-

铅酸蓄电池具有价格低廉、安全性能高、适用范围广和再生性强等优点,广泛应用于电力、储能、国防、交通运输等重要领域[1]。据统计,铅酸蓄电池中的铅用量占我国铅消费总量的68%[2]。随着铅酸蓄电池在汽车、电动自行车和储能领域的大规模应用,废铅酸蓄电池回收处理与再生铅行业发展迅速。废铅酸蓄电池是一类典型的社会源危险废物,来源广泛且分散,非正规企业和个人开展非法收集处理导致的污染问题时有发生,严重危害人体健康和生态环境安全[3]。在危废管理制度下开展废铅酸蓄电池规范化回收处理,是我国推进“无废城市”建设试点工作的重要内容[4]。同时,废铅酸蓄电池循环利用所带来的减污降碳协同效益[5],也体现了发展循环经济对“双碳”目标实现的贡献和潜力。

生命周期评价方法 (Life cycle assessment, LCA) 是辨识、分析、评估产品环境影响的有效工具,可对铅酸蓄电池生产过程产生的环境影响和报废后回收处理过程产生环境效益进行全面评价。针对铅酸蓄电池的生命周期环境影响,有研究关注了铅酸蓄电池“从摇篮到坟墓”全过程[6-7],也有研究只关注了“从摇篮到大门”对应的生产过程[8]。同时,不少研究关注了回收处理过程的环境表现,如PAN等[9]基于能值评估企业回收废铅酸蓄电池的环境排放对人类健康和生态系统的影响。YU等[10]利用改进的能值分析方法评价废铅酸蓄电池资源化系统的效率和可持续性。有研究则对不同回收处理方案进行比较,如SUN等[11]基于中国铅行业的调查以及废铅酸蓄电池技术的发展,对不同资源化技术方案进行了半定量化评估;TIAN等[12]则利用生命周期评价方法比较了5种典型的废铅酸蓄电池资源化工艺,发现并非所有的湿法冶金工艺都在环境绩效上具有合理性;王琢璞等[13]也采用生命周期评价方法对废铅酸蓄电池回收制取再生铅合金、回收制铅锭再制电池材料和原生材料生产电池材料过程的环境影响进行比较,分析出不同回收过程中环境污染的关键环节和主要因子。

我国废铅酸蓄电池具有跨区域转移特征[14]。相应地,在生产者责任延伸制度 (Extended Producer Responsibility, EPR) 框架下,国家自2019年开展针对铅酸蓄电池生产企业集中收集和跨区域转移的试点工作。在政策影响下,废铅酸蓄电池回收处理的物质流过程及环境绩效均发生了变化[15-16]。然而,现有研究尚未清晰刻画EPR制度下的物质代谢特征和减污降碳效益。本研究针对已建立危险废物跨省市转移“白名单”机制的贵州省,聚焦废铅酸蓄电池收集、转运、拆解和再生处置的全过程,在现有回收处理模式调研和情景模拟的基础上,采用LCA对集中收集和跨区域转运制度下废铅酸蓄电池物质流过程与碳减排效益进行分析,为废铅酸蓄电池回收政策评估与优化提供决策支持。

-

本研究选定地区为位于长江经济带上游区域的贵州省。该省于2020年签订了《关于建立长江经济带上游四省市危险废物联防联控机制协议》与《四省市危险废物跨省市转移“白名单”合作机制》,以废酸、废矿物油、废铅酸蓄电池、电镀污泥等危险废物为重点,持续联合开展跨省市打击危险废物非法转移倾倒环境违法犯罪活动。同时,通过建立危险废物跨省市转移“白名单”制度,简化危险废物跨省、市转移审批程序,防范危险废物环境风险[17]。

在贵州省域范围内,聚焦贵阳市城区开展废铅酸蓄电池产生主体的实地调研,跟踪掌握跨区域转移“白名单”机制实施前后的收运体系和物质流过程,并基于贵州台江经济开发区的再生铅企业确定废铅酸蓄电池处理处置方案。

-

针对调研区域中的4S店、汽车维修厂、助力车修理店、新电池经销商以及新电动车销售商等产废主体,开展废铅酸蓄电池产生特征问卷调查,内容涉及废铅酸蓄电池产生单位基本信息、废铅酸蓄电池类别、产生数量和去向等情况。共实地走访调查746家产废主体,其中539家获得有效调查数据。

调研发现市场主流的铅酸蓄电池品牌为超威、天能、统一、旭派和风帆等,主流型号为14 Ah以下、20 Ah、32 Ah、45 Ah以上4类,其占比约为1∶7∶1∶1。采用直接称重法对相应品牌和型号的废铅酸蓄电池进行称重测量,通过加权平均计算得出助力车主体产生的废铅酸蓄电池重量为6.2 kg∙只−1,汽修主体产生的废铅酸蓄电池重量为15 kg∙只−1。

进一步实地走访区域内废铅酸蓄电池回收企业和处理处置企业,掌握废铅酸蓄电池物流去向、收运方式和运输距离,以及拆解处理的技术方案和关键参数,重点关注以废铅酸蓄电池为代表的社会源危险废物的收运现状和在EPR制度影响下收集与跨区域转运过程的变化。

-

废铅酸蓄电池在回收处理全过程中,一方面随收集、转运、拆解、再生利用、处置等工序产生直接或间接碳排放;另一方面,通过再生利用可获得再生铅和塑料等再生材料,能避免相应原生材料的生产过程,带来碳减排贡献。基于生命周期思想,解析废铅酸蓄电池生命周期过程中碳排放和碳减排的关键环节,通过计算综合碳减排量E来表征碳减排效益,见式 (1) 。

式中:

$ {\mathrm{E}}_{\mathrm{再}\mathrm{生}\mathrm{材}\mathrm{料}\mathrm{避}\mathrm{免}\mathrm{排}\mathrm{放}} $ 为废铅酸蓄电池拆解处理后获得的再生材料通过替代原生材料生产过程所避免的碳排放量;$ {\mathrm{E}}_{\mathrm{收}\mathrm{集}\mathrm{环}\mathrm{节}\mathrm{排}\mathrm{放}} $ 为废铅酸蓄电池收集过程产生的碳排放量;$ {\mathrm{E}}_{\mathrm{转}\mathrm{运}\mathrm{环}\mathrm{节}\mathrm{排}\mathrm{放}} $ 为废铅酸蓄电池转运过程产生的碳排放量;$ {\mathrm{E}}_{\mathrm{拆}\mathrm{解}\mathrm{环}\mathrm{节}\mathrm{排}\mathrm{放}} $ 为废铅酸蓄电池拆解过程的碳排放量;$ {\mathrm{E}}_{\mathrm{再}\mathrm{生}\mathrm{处}\mathrm{置}\mathrm{环}\mathrm{节}\mathrm{排}\mathrm{放}} $ 为废铅酸蓄电池再生利用过程与废弃物处置过程产生的碳排放量。本研究所指碳减排和碳排放是所有温室气体的减排或排放总量,且包括各工序环节自身的直接排放和由原辅材料或能源生产过程带来的间接排放。对于综合碳减排量的计算,采用GaBi软件进行系统建模,选用IPCC评估模型中的全球变暖潜值 (GWP 100 years, kgCO2eq) 进行表征。

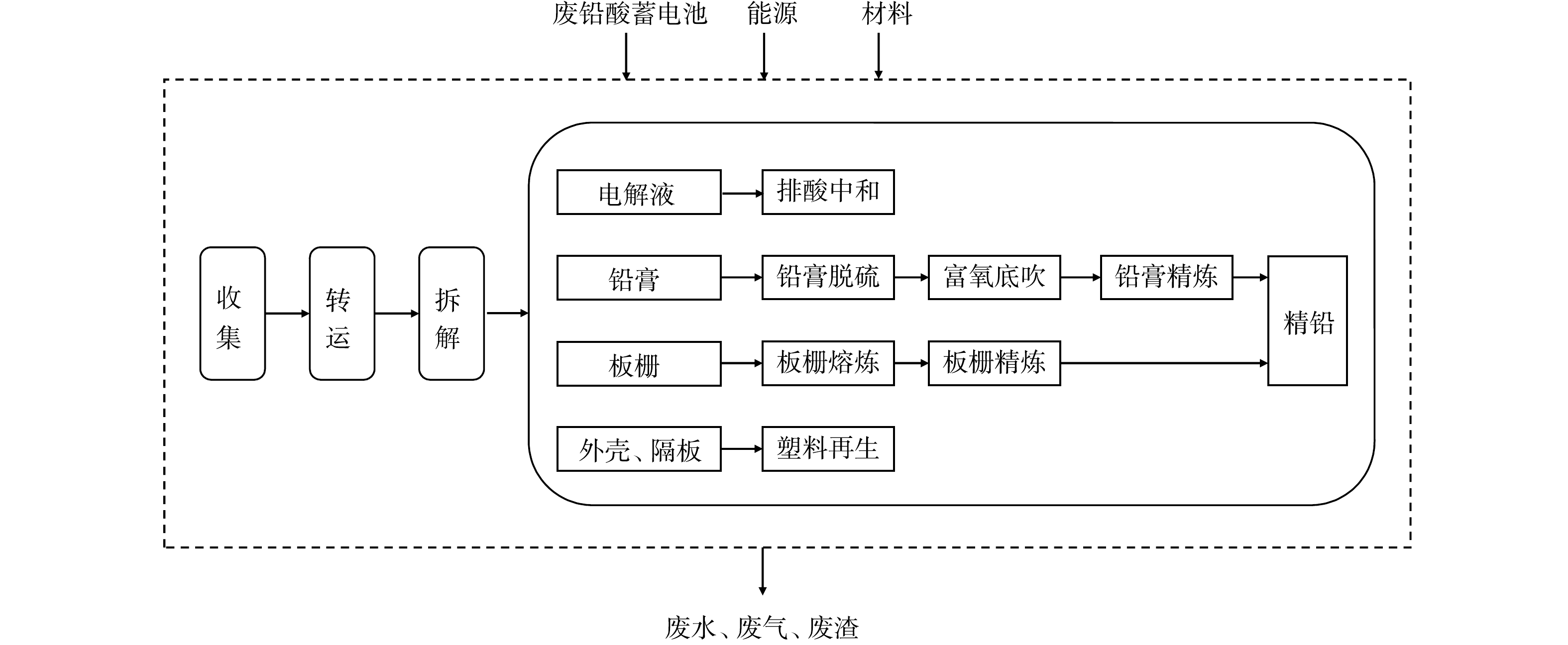

在生命周期模型构建过程中,将功能单位确定为回收处理1 t废铅酸蓄电池。系统边界包括废铅酸蓄电池从收集、转运到处理处置的全过程,具体包括废铅酸蓄电池个体商流动回收、专业第三方回收、生产商以旧换新回收、区域内和跨区域转运、拆解、电解液处理、塑料再生、铅膏处理处置、板栅处理处置等过程,按生命周期阶段划分为收集 (含贮存) 、 转运、拆解、再生处置4个环节 (图1) 。具体来看,废铅酸蓄电池从电池销售点、助力车销售和维修点、汽车4S店等处产生后,回收商对其进行收集,采用人工分类、分拣、人工+叉车等方式上卸货,运输至贮存点。贮存点的废铅酸蓄电池达到一定数量后,由危险废物运输公司运输至再生铅企业进行拆解和再生处置。废铅酸蓄电池经破碎分选后分出板栅和铅膏部分。其中,板栅的铅含量高,铅膏部分经脱硫转化,然后再用富氧底吹炉进行冶炼,得到粗铅后进行深度除渣精炼生产精铅。同时,废旧铅酸蓄电池的外壳与隔板通过破碎分离系统进行拆解分离获得废旧塑料,经分类后用于生产再生塑料。

-

针对主要依靠市场驱动建立的废铅酸蓄电池回收处理现状模式 (称为基准情景,S1) ,结合当前铅酸蓄电池生产企业集中收集和跨区域转运制度及EPR政策导向[18-20],分别提出集中收集优化情景 (S2) 和跨区域转运优化情景 (S3) 2种系统方案,分析各自物质流过程和碳减排效益。

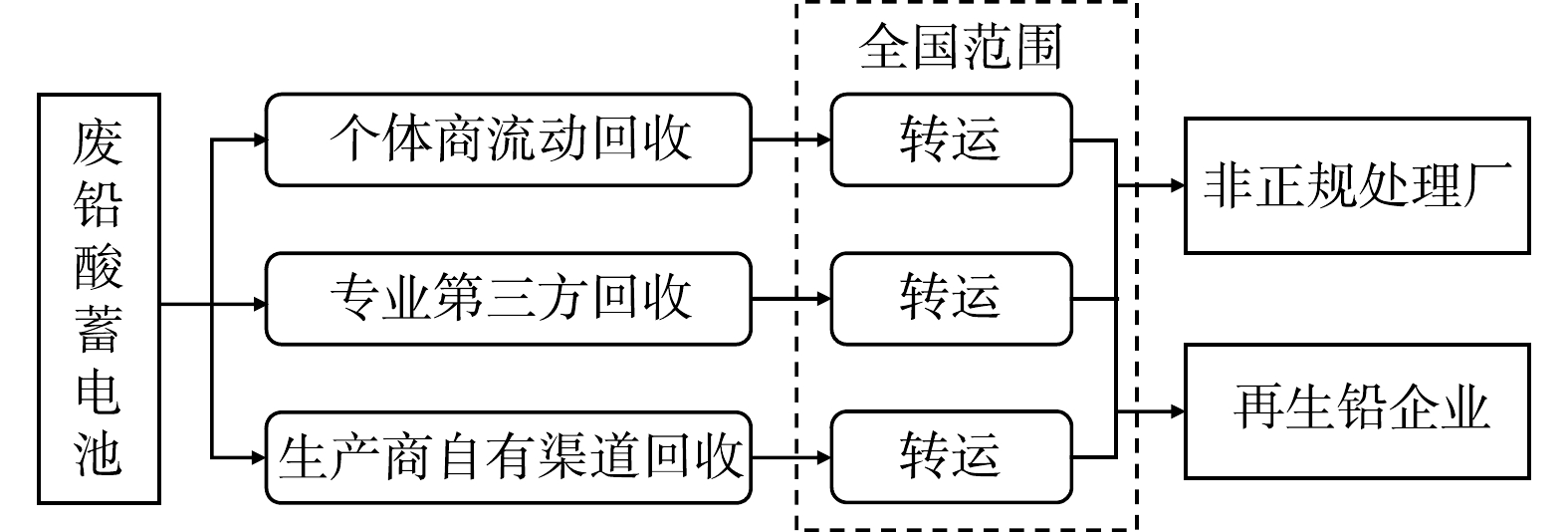

基准情景 (S1) 。根据当前回收市场调研,废铅酸蓄电池收集方式由三种渠道组成:1) 个体回收商采取全方面、多点位的流动回收方式;2) 第三方专业回收公司通过与废铅酸蓄电池产生主体签署合作协议定期回收;3) 生产商通过自有销售渠道以逆向物流的形式进行回收 (图2)。其中,个体商流动回收的废铅酸蓄电池大部分进入具有危废处置资质的再生铅企业,进行正规的处理处置,小部分在经济利益驱动下流入非正规处理厂,并且在长距离运输前将废电解液非法处置直排进入环境;专业第三方回收和生产商自有回收渠道收集的电池,均转运至正规再生铅企业,通过危险废物转移联单避免了非法处置行为,但目前以这2种方式回收的废铅酸蓄电池量较少[21]。

基于实地调研,每收集1 t废铅酸蓄电池,个体商流动收集距离为302.77 km,贮存周期为1周,用电1.86 kW·h,装卸采用人力搬运;专业第三方回收距离为160 km;贮存周期为2周,用电3.71 kW·h,使用“叉车+人工”的方式进行装卸,消耗柴油0.28 kg,产生的废抹布、废拖把、废劳保用品均经收集转入耐酸容器包装后送至有资质单位处理;生产商自有渠道收集距离采用文献[22]数据 (24 km) ,生产商自有渠道贮存周期设定为3周,其余贮存情况与第三方专业回收相同。转运阶段通过再生铅企业在全国范围内收集到的废铅酸蓄电池来源分布,确定运输距离为412.5 km。再生铅生产的清单数据来自贵州某再生铅企业的工艺数据和环评报告数据,缺失的数据以调研和文献数据作为补充。建模中对比的原生铅生产过程,来自GaBi软件专业数据库的基础数据。

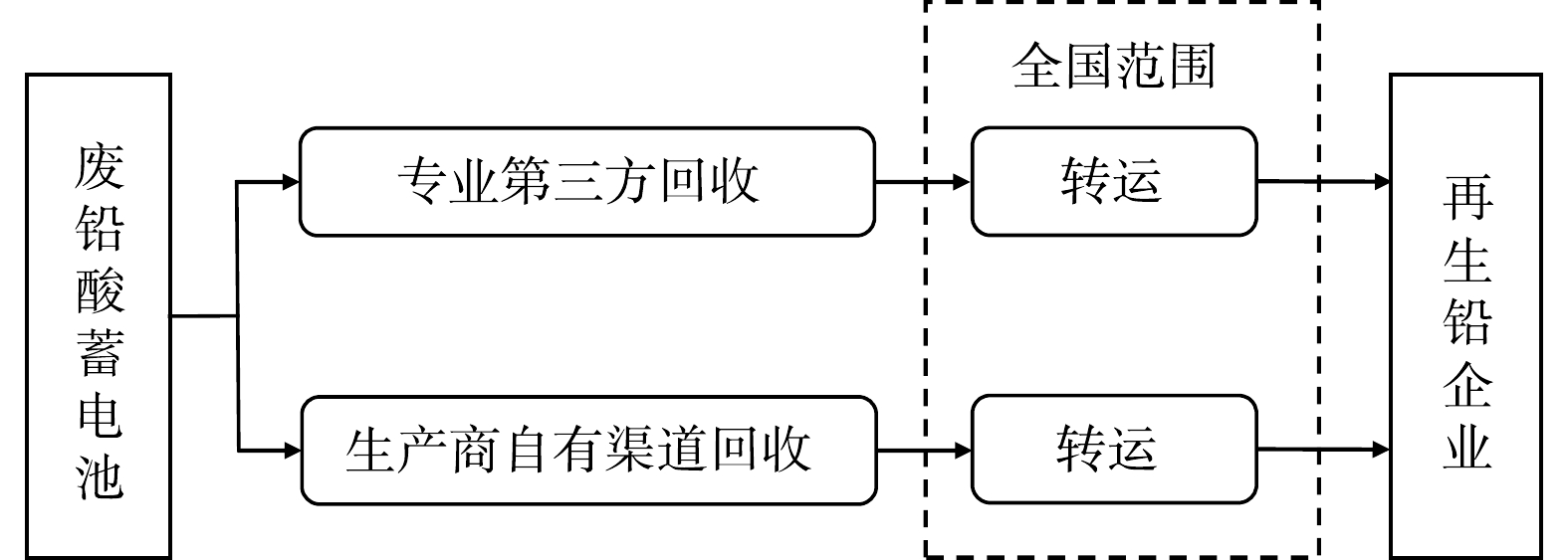

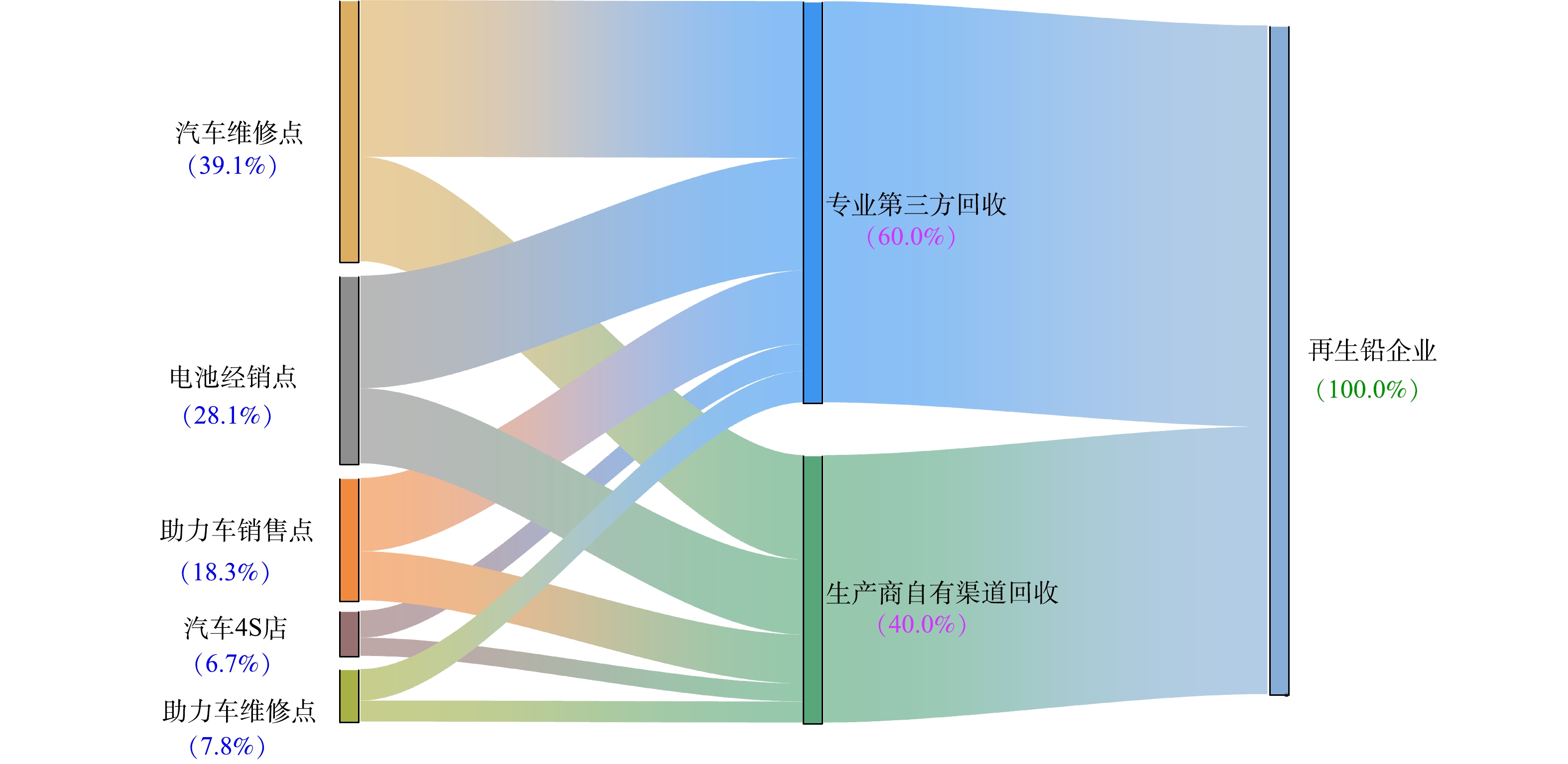

集中收集优化情景 (S2) 。在基准情景的基础上对收集环节进行优化。社会源中产生的废铅酸蓄电池由第三方专业回收公司 (60.0%) 和生产商自有回收渠道 (40.0%) 以联合收集的方式进行,可依托铅酸蓄电池销售网点、机动车4S店、维修网点等设立收集网点,不采用个体商流动回收。收集到的废铅酸蓄电池全部进入正规再生企业进行处理处置 (图3) 。

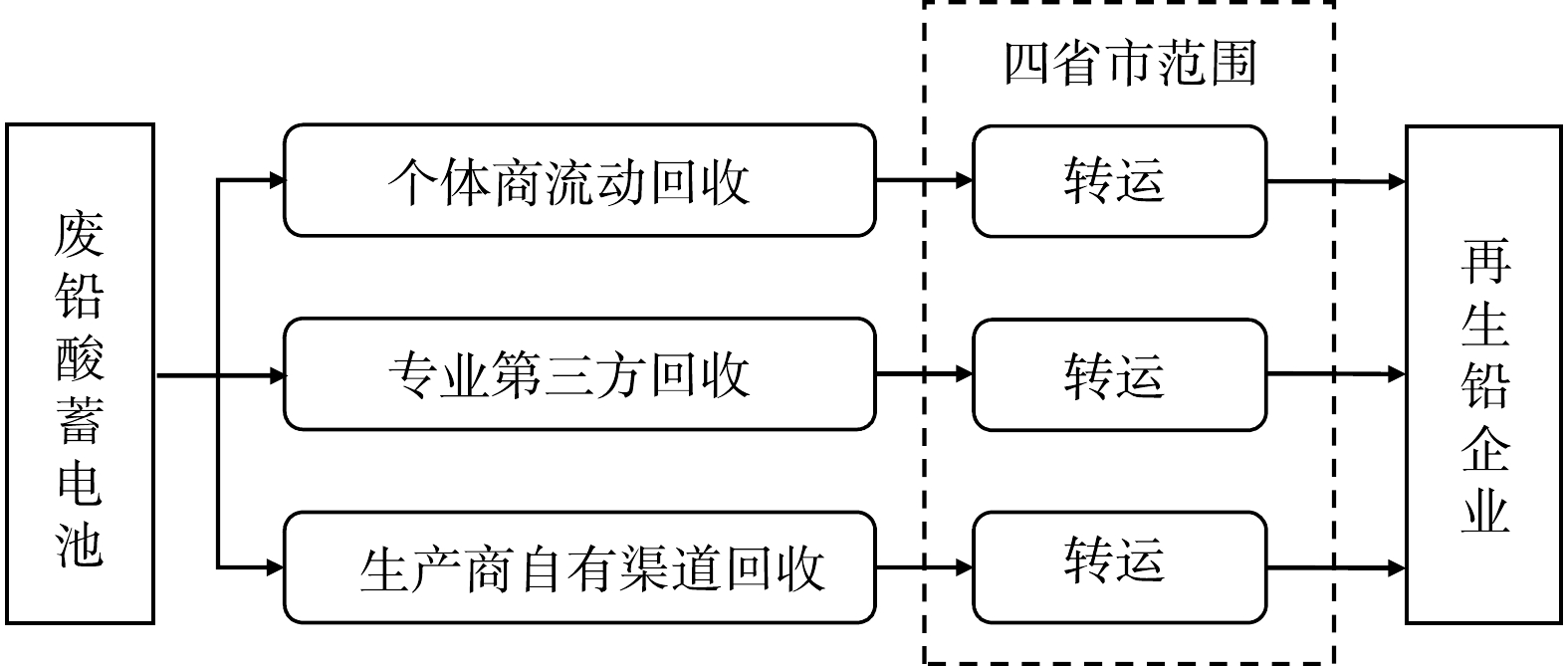

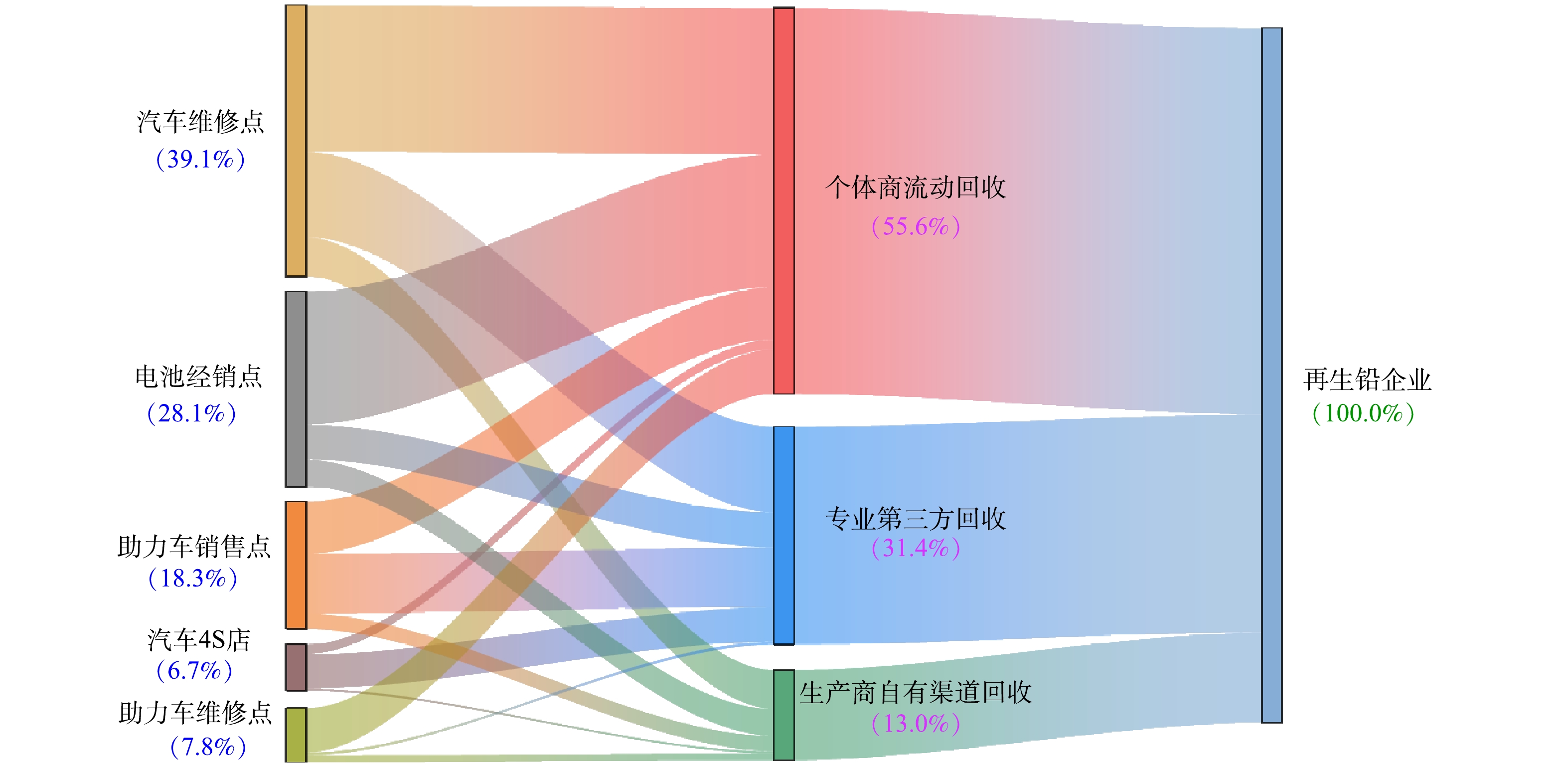

跨区域转运优化情景 (S3) 。在基准情景的基础上对转运环节进行优化。通过省级生态环境部门之间开展区域合作,实行“白名单”制度,简化跨区域审批程序。设定收集模式与基准情景相同,即个体商流动回收 (55.6%) 、专业第三方回收 (31.4%) 和生产商自有渠道回收 (13.0%) ,转运阶段则从全国范围分散式运输向四省市区域一体化集约式运输转变,降低跨区域转运距离,实现废铅酸蓄电池的高效回收 (图4) 。废铅酸蓄电池回收处理系统基准情景和优化情景设定及关键参数详见表1。

-

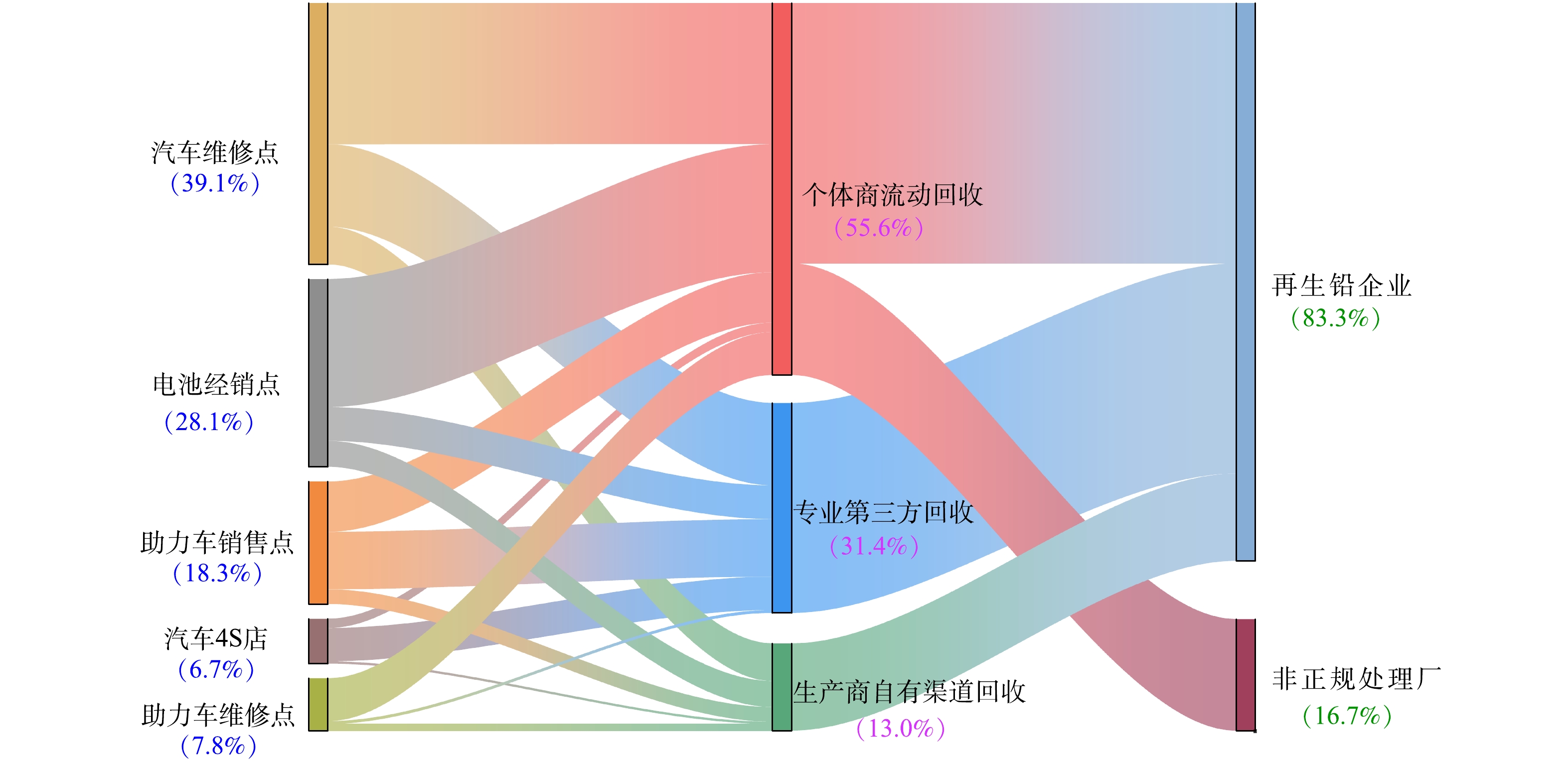

基于调研数据,模拟分析贵阳市废铅酸蓄电池在基准情景下的产生特征和物质流过程。如图5所示,从产废主体来看,45.8%废铅酸蓄电池来自汽修主体,54.2%来自助力车主体。具体来看,汽车维修点产生量最多 (39.1%) ,其次是电池经销点 (28.1%) 和助力车销售点 (18.3%) ,助力车维修点 (7.8%) 与汽车4S店 (6.7%) 的产生量相对较少。

在汽修主体中,85.3%的废铅酸蓄电池来自维修点,其中54.0%流向个体流动商回收;在助力车主体中,51.8%来自电池经销点,大部分 (68.2 %) 流入个体流动商回收体系。无论是汽修主体还是助力车主体,生产商逆向物流回收占比均较小。从废铅酸蓄电池回收量来看,个体商流动回收占比最大 (55.6%) ,其次是专业第三方回收 (31.4%) ,生产商自有渠道回收占比最少 (13.0%) 。

进一步分析废铅酸蓄电池的去向发现,受目前废铅酸蓄电池的正规收集体系尚未完全建立的影响,后端再生利用环节仍然存在非法冶炼的现象。根据对行业龙头企业的走访调查,个体商回收后仍有约30.0%的废铅酸蓄电池流入非正规处理厂,体现在整体物质流去向上占比为16.7%。

-

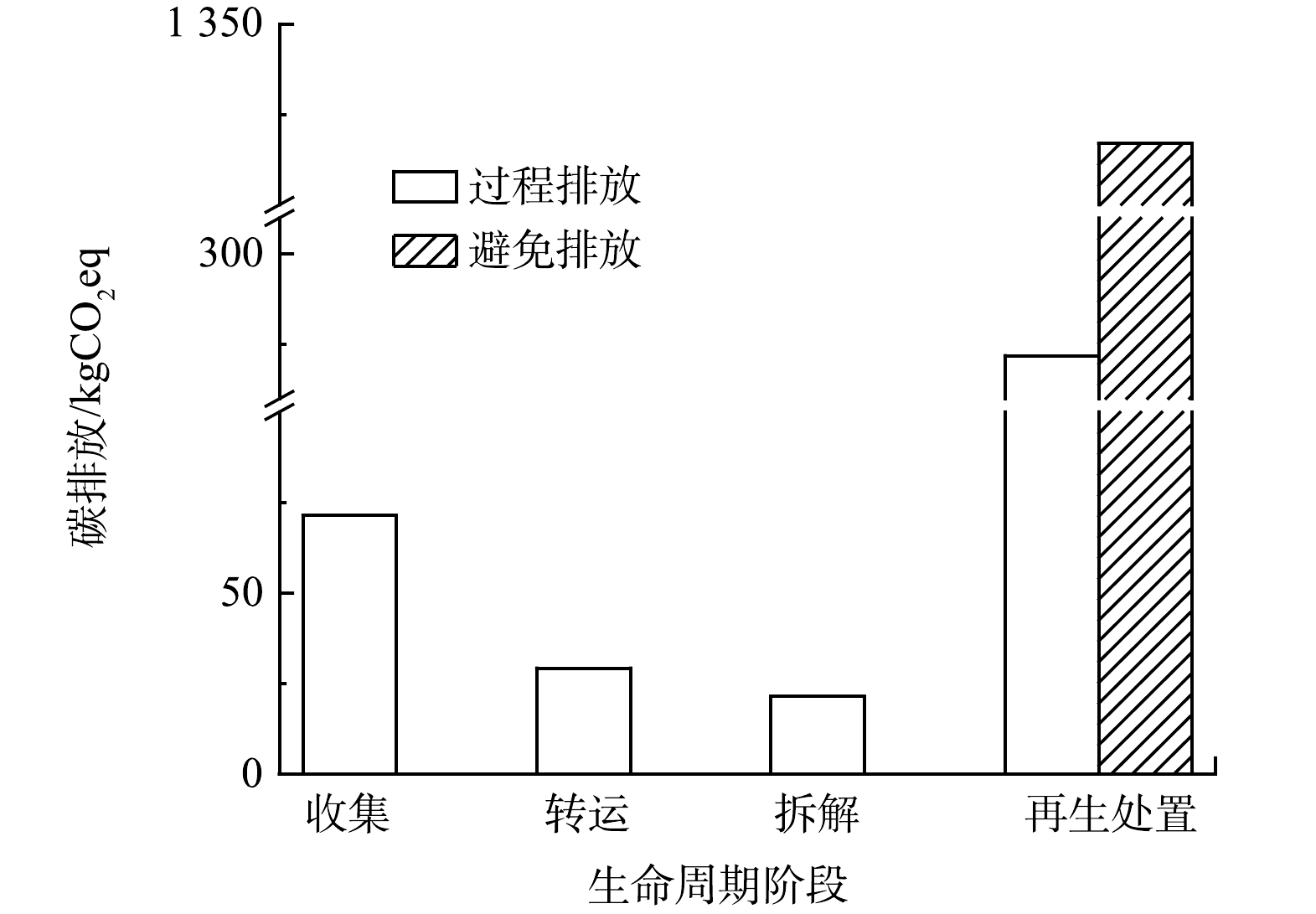

生命周期评价结果显示,在基准情景S1中,回收处置1 t废铅酸蓄电池的碳排放量为393.91 kgCO2eq,主要的碳排放过程是再生处置阶段 (271.93 kgCO2eq) ,其次是收集阶段71.35 kgCO2eq、转运阶段29.21 kgCO2eq和拆解阶段21.42 kgCO2eq (图6) 。在收集、转运和拆解阶段,柴油与电力的消耗是产生碳排放的主要原因。再生处置阶段再生产品的产出,替代了原生产品的开采过程,避免的碳排放量为1 317.01 kgCO2eq。从废铅酸蓄电池全生命周期来看,碳减排效益为923.1 kgCO2eq。

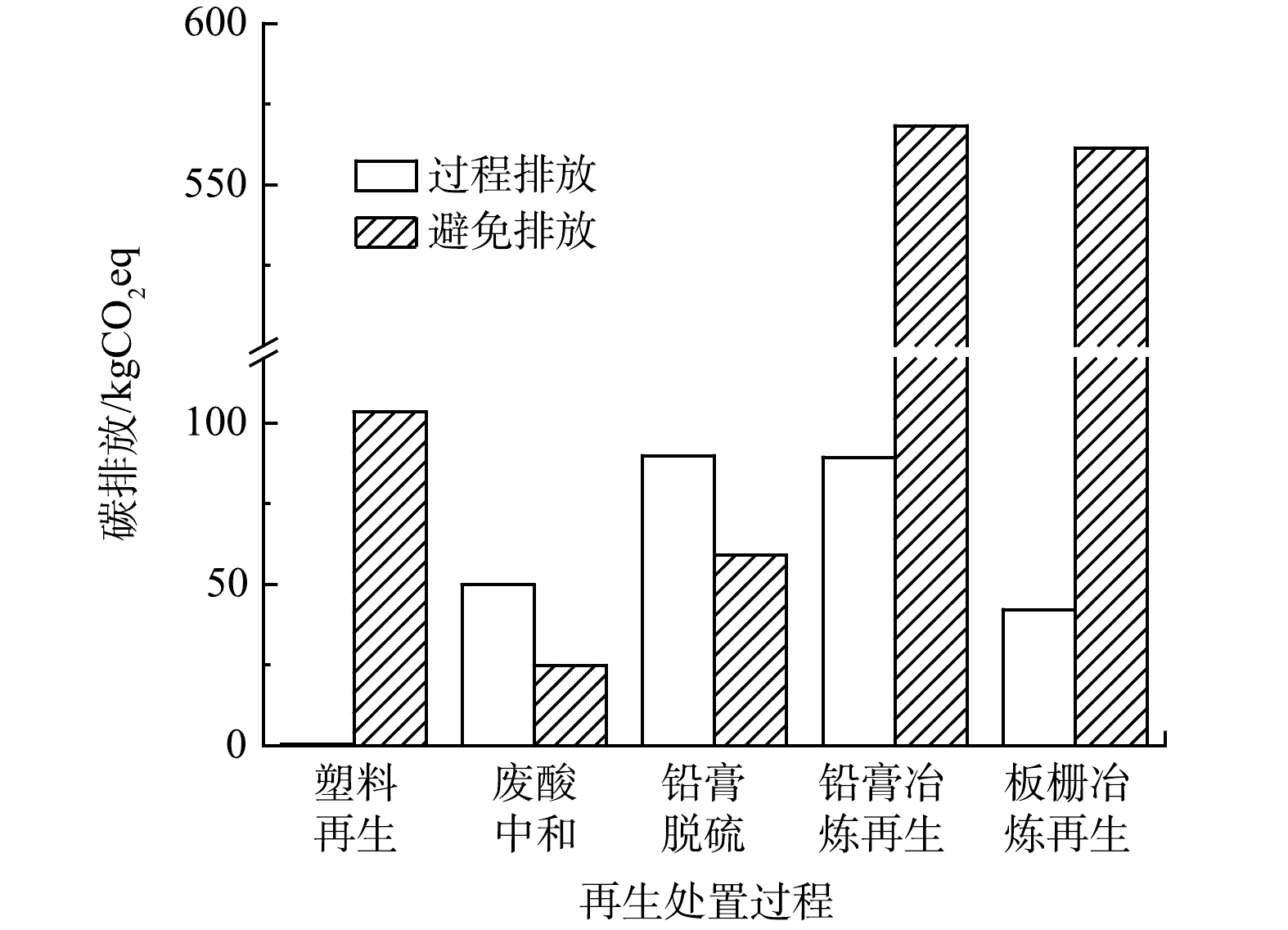

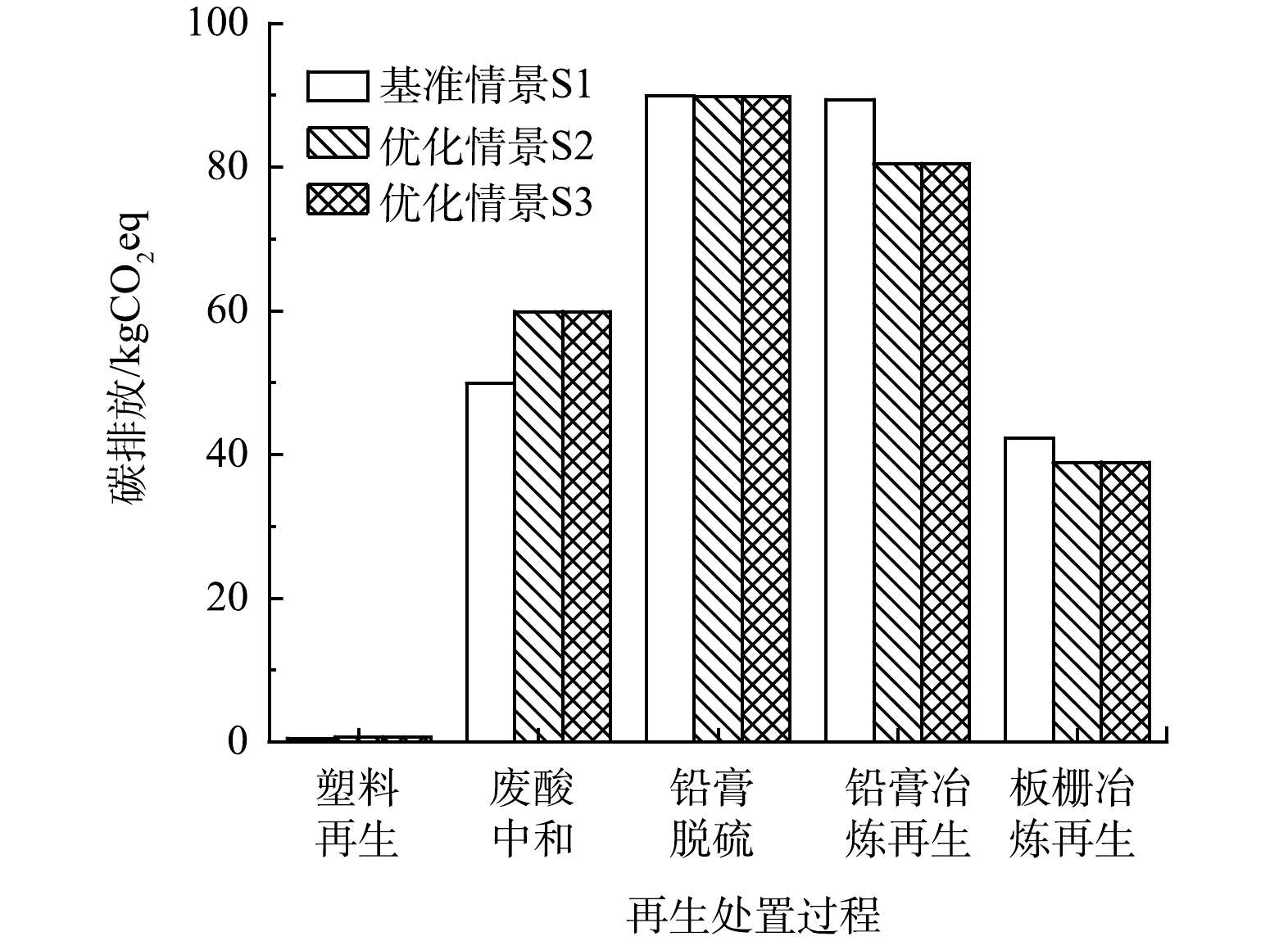

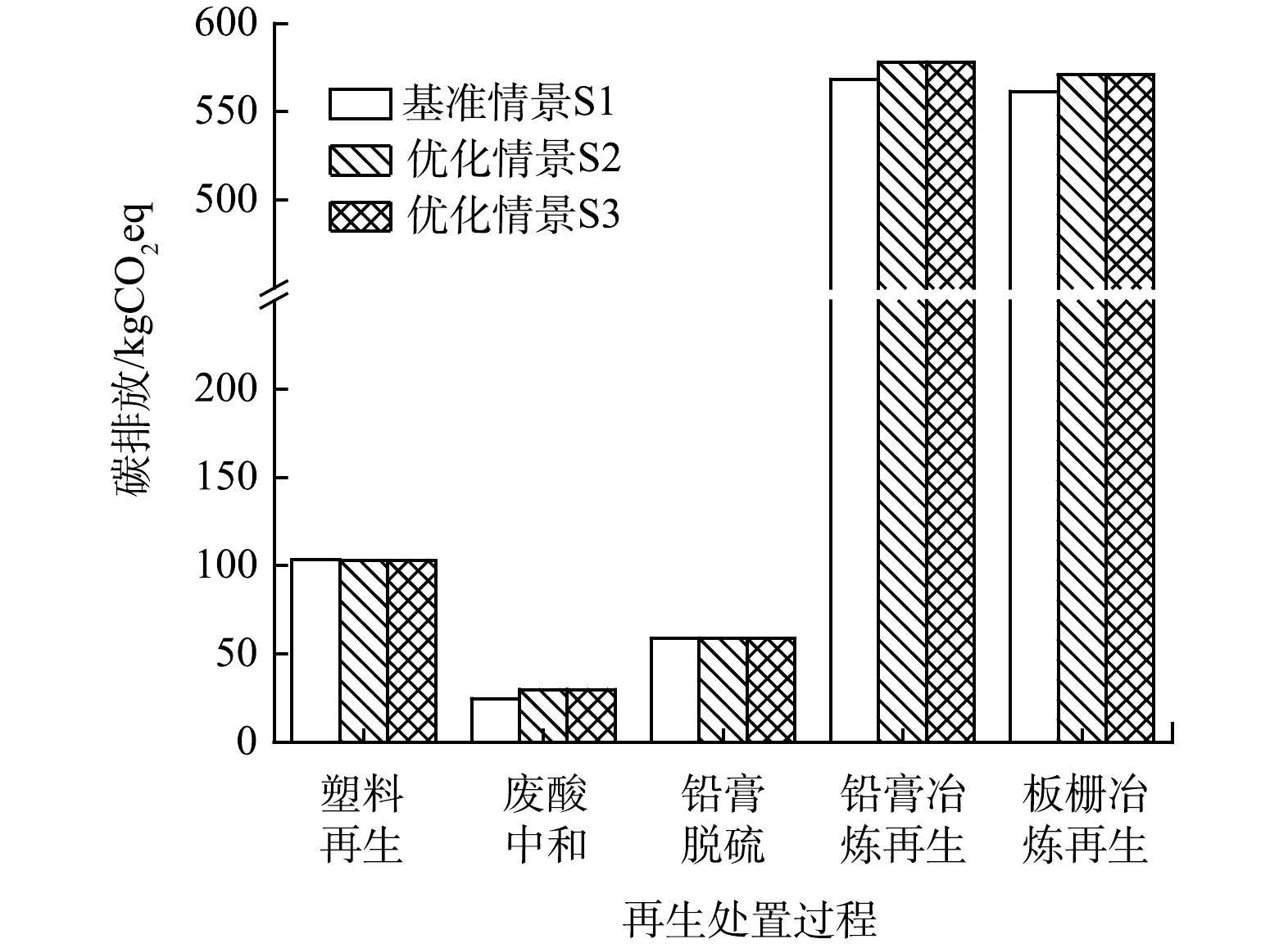

进一步对再生处置阶段的碳排放量和碳减排量进行分析。如图7所示,再生处置阶段碳排放贡献较大的是铅膏脱硫 (89.89 kgCO2eq) 和铅膏冶炼再生 (89.4 kgCO2eq) 过程,其次是废酸中和 (49.9 kgCO2eq) 和板栅冶炼再生 (42.24 kgCO2eq) 过程。塑料再生过程中的碳排放最小 (0.5 kg CO2eq) ,原因是该过程消耗能源较少。再生铅和再生塑料等再生产品的产出,替代了原生材料 (或产品) 的生产过程,避免了一定的碳排放,即带来碳减排量。在避免的碳排放中,贡献较大的是铅膏冶炼再生和板栅冶炼再生过程,分别避免碳排放568.3和561.4 kgCO2eq,随后是塑料再生、铅膏脱硫和废酸中和过程,其避免碳排放量依次为103.4、59.01和24.9 kgCO2eq。综合各单元过程碳排放量和碳减排量,板栅冶炼再生、铅膏冶炼再生和塑料再生环节均产生了碳减排效益,依次为519.16、478.9和102.9 kgCO2eq;但在废电解液处理和铅膏脱硫2个单元过程中,由于碳酸钠的加入,使得反应过程中产生大量的碳排放,虽然有副产品的产出,部分抵消了部分的碳排放,但总体上还是碳排放量大于碳减排量。

-

1) 物质流过程。与基准情景S1相比,优化情景S2中专业第三方回收比例从31.4%提高至60.0%,生产商自有渠道回收比例从13.0%提高至40.0%,没有个体回收参与,从而确保废铅酸蓄电池全部转运至正规再生铅企业 (图8) 。

在基准情景S1收集方式的基础上,优化情景S3将跨区转移范围从全国缩小至长江经济带上游区域,运输效率提高,并且在“白名单”制度下,废铅酸蓄电池非法处理处置得到遏制,全部进入正规再生铅企业 (图9) 。

2) 碳减排效益。基于情景分析的碳减排效益评估发现,优化情景S2和优化情景S3的碳减排效益均为正值,且2种优化情景的碳减排效益值均高于基准情景S1。这表明,废铅酸蓄电池在集中收集和跨区域转运制度下的优化情景中均表现出更优的碳减排效益。具体来看,优化情景S2、优化情景S3的碳减排量分别为994.44和953.53 kgCO2eq。与基准情景S1对比,优化情景S2的碳减排效益增加了71.34 kgCO2eq,其中,48.5 kgCO2eq来自于收集阶段,26.02 kgCO2eq来自于再生处置阶段,拆解阶段则增加了3.18 kgCO2eq排放;优化情景S3的碳减排效益增加了30.43 kgCO2eq,其中7.59 kgCO2eq来自于转运阶段,再生处置阶段和拆解阶段与优化情景S2相同。

图10显示不同情景下废铅酸蓄电池回收处理系统的碳排放情况。在优化情景S2中,废铅酸蓄电池的碳排放量为346.46 kgCO2eq,最大的碳排放过程是再生处置阶段 (269.8 kgCO2eq) ,随后依次是转运阶段 (29.21 kgCO2eq) 、拆解阶段 (24.6 kgCO2eq) 和收集阶段 (22.85 kgCO2eq) 。在优化情景S3中,废铅酸蓄电池的碳排放量为387.37 kgCO2eq,主要的碳排放过程同样是再生处置阶段 (269.8 kgCO2eq) ,随后是收集阶段 (71.35 kgCO2eq) 、拆解阶段 (24.6 kgCO2eq) 和转运阶段 (21.62 kgCO2eq) 。从各情景间的差异来看,优化情景S2由于在收集阶段采用专业第三方回收和生产商自有渠道回收相结合的模式,与基准情景S1对比,其碳排放减少47.45 kgCO2eq;优化情景S3在基准情景S1收集的基础上,其转运范围从全国缩小至长江经济带上游区域,碳排放减少6.54 kgCO2eq,反映出运输距离的减少带来的碳减排量并不明显。

图11和图12分别显示了不同情景下废铅酸蓄电池再生处置阶段实际碳排放量和避免的碳排放量。优化情景S2、S3的再生处置方案相同,因此该阶段各单元过程的碳排放量和避免的碳排放量均相同。从碳排放来看,贡献较大的是铅膏脱硫 (89.8 kgCO2eq) 单元过程,铅膏冶炼再生 (80.5 kgCO2eq) 单元过程次之。铅膏冶炼再生和板栅冶炼再生单元过程的碳排放量低于基准情景S1,但避免的碳排放量均高于S1,表明这2个环节是优化情景在再生处置阶段最主要的减碳来源。值得注意的是,由于S2和S3对废酸进行中和处理,导致其碳排放量高于S1,同时所避免的碳排放量不及增加的碳排放量,因此其不具有减碳贡献。可以预见的是,若研究中考虑其他环境影响类型,如酸化、富营养化、生态毒性等与废酸排放相关的环境类别,则可体现其环境优势。此外,由图11和图12可见,废塑料再生单元过程由于工序相对简单,其碳排放量并不高,但再生塑料的产出可替代石油基原生塑料,避免的碳减排量较为显著,并且三种情景的差异不大。

-

1) 基于对贵州省的市场调研发现,汽车维修点和电池经销点是当前社会源废铅酸蓄电池的主要产生主体,其中来自汽修主体的废铅酸蓄电池数量略低于助力车主体。

2) 在缺乏EPR制度引导下,回收处置1 t废铅酸蓄电池的碳排放量为393.91 kgCO2eq,再生材料产出所避免的碳排放量为1 317.01 kgCO2eq,综合碳减排量为923.1 kgCO2eq,表明废铅酸蓄电池回收处理具有碳减排效益。

3) 相对于基准情景,优化情景下废铅酸蓄电池收集和转运效率有明显提高,并且全部进入正规处理企业。2种优化情景的综合碳减排量分别为994.44、953.53 kgCO2eq,碳减排效益分别比基准情景提高71.34和30.43 kgCO2eq。

4) 推行铅酸蓄电池生产者责任延伸制,可重点引导生产企业采取自主回收、联合回收或委托回收模式,通过销售渠道或专业企业在消费末端建立的网络开展铅酸蓄电池集中回收,探索“以旧换新”等方式提高回收率,从全生命周期改进废铅酸蓄电池回收处理系统的资源环境绩效。

集中收集和跨区域转运制度下废铅酸蓄电池物质流过程与碳减排效益分析——以贵州省为例

Material flow and carbon reduction benefit of spent lead-acid batteries under centralized collection and trans-regional transport system: Take Guizhou Province as an example

-

摘要: 集中收集和跨区域转运制度确立了我国铅酸蓄电池生产者责任延伸制 (EPR) 的实施路径。在危险废物管理框架下,集中收集和跨区域转运改变了废铅酸蓄电池的物质流过程,与之相关的资源环境效应变化也成为当前的重要研究课题。以贵州省为例,基于实地调研和系统模拟,采用物质流分析和生命周期评价方法分析了废铅酸蓄电池的产生特征、物质流过程和碳减排效益。结果表明,在集中收集与跨区域转运制度实施前,83.3%的废铅酸蓄电池进入再生铅企业,16.7%流入非正规处理企业,回收处理1 t废铅酸蓄电池的碳减排效益为923.1 kgCO2eq。开展情景分析发现,相对于无政策驱动的基准情景,集中收集和跨区域转运优化情景均能提升废铅酸蓄电池进入正规回收处理企业的比例,且碳减排效益分别提高到994.44和953.53 kgCO2eq∙t−1。这表明,基于EPR政策驱动的系统情景具有环境正效应,可作为当前废铅酸蓄电池回收处理系统完善和政策优化的方向。Abstract: The centralized collection and cross-regional transport system establishes the implementation path of the extended producer responsibility system (EPR) of lead-acid battery in China. Under the framework of hazardous waste management, centralized collection and cross-regional transfer have changed the material flow of spent lead-acid batteries, and the related changes in resource and environmental effects have also become an important research topic. Take Guizhou Province as an example, material flow analysis and life cycle assessment method were used to analyze the generation characteristics, material flow process and carbon emission reduction benefits of spent lead-acid batteries based on field investigation and system simulation. The results showed that before the implementation of the centralized collection and cross-regional transport system, 83.3% of the waste lead-acid batteries entered the lead-recycling enterprises, and 16.7% entered the informal processing enterprises. The carbon reduction benefit of spent lead-acid batteries recycling was 923.1 kgCO2eq/t. Through the scenario analysis, it was found that compared with the baseline system without policy driving force, the centralized collection and cross-regional transfer optimization scenarios could significantly increase the proportion of spent lead-acid batteries entering formal recycling enterprises, and the carbon reduction benefits were increased to 994.44 kgCO2eq/t and 953.53 kgCO2eq/t, indicating that the system scenario driven by the EPR policy had a positive environmental effect, and could be used as the direction for the improvement and policy optimization of the current spent lead-acid battery recycling system.

-

-

表 1 废铅酸蓄电池回收处理情景设置

Table 1. Optimization scenario setting of spent lead-acid battery recycling

关键环节 基准情景S1 优化情景S2 优化情景S3 收集方式 个体商流动回收 (55.6%) 专业第三方回收 (60.0%) 生产商自有渠道回收 (40.0%) 个体商流动回收 (55.6%) 专业第三方回收 (31.4%) 专业第三方回收 (31.4%) 生产商自有渠道回收 (13.0%) 生产商自有渠道回收 (13.0%) 收集距离 3 t卡车,运距302.77 km 9 t卡车,运距160 km9 t卡车,运距24 km 3 t卡车,运距302.77 km 9 t卡车,运距160 km 9 t卡车,运距160 km 9 t卡车,运距24 km 9 t卡车,运距24 km 转运范围 全 国 全 国 长江经济带上游区域 转运距离 30 t重卡,运距412.5 km 30 t重卡,运距412.5 km 30 t重卡,运距306.25 km 拆解过程 机械拆解+人工拆解 机械拆解 机械拆解 处置企业 再生铅企业+非正规处理厂 再生铅企业 再生铅企业 -

[1] 何艺, 靳晓勤, 金晶, 等. 废铅蓄电池收集利用污染防治主要问题分析和对策[J]. 环境保护科学, 2017, 43(3): 75-79. [2] 何艺, 郑洋, 何叶, 等. 中国废铅蓄电池产生及利用处置现状分析[J]. 电池工业, 2020, 24(4): 216-224. doi: 10.3969/j.issn.1008-7923.2020.04.009 [3] CHOWDHURY K, NURUNNAHAR S, KABIR M L, et al. Child lead exposure near abandoned lead acid battery recycling sites in a residential community in Bangladesh: Risk factors and the impact of soil remediation on blood lead levels[J]. Environmental Research, 2021, 194(25): 110689. [4] 生态环境部. 关于印发《“十四五”时期“无废城市”建设工作方案》的通知 [EB/OL]. [2022-6-1]. https://www.mee.gov.cn/xxgk2018/xxgk/xxgk03/202112/t20211215_964275.html. [5] 张喆, 陈小亮, 何艺, 等. 我国危险废物收集经营现状与创新实践[J]. 环境工程学报, 2021, 15(5): 1481-1486. doi: 10.12030/j.cjee.202008153 [6] MA Y, YU S, WANG J, et al. LCA/LCC analysis of starting-lighting-ignition lead-acid battery in China[J]. Peerj, 2018, 6(3): 5238. [7] LIU W, SANG J, CHEN L, et al. Life cycle assessment of lead-acid batteries used in electric bicycles in China[J]. Journal of Cleaner Production, 2015, 108: 1149-1156. doi: 10.1016/j.jclepro.2015.07.026 [8] GAO T, HU L, WEI M. Life Cycle Assessment (LCA)-based study of the lead-acid battery industry[J]. IOP Conference Series Earth and Environmental Science, 2021, 651(4): 042017. doi: 10.1088/1755-1315/651/4/042017 [9] PAN H, GENG Y, DONG H, et al. Sustainability evaluation of secondary lead production from spent lead acid batteries recycling[J]. Resources Conservation and Recycling, 2018, 140: 13-22. [10] YU J, YANG J, JIANG Z, et al. Emergy based sustainability evaluation of spent lead acid batteries recycling[J]. Journal of Cleaner Production, 2020, 250: 119467. doi: 10.1016/j.jclepro.2019.119467 [11] SUN Z, CAO H, ZHANG X, et al. Spent lead-acid battery recycling in China - A review and sustainable analyses on mass flow of lead[J]. Waste Management, 2017, 64: 190-201. doi: 10.1016/j.wasman.2017.03.007 [12] TIAN X, WU Y, HOU P, et al. Environmental impact and economic assessment of secondary lead production: Comparison of main spent lead-acid battery recycling processes in China[J]. Journal of Cleaner Production, 2017, 144: 142-148. doi: 10.1016/j.jclepro.2016.12.171 [13] 王琢璞, 温宗国. 废铅酸蓄电池回收制取再生铅合金技术的生命周期评价[J]. 环境科学学报, 2018, 38(3): 1245-1255. [14] TIAN X, WU Y, QU S, et al. Modeling domestic geographical transfers of toxic substances in WEEE: A case study of spent lead-acid batteries in China[J]. Journal of Cleaner Production, 2018, 198: 1559-1566. doi: 10.1016/j.jclepro.2018.07.089 [15] 何艺, 王维, 丁鹤, 等. 铅蓄电池落实生产者责任延伸制度成效与展望[J]. 环境工程学报, 2021, 15(7): 2218-2222. doi: 10.12030/j.cjee.202008156 [16] 李雪, 郭春霞, 陈耀宏, 等. 铅酸蓄电池行业生产者责任延伸制在我国实施的难点和解决方案[J]. 环境工程学报, 2020, 14(1): 3-8. doi: 10.12030/j.cjee.201910042 [17] 重庆市生态环境局. 长江经济带上游四省市建立危险废物联防联控机制与跨省市转移“白名单”合作机制 [EB/OL]. [2022-6-1]. http://sthjj.cq.gov.cn/zwgk_249/xwfb_67131/202011/t20201113_8459151.html. [18] 国务院办公厅. 国务院办公厅关于印发生产者责任延伸制度推行方案的通知 [EB/OL]. [2022-6-1]. http://www.gov.cn/zhengce/content/2017-01/03/content_5156043.htm. [19] 生态环境部办公厅. 关于印发《铅蓄电池生产企业集中收集和跨区域转运制度试点工作方案》的通知 [EB/OL]. [2021-6-1]. https://www.mee.gov.cn/xxgk2018/xxgk/xxgk05/201901/t20190131_691777.html. [20] 生态环境部办公厅. 关于继续开展铅蓄电池生产企业集中收集和跨区域转运制度试点工作的通知 [EB/OL]. [2022-6-1]. https://www.mee.gov.cn/xxgk2018/xxgk/xxgk06/202012/t20201230_815495.html. [21] 王红梅, 夏月富, 席春青, 等. 铅酸蓄电池企业生产者责任延伸制度实施“瓶颈”分析[J]. 环境保护, 2018, 46(3/4): 56-59. doi: 10.14026/j.cnki.0253-9705.2018.z1.010 [22] WANG S, YU J, OKUBO K. Life cycle assessment on the reuse and recycling of the nickel-metal hydride battery: Fleet‐based study on hybrid vehicle batteries from Japan[J]. Journal of Industrial Ecology, 2021, 25(5): 1236-1249. doi: 10.1111/jiec.13126 -

下载:

下载: