-

厌氧发酵是一种能够有效实现有机废物资源化和能源化的生物反应过程[1]。在我国,餐厨垃圾(FW)每年的产生量约为6×107 t,占城市固体废弃物总量的40%以上[2]。FW主要由易于降解的碳水化合物、蛋白质和脂质组成,具有较高的产甲烷潜力[3-4]。但是,单独发酵FW时,由于FW水解速度较快会积累挥发性脂肪酸(VFA),易发生系统抑制崩溃的后果[5]。已经有研究证明将剩余活性污泥(WAS)添加到FW厌氧发酵系统提高混合发酵运行性能的可行性[6]。与单独FW或WAS厌氧发酵相比,将2者进行厌氧混合发酵能够促使微生物发挥协同作用,稳定厌氧发酵性能。

目前,有关FW和WAS厌氧混合发酵系统的构型主要采用间歇进料的连续搅拌反应器(CSTR)[7-8]。然而,CSTR不能实现污泥停留时间(SRT)和水力停留时间(HRT)的有效分离,使得微生物难以持留,难以保障微生物的持续生长,而且CSTR的间歇式进料方式容易引起负荷冲击。动态膜生物反应器(DMBR)使用在膜基材表面上沉积/吸附形成的滤饼层作为过滤层,能有效防止生长缓慢的厌氧微生物尤其是产甲烷菌的流失,提供了较长SRT来维持大量微生物种群生长[9]。已有研究利用板框内置式膜组件,采用连续流运行模式,在2.8 g·L−1·d−1的负荷下,实现了基于DMBR进行玉米秸秆和FW的混合发酵[10]。连续流进料方式可以有效缓解间歇式进料方式引起的基质冲击,增加系统的缓冲能力。目前,有关连续流动态膜厌氧混合发酵系统的稳定运行的解析鲜见报道。

在厌氧混合发酵系统中,基质的混合比例是影响厌氧发酵的关键参数,李浩等[11]的研究结果表明,在FW和WAS厌氧混合发酵过程中,FW所占比例影响混合发酵的反应速率。同时,厌氧发酵系统的最优基质混合比也会随着系统的长期运行和菌群结构的驯化改变而变化[12]。食微比(F/M)是衡量有机负荷的重要参数[13],F/M与基质种类和接种物中微生物菌群密切相关,不同的F/M会影响系统的效能潜力。截至目前,很少有研究考虑基质混合比(FW/WAS)和F/M对厌氧混合发酵系统长期运行的影响。

本研究构建了FW和WAS的外置式动态膜厌氧混合发酵系统。在连续流条件下启动动态膜厌氧混合发酵系统,以实现系统的稳定运行;同时,对DMBR运行过程中动态膜的形成和固液分离的效果进行解析。通过FW/WAS的产甲烷潜能和动力学实验,优化连续流厌氧混合发酵系统的因素,结合F/M 动力学实验,评价FW/WAS与F/M对连续流厌氧混合发酵系统运行效能的影响。

-

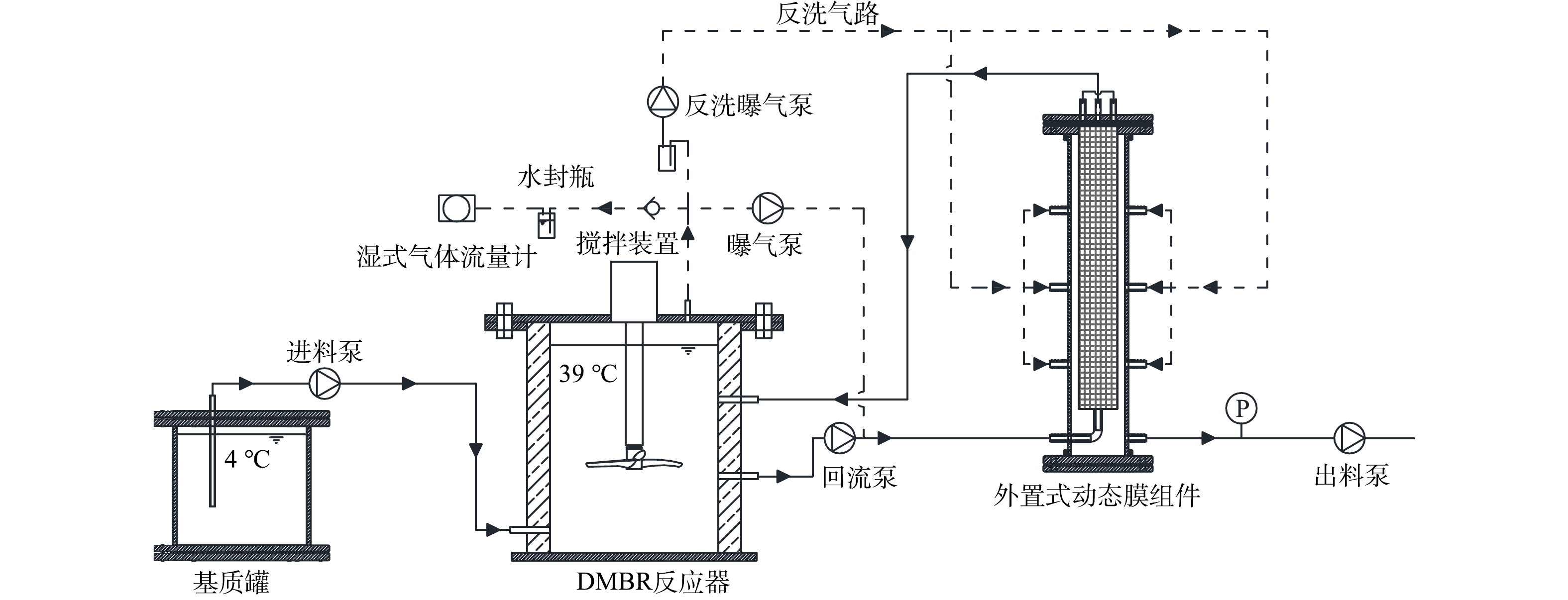

本研究使用的外置式动态膜生物反应器如图1所示。反应器的有效体积为9.0 L,外部使用水浴层和恒温槽来控制反应器的温度为 (39±1) ℃,基质罐连接4 ℃恒温冷水浴。外置式膜组件由300目不锈钢筛网定制加工而成,平均孔径为48 µm,有效过滤面积为0.047 m2。系统的运行模式为连续进出料,产生的生物气通过水封瓶后用湿式气体流量计计量产气量。通过曝气泵将系统内顶空生物气泵入膜组件腔体底部,对膜组件进行气擦洗后回流至系统内;同时,通过反洗曝气泵将系统内顶空生物气定期泵入膜组件腔体外侧,对膜组件进行气反洗后回流至系统内。当膜组件和出料泵间跨膜压差增加到40 kPa时,开启反洗曝气泵进行气反洗,反洗强度为10 L·min−1,气反洗时间为10 min。当进行气反洗不能提高膜通量时,通过增大曝气泵流量、回流量或气反洗频率进行调控。

-

本研究所采用的FW依据学生食堂餐厨剩余物的主要成分进行人工模拟配制[14],WAS取自西安市第五污水处理厂,2者混合后添加微量元素作为最终混合基质[8]。启动阶段FW和WAS的混合比例为4∶1(基于湿重),该最优混合基质比是启动前期批次实验优化的结果[15]。研究所用接种污泥为FW和WAS中温厌氧CSTR的排泥[15],接种体积为9.0 L。本研究中使用的FW、WAS、混合基质和接种污泥的理化特性如表1所示。

-

设置DMBR系统的初始OLR和HRT分别为(1.84±0.45) g·L−1·d−1和62.5 d,启动运行72 d,测定系统的运行性能参数和动态膜截留性能。启动阶段运行结束后,采用批次实验进行FW/WAS和F/M参数优化,实验设置见表2。FW/WAS批次实验在F/M为0.145 (基于VS)时共设置7组,其中2组为FW和WAS单发酵。F/M批次实验在FW/WAS为4.4∶1时共设置8组。所有批次实验均在120 mL血清瓶中分批进行,同时设置空白组。其中,空白组与实验组均设置2组平行。当混合基质和接种污泥加入血清瓶摇晃均匀后,用氮气吹脱约3 min,橡皮塞封瓶后置于39 ℃恒温摇床内,摇床转速为120 r·min−1,2 min后血清瓶顶空放气,定时测定气组和气量。

-

TS、VS、COD、碱度和NH4+-N的测定采用标准方法[16]。pH采用便携式pH计进行测定(pHS-25型,上海精密科学仪器有限公司)。蛋白质和多糖分别采用Folin-酚试剂法[17]和硫酸-蒽酮法[18]。CH4、CO2、N2、H2和VFA均采用气相色谱法进行测定[8]。浊度采用便携式浊度仪 (Turb®355 IR,德国赛莱默公司) 测定。采用修正的Gompertz方程 (公式1) 拟合批次实验数据,以确定产甲烷潜力、最大产甲烷速率和延滞期[19-20]。采用一级动力学模型 (公式2) 进行数据拟合可得水解常数[21]。

式中:P为生物气产量,mL;P0为生物气潜能,mL;Rmax为最大生物气产生速率,mL·d−1;t0为延滞期,d;k为产甲烷速率常数,d−1。

-

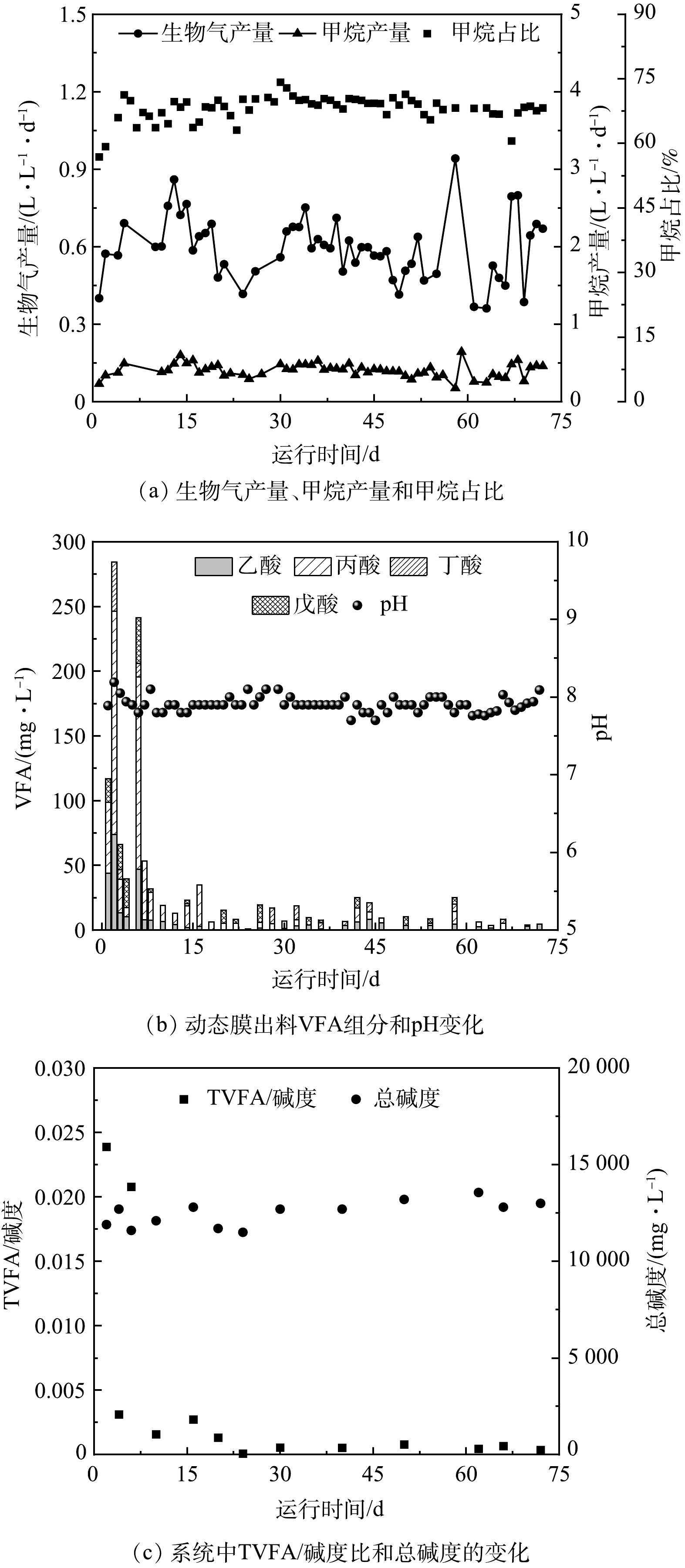

在HRT和OLR分别为62.5 d和(1.84±0.45) g·L−1·d−1的初始条件下,启动连续流FW和WAS厌氧混合发酵动态膜生物反应器。反应器启动运行过程中,系统的生物气产量、甲烷产量和甲烷占比如图2(a)所示。前5 d启动过程中,系统的生物气产量、甲烷产量和甲烷占比逐渐增加,然后趋于稳定。72 d的运行过程中,系统的平均生物气产量达到(0.60±0.11) L·L−1·d−1,平均甲烷产量达到(0.41±0.08) L·L−1·d−1,甲烷占比稳定在66%~71%,平均甲烷占比达到69.00%。pH和VFA的变化趋势能够直观的表明反应器的运行状况。如图2(b)所示,启动过程中,系统的pH始终稳定在7.6~8.0,在产甲烷菌最适pH(7.0~8.0)内[8]。本研究VFA最大质量浓度仅为284 mg·L−1,无VFA积累现象。这表明,连续流动态膜混合发酵系统启动成功[22]。如图2(c)所示,TVFA/碱度最大值仅为0.024,低于阈值0.4[23]。VFA和TVFA/碱度均未超过阈值,这表明厌氧发酵系统稳定性良好。厌氧发酵系统成功启动后,系统的平均TVFA质量浓度为(15.9±1.89) mg·L−1,低于产甲烷菌TVFA的抑制浓度5 000 mg·L−1,相应的总碱度为11 000~14 000 mg·L−1,也在稳定运行范围内[24]。上述结果表明,连续流FW和WAS厌氧混合发酵DMBR启动成功且能稳定运行。此外,对系统进行物料平衡分析可知,在该系统基质VSS的生物降解转化去除率为84%±3.8%,去除单位质量COD的基质甲烷产量为(294±13) mL。

-

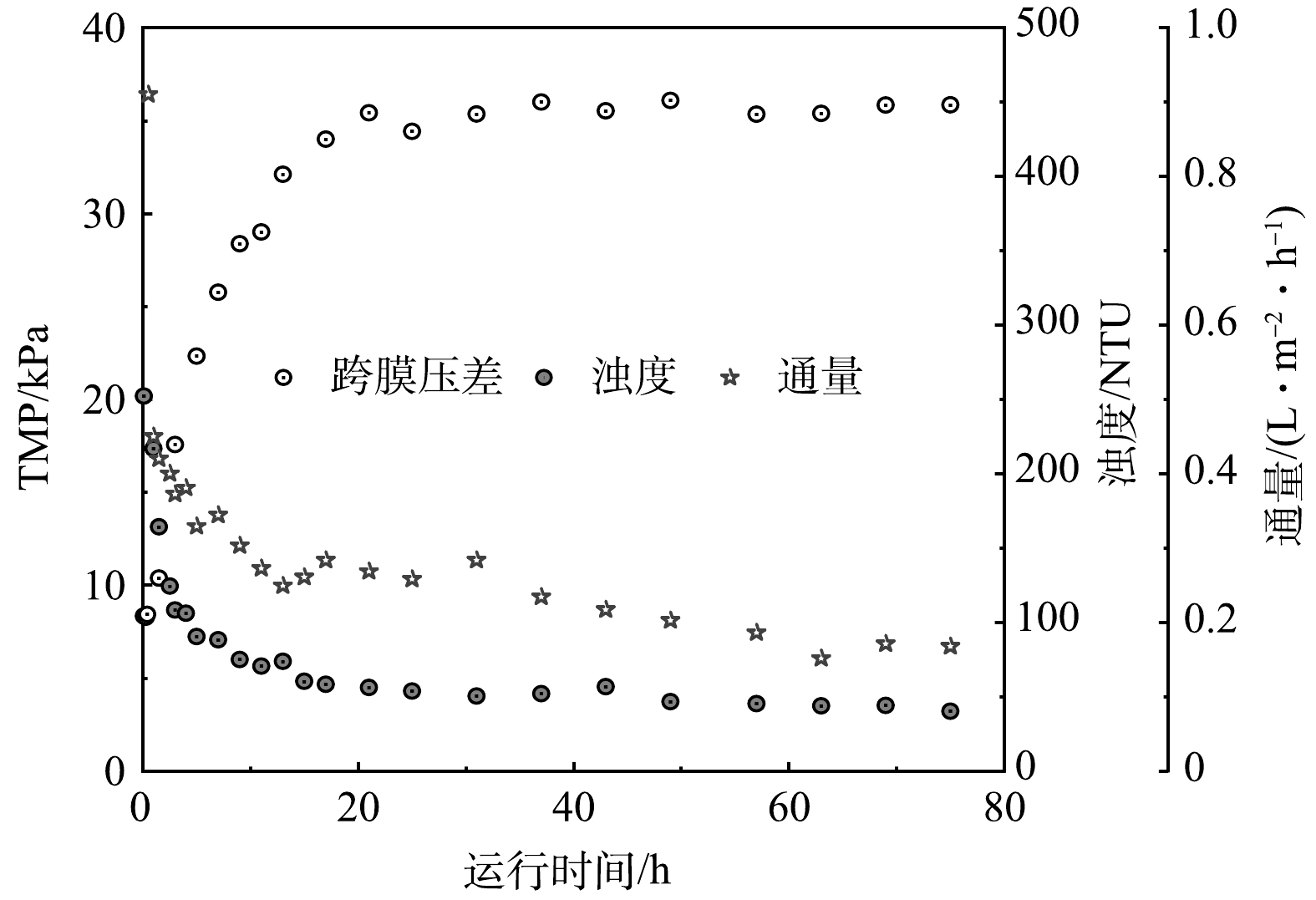

本实验的反应器装置为外置式的柱型动态膜组件,开启出料泵后,反应器内污泥先通过回流泵进入膜组件腔体内部,当回流污泥充满膜组件内部腔体后附着在动态膜基材上,逐渐形成过滤层。在第35 d膜组件清洗后,动态膜组件的跨膜压差、膜通量和浊度变化如图3所示。前4 h,动态膜组件的跨膜压差快速升高,由8.34 kPa增至22.3 kPa,相应的出料浊度由252 NTU降低至90.4 NTU,通量降低至0.42 L·m−2·h−1,2者均呈现快速下降的趋势。这是因为,动态膜组件腔体内充满了污泥,污泥开始附着在动态膜基材上,具有一定的截留效果。从4 h至21 h,通量降低了约40% (由0.42 L·m−2·h−1降至0.25 L·m−2·h−1) ,浊度也降至100 NTU以下,表明动态膜逐渐形成。随着过滤过程的进行,通量下降速度减缓,出料浊度趋于稳定。约40 h后,出料浊度稳定在50 NTU,通量在0.2 L·m−2·h−1左右。动态膜层逐渐增厚,进入稳定过滤阶段,具有稳定的截留效果。此外,当跨膜压差增至40 kPa时,进行动态膜气反洗后,能够快速形成动态膜,相应的压差逐渐增加 (如图3),长期运行过程中动态膜跨膜压差呈现周期性变化。袁宏林等[10]采用相同材质和孔径的动态膜基材,以玉米秸秆和FW为混合基质进行厌氧混合发酵,也获得了较优的固液分离效果,相应的有机物截留率达到95.9%,与本研究动态膜截留效果相当。通过借用在大孔径膜基材上形成的滤饼层作为过滤层,能够将传统膜生物反应器运行中存在的“膜污染”瓶颈问题转化为过滤层加以利用。本研究虽然对动态膜的过滤周期进行了表征,但仍需进一步解析动态膜滤饼层的过滤机理。此外,对接种物、运行末期动态膜滤饼层和系统排泥进行宏全基因组菌群分析可知:混合发酵系统以细菌为主,其中细菌主要包括Bacteroidetes (30.5%~44.6%) 、Chloroflexi (10.5%~24.5%) 和Firmicutes (23.1%~36.5%) ,古菌主要包括Methanosarcina (53.0%~97.9%) 和Methanobacterium (0.16%~18.7%) 。不同的微生物菌群结构组成及其变化,对于动态膜的形成和过滤效能均有一定程度的影响,但其作用机理仍需进一步研究。

为进一步揭示动态膜过滤截留效能的周期稳定性,在反应器运行的第7、15、21、28、41、53和60 d取样分析动态膜过滤液中TCOD、蛋白质及多糖质量浓度。如图4(a)所示,出料TCOD均低于3 g·L−1,且动态膜对TCOD的截留率可达到99.5%,最终可稳定在99%以上。这表明,该外置式动态膜组件可实现较好的出料质量,实现有机物和微生物的稳定截留。如图4(b)所示,经过动态膜出料的蛋白质和多糖质量浓度均低于300 mg·L−1,相应的蛋白质和多糖截留率均不低于95%。其中,出料蛋白质质量浓度始终高于多糖,主要由于混合基质中蛋白质质量浓度是多糖质量浓度的3倍以上 (表1) ;同时,出料蛋白质质量浓度逐渐下降,相应的去除率逐渐增加。分析其原因主要是,由于形成的动态膜对蛋白质的截留效果逐渐增强;相反,出料多糖质量浓度略有增加,相应的多糖截留率略有降低,但仍维持较高水平 (>95%) ,也与动态膜的过滤效能密切相关。动态膜滤饼层中蛋白质和多糖以及凝胶层对混合发酵系统中物质的截留作用是目前膜生物反应器探究的热点,相应的过滤截留机理有待进一步深入解析,以实现动态膜对蛋白质和多糖的截留调控。

-

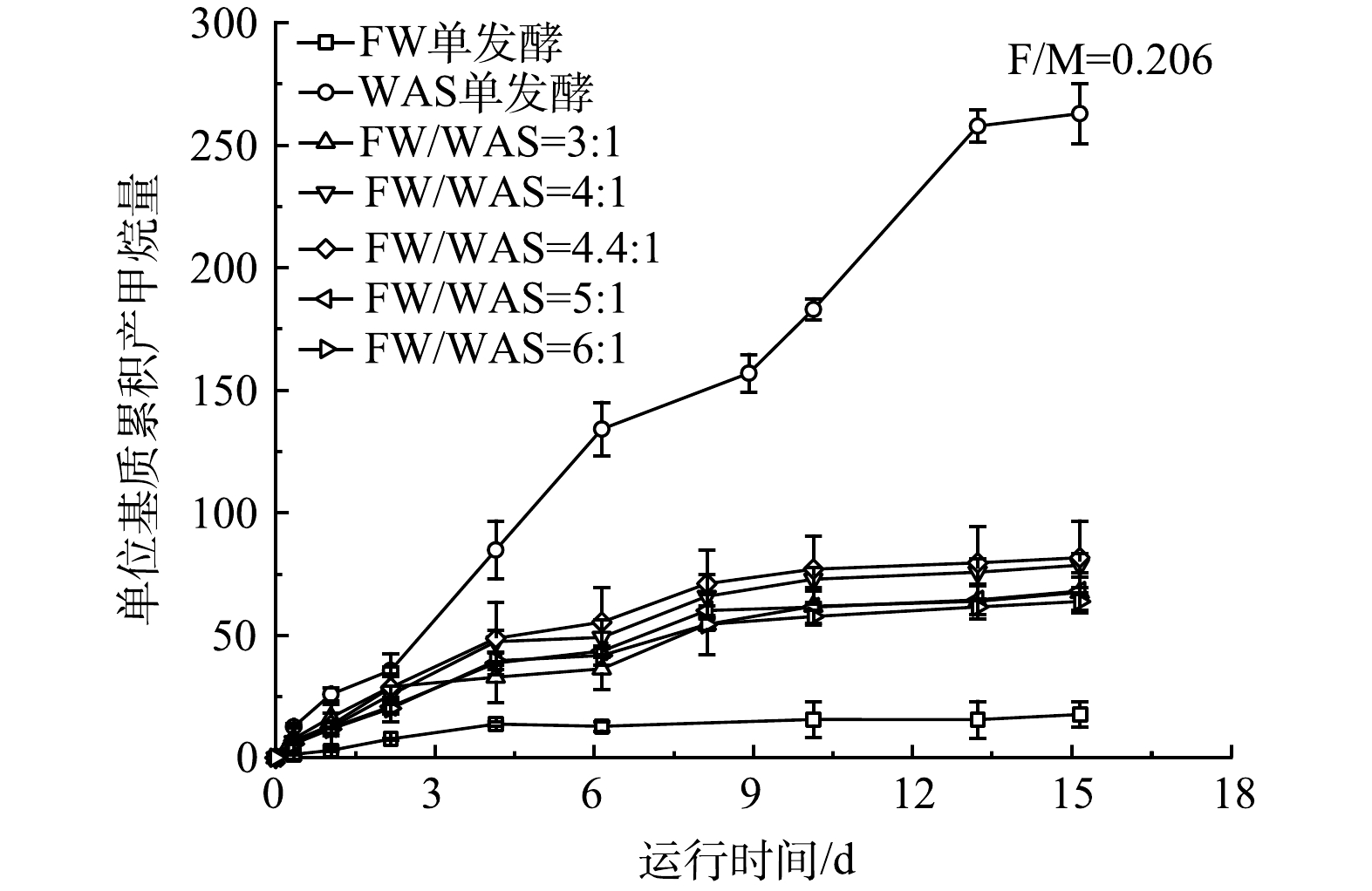

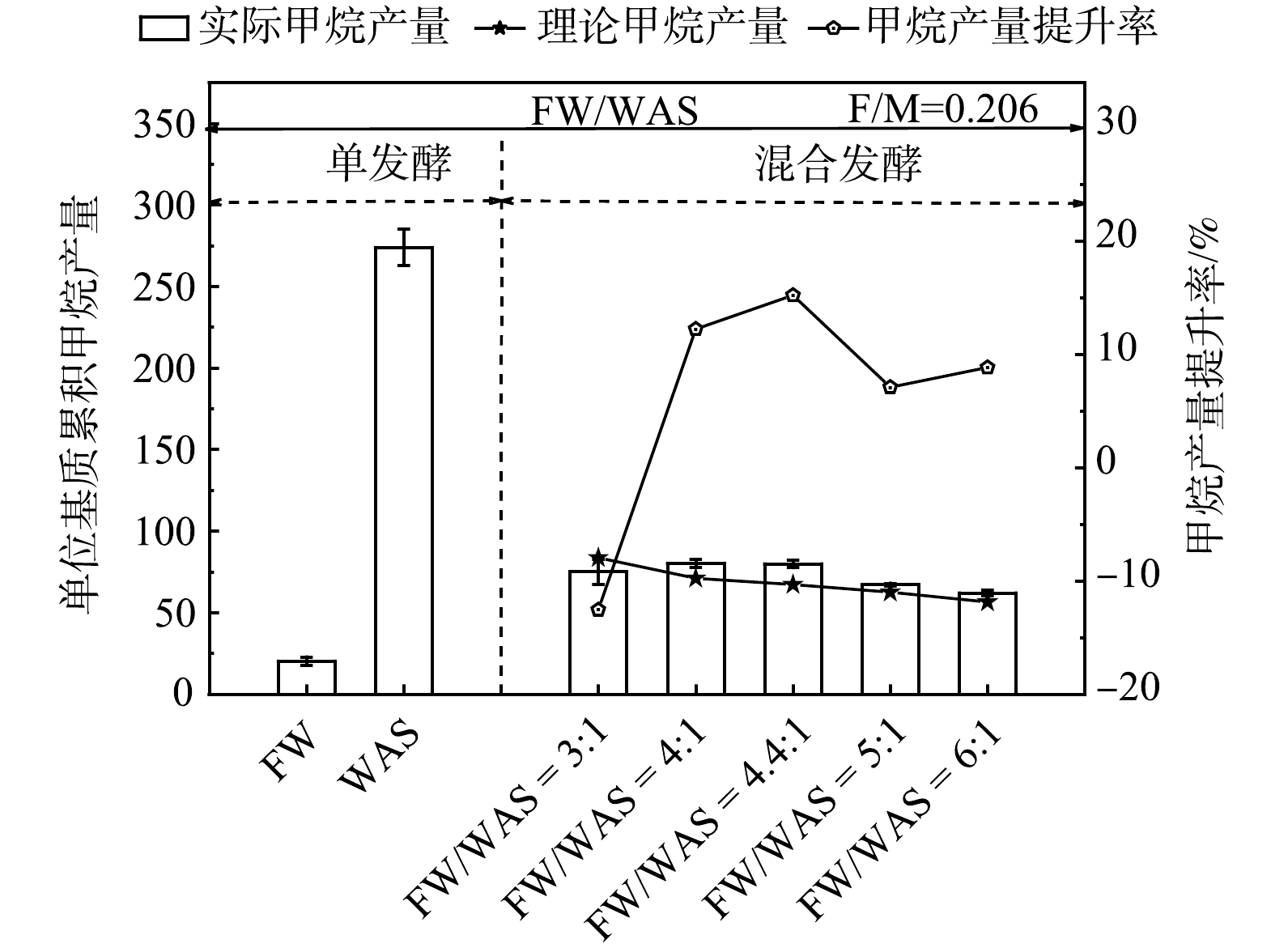

1) FW/WAS的优化。如表3所示,一级动力学模型和修正的Gompertz模型的拟合相关系数分别为0.971~0.991和0.975~0.987。这表明,2者均可较好地拟合FW和WAS厌氧发酵系统的累积产甲烷量。FW和WAS混合发酵的t0值趋近于0,表明FW和WAS混合发酵产甲烷基本无延滞期。在F/M为0.206条件下,不同FW/WAS的单位基质累积产甲烷量如图5所示。当厌氧发酵时间约为15 d时,FW/WAS等于4∶1和4.4∶1的单位基质累积产甲烷量明显高于3∶1、5∶1和6∶1时的单位基质累积产甲烷量。这表明,FW/WAS等于4∶1或4.4∶1时,FW和WAS混合发酵产甲烷的互促效果最佳。在FW/WAS为4∶1和4.4∶1时,运用Gompertz模型拟合分析可得P0和Rmax,如表3所示。可看出,在4.4∶1时,可获得更高的产甲烷潜能和最大生物气产率。如图6所示,当FW/WAS为4∶1和6∶1外,混合发酵的实际甲烷产率相对于单独发酵的加权平均值 (即理论甲烷产量) 均有不同程度的提升 (7.1%~15.2%)。其中,FW/WAS为4.4∶1时,相应的甲烷产量提升率最高。对比先前优化结果可发现[1],FW和WAS厌氧混合发酵系统经过长期驯化,最优基质混合比由初始最优值4∶1逐渐变为4.4∶1。因此,定期调整优化FW/WAS有利于厌氧混合发酵系统获得更高的产甲烷效能。

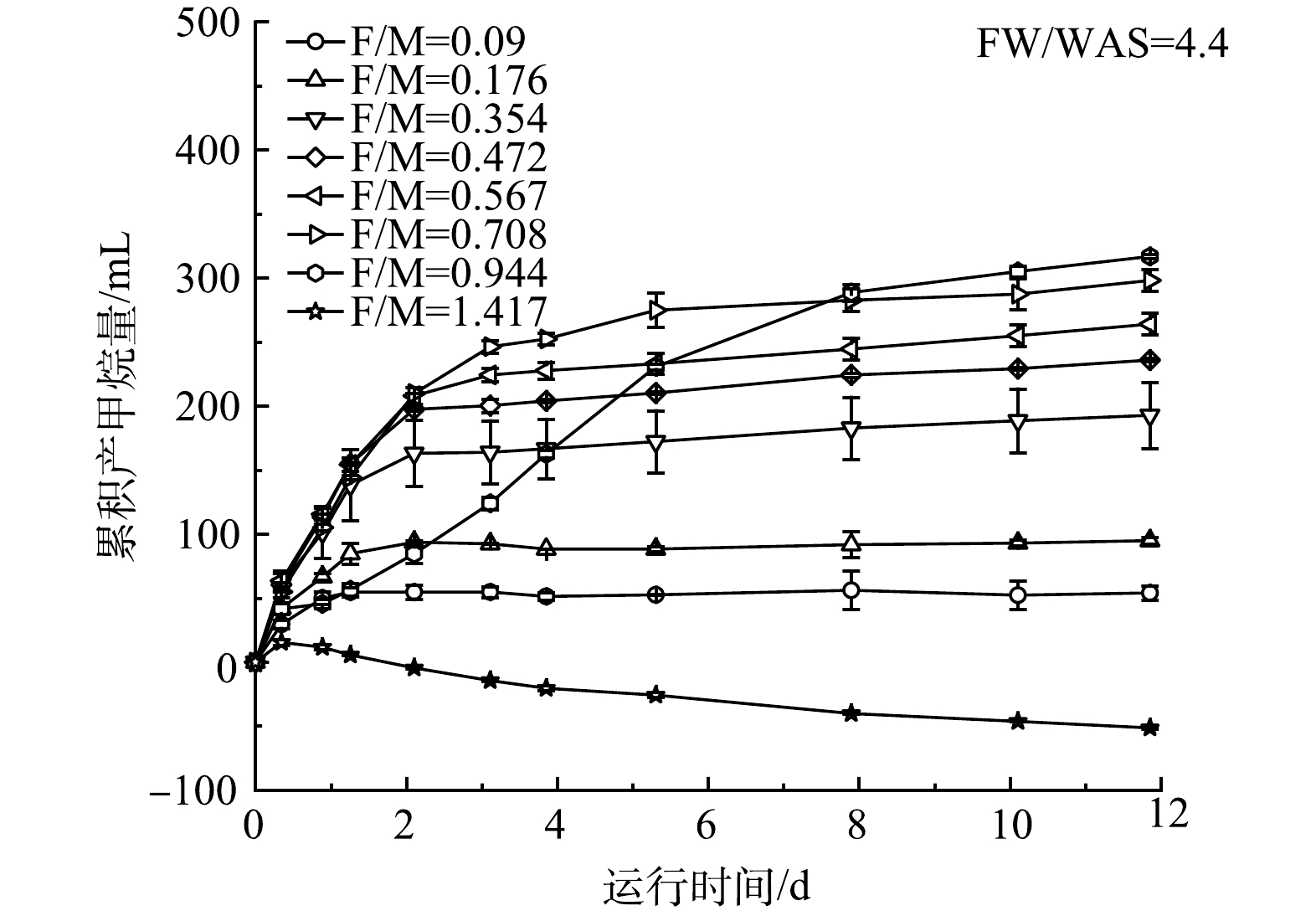

2) F/M实验。将FW/WAS的最优值4.4∶1作为基质混合比,使用相同接种物评价F/M的影响。不同F/M下,FW和WAS厌氧发酵系统的累积产甲烷量如图7所示。当厌氧发酵时间约为12 d,F/M分别为0.09、0.176、0.354、0.472、0.567、0.708和0.944时,相应的甲烷产量对应为54.0、94.8、192、236、264、298和317 mL。如表3所示,运用Gompertz模型模拟分析可知相应的产甲烷潜能分别为51、91、166、219、240、277和325 mL,模型拟合相关系数为0.969~0.994,这表明拟合结果与实际吻合较好。此外,FW和WAS混合发酵的t0值也都趋于0,与前述结果一致。如图7和表3所示,当F/M为1.42时,累积产甲烷量和Rmax均为负值,这表明该结果无法用一级动力学模型和Gompertz模型拟合。其原因在于,在此负荷下,产甲烷菌的活性受到严重抑制。当F/M由0.090增至0.944时,累积产甲烷量和P0逐渐增加。当F/M为0.944时,与F/M为0.708相比,Rmax由106 mL降至43 mL,k由0.575 d−1降为0.135 d−1,分别降低了59.8%和76.5%。这表明,当F/M>0.708时,FW和WAS 混合发酵产甲烷的速率减缓。综上,FW和WAS厌氧混合发酵的最大耐受F/M为0.944,且当F/M>0.708时,相应的产甲烷速率减缓。

-

1) 在较低的有机负荷条件下能够实现连续流FW和WAS厌氧动态膜混合发酵系统的启动及其长期稳定运行,且系统碱度缓冲能力强、无酸累积,系统甲烷产量稳定。

2) 在连续流厌氧动态膜系统启动和长期运行过程中,能短时间形成动态膜,且对TCOD、蛋白质和多糖具有良好的截留率 (>95%) ,固液分离效果显著且能实现低浊度出料 (<50 NTU) 。

3) 厌氧动态膜混合发酵系统长期运行后,最优混合基质比为4.4∶1,同时,该系统的最大食微比为0.944,为该系统后续运行效能的优化提升提供了调控依据,以最大限度的快速实现连续流动态膜混合发酵系统的高效稳定运行。

连续流动态膜餐厨垃圾和剩余污泥厌氧混合发酵系统的运行效能

Operational efficiency of continuous anaerobic dynamic membrane co-digestion system with food waste and waste activated sludge

-

摘要: 为探究厌氧动态膜生物反应器(DMBR)在典型城市有机废弃物厌氧发酵领域应用的可行性,以餐厨垃圾(FW)和剩余污泥(WAS)为处理对象,在连续流条件下探究动态膜FW和WAS厌氧混合发酵系统的运行效能,并优化基质混合比(FW/WAS)和食微比(F/M)。结果表明,以水力停留时间(HRT)和有机负荷(OLR)分别为62.5 d和(1.84±0.45) g·L−1·d−1为初始条件,在连续流下启动FW和WAS厌氧混合发酵系统,经过72 d的运行,系统pH稳定在7.6~8.0,平均甲烷产量达到(0.41±0.08) L·L−1·d−1,无短链挥发性脂肪酸(VFA)累积且TVFA/碱度最大比值仅为0.024,表明系统启动成功且运行稳定。通过对动态膜的特性分析可知,动态膜形成快速,可在较短时间内实现低浊度(<50 NTU)出料,动态膜截留效果显著。通过FW/WAS和F/M的批次优化实验可知,厌氧混合发酵系统最优FW/WAS为4.4∶1 (基于VS),定期调整优化FW/WAS有望取得更高的系统甲烷产率;相应的系统能够耐受的最大F/M为0.944,为后续充分发挥连续流动态膜FW和WAS混合发酵系统的最大效能提供依据。本研究结果可为典型城市有机废物厌氧发酵产甲烷系统的低碳高效稳定运行提供参考。Abstract: To explore the feasibility of anaerobic dynamic membrane bioreactor (DMBR) in the field of anaerobic digestion with typical urban organic wastes, the operating efficiency of the continuous anaerobic dynamic membrane co-digestion system with food waste (FW) and waste activated sludge (WAS) was investigated, and the substrate mixing ratio (FW/WAS) and the food to microorganism (F/M) ratio of the co-digestion system were also optimized. The results showed that the continuous anaerobic co-digestion with FW and WAS can be start-up under hydraulic retention time (HRT) of 62.5 days and organic loading rate (OLR) of (1.84±0.45) g·L−1·d−1. After 72 days of long-term operation, the system pH and average methane production were stable realized at 7.6-8.0 and (0.41±0.08) L·L−1·d−1, respectively without volatile fatty acids (VFA) accumulated and maximum TVFA/Alkalinity less than 0.024, which indicated that the stable system was realized. Through analysis of the dynamic membrane characteristics, the dynamic membrane can be formed rapidly with a low permeate turbidity (<50 NTU), indicated that the dynamic membrane interception effect was remarkable to achieve good permeate. Through the batch experiments to optimize the FW/WAS and F/M ratios, the optimal FW/WAS ratio of the co-digestion system was 4.4∶1 (based on VS) after long-term operation. Thus, a higher methane yield can be achieved through adjust FW/WAS ratio regularly. Moreover, the corresponding maximum F/M ratio was 0.944, which can be used to guide the subsequent operation of the continuous dynamic membrane co-digestion system with FW and WAS. This study can provide a reference for the low-carbon, high-rate and stable operation of anaerobic digestion system with typical urban organic wastes.

-

-

表 1 基质和接种污泥的理化特性

Table 1. Physicochemical properties of substrate and seed sludge

供试对象 TS/

(g·L−1)VS/

(g·L−1)TCOD/

(g·L−1)SCOD/

(g·L−1)pH 乙酸/

(g·L−1)蛋白质/

(g·L−1)多糖/

(g·L−1)NH4+-N/

(g·L−1)FW 140.0±15.3 134.0±13.2 220.0±18.5 104.0±8.3 4.4 1.730 2.74±0.03 85.30±4.10 0.31±0.01 WAS 56.0±8.3 30.4±4.2 52.2±7.3 — — — — — — 混合基质 124.0±0.6 115.0±0.5 181.0±2.3 74.5±1.4 3.9 0.001±0.000 8.20±0.12 2.71±0.03 0.10±0.01 接种污泥 39.1±0.6 19.7±1.5 27.2±0.3 3.1±0.0 7.9 0.003±0.000 0.81±0.03 0.27±0.02 2.62±0.17 注:“—”表示未测定。 表 2 批次实验的运行设置

Table 2. Operating characteristics of the batch experiments

实验项目 FW/WAS F/M 接种物/mL FW/mL WAS/mL 混合基质/mL 蒸馏水/mL FW单发酵 1∶0 0.206 30 0.905 0 — 3.095 WAS单发酵 0∶1 0.206 30 0 4.000 0 FW/WAS混合发酵 3∶1 0.206 30 0.680 1.000 — 2.320 FW/WAS混合发酵 4∶1 0.206 30 0.725 0.800 2.475 FW/WAS混合发酵 4.4∶1 0.206 30 0.740 0.740 2.520 FW/WAS混合发酵 5∶1 0.206 30 0.755 0.670 2.575 FW/WAS混合发酵 6∶1 0.206 30 0.775 0.575 2.650 F/M混合发酵 4.4∶1 0.090 30 — 0.960 14.040 F/M混合发酵 4.4∶1 0.176 30 1.865 13.135 F/M混合发酵 4.4∶1 0.354 30 3.750 11.250 F/M混合发酵 4.4∶1

4.4∶10.472

0.56730

305.000

6.00010.000

9.000F/M混合发酵 F/M混合发酵 4.4∶1 0.708 30 7.500 7.500 F/M混合发酵 4.4∶1 0.944 30 10.000 5.000 F/M混合发酵 4.4∶1 1.417 30 15.000 0 注:“—”表示不适用。 表 3 不同FW/WAS和F/M通过修正Gompertz模型和一级动力学模型拟合后产甲烷性能参数

Table 3. Kinetic parameters of CH4 production with respect to different FW/WAS and F/M obtained from the modified Gompertz model and first-order model

实验项目 FW/WAS F/M 修正的Gompertz模型 一级动力学模型 P0/mL Rmax/mL t0/d R2 P0/mL k/d-1 R2 FW单发酵 1∶0 0.206 16 4 0.2 0.975 17 0.287 0.971 WAS单发酵 0∶1 0.206 325 22 0.7 0.984 344 0.022 0.988 FW/WAS混合发酵 3∶1 0.206 70 6 0 0.984 74 0.160 0.993 FW/WAS混合发酵 4∶1 0.206 78 10 0 0.982 86 0.169 0.989 FW/WAS混合发酵 4.4∶1 0.206 82 11 0 0.985 88 0.172 0.994 FW/WAS混合发酵 5∶1 0.206 67 9 0 0.987 74 0.179 0.990 FW/WAS混合发酵 6∶1 0.206 63 8 0 0.985 68 0.181 0.991 F/M混合发酵 4.4∶1 0.090 51 105 0 0.985 51 2.610 0.977 F/M混合发酵 4.4∶1 0.176 91 85 0 0.979 91 1.610 0.989 F/M混合发酵 4.4∶1 0.354 166 99 0 0.969 169 0.968 0.981 F/M混合发酵 4.4∶1 0.472 219 126 0 0.980 223 0.874 0.987 F/M混合发酵 4.4∶1 0.567 240 118 0 0.982 246 0.751 0.990 F/M混合发酵 4.4∶1 0.708 277 106 0 0.989 286 0.575 0.996 F/M混合发酵 4.4∶1 0.944 325 43 0.02 0.994 402 0.135 0.984 F/M混合发酵 4.4∶1 1.417 0 0 2.0 0.902 0 0 0 -

[1] LI Q, YUWEN C S, CHENG X R, et al. Responses of microbial capacity and community on the performance of mesophilic co-digestion of food waste and waste activated sludge in a high-frequency feeding CSTR[J]. Bioresource Technology, 2018, 260: 85-94. doi: 10.1016/j.biortech.2018.03.087 [2] OGUNMOROTI A, LIU M, LI M Y, et al. Unraveling the environmental impact of current and future food waste and its management in Chinese provinces[J]. Resources, Environment and Sustainability, 2022, 9: 100064. doi: 10.1016/j.resenv.2022.100064 [3] XIAO B Y, QIN Y, ZHANG W Z, et al. Temperature-phased anaerobic digestion of food waste: A comparison with single-stage digestions based on performance and energy balance[J]. Bioresource Technology, 2018, 249: 826-834. doi: 10.1016/j.biortech.2017.10.084 [4] ZHANG J X, LOH K C, LI W L, et al. Three-stage anaerobic digester for food waste[J]. Applied Energy, 2017, 194: 287-295. doi: 10.1016/j.apenergy.2016.10.116 [5] ZHANG C S, SU H J, BAEYENS J, et al. Reviewing the anaerobic digestion of food waste for biogas production[J]. Renewable and Sustainable Energy Reviews, 2014, 38: 383-392. doi: 10.1016/j.rser.2014.05.038 [6] NGHIEM L D, KOCH K, DAVID B, et al. Full scale co-digestion of wastewater sludge and food waste: Bottlenecks and possibilities[J]. Renewable and Sustainable Energy Reviews, 2017, 72: 354-362. doi: 10.1016/j.rser.2017.01.062 [7] GOU C L, YANG Z H, HUANG J, et al. Effects of temperature and organic loading rate on the performance and microbial community of anaerobic co-digestion of waste activated sludge and food waste[J]. Chemosphere, 2014, 105: 146-151. doi: 10.1016/j.chemosphere.2014.01.018 [8] LI Q, LI H, WANG G J, et al. Effects of loading rate and temperature on anaerobic co-digestion of food waste and waste activated sludge in a high frequency feeding system, looking in particular at stability and efficiency[J]. Bioresource Technology, 2017, 237: 231-239. doi: 10.1016/j.biortech.2017.02.045 [9] YEONGMI J, SLAWOMIR W H, CHANHYUK P. Treatment of food waste recycling wastewater using anaerobic ceramic membrane bioreactor for biogas production in mainstream treatment process of domestic wastewater[J]. Water Research, 2017, 123: 86-95. doi: 10.1016/j.watres.2017.06.049 [10] 袁宏林, 韩宇乐, 邢保山, 等. 膜基材对连续流动态膜厌氧混合发酵系统的影响[J]. 环境科学学报, 2019, 39(12): 4114-4121. doi: 10.13671/j.hjkxxb.2019.0221 [11] 李浩, 黄慧群. 餐厨垃圾与污泥厌氧发酵动力学特性分析[J]. 环境工程, 2018, 36(7): 107-112. doi: 10.13205/j.hjgc.201807022 [12] XING B S, HAN Y L, CAO S F, et al. Effects of long-term acclimatization on the optimum substrate mixture ratio and substrate to inoculum ratio in anaerobic codigestion of food waste and cow manure[J]. Bioresource Technology, 2020, 317: 123994. doi: 10.1016/j.biortech.2020.123994 [13] LI L, HE Q M, WEI Y M, et al. Early warning indicators for monitoring the process failure of anaerobic digestion system of food waste[J]. Bioresource Technology, 2014, 171: 491-494. doi: 10.1016/j.biortech.2014.08.089 [14] 李浩, 李倩, 王高骏, 等. 不同条件下厨余与污泥共发酵效率及能耗分析[J]. 环境工程学报, 2017, 11(7): 4305-4312. doi: 10.12030/j.cjee.201605057 [15] 袁宏林, 马静, 邢保山, 等. 污泥停留时间对餐厨垃圾与剩余污泥中温厌氧混合发酵系统的影响[J]. 环境科学, 2019, 40(2): 994-1002. doi: 10.13227/j.hjkx.201808114 [16] APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed[Z]. 2005. [17] LOWRY O H, ROSEBROUGH N J, FARR A L, et al. Protein measurement with the Folin phenol reagent[J]. The Journal of Biological Chemistry, 1951, 193(1): 265-275. doi: 10.1016/S0021-9258(19)52451-6 [18] DUBOIS M, GILLES K A, HAMILTON J K, et al. Colorometric method for determination of sugars and related substances[J]. Analytical Chemistry, 1956, 28(3): 350-356. doi: 10.1021/ac60111a017 [19] LAY J J, LI Y Y, NOIKE T. Interaction between homoacetogens and methanogens in lake sediments[J]. Journal of Fermentation and Bioengineering, 1998, 86(5): 467-471. doi: 10.1016/S0922-338X(98)80153-0 [20] 张念瑞, 李倩, 许曼娟, 等. 进料频率对餐厨垃圾与剩余污泥中温共发酵系统稳定性的影响[J]. 环境工程学报, 2018, 12(2): 638-644. doi: 10.12030/j.cjee.201707224 [21] GUNASEELAN V N. Biochemical methane potential of fruits and vegetable solid waste feedstocks[J]. Biomass Bioenergy, 2004, 26(4): 389-399. doi: 10.1016/j.biombioe.2003.08.006 [22] YANG W W, YOUNG S, MUNOZ A, et al. Dynamic modeling of a full-scale anaerobic mesophilic digester start-up process for the treatment of primary sludge[J]. Journal of Environmental Chemical Engineering, 2019, 7(3): 103091. doi: 10.1016/j.jece.2019.103091 [23] SANCHEZ E, BORJA R, TRAVIESO L, et al. Effect of organic loading rate on the stability, operational parameters and performance of a secondary upflow anaerobic sludge bed reactor treating piggery waste.[J]. Bioresource Technology, 2005, 96(3): 335-344. doi: 10.1016/j.biortech.2004.04.003 [24] MAO C L, XI J C, FENG Y Z, et al. Biogas production and synergistic correlations of systematic parameters during batch anaerobic digestion of corn straw[J]. Renewable Energy, 2019, 132: 1271-1279. doi: 10.1016/j.renene.2018.09.009 -

下载:

下载: