-

随着社会生活中大量餐厨垃圾的产生,对此类垃圾的处理处置已成为亟待解决的环境问题。根据2021年《中国统计年鉴》[1],2020年中国产生了约2.35×108 t城市固体废物,其中餐厨垃圾产量约占城市固体废物的50%~60%[2]。餐厨垃圾中有机物含量高,可生化性强,将其进行厌氧消化既可减少环境污染,又可将沼气等副产物进行资源回收。虽然厌氧消化已经是一项相对成熟且应用广泛的技术,但当将餐厨垃圾用作唯一的消化基质时,仍然面临着一些挑战,包括挥发性脂肪酸(VFAs)的抑制、微量金属元素的缺乏和高氨氮的抑制等问题[3]。将餐厨垃圾进行联合厌氧共消化,能表现出比单一厌氧消化更好的性能,这可增强厌氧消化系统的稳定性进而提高沼气生产率。拟通过系统梳理餐厨垃圾与其它生物质废物厌氧共消化的研究进展,从产甲烷角度分析餐厨垃圾与其它生物质厌氧共消化的协同效益,并归纳餐厨垃圾厌氧共消化的性能提高策略。

-

餐厨垃圾的厌氧消化技术主要存在2种挑战。一种是VFAs的抑制,VFAs大量积累将会导致厌氧消化过程停滞在水解酸化阶段。餐厨垃圾由于有机物含量高及可生物降解性好的特点,常引起厌氧发酵系统快速酸化产生大量的短链VFAs,并导致pH迅速下降,从而影响产甲烷菌的活性。另一种是氨氮的抑制,过多的氨氮积累会影响微生物的活性,导致甲烷产量低且不稳定。有研究表明,氨可能通过2种方式影响产甲烷菌的生长代谢:1)NH4+可直接抑制产甲烷酶的合成作用;2)游离氨(NH3)被动扩散到细菌细胞内,吸收质子转化为NH4+,导致pH变化(图1)。为了维持细胞内pH,细胞必须在质子稳态期间消耗钾(K+)泵进而提供的更多能量,并可能抑制特定的酶反应[4-5]。氨抑制和VFAs的抑制影响了厌氧消化系统的稳定性和可持续性,将餐厨垃圾与其它有机废物厌氧共消化,不仅能联合2种或2种以上的有机废物实现较为稳定的处理,而且还增强了甲烷生产的潜力。

厌氧共消化技术不是简单的物料混合,而是综合考虑了营养物质的均衡、系统稳定性及其处理效率,是解决单一底物厌氧消化不足的重要手段[6]。餐厨垃圾与其它有机废物共消化可在不同基质之间产生互补和协同效应,以利用微生物的效益提高厌氧消化的有机负载能力和缓冲能力进而提高甲烷产量。餐厨垃圾的厌氧共消化技术可以使2种甚至多种共消化废物得到适宜的处理处置,不论从环境还是经济角度上来看都具有较好的协同效益。

-

现有研究趋向于联合不同的生物质作为餐厨垃圾共消化的底物,其主要关注的是餐厨垃圾与共消化基质的混合配比、进料的有机负荷以及不同温度条件下对产甲烷性能的影响(表1)。目前,较为常见的共消化的基质有剩余污泥、动物粪便、垃圾渗滤液和农作物秸秆等。

-

国内外关于餐厨垃圾和剩余污泥的厌氧共消化的研究与案例较多,多数研究结果表明,餐厨垃圾和剩余污泥的最佳比例为1∶1,且在中温条件下进行厌氧共消化作用有较高的产气效率和性能。餐厨垃圾和剩余污泥的厌氧共消化系统中,不仅可以稀释对系统有冲击作用的Na+、K+等,还能够增加短链VFAs的产生,为产甲烷菌的生长提供足够的底物。FENG等[19]发现,餐厨垃圾和剩余污泥的联合厌氧消化短链脂肪酸的产量可达到520.1 mg·g−1(以COD计),比餐厨垃圾单独厌氧消化时的短链脂肪酸产量提高了50%。有学者还对剩余污泥与餐厨垃圾厌氧共消化系统下的优势微生物种群以及微生物作用的机理进行了研究。GOU等[20]利用16sRDNA聚合酶链反应和变性梯度凝胶电泳对污泥和餐厨垃圾厌氧共消化系统中的微生物群落进行分析,发现,此系统的微生物群落结构较为稳定且具有较高的厌氧消化效率。剩余污泥与餐厨垃圾虽然可以为期提供较好的C/N比,但是也存在一些问题。污泥表面易被餐厨垃圾的油脂包裹,使污泥缓慢地漂浮到厌氧系统的上层,造成污泥流失,若配比不适极易引起严重的抑制作用[21]。因此,在实际工程中对污泥与餐厨垃圾的系统条件要进行合理适宜的调整控制,才能使厌氧共消化顺利进行。

-

由于动物粪便的C/N较低,若将其进行单独厌氧消化极易出现氨氮抑制的问题[22]。因此,将动物粪便与高C/N比的餐厨垃圾进行联合厌氧共消化有利于提高厌氧消化过程中的甲烷产量。除了在粪便和餐厨垃圾的厌氧共消化过程中提高甲烷产量外,粪便与餐厨垃圾的共消化效益还包括:1)粪便因其高水分含量而充当干燥原料的载体[23];2)粪便具有较高的缓冲能力,可维持消化池的pH[24];3)粪便营养物质丰富,可提供微生物生长所必需的营养物质[25]。因此,具有上述特性的粪便作为共消化基质可快速驱动餐厨垃圾的厌氧消化进程[26]。大部分对餐厨垃圾和动物粪便的厌氧共消化系统的研究为了提高厌氧消化效率涉及到基质配比和初始进料的有机负荷以及系统内的温度条件等问题。动物粪便和餐厨垃圾的联合厌氧消化可以改善系统的动力学条件,提高甲烷产率,加快厌氧消化的进程。

-

垃圾渗滤液是一类具有极强污染特性的有毒废水,若不经过处理直接进入受纳水体将会对生态环境和人体健康造成极为重大的影响[27]。但同时,城市生活垃圾渗滤液也是一种有机废液,通常含有高浓度的氨氮、无机盐、微量金属元素离子并具有较高的COD。鉴于垃圾渗滤液和餐厨垃圾的互补特性,餐厨垃圾与成熟渗滤液的厌氧共消化比餐厨垃圾的单一消化效果好,具有更多的潜在效益[28]。由于渗滤液具有较高的氨氮浓度,可以减弱水解酸化阶段积累的VFAs形成的酸抑制效应,具有一定的缓冲作用,可使产甲烷菌保持较高的活性以更好地产气[29]。此外,通过渗滤液和餐厨垃圾的联合共消化以补充微量金属元素(Fe、Co、Mo和Ni等)可恢复因丙酸积累而导致的餐厨垃圾单消化的不稳定性[30]。廖筱锋[31]研究发现,渗滤液中含有的腐殖质可以作为终端电子受体直接参与厌氧消化反应,促进微生物的胞外呼吸,加速乙酸的酸化进程。需要注意的是,过量的微量金属元素也会有抑制作用,铁、钴和镍的抑制质量浓度分别为8 000、160和35 mg·L−1。因此,要控制适宜的渗滤液添加量以进行厌氧消化。垃圾渗滤液对餐厨垃圾的厌氧共消化处理不仅可以提高厌氧消化的营养平衡,提高甲烷产量,而且可以最大限度地减少废物流对环境的负面影响。

-

全球范围内,每年会产生大量的农作物废弃物。这些废弃物中大多是农作物秸秆,农作物秸秆的主要成分是木质素和纤维素等难水解的物质。但农作物秸秆具有较高的C/N,可以通过调节餐厨垃圾和农作物秸秆的混合比例来达到适宜的C/N,以保证联合厌氧消化系统的稳定性。餐厨垃圾含有大量易降解有机质,水解酸化阶段的产物可以增强农作物秸秆的水解作用,降低酸的抑制作用。关于农作物秸秆和餐厨垃圾的厌氧共消化体系中的研究大都是通过控制系统内部的pH、调整初始有机负荷和控制中温或高温条件来寻求最佳的厌氧共消化系统的工艺运行参数。周祺等[32]通过调节餐厨垃圾与玉米秸秆的混合比例来控制C/N=20时,产气量相比餐厨垃圾单独厌氧消化提高了28.7%。陈雪等[33]通过响应面实验发现,餐厨垃圾和稻草厌氧共消化时,产酸效果最优,比单因素最优水平组合VFAs和乙醇总量提高30.4%。农作物秸秆和餐厨垃圾的厌氧共消化处理不仅能对2种废物进行有效处理,还对作物的经济循环有极大的促进作用。其中,剩余污泥作为与餐厨垃圾厌氧共消化的基质有较好的可利用性和研究价值;而且,有学者通过生命周期评价法研究发现,剩余污泥与餐厨垃圾的厌氧共消化作用是最为经济有效的处理方法[34]。

-

餐厨垃圾联合厌氧消化技术利用不同废物之间的互补效应,调节营养平衡,并对有毒有害物质进行稀释,进而维持产甲烷菌等微生物的稳定生长。表2列出了餐厨垃圾联合厌氧消化的典型影响因素(C/N比值、温度、pH和微量金属元素)对厌氧消化系统稳定性的影响的研究。这些研究在不同的反应环境中,确定了特定影响因素下的最佳条件范围,在促进厌氧消化系统性能的提升改进上具有一定的贡献和参考价值。

-

对于厌氧共消化来说,C/N是促进厌氧消化效率的关键参数。C/N代表基质中碳与氮的相对含量,碳源主要用于生成CH4,而氮则被产甲烷菌利用,并合成自身的蛋白质,高C/N意味着微生物中蛋白质的形成将受到氮的限制[44]。厌氧消化适宜的 C/N 一般为 20~30[45],C/N过低则会出现氨抑制的现象,不利于产甲烷菌的生存[46];C/N过高时有机物降解速率快,会引起短链脂肪酸的积累,从而形成酸的抑制。因此,C/N是影响厌氧消化产甲烷的一个重要因素。其主要原因在于,适宜的C/N是保证微生物正常生命活动的必要条件,可以提高生物酶的活性,能更有效地降解蛋白质、多糖等有机物,从而提高厌氧消化系统的产甲烷性能。虽然学者们通过研究得到了适宜的C/N,但最佳C/N比值因厌氧共消化的原料不同而呈现出不同的配比。

-

餐厨垃圾厌氧共消化适宜在中温(35~40 ℃)和高温(50~55 ℃)条件下进行[47]。尽管餐厨垃圾中大多数微生物都能在较宽的温度范围内存活,但有些微生物对温度变化高度敏感。例如,嗜热产甲烷菌,其代谢过程需要最佳温度以应对较高的有机负荷率。高温条件下的厌氧消化体系含有较高的有机负荷,可提高生化反应速率,并产生较高的甲烷产量[48]。较高的工作温度会导致氨氮的增加,进而会对微生物的生命活动产生抑制[48]。在中温条件下,餐厨垃圾厌氧共消化系统通常具有更高的微生物多样性,这可以提高整个厌氧消化过程中的稳定性和耐冲击性[49]。此外,中温条件下的餐厨垃圾等高生物降解基质可表现出较高的溶解速率和工艺稳定性[50]。

-

大部分研究表明,pH是决定厌氧消化工艺稳定性的关键因素,对厌氧共消化过程有很大影响。发酵细菌可在广泛的pH(4.0~8.0)范围内有效运行,而产甲烷细菌在pH为6.5至7.5范围内才具有功能活性[51]。低pH(pH<4)有利于VFAs的产生,尤其是乙酸、丙酸和丁酸,而高pH(pH>8)有利于氨的产生[52]。从已报道的研究中可以看出,厌氧共消化系统的性能在很大程度上取决于其缓冲能力,而缓冲能力可通过添加缓冲剂来实现。同样,污水污泥和渗滤液富含各种盐。因此,餐厨垃圾共消化的基质进行适当比例的调整也能缓冲系统。一项将餐厨垃圾与牛粪共同消化的研究发现,使用污水污泥调节pH和补充接种物对于平衡整个系统pH至关重要[53]。

-

除了基本的大量营养元素(C、N、P和S)外,微量营养元素对维持微生物活性和促进新陈代谢也很重要[54]。某些特定的微量金属元素(Fe、Co、Mo和Ni等)不仅是微生物细胞生长的基本营养元素,而且也是合成一些与产甲烷过程相关的关键辅酶所必需的[55]。在各种微量金属元素中,铁是最重要的元素,它既可以作为电子受体也可以作为电子供体,参与产甲烷过程的氧化还原反应。此外,补充微量金属元素可恢复因丙酸积累而导致的餐厨垃圾厌氧消化的不稳定性[56]。

-

目前,餐厨垃圾的厌氧共消化工艺虽然解决了普遍存在的系统酸化、氨抑制和脂肪酸抑制等问题,但为了获得高的处理效率、稳定的运行状态和高的甲烷产量,已经开始对预处理、添加酶和导电材料等方法进行研究。

-

为了提高餐厨垃圾和其它生物质的厌氧共消化甲烷回收率,对2种基质的有效预处理非常重要[57]。良好的预处理技术能够保存生物质中的有机物,有利于水解过程,避免形成任何有毒或抑制性化合物。表3总结了几种预处理技术对厌氧共消化基质的积极促进作用,这些预处理方式通过提前控制温度条件或者将粒径处理到适宜进行厌氧消化的尺寸等方式,使厌氧消化系统的稳定性得到了极大的提升。在不同预处理类型下选择最适宜的预处理条件,不仅促进了甲烷产量的提高,还有利于产甲烷速率的增大。

热预处理的主要作用是分解生物体的细胞膜,促进有机化合物的水解过程[58]。ARIUNBAATAR等[59]通过一系列高温预处理和常规热预处理的分批实验,在50 ℃下预处理6~12 h和80 ℃下预处理1.5 h,使系统的甲烷产量增加了40%。机械预处理主要是通过研磨等降低基质粒径来增加可用于吸附水解酶的表面积,有利于产生更多的沼气[60]。但是,过小的粒径极有可能过度刺激水解和产酸,造成氨和VFAs的积累,从而导致产甲烷菌的抑制作用[61]。超声波处理的工作原理是基于超声波通过水介质或泥浆介质形成气泡的空化作用来破坏细胞结构和絮状物。虽然超声波的预处理效果较好,但由于其较高的能耗需要极高的经济成本,故下一步的研究应集中于降低超声波和微波预处理的能耗上。

-

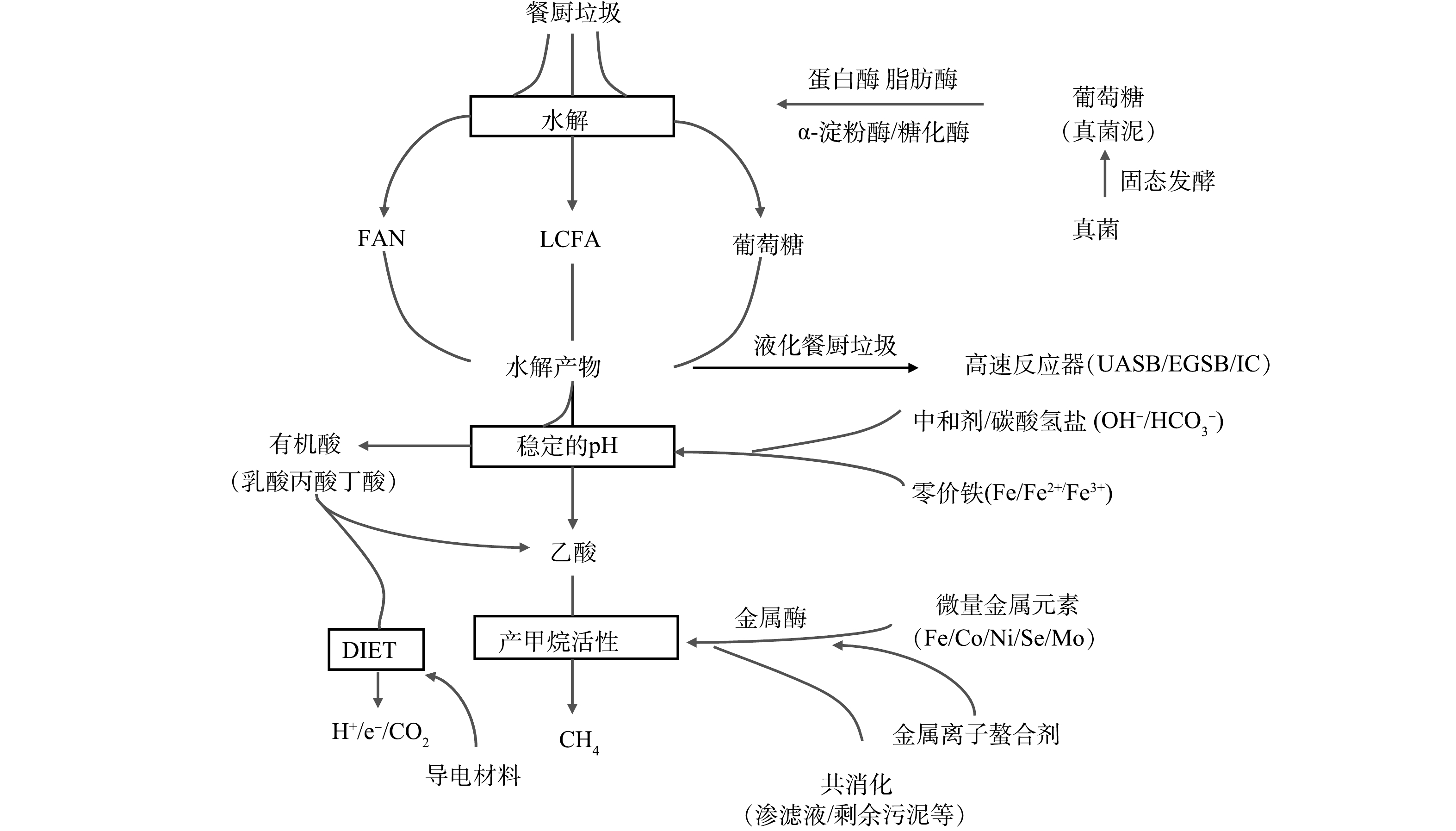

使用添加剂在解决餐厨垃圾厌氧共消化中发挥着重要作用,从而使厌氧消化系统保持稳定和高效。添加剂的加入有以下3种积极作用:1)促进水解酸化阶段进行;2)保持稳定的pH;3)减少滞后时间并加强种间直接电子传递(DIET)途径。图2展示了一些主要使用的添加剂在不同厌氧消化阶段(即水解、产酸、产甲烷)提高餐厨垃圾厌氧共消化系统的性能及效率的作用[72-73]。

酶主要是在餐厨垃圾预水解阶段表现出优异的性能,几乎所有的大分子物质都能被酶迅速分解。餐厨垃圾中含有的淀粉、蛋白质和脂质等这类大分子物质,均可通过相应的酶分解为葡萄糖、游离氨基酸和长链脂肪酸等小分子物质[74]。在淀粉水解过程中,添加α-淀粉酶或者糖化酶有助于打破糖苷键,从而加速水解[75]。蛋白酶的添加能有效分解蛋白质的肽链结构,同时还能加速氨的释放,应对餐厨垃圾的酸化过程[76]。而真菌泥是富含多种酶的物质,相比其它单一的酶类物质可极大加快水解酸化阶段的反应[77]。

由于pH是微生物生长的关键影响因素,在厌氧消化系统中添加中和剂(如氢氧化钠)、碳酸氢盐和缓冲材料(如零价铁)被认为是直接和立即控制系统pH的有效方法。WANG等[2]研究表明,使用低水平的中和剂可实现较高的VS去除率。与中和剂相比,添加碳酸氢盐只需一次添加即可实现等效功能,因此被广泛用作常规pH的控制策略。

导电材料作为添加剂能够有效提高餐厨垃圾厌氧消化效率,其机理主要包括提高厌氧消化系统稳定性、促进直接种间电子传递(DIET)、影响微生物群落等[78]。DIET能够以具备电子传递能力的微生物细胞结构(如细胞色素蛋白、导电菌毛)以及具备电子传递能力的外源物质(如导电材料等)为媒介完成电子的快速和定向传递,同时需要更少的生物酶参与[79]。导电材料(铁基和碳基材料等)投加至厌氧消化体系中,既可以利用其自身的良好导电性替代细菌鞭毛实现DIET,又可以吸附富集某些具有胞外电子转移能力的微生物,强化厌氧消化体系微生物之间的DIET[72]。YAMADA等[80]向嗜热厌氧消化反应器中添加磁铁矿,构建有机酸降解菌和产甲烷菌之间的电子传递过程,加速了乙酸和丙酸的产甲烷转化。

-

餐厨垃圾厌氧共消化处技术提高了厌氧消化过程的稳定性和效率。与单独厌氧消化相比,餐厨垃圾的厌氧共消化系统具有更好的性能、稳定性、和缓冲能力。目前,对于联合厌氧消化的物料配比、影响因素等已经进行了广泛深入研究。且近年来,DIET的出现被认为是提高厌氧共消化系统性能的有效策略。因此,联合厌氧消化应根据但是目前对于餐厨垃圾和其它生物质联合厌氧共消化的研究中还存在一些问题与挑战。

餐厨垃圾联合厌氧共消化基质的性质差异较大,从实验研究中得到的最适配比和系统操作参数的适用性不高,不足以指导并应用实际工程中。因此,要根据不同地区废弃物种类,选用合适处理方式,最大限度实现餐厨垃圾与其它有机废物的资源化。

餐厨垃圾和其它生物质的厌氧共消化大多只关注如何提高厌氧消化系统的性能上,对于餐厨垃圾厌氧共消化的机理研究还尚未得到清晰的揭示。

餐厨垃圾厌氧共消化已经应用到实际工程中,但目前缺乏综合管理系统。未来的研究需要侧重于操作参数的优化、动力学和热力学建模、成本分析和生命周期评估等方面,以保证餐厨垃圾厌氧共消化技术的优良性。

餐厨垃圾厌氧共消化研究进展

Research progress and performance improvement strategies of anaerobic co-digestion of food waste

-

摘要: 餐厨垃圾厌氧发酵系统长期运行时极易失衡,且失衡机制错综复杂;而且,目前缺乏对餐厨垃圾厌氧发酵消化性能的有效调控策略,这限制了餐厨垃圾厌氧消化技术的发展和应用。餐厨垃圾与其它基质进行厌氧共消化不仅能解决餐厨垃圾单一消化的性能限制问题,还可以实现废物的互相利用和资源回收。梳理了餐厨垃圾厌氧消化面临的问题及挑战,深入探讨了餐厨垃圾与其它生物质联合厌氧共消化的协同效应及影响因素,总结了提升餐厨垃圾厌氧共消化性能的强化策略,以期为餐厨垃圾厌氧共消化技术研究提供参考。Abstract: The anaerobic fermentation system of food waste is easily unbalanced when it is running for a long time, and the imbalance mechanism is complicated. Moreover, the lack of effective regulation strategies on anaerobic digestion performance of food waste restricts the application and development of anaerobic digestion technology of food waste. Anaerobic co-digestion of kitchen waste and other substrates can not only overcome the performance limitation of single digestion of kitchen waste, but also realize the mutual utilization of waste and resource recovery. Therefore, this research reviewed the latest research progress of the anaerobic co-digestion of food waste and other substrates. In this review, the problems and challenges faced by the anaerobic digestion of kitchen waste were analyzed, the synergistic effect and influencing factors of the anaerobic co-digestion of kitchen waste and other biomass were discussed, and the strengthening strategies to improve the performance of the anaerobic co-digestion of kitchen waste were summarized. This review can provide reference for the related research on the anaerobic co-digestion technology of kitchen waste.

-

Key words:

- food waste /

- anaerobic co-digestion /

- synergistic effect /

- strengthening strategies

-

-

表 1 餐厨垃圾与其它生物质联合厌氧共消化的研究

Table 1. Summary of the recent studies on anaerobic co-digestion of kitchen waste and other biomass

序号 共消化基质的质量比 反应器

运行模式温度/℃ pH 停留

时间/d总固体质量分数

或质量浓度C/N 最大甲烷产率/

(mL·g−1)参考

文献1 餐厨垃圾∶剩余污泥=1∶1 序批式 35 ± 0.2 7.1~7.8 — 15%~30% — 224.1 [7] 2 餐厨垃圾∶剩余污泥=2∶5 连续式 34 0.75 ± 0.1 20 27.6 ± 0.4 g·L−1 19.5 476.6 [8] 3 餐厨垃圾∶剩余污泥=1∶1 半连续式 55 ± 2 6.8 33.3 45 g·L−1 13 300 [9] 4 餐厨垃圾∶脱水污泥=0.4∶1 半连续式 35 ± 1 7.6 ± 0.1 20 20. 8% 11. 2 376.2 [10] 5 餐厨垃圾∶牛粪=2.5∶1 序批式 35 6.4~7.4 — — — 588.02 [11] 6 餐厨垃圾∶马粪=25∶100 连续式 — 7.9 ± 0.1 — — — 370 [12] 7 餐厨垃圾∶羊粪∶污泥=20∶70∶10 序批式 36 7.9~8.2 22 22~24

g·L−116~18 603 [13] 8 餐厨垃圾∶渗滤液 序批式 35 ± 1 8.5~8.8 30 40 g·L−1 — — [14] 9 餐厨垃圾∶渗滤液 序批式 35 ± 1 7.7~8.8 35 40 g·L−1 — 584 [15] 10 餐厨垃圾∶渗滤液 序批式 35 ± 1 7.5~8.3 32 40 g·L−1 — 375 [16] 11 餐厨垃圾∶玉米秸秆=5∶5 序批式 55 ± 1 — 30 28.99 g·L−1 — 402. 3 [17] 12 餐厨垃圾∶玉米秸秆=1∶2 序批式 37 ± 1 6.5~7.8 45 21.7 g·L−1 55.76 383.9 [18] 表 2 餐厨垃圾联合厌氧共消化的影响因素

Table 2. Influencing factors of anaerobic co-digestion of food waste

序号 消化基质 反应器

类型影响

因素最优条件 运行参数 最大产

甲烷性能参考

文献1 餐厨垃圾和猪粪 序批式 pH 7.11 TS=10.08% 30 459.5 mL [33] 2 餐厨垃圾和牛粪 序批式 pH 8.0 SRT=50 d;C/N=25 2 5626 mL [35] 3 餐厨垃圾和稻草 CSTR C/N 16.94 OLR=15.8 g·L−1;t=37 ℃ 296 mL·g−1 [36] 4 餐厨垃圾和牛粪 序批式 C/N 15.8 t=35 ℃;TS=3.2% 388 mL·g−1 [37] 5 餐厨垃圾、玉米秸秆和鸡粪 间歇式 C/N 38 t=37 ℃;pH=7.0~8.2 432 mL·g−1 [38] 6 餐厨、牛粪和污泥 CSTR 温度 36 ℃ OLR=1.2 g·(L·d)−1;HRT=22 d 603 mL·g−1 [39] 7 餐厨垃圾和剩余污泥 CSTR 温度 55 ℃ HRT=33 d;C/N=13;pH=6.8;TS=45 g·L−1 300 mL·g−1 [10] 8 餐厨垃圾和剩余污泥 连续式 温度 35 ℃ OLR=15.8 g·L−1 320 mL·g−1 [40] 9 餐厨垃圾、猪粪和废水 CSTR Co

Mo

Ni

Fe2 mg·L−1

5 mg·L−1

10 mg·L−1

100 mg·L−1HRT=20 d;pH=7.37;

VS=75.6%396 mL·g−1 [41] 10 餐厨垃圾和猪粪废水 半连续 Fe

Co

Ni5 mg·L−1

1 mg·L−1

1 mg·L−1TS= 21.75%;C/N=19.3;t=37 ℃ 456.4 mL·g−1 [42] 11 餐厨垃圾和玉米秸秆 序批式 Ni

Co

Mo0.5mg·L−1

0.5mg·L−1

0.25mg·L−1OLR=1.0~5.5 g·L−1;t=37 ℃ 429 mL·g−1 [43] 注:CSTR为混合连续搅拌釜式反应器。 表 3 预处理强化厌氧共消化性能研究

Table 3. Pretreatment methods and their impact on anaerobic co-digestion of food waste

序号 预处理类型 消化基质 预处理条件 处理效果 参考文献 1 热预处理 餐厨垃圾和油脂 pH=10; t=55 ℃ 甲烷产量提高9.9% [62] 2 热预处理 餐厨垃圾和农作物 t=50 ℃,反应时间=6~12 h;

t=80 ℃,反应时间=1.5 h生物甲烷产量>40% [63] 3 机械预处理 餐厨垃圾和牛粪 300~2 000 r·min−1,反应时间=1~20 min 粒径从0.84 mm减小到0.39 mm,

甲烷产率提高28%[64] 4 超声预处理 餐厨垃圾和剩余污泥 反应时间=30 min 最大甲烷产率206 mL·g−1 [65] 5 超声预处理 餐厨垃圾、牛粪和剩余污泥 7 500 kJ·kg−1 最大甲烷产率376 mL·g−1 [66] 6 超声预处理 餐厨垃圾和活性污泥 90 000 kJ·kg−1 沼气生成量增加24% [67] 7 超声预处理 牛粪、餐厨垃圾和活性污泥 7 500 kJ·kg−1 中温条件下产甲烷量提高31% [68] 8 碱预处理 餐厨垃圾和农作物秸秆 NaOH浓度=4% 最大甲烷产率311.5 g·L−1 [69] 9 碱度预处理 餐厨垃圾和牛粪 t=37 °C;NaOH浓度=1.5% 最高甲烷产量800 mL·d−1 [70] 10 电化学预处理 餐厨垃圾和剩余污泥 pH=7.0~7.4;电压=1 V VFAs最高达132.2 mg·L−1 [71] -

[1] 国家统计局. 中国统计年鉴[M]. 北京: 中国统计出版社, 2021. [2] WANG Y Y, ZANG B, LI G X, et al. Evaluation the anaerobic hydrolysis acidification stage of kitchen waste by pH regulation[J]. Waste Management, 2016, 53: 62-67. doi: 10.1016/j.wasman.2016.04.018 [3] XU F Q, LI Y Y, Ge X M, et al. Anaerobic digestion of food waste – Challenges and opportunities[J]. Bioresource Technology, 2018, 247: 1047-1058. doi: 10.1016/j.biortech.2017.09.020 [4] KAYHANIAN M. Ammonia inhibition in high-solids biogasification: An overview and practical solutions[J]. Environmental Technology, 1999, 20(4): 355-365. doi: 10.1080/09593332008616828 [5] JIN C X, SUN S Q, YANG D H, et al. Anaerobic digestion: An alternative resource treatment option for food waste in China[J]. Science of the Total Environment, 2021, 779: 146397. doi: 10.1016/j.scitotenv.2021.146397 [6] CHAKRABORTY D, KARTHIKEYAN O P, Selvam A, et al. Co-digestion of food waste and chemically enhanced primary treated sludge in a continuous stirred tank reactor[J]. Biomass and Bioenergy, 2017, 111(8): 232-240. [7] 王永会, 赵明星, 阮文权. 餐厨垃圾与剩余污泥混合消化产沼气协同效应[J]. 环境工程学报, 2014, 8(6): 2536-2542. [8] DE VRIEZE J, PLOVIE K, VERSTRAETE W, et al. Co-digestion of molasses or kitchen waste with high-rate activated sludge results in a diverse microbial community with stable methane production[J]. Journal of Environmental Management, 2015, 152: 75-82. doi: 10.1016/j.jenvman.2015.01.029 [9] ZHU H G, PARKER W, CONIDI D, et al. Eliminating methanogenic activity in hydrogen reactor to improve biogas production in a two-stage anaerobic digestion process co-digesting municipal food waste and sewage sludge[J]. Bioresource Technology. 2011, 102(14): 7086-7092. [10] 段妮娜, 董滨, 李江华, 等. 污泥和餐厨垃圾联合干法中温厌氧消化性能研究[J]. 环境科学, 2013, 34(1): 321-327. doi: 10.13227/j.hjkx.2013.01.060 [11] 李轶, 李磊, 熊菊元, 等. 餐厨垃圾与牛粪混合厌氧发酵最佳配比筛选[J]. 沈阳农业大学学报, 2012, 43(5): 5. doi: 10.3969/j.issn.1000-1700.2012.05.009 [12] ZHANG J X, LOH K C, Lee J, et al. Three-stage anaerobic co-digestion of food waste and horse manure[J]. Scientific Reports, 2017, 7(1): 1269. doi: 10.1038/s41598-017-01408-w [13] MARANON E, CASTRILLON L, QUIROGA G, et al. Co-digestion of cattle manure with food waste and sludge to increase biogas production[J]. Waste Management, 2012, 32(10): 1821-1825. doi: 10.1016/j.wasman.2012.05.033 [14] 张竣. 餐饮垃圾与渗滤液联合厌氧消化实验研究[D]. 湖北: 华中科技大学, 2016. [15] 朱双燕. 餐饮垃圾与渗滤液联合厌氧消化实验研究[D]. 武汉: 华中科技大学, 2014. [16] 廖筱锋, 朱双艳, 朱菁萍, 等. 渗滤液添加量对餐饮垃圾厌氧消化的影响机制[J]. 环境工程学报, 2016, 10(7): 3835-3840. doi: 10.12030/j.cjee.201502025 [17] 郭香麟, 左剑恶, 史绪川, 等. 餐厨垃圾与秸秆混合中温和高温厌氧消化对比[J]. 环境科学, 2017, 38(7): 3070-3077. doi: 10.13227/j.hjkx.201612267 [18] 申兰兰. 餐饮垃圾和玉米秸秆联合厌氧消化实验研究[D]. 湖北: 华中科技大学, 2016. [19] FENG L. Enhancement of waste activated anaerobic fermentation by carbohydrate substrate addition: the effect of pH[J]. Environment Science Technology, 2009, 43(3): 4373-4380. [20] GOU C, YANG Z, JING H, et al. Effects of temperature and organic loading rate on the performance and microbial community of anaerobic co-digestion of waste activated sludge and food waste[J]. Chemosphere, 2014, 105: 146-151. doi: 10.1016/j.chemosphere.2014.01.018 [21] 彭爽, 何琴, 李蕾, 等. 底物和中间产物对餐厨垃圾厌氧消化污泥表面张力、黏度和发泡潜能的影响[J]. 环境科学学报, 2017, 37(10): 8. doi: 10.13671/j.hjkxxb.2017.0122 [22] 邓云盼, 周颖君, 杨波, 等. 餐厨垃圾联合厌氧消化研究进展[J]. 安徽农业科学, 2015(35): 112-114. doi: 10.3969/j.issn.0517-6611.2015.35.040 [23] MONTORO S B, LUCAS J, SANTOS D F L, et al. Anaerobic co-digestion of sweet potato and dairy cattle manure: A technical and economic evaluation for energy and biofertilizer production[J]. Journal of Cleaner Production, 2019, 226: 1082-1091. doi: 10.1016/j.jclepro.2019.04.148 [24] SUN H, KOVALOVSZKI A, TSAPEKOS P, et al. Co-digestion of Laminaria digitata with cattle manure: A unimodel simulation study of both batch and continuous experiments[J]. Bioresource Technology, 2019, 276: 361-368. doi: 10.1016/j.biortech.2018.12.110 [25] WANG Z Q, YUN S, XU H F, et al. Mesophilic anaerobic co-digestion of acorn slag waste with dairy manure in a batch digester: Focusing on mixing ratios and bio-based carbon accelerants[J]. Bioresource Technology, 2019, 286: 121394. doi: 10.1016/j.biortech.2019.121394 [26] MA G L, NDEGWA P, HARRISON J H, et al. Methane yields during anaerobic co-digestion of animal manure with other feedstocks: A meta-analysis[J]. Science of The Total Environment, 2020, 728: 138224. doi: 10.1016/j.scitotenv.2020.138224 [27] VIEGAS C, NOBRE C, MOTA A, et al. A circular approach for landfill leachate treatment: Chemical precipitation with biomass ash followed by bioremediation through microalgae[J]. Journal of Environmental Chemical Engineering, 2021, 9(3): 105187. doi: 10.1016/j.jece.2021.105187 [28] 廖筱锋, 卢加伟, 万惠丹, 等. 联合厌氧消化改善渗沥液可生化性实验研究[J]. 环境卫生工程, 2010, 18(5): 12-14. doi: 10.3969/j.issn.1005-8206.2010.05.005 [29] 汪伟. 生物质垃圾与填埋场渗滤液联合厌氧消化实验研究[D]. 湖北: 华中科技大学, 2012. [30] ZHANG W L, ZHANG L, LI A L. Anaerobic co-digestion of food waste with MSW incineration plant fresh leachate: process performance and synergistic effects[J]. Chemical Engineering Journal, 2015, 259: 795-805. doi: 10.1016/j.cej.2014.08.039 [31] 廖筱锋. 餐厨垃圾与渗滤液联合厌氧消化协同增效机制研究[D]. 湖北: 华中科技大学, 2017. [32] 周祺, 刘研萍, 邹德勋, 等. 餐厨垃圾与玉米秸秆联合厌氧消化产甲烷性能的试验研究[J]. 中国沼气, 2014(1): 27-31. doi: 10.3969/j.issn.1000-1166.2014.01.006 [33] 陈雪, 袁海荣, 邹德勋, 等. 餐厨垃圾和稻草两相厌氧发酵及其动力学[J]. 环境工程学报, 2015, 9(5): 2405-2411. doi: 10.12030/j.cjee.20150561 [34] 王凯军, 王婧瑶, 左剑恶, 吴静, 李坤. 我国餐厨垃圾厌氧处理技术现状分析及建议[J]. 环境工程学报, 2020, 14(7): 1735-1742. doi: 10.12030/j.cjee.201911085 [35] 谷士艳, 于美玲, 寇巍, 等. 猪粪与餐厨废弃物混合厌氧消化工艺优化研究[J]. 可再生能源, 2015, 33(2): 308-313. doi: 10.13941/j.cnki.21-1469/tk.2015.02.024 [36] REN G X, MAO C L, ZHAI N, et al. A new adjustment strategy to relieve inhibition during anaerobic co-digestion of food waste and cow manure[J]. Sustainability, 2019, 11(10): 1-14. [37] CHEN G Y, LIU G, YAN B B, et al. Experimental study of co-digestion of food waste and tall fescue for bio-gas production[J]. Renewable Energy, 2016, 88: 273-279. doi: 10.1016/j.renene.2015.11.035 [38] ZHANG C S, XIAO G, PENG L Y, et al. The anaerobic co-digestion of food waste and cattle manure[J]. Bioresource Technology, 2013, 129(10): 170-176. [39] LI Y Q, ZHANG R H, LIU X Y, et al. Evaluating methane production from anaerobic mono- and co-digestion of kitchen waste, corn stover, and chicken manure[J]. Energy & Fuels, 2013, 27(4): 2085-2091. [40] PAN Y, ZHI Z, ZHEN G, et al. Synergistic effect and biodegradation kinetics of sewage sludge and food waste mesophilic anaerobic co-digestion and the underlying stimulation mechanisms[J]. Fuel, 2019, 253: 40-49. [41] DAI X, DUAN N, DOG B, et al. High-solids anaerobic co-digestion of sewage sludge and food waste in comparison with mono digestions: Stability and performance[J]. Waste Management, 2013, 33(2): 308-316. doi: 10.1016/j.wasman.2012.10.018 [42] ZHANG L, LEE Y W, JAHNG D. Anaerobic co-digestion of food waste and piggery wastewater: Focusing on the role of trace elements[J]. Bioresource Technology, 2011, 102(8): 5048-5059. doi: 10.1016/j.biortech.2011.01.082 [43] WEI Q Y, ZHANG W Q, GUO J B, et al. Performance and kinetic evaluation of a semi-continuously fed anaerobic digester treating food waste: Effect of trace elements on the digester recovery and stability[J]. Chemosphere, 2014, 117: 477-485. doi: 10.1016/j.chemosphere.2014.08.060 [44] EVRANOS B, DEMIREL B. The impact of Ni, Co and Mo supplementation on methane yield from anaerobic mono-digestion of maize silage[J]. Environmental Technology, 2015, 36(12): 1556-1562. doi: 10.1080/09593330.2014.997297 [45] KHALID A, ARSHAD M, ANJUM M, et al. The anaerobic digestion of solid organic waste[J]. Waste Management, 2011, 31(8): 1737-1744. doi: 10.1016/j.wasman.2011.03.021 [46] ZHANG W Q, WU S B, GUO J B, et al. Performance and kinetic evaluation of semi-continuously fed anaerobic digesters treating food waste: Role of trace elements[J]. Bioresource Technology, 2015, 178: 297-305. doi: 10.1016/j.biortech.2014.08.046 [47] RAJAGOPAL R, DI MASSE, SINGH G. A critical review on inhibition of anaerobic digestion process by excess ammonia - ScienceDirect[J]. Bioresource Technology, 2013, 143(17): 632-641. [48] LI R, LI C X. Biogas production from anaerobic co-digestion of food waste with dairy manure in a two-phase digestion system[J]. Applied Biochemistry& Biotechnology, 2010, 160(2): 643-654. [49] LIU C, WANG W, ANWAR N, et al. Effect of organic loading rate on anaerobic digestion of food waste under mesophilic and thermophilic conditions[J]. Energy & Fuels, 2017, 31(3): 2976-2984. [50] LEE J, HONG J, JEONG S, et al. Interactions between substrate characteristics and microbial communities on biogas production yield and rate[J]. Bioresource Technology, 2020, 303(7): 122934. [51] BLASIUS J P, CASTRO M, MAINTINGUER S I, et al. Effects of temperature, proportion and organic loading rate on the performance of anaerobic digestion of food waste[J]. Biotechnology Reports, 2020, 27: 503. [52] MATHERI A N, BELAID M, SEODIGENG T, et al. Modelling the Kinetics of Biogas Production from Co-digestion of Pig waste and Grass clippings[M]. 2016, 201-203. [53] YANG Y Q, SHEN D S, LI N. Co-digestion of kitchen waste and fruit-vegetable waste by two-phase anaerobic digestion.[J]. Environmental Science & Pollution Research, 2013, 20(4): 2162-2171. [54] ZALA M, SOLANKI R, BHALE P V, et al. Experimental investigation on anaerobic co-digestion of food waste and water hyacinth in batch type reactor under mesophilic condition[J]. Biomass Conversion and Biorefinery, 2020, 10(3): 707-714. doi: 10.1007/s13399-019-00522-1 [55] LEE E, BITTENCOURT P, Casimir L, et al. Biogas production from high solids anaerobic co-digestion of food waste, yard waste and waste activated sludge[J]. Waste Management, 2019, 95: 432-439. doi: 10.1016/j.wasman.2019.06.033 [56] LUO J H, QIAN G R, LIU J Y, et al. Anaerobic methanogenesis of fresh leachate from municipal solid waste: A brief review on current progress[J]. Renewable and Sustainable Energy Reviews, 2015, 49: 21-28. doi: 10.1016/j.rser.2015.04.053 [57] CAVINATO C, BOLZONELLA D, PAVAN P, et al. Mesophilic and thermophilic anaerobic co-digestion of waste activated sludge and source sorted biowaste in pilot- and full-scale reactors[J]. Renewable Energy, 2013, 55: 260-265. doi: 10.1016/j.renene.2012.12.044 [58] XING W, ZHAO Y C. A bench scale study of fermentative hydrogen and methane production from food waste in integrated two-stage process[J]. International Journal of Hydrogen Energy, 2009, 34(1): 245-254. doi: 10.1016/j.ijhydene.2008.09.100 [59] MARIN J, KENNEDY K J, ESKICIOGLU C. Effect of microwave irradiation on anaerobic degradability of model kitchen waste[J]. Waste Management, 2010, 30(10): 1772-1779. doi: 10.1016/j.wasman.2010.01.033 [60] AGYEMAN F O, TAO W. Anaerobic co-digestion of food waste and dairy manure: Effects of food waste particle size and organic loading rate[J]. Journal of Environmental Management, 2014, 133: 268-274. [61] Izumi K, OKISHIO Y, Nagao N, et al. Effects of particle size on anaerobic digestion of food waste[J]. International Biodeterioration & Biodegradation, 2010, 64(7): 601-608. [62] PROROT A, JULIEN L, CHRISTOPHE D, et al. Sludge disintegration during heat treatment at low temperature: A better understanding of involved mechanisms with a multiparametric approach[J]. Biochemical Engineering Journal, 2011, 54(3): 178-184. doi: 10.1016/j.bej.2011.02.016 [63] LI Y B, GUO L S, HUANG D K, et al. Support-dependent active species formation for CuO catalysts: Leading to efficient pollutant degradation in alkaline conditions[J]. Journal of Hazardous Materials, 2017, 328: 56-62. doi: 10.1016/j.jhazmat.2016.12.063 [64] ARIUNBAATAR J, PANICO A, YEH D H, et al. Enhanced mesophilic anaerobic digestion of food waste by thermal pretreatment: Substrate versus digestate heating[J]. Waste Management, 2015, 46: 176-181. doi: 10.1016/j.wasman.2015.07.045 [65] LIN Y Q, WANG D H, LIANG J J, et al. Mesophilic anaerobic co-digestion of pulp and paper sludge and food waste for methane production in a fed-batch basis[J]. Environmental Technology, 2012, 33(23): 2627-2633. doi: 10.1080/09593330.2012.673012 [66] QUIOGA G, CASTRILLON L, FERNANDEZ-NAVA Y, et al. Effect of ultrasound pre-treatment in the anaerobic co-digestion of cattle manure with food waste and sludge[J]. Bioresource Technology, 2014, 154: 74-79. doi: 10.1016/j.biortech.2013.11.096 [67] CEASRO A, NADDEO V, AMODIO V, et al. Enhanced biogas production from anaerobic codigestion of solid waste by sonolysis[J]. Ultrasonics Sonochemistry, 2012, 19(3): 596-600. doi: 10.1016/j.ultsonch.2011.09.002 [68] BEGUM S, ANUPOJU G R, ESHTIAGHI N. Anaerobic co-digestion of food waste and cardboard in different mixing ratios: Impact of ultrasound pre-treatment on soluble organic matter and biogas generation potential at varying food to inoculum ratios[J]. Biochemical Engineering Journal, 2021, 166: 107853. [69] A Q Z, B F S A, A H Y, et al. Minimizing asynchronism to improve the performances of anaerobic co-digestion of food waste and corn stover[J]. Bioresource Technology. 2014, 166: 31-36. [70] IQBAL S A, RAHAMAN S, RAHMAN M, et al. Anaerobic digestion of kitchen waste to produce biogas[J]. Procedia Engineering, 2014, 90: 657-662. doi: 10.1016/j.proeng.2014.11.787 [71] 陈沂塽, 魏桃员, 周涛, 等. 电化学预处理餐厨垃圾-污泥耦合厌氧发酵产挥发性脂肪酸的影响[J]. 环境工程, 2021, 39(9): 187-192. [72] WANG D, AI J, Shen F, et al. Improving anaerobic digestion of easy-acidification substrates by promoting buffering capacity using biochar derived from vermicompost[J]. Bioresource Technology, 2017, 227: 286-296. doi: 10.1016/j.biortech.2016.12.060 [73] YE M, LIU J, MA C, et al. Improving the stability and efficiency of anaerobic digestion of food waste using additives: A critical review[J]. Journal of Cleaner Production, 2018, 192: 316-326. doi: 10.1016/j.jclepro.2018.04.244 [74] YAN S B, LI J, CHEN X S, et al. Enzymatical hydrolysis of food waste and ethanol production from the hydrolysate[J]. Renewable Energy, 2011, 36(4): 1259-1265. doi: 10.1016/j.renene.2010.08.020 [75] HAN W, YE M, ZHU A J, et al. A combined bioprocess based on solid-state fermentation for dark fermentative hydrogen production from food waste[J]. Journal of Cleaner Production, 2016, 112: 3744-3749. doi: 10.1016/j.jclepro.2015.08.072 [76] HAN W, YE M, ZHU A J, et al. Batch dark fermentation from enzymatic hydrolyzed food waste for hydrogen production[J]. Bioresource Technology, 2015, 191: 24-29. doi: 10.1016/j.biortech.2015.04.120 [77] MENG Y, LUAN F B, YUAN H R, et al. Enhancing anaerobic digestion performance of crude lipid in food waste by enzymatic pretreatment[J]. Bioresource Technology, 2017, 224: 48-55. doi: 10.1016/j.biortech.2016.10.052 [78] 姜谦, 张衍, 刘和. 导电碳颗粒促进污泥厌氧消化及微生物种间电子传递的研究进展[J]. 微生物学通报, 2019, 46(8): 1998-2008. doi: 10.13344/j.microbiol.china.190323 [79] LIANG J L, LUO L W, Wong J W C, et al. Recent advances in conductive materials amended anaerobic co-digestion of food waste and municipal organic solid waste: Roles, mechanisms, and potential application[J]. Bioresource Technology, 2022, 360: 127613. [80] YAMADA C, KATO S, UENO Y, et al. Conductive iron oxides accelerate thermophilic methanogenesis from acetate and propionate[J]. Journal of bioscience and bioengineering, 2015, 119(6): 678-682. doi: 10.1016/j.jbiosc.2014.11.001 -

下载:

下载: