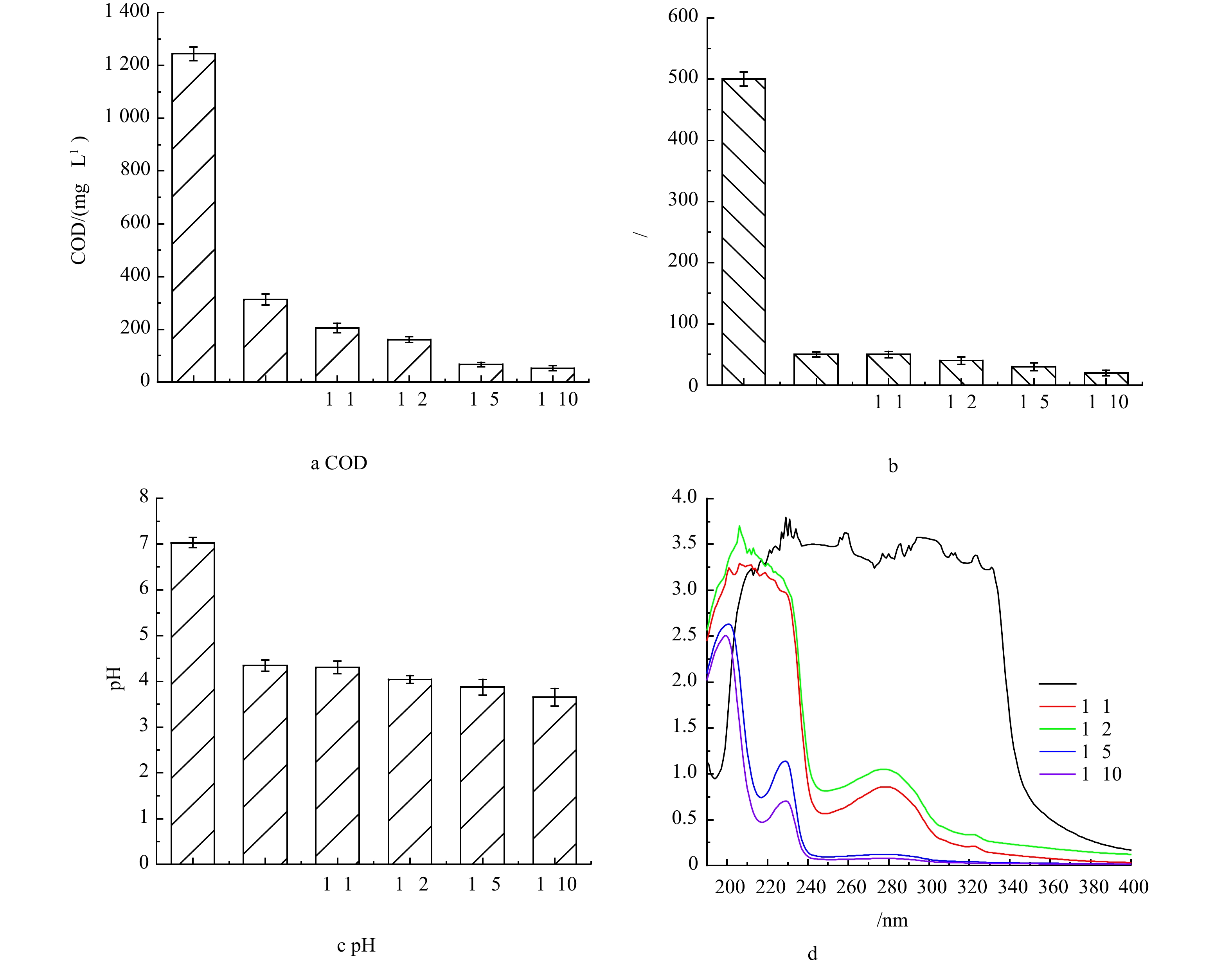

在过硫酸钠以及反应生成含氧自由基的共同氧化作用下(式(1)~(2)),实际含糖废水的COD和色度也可得到一定程度的去除,如图3(a)和3(b)所示。当Fe2+与过硫酸钠比例从1∶10提高到1∶1时,实际含糖废水中COD去除率由39.63%下降到24.28%,色度去除率同样也由80%下降到60%。上述结果表明,过多的Fe2+投加量并不能提高过硫酸钠氧化体系的去除效率,这是由于过量Fe2+会猝灭氧化体系中生成的硫酸根自由基 (式(3)),导致污染物去除率下降。不同Fe2+与过硫酸钠比例下氧化体系处理后废水pH由于小分子有机酸的生成呈现下降趋势(图3(c)),但由于单一过硫酸盐氧化体系对实际、复杂含糖废水有限的处理效果,处理后废水pH下降幅度非常微弱。

原水和Fe2+催化Na2S2O8氧化体系处理后废水的紫外全波长扫描结果如图3(d)所示。结果表明,和原水相比,Fe2+催化Na2S2O8氧化体系处理后含糖废水在240~300 nm的吸光度显著下降,但随着Fe2+与Na2S2O8比例的变化,该波长范围内的吸光度并没有显著变化。对比单一絮凝沉淀体系和Fe2+催化Na2S2O8氧化体系对实际含糖废水中COD、色度去除以及紫外全波长扫描结果,推断Fe2+催化Na2S2O8氧化体系优先去除包含发光基团的大分子有机污染物(如芥酸酰胺、邻苯二甲酸丁酯等),但对大分子聚合物的去除能力非常有限。此外,在近中性实际废水中,二价铁难以以离子形式存在,倾向与氢氧根生成沉淀物,进而影响过硫酸钠生成硫酸根自由基的速率[24]。综上所述,Fe2+催化Na2S2O8氧化体系无法实现对实际、复杂含糖废水的高效处理。

-

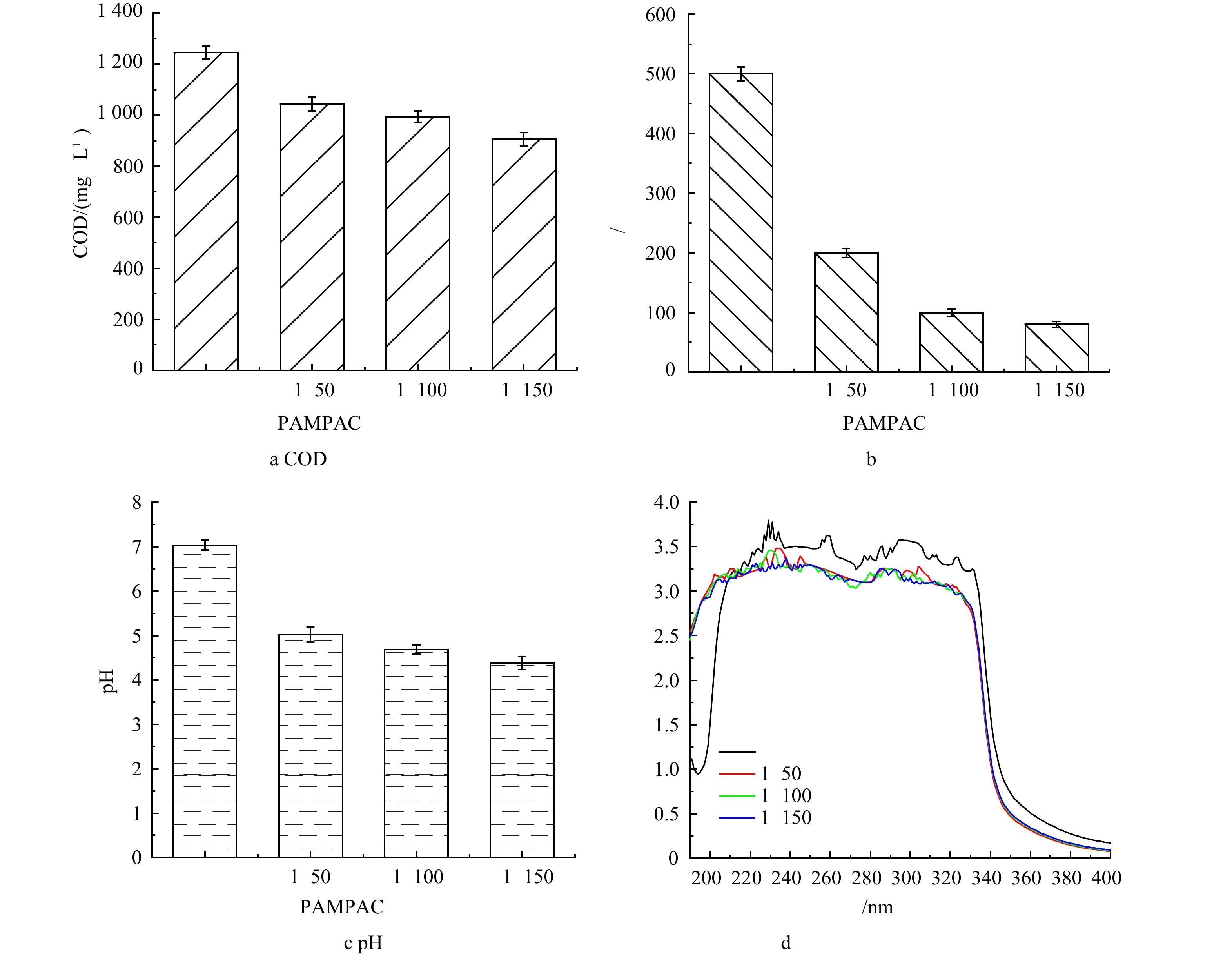

絮凝耦合过硫酸钠氧化体系对实际含糖废水中COD、色度去除率如图4(a)和图4(b)所示。根据上述分析,絮凝沉淀优先去除实际含糖废水中不含发光基团的聚合物、长链烷烃以及包含发光基团的大分子有机污染物(如芥酸酰胺、邻苯二甲酸丁酯等),处理后废水COD由1 244 mg·L−1降低到313 mg·L−1,色度由500 倍降至50 倍,pH也由7.03降到更有利后续氧化过程的酸性环境。经过进一步的过硫酸盐氧化处理,当Fe2+与过硫酸钠比例为1:10时,实际废水COD值可低至53 mg·L−1,色度持续降低了20 倍。如图4(d)所示,当Fe2+与Na2S2O8比例为1∶5和1∶10时,处理后废水在240~300 nm内的吸光度几乎降低为0,在220~240 nm内的吸光度大幅度降低。紫外全波长扫描结果表明,经絮凝沉淀处理后的实际废水在经过过硫酸钠氧化体系进一步处理后,废水中含发光基团的大分子有机污染物几乎被彻底去除,另外,在单一絮凝沉淀体系和Fe2+催化Na2S2O8氧化体系中几乎无法去除的含发光基团的小分子有机污染物也得到有效去除。综上所述,絮凝耦合过硫酸钠氧化体系可高效去除实际、复杂含糖废水中的高COD和色度,处理后的水质可满足城镇污水处理厂污染物排放标准一级标准(GB 18918-2002)。本研究在使用絮凝耦合过硫酸盐氧化处理废水工艺中,参考市场药剂价格得出:絮凝部分所需药剂花费为8.2元·t−1,过硫酸盐氧化过程所需药剂花费为1元·t−1,则本工艺处理含糖废水药剂花费为9.2元·t−1。

-

为进一步阐明实际含糖废水在絮凝耦合过硫酸钠氧化体系降解过程中污染物的转化机理,原水和耦合体系处理后废水中污染物类型采用气相色谱-质谱联用仪(GC-MS)分析。如表1所示,原水中主要包括苯系物、长链烷烃、酰胺及酯类。经过絮凝耦合过硫酸盐氧化处理后,废水中的乙酸,1-甲基丙酯、乙酸丁酯、对二甲苯、乙苯、1,2,4,5-四甲基苯、十七烷、1,8-二甲基萘、邻苯二甲酸二丁酯、十八酰胺、三十四烷、芥酸酰胺、二十九烷、1,1'-双萘和二甲基砜这14种有机物被完全去除,而甲苯、丁二酸二甲酯、柠檬酸丁酯、9-十八碳酰胺,(z)和油酸甘油酯的去除率分别为48.32%、37.22%、41.42%、90.74%和43.94%。此外,耦合处理后废水中也检测到由大分子有机物转化而成的小分子有机物,例如甲酸丁酯。

综合GC-MS和紫外全波长扫描分析可知,单一絮凝过程中PAC在水中形成微小的絮状体优先去除实际含糖废水中不含紫外或可见光吸收基团的大分子有机污染物,例如聚合物和长链烷烃(如二十九烷烃、三十四烷烃等)等。然而,随着絮凝剂的持续加入,含有发光基团的大分子有机污染物(如芥酸酰胺、邻苯二甲酸丁酯等)也进一步被絮凝去除。不同于单一絮凝过程,Fe2+催化Na2S2O8过程中生成的硫酸根自由基(

$ {\text{SO}}_{\text{4}}^{\text{-}}\text{∙} $ )和羟基自由基($ \text{∙}\text{OH} $ )更优先倾向于攻击含有发光基团的有机污染物,而其对大分子聚合物的去除有限。基于絮凝和氧化过程中不同的污染物转化机理,本研究提出了絮凝耦合过硫酸盐氧化去除实际含糖废水的污染物转化机理:絮凝过程优先去除不含发光基团的大分子聚合物、长链烷烃等有机污染物,这些物质的去除可使实际废水的色度下降近80%。随着絮凝剂的持续投加,含发光基团的有机污染物也被进一步去除,色度也会进一步降低。值得注意的是,絮凝处理后实际废水的pH由最初的7.03降低到4.35,这是由于PAC水解造成的。pH的降低有利于后续过硫酸盐氧化过程的进行,因为二价铁在酸性环境下更倾向于以离子形式存在。随着自由基氧化过程的进行,实际废水中含发光基团的大分子有机污染物(如芥酸酰胺、邻苯二甲酸二丁酯等)和小分子有机污染物(如乙酸丁酯等)得到进一步氧化降解,实际废水的COD和色度持续下降[25]。

-

1)助凝剂PAM和絮凝剂PAC投加量及配比对絮凝效果影响较大,当复合絮凝剂投加量为1%,助凝剂PAM与絮凝剂PAC的投加配比为1∶100时,可在较小的药剂投加量下使得废水中色度和COD的去除率分别达到84%和74.84%。

2)单一Fe2+催化Na2S2O8对原废水中的高浓度聚合物去除效果差,在Fe2+与Na2S2O8配比为1∶10时,COD和色度的去除率分别只有38.58%和80%,需先对废水进行絮凝处理才有利于催化氧化过程的进行。

3)经过絮凝耦合过硫酸钠氧化体系处理后的废水的色度和COD的去除率分别达到96%和95.74%,絮凝沉淀过程持续将大分子聚合物、长链烷烃等有机污染物去除,过硫酸钠氧化过程使实际废水中大分子有机污染物几乎彻底去除,小分子有机污染物也得到高效去除。

絮凝耦合过硫酸钠氧化处理实际含糖废水

Treatment of actual sugar-containing wastewater by flocculation coupled with sodium persulfate oxidation

-

摘要: 含高浓度污染物和色度实际含糖废水的高效处理一直是水处理领域的难点。针对单一絮凝沉淀和过硫酸钠氧化体系的技术局限性,首次构建了絮凝耦合过硫酸钠氧化体系,同步实现了对废水中COD和色度的高效去除,并深入探究了污染物的转化机理。结果表明:在最佳实验条件下,絮凝耦合过硫酸钠氧化体系对实际含糖废水中COD的去除率高达 95.74%,色度去除率高达96%。紫外全波长扫描和GC-MS分析结果表明,絮凝沉淀过程优先去除不含发光基团的大分子聚合物、长链烷烃等有机污染物,含发光基团的大分子有机污染物部分被去除;在后续过硫酸钠氧化过程中,实际废水中含发光基团的大分子有机污染物几乎被彻底去除,小分子有机污染物得到高效去除。本研究可为复杂的实际含糖废水的达标排放提供参考。Abstract: The efficient treatment of actual sugar-containing wastewater with high concentration of pollutants and chroma has always been a difficulty in the field of water treatment. In view of the technical limitations of the single flocculation sedimentation and sodium persulfate oxidation system, the flocculation coupling sodium persulfate oxidation system was constructed for the first time, which simultaneously realized the efficient removal of COD and chroma in wastewater, and the transformation mechanism of pollutants was deeply explored. The results showed that under the optimal experimental conditions, the removal rates of COD and chroma in the actual sugar-containing wastewater by the flocculation-coupling sodium persulfate oxidation system were 95.74% and 96%, respectively. The results of UV-wavelength scanning and GC-MS analysis showed that the organic pollutants such as macromolecular polymers and long-chain alkanes without luminescent groups were preferentially removed by the flocculation and precipitation process, and the macromolecular organic pollutants with luminescent groups were partially removed. In the subsequent sodium persulfate oxidation process, the macromolecular organic pollutants containing luminescent groups in the actual wastewater were almost completely removed, and the small molecular organic pollutants were effectively removed. This study can provide a reference for the complex actual sugar-containing wastewater meeting the national discharge standards.

-

-

表 1 原水与耦合体系处理后废水中物质分析

Table 1. Analysis of substances in raw wastewater and treated wastewater by the coupled system

组分 分子式 保留时间/min 原水中物质相对含量/% 耦合体系处理水样后 去除率/% 甲酸丁酯 C5H10O2 3.965 — 存在 0 乙酸,1-甲基丙酯 C6H12O2 4.576 2.21 不存在 100 甲苯 C7H8 4.776 0.46 存在 48.32 乙酸丁酯 C6H12O2 6.290 47.59 不存在 100 对二甲苯 C8H10 6.560 0.05 不存在 100 乙苯 C8H10 7.377 4.92 不存在 100 丁二酸二甲酯 C6H10O4 11.216 0.11 存在 37.22 1,2,4,5-四甲基苯 C10H14 13.249 0.26 不存在 100 十七烷 C17H36 13.439 0.04 不存在 100 1,8-二甲基萘 C12H12 17.306 0.03 不存在 100 邻苯二甲酸二丁酯 C16H22O4 23.212 8.51 不存在 100 柠檬酸丁酯 C18H32O7 25.583 0.85 存在 41.42 9-十八碳酰胺,(z) C18H35NO 27.035 2.80 存在 90.74 十八酰胺 C18H37NO 27.222 0.77 不存在 100 油酸甘油酯 C18H33N 27.930 1.22 存在 43.94 三十四烷 C34H70 28.629 0.20 不存在 100 芥酸酰胺 C22H43NO 30.128 27.17 不存在 100 二十九烷 C29H60 32.519 0.19 不存在 100 1,1'-双萘 C20H14 33.345 0.32 不存在 100 二甲基砜 C20H14O2S 34.475 2.30 不存在 100 -

[1] CASTIGLIONI M, RIVOIRA L, GALLO M, et al. Removal of sugars from food and beverage wastewaters by amino-modified SBA-15[J]. Journal of Cleaner Production, 2021, 324(15): 129236. [2] QIU Y B, WU S F, XIA L, et al. Ionic resource recovery for carbon neutral papermaking wastewater reclamation by a chemical self-sufficiency zero liquid discharge system[J]. Water Research, 2023, 229(1): 119451. [3] 许文, 董莉, 毕莹莹, 等. 我国制糖工业废水污染物排放现状及建议[J]. 现代化工, 2019, 39(10): 5-8. doi: 10.16606/j.cnki.issn0253-4320.2019.10.002 [4] 吴远楠, 李大为, 陶玉仑, 等. 聚苯胺纳米粉体对糖汁的脱色吸附性能研究[J]. 广州化工, 2021, 49(20): 41-44. doi: 10.3969/j.issn.1001-9677.2021.20.015 [5] 段梦雯, 梁达奉, 马瑞佳, 等. 微生物絮凝剂在甘蔗糖业中的应用研究进展[J]. 中国调味品, 2019, 44(7): 164-167. doi: 10.3969/j.issn.1000-9973.2019.07.037 [6] ZHANG Y L, LI M, ZHANG G H, et al. Efficient treatment of the starch wastewater by enhanced flocculation–coagulation of environmentally benign materials[J]. Separation and Purification Technology, 2023, 307(15): 122788. [7] SAHU O. Electro-oxidation and chemical oxidation treatment of sugar industry wastewater with ferrous material: An investigation of physicochemical characteristic of sludge[J]. South African Journal of Chemical Engineering, 2019, 28: 26-38. doi: 10.1016/j.sajce.2019.01.004 [8] RIVERA-UTRILLA J, FERRO-GARCIA M A, BAUTISTA-TOLEDO I, et al. Regeneration of ortho-chlorophenol-exhausted activated carbons with liquid water at high pressure and temperature[J]. Water Research, 2003, 37(8): 1905-1911. doi: 10.1016/S0043-1354(02)00552-3 [9] 吴红萍, 刘勇, 黄辉, 等. 微生物絮凝剂产生菌的筛选及其絮凝特性初步研究[J]. 生物技术, 2014, 24(3): 68-73. [10] RAJ P, BATCHELOR W, BLANCO A, et al. Effect of polyelectrolyte morphology and adsorption on the mechanism of nanocellulose flocculation[J]. Journal of Colloid and Interface Science, 2016, 481(1): 158-167. [11] JABIN S, KAPOOR J K, JADOUN S, et al. Synthesis and characterization of polyamine-based polyelectrolytes for wastewater treatment in the sugar industry[J]. Journal of Molecular Structure, 2023, 1275(5): 134573. [12] LI J F, WU J, SUN H F, et al. Advanced treatment of biologically treated coking wastewater by membrane distillation coupled with pre-coagulation[J]. Desalination, 2016, 380(15): 43-51. [13] HJORTH M, JORGENSEN B U. Polymer flocculation mechanism in animal slurry established by charge neutralization[J]. Water Research, 2012, 46(4): 1045-1051. doi: 10.1016/j.watres.2011.11.078 [14] LIU Z B, REN X, DUAN X Y, et al. Remediation of environmentally persistent organic pollutants (POPs) by persulfates oxidation system (PS): A review[J]. Science of the Total Environment, 2023, 863(10): 160818. [15] 秦文欣, 张环, 李欣, 等. 聚多巴胺/聚乙烯亚胺复合非织造布/Fe2+活化过硫酸盐催化氧化酸性红B的效果分析[J]. 环境工程学报, 2020, 14(12): 3290-3297. doi: 10.12030/j.cjee.202001087 [16] SHI Y F, YANG J K, MAO W, et al. Influence of Fe2+-sodium persulfate on extracellular polymeric substances and dewaterability of sewage sludge[J]. Desalination and Water Treatment, 2015, 53(10): 2655-2663. doi: 10.1080/19443994.2013.868833 [17] LUO M N, YANG H C, WANG K T, et al. Coupling iron-carbon micro-electrolysis with persulfate advanced oxidation for hydraulic fracturing return fluid treatment[J]. Chemosphere, 2023, 313: 137415. doi: 10.1016/j.chemosphere.2022.137415 [18] 郑铭灏, 赵飞, 张净瑞, 等. PAC-PAM复合絮凝剂处理燃煤电厂脱硫废水的研究[J]. 现代化工, 2022, 42(5): 178-182. doi: 10.16606/j.cnki.issn0253-4320.2022.05.034 [19] ZOU W J, ZHAO J L, SUN C B. Adsorption of anionic polyacrylamide onto coal and kaolinite calculated from the extended DLVO theory using the van Oss-Chaudhury-Good theory[J]. Polymers, 2018, 10(2): 113. doi: 10.3390/polym10020113 [20] LIN Z, WANG Q W, WANG T Q, et al. Dynamic floc characteristics of flocculated coal slime water under different agent conditions using particle vision and measurement[J]. Water Environment Research, 2019, 92(5): 706-712. [21] HE K, WANG S C, LIU Y, et al. Insights into the corrosion of sulfidated microscale zero valent iron in the presence of benzoic acid: inhibited oxidation capacity and promoted zinc immobilization[J]. Journal of Environmental Chemical Engineering, 2022, 10(6): 108950. doi: 10.1016/j.jece.2022.108950 [22] 张克峰, 岳浩伟, 王珊, 等. 不同碱化度钛铁复合药剂微絮凝强化过滤性能研究[J]. 工业水处理, 2022, 42(9): 160-166. doi: 10.19965/j.cnki.iwt.2021-1226 [23] 杨锐, 李宁杰, 刘洁, 等. 不同絮凝剂对生活污水处理中溶解性有机物的影响[J]. 水处理技术, 2022, 48(5): 90-94. doi: 10.16796/j.cnki.1000-3770.2022.05.018 [24] ZOU J, MA J, CHEN L W, et al. Rapid acceleration of ferrous iron/peroxymonosulfate oxidation of organic pollutants by promoting Fe(III)/Fe(II) cycle with hydroxylamine[J]. Environmental Science & Technology, 2013, 47(20): 11685-11691. [25] DONG C D, HUANG C P, NGUYEN T B, et al. The degradation of phthalate esters in marine sediments by persulfate over iron–cerium oxide catalyst[J]. Science of the Total Environment, 2019, 696(15): 133973. -

下载:

下载: