-

生化需氧量(biochemical oxygen demand,BOD)是表征天然水体及各类废水中有机物污染程度,并衡量水质的重要指标,与微生物代谢活动密切相关[1]。通常情况下,BOD以BOD5(五日生化需氧量)表示。传统的BOD5检测步骤为:水样采集、充氧、水样培养、测定。传统方法的优点是适用于大多数水样的检测,无需昂贵的设备。然而,传统方法也存在明显的局限性,比如操作比较复杂、重复性较差、干扰因素较多。其中,最大的缺点是检测所需时间长达5 d。因此,传统方法仅适合离线测定,较难用于污水处理工艺运行过程的在线调控。为此,国内外研究人员试图开发更可靠、响应速度更快、且满足在线监测需求的BOD测定方法。

微生物燃料电池(microbial fuel cell,MFC)传感器法是当前最有前景的BOD快速检测方法之一[2]。利用MFC测定BOD的基本原理是:MFC产生的电流强度及转移的库仑电荷量,与阳极有机物浓度高低直接相关,且在一定BOD范围内,电信号响应与BOD呈现良好的线性关系。KIM等[3]开发了双室无介体曝气微生物燃料电池并用其测定了淀粉废水BOD,线性检测限为0~206 mg·L−1,反应器总运行时间超过5年。ALFEROVA等[4]开发了一种双室MFC型BOD传感器。以电压为校准信号,该传感器对于标准底物葡萄糖/谷氨酸溶液(glucose and glutamic acid solution,GGS)的BOD线性检测范围(以O2计)为2.6~58 mg·L−1,检测时间为50~200 min,灵敏度系数为2.3 mV·L·mg−1,主要适用于较清洁的天然水体。WANG等[5]开发了一种以高锰酸钾为阴极电子受体的双室有膜MFC型BOD传感器,观察到电荷与BOD呈良好的线性关系(R2>0.992)。当采用浓度为10 mmol·L−1 的KMnO4溶液时,BOD检测范围为25~500 mg·L−1。但这种传感器长期运行时,质子交换膜和电极都可能会被高锰酸钾腐蚀,从而缩短生物传感器寿命。DI LORENZO等[6]设计了一种单室有膜MFC型BOD传感器,考察了人工废水为底物时,电信号与BOD呈线性相关时,BOD检测范围为0~350 mg·L−1。WANG等[7]开发了一种基于活性炭空气阴极的单室无膜MFC型BOD传感器,利用库仑量为电信号,将醋酸钠底物BOD直接检测的线性检测范围扩至1 280 mg·L−1,该浓度下检测时间为50 h。

现有研究表明,每种构型MFC各具优势和局限,均在不同程度上扩展了基于MFC的BOD检测方法的检测限和适用场景。其中,空气阴极型MFC相对更环保、研究最为广泛。但其作为传感器在检测时间、准确性、稳定性上仍存在优化空间,因此,有必要对其构型进行创新改进。本研究设计了一种新型空气阴极MFC,并评价其用于BOD快速检测的性能,以期为优化MFC型BOD传感器的性能提供参考。

全文HTML

-

MFC启动阶段所用接种污泥为经厌氧培养的广州市某城市污水处理厂二沉池剩余污泥。阳极液组成:NH4Cl 0.31 g·L−1,KCl 0.13 g·L−1,NaH2PO4·2H2O 3.32 g·L−1,Na2HPO4·12H2O 10.32 g·L−1,微量元素 12.5 mL·L−1,底物为C6H12O6 1.0 g·L−1;其中微量元素的具体组分为:N(CH2COOH)3 2.0 mg·L−1,MgSO4 3.0 mg·L−1,MnSO4 0.5 mg·L−1,NaCl 1.0 mg·L−1,GuSO4·5H2O 0.01 mg·L−1,KAl(SO4)2·12H2O 0.01 mg·L−1,CoCl2·6H2O 0.1 mg·L−1GaCl2·2H2O 0.1 mg·L−1,ZnCl2 0.13 mg·L−1,H3BO3 0.01 mg·L−1,Na2MoO4 0.025 mg·L−1,NiCl2·6H2O 0.024 mg·L−1,Na2WO4·2H2O 0.025 mg·L−1。阴极液组成:NH4Cl 0.31 g·L−1,KCl 0.13 g·L−1,NaH2PO4·2H2O 3.32 g·L−1,Na2HPO4·12H2O 10.32 g·L−1。系统启动成功后,阳极不再投加接种污泥。阳极底物根据实验需要从葡萄糖替换为醋酸钠或者葡萄糖/谷氨酸混合液(glucose and glutamic acid,GGA)(葡萄糖和谷氨酸质量比1∶1的混合物)。

-

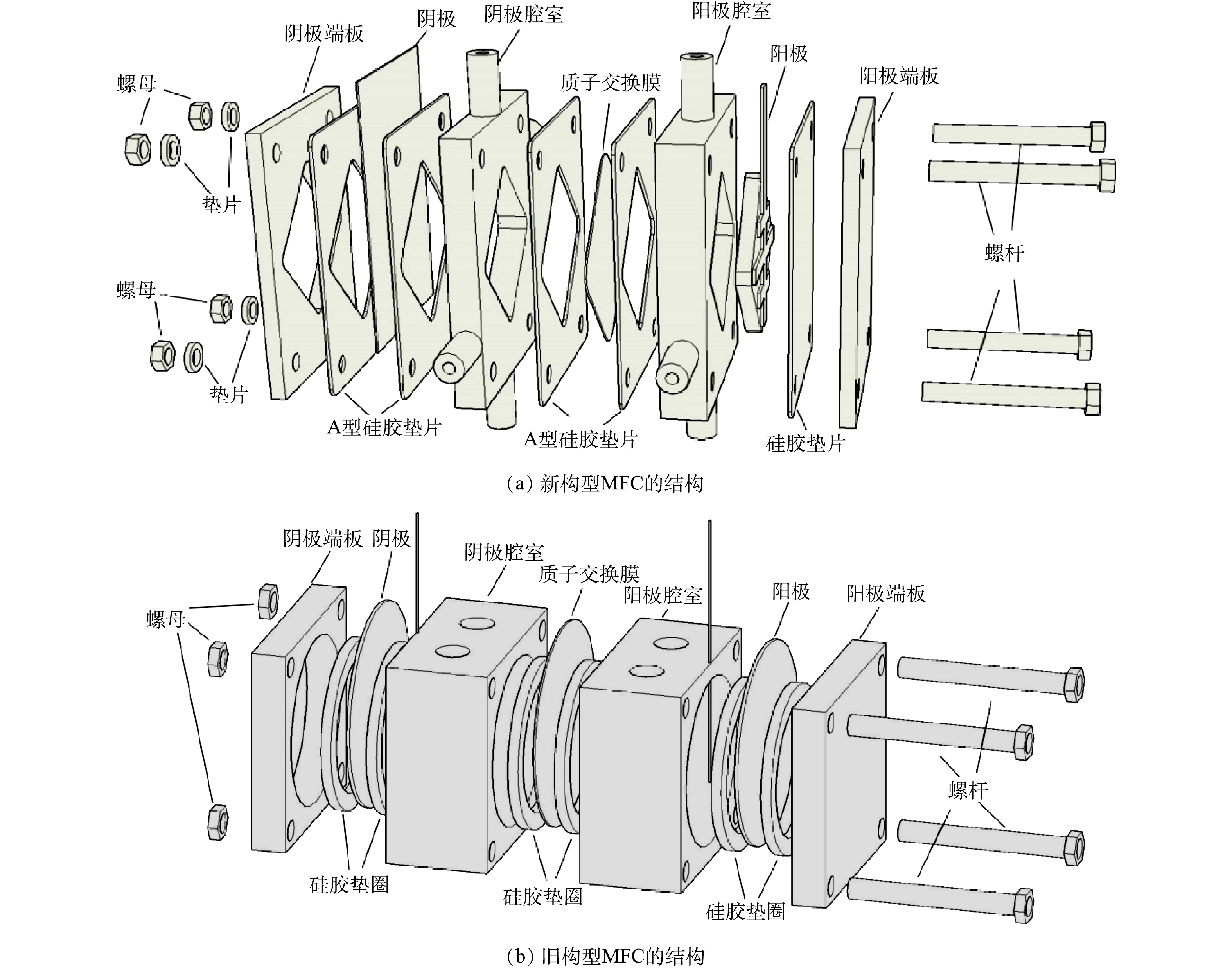

设计了一种新型双室空气阴极MFC,其阴极和阳极腔室的截面均设计为圆角菱形,以此促进底物中悬浮物的沉降分离,减少对质子膜的污染。将阳极和阴极腔室宽度设计为不同尺寸,在保证阳极室厌氧特性的前提下,尽可能缩小质子交换膜与阴极电极的间距。阳极采用3 mm厚度的碳毡,阴极采用疏水碳布(台湾碳能),电极在组装前均需预处理。阴极一侧端板开有菱形孔,孔大小与阴极电极面积相同,使得阴极有一侧可以直接与空气接触,运行过程中不曝气。2个电极有效尺寸均为4 cm×4 cm。阳极室宽度设计为1.5 cm,阴极室宽度设计为1.0 cm,电极间距为2.5 cm,阳极室体积为24 cm3,阴极室体积为16 cm3。阳极室和阴极室中间隔膜采用Nafion117质子交换膜(美国DuPont公司),规格也是4 cm×4 cm,外接电阻为1 000 Ω。总共制备4套反应器用于平行实验,分别命名为M3、M4、M5和M6。具体结构如图1(a)所示。

另外,根据KIM等[8]的方法制作了2套经典构型的双室空气阴极MFC用于性能对比,分别命名为M1和M2。2套反应器的阳极和阴极截面均为圆形。阳极采用3 mm厚度的碳毡,阴极采用疏水碳布(品牌为台湾碳能),电极在组装前均已预处理。阴极一侧端板开有圆形孔,孔大小与阴极电极面积相同,使得阴极有一侧可直接与空气接触,运行过程中不需要曝气。电极直径均为3 cm,阴极和阳极腔室宽度均为2 cm,电极间距为4 cm。各腔室有效体积分别为14 cm3,阴极室和阳极室之间用Nafion117质子交换膜(美国DuPont公司)分隔开,外接电阻为1 000 Ω。反应器结构如图1(b)所示。

-

1) MFC电极预处理方法。阳极碳毡的预处理方法[9]为:分别用丙酮和1 mol·L−1盐酸浸泡碳毡,以除去其表面的油性物质及残余重金属离子,提高碳毡表面的亲水性和生物吸附性,最后用去离子水洗涤至中性,然后置于120 ℃烘箱中烘干备用。阴极碳布的预处理方法[10]为:采用刮膜法制备PTFE扩散层,并用刷涂法制备催化层,选用20%的Pt/C催化剂,最终确保每平方厘米碳布上有0.5 mg Pt,之后自然晾干备用。

2) MFC启动和运行。所有MFC均采用序批式启动,启动阶段分批次向阳极液中投加20 mL·L−1接种泥,以促进阳极产电微生物的富集和驯化。当输出电压低于50 mV时,可认为电池1个运行周期结束,并重新更换新鲜阳极液和阴极液。在更换阳极液前,需曝氮气30 min除氧,更换时用注射器快速注入阳极腔室中,尽量避免将空气带入阳极腔室。当电池在1个周期内的输出电压峰值连续3 d变化不超过 ±5%,即可认为电池启动成功。启动成功后停止向阳极投加底泥,并将阳极底物更换为1.282 g·L−1醋酸钠。待电压再次稳定后,进行后续电化学性能测试以及BOD检测实验。

3)电信号数据采集方法。MFC电压信号采用安捷伦数字万用表(Agilent 34970A)联机采集。数据采集和记录的时间间隔为5 min。

4)极化曲线和功率密度测试。在电阻100~30 000 Ω范围内,由高到低依次调整MFC外电阻,每次调整后稳定10 min,再测定外电阻两端的电压,计算电流密度和功率密度,之后绘制极化曲线和功率密度变化曲线,并通过极化曲线的线性段的斜率确定反应器的内阻。

5) MFC产电性能与不同底物BOD间关系的分析方法。以醋酸钠为底物:待培养稳定后MFC系统的输出电压值降低至背景电压值(50 mV)时,依次更换不同BOD5(分别为40、80、160、320、640、960和1 280 mg·L−1,共7种不同浓度)的醋酸钠溶液。每次更换底物时,均待到电池电压降至背景值,即(50±10)mV,采集并记录每个产电周期内电压变化数据,并分析BOD与产电量之间的关系。以GGA为底物:完成醋酸钠底物的BOD检测实验后,依次更换不同BOD5(分别为50、100、200、400、800和1 250 mg·L−1,共6种不同浓度)的GGA溶液。每次更换底物时,均待到电池电压降至背景值,即(50±10)mV,采集并记录每个产电周期内的电压变化数据,并分析BOD与产电量之间的关系。

6) MFC快速检测BOD性能的方法。配制2个未知BOD的醋酸钠溶液,用MFC预测其BOD,并与稀释接种法(参考国标HJ 505-2009)测定的BOD5结果进行对照。每个样品均平行测定3次,取平均值,对比预测值与实际BOD5的差异,以此验证利用新构型MFC快速检测BOD的性能。以上所有实验过程均在30 ℃恒温房内进行。

7)其余水质指标测定方法。采用分光光度法测定阳极底物降解前后的COD(所用设备为HACH 5000),采用玻璃电极法测定底物及阴极液的pH。

-

1) MFC产电量计算方法。利用欧姆定律(见式(1))计算电路中的电流;计算一段时间内MFC产生的电荷量(见式(2))。以电流对时间的积分,采用公式(3)计算收集的库仑电荷量。

式中:I为电流,A;U为电压,V;R为电阻,Ω;Q为电荷量,C;t为时间,s;t1表示MFC更换底物的时间,s;t2表示产电周期结束时间(选取不同浓度下MFC达到电压峰值5%的电压时所处时刻),s。

2)库仑效率(coulombic efficiency,CE)计算方法。库仑效率是指MFC从底物中回收的电子与底物理论上可提供的电子比值,其计算公式见式(4)。

式中:Q为实际产生电荷量,计算见式(3);Qt为理论产生电荷量,计算见式(5)。

式中:F为法拉第常数,取值为96 485 C·mol−1;b为氧气还原产生的电子数量,取8;V为阳极室有效体积,mL;ΔCOD为阳极底物反应前后的COD之差,mg·L−1;Mo为氧气的摩尔质量,32 g·mol−1 。

3)利用MFC快速检测BOD的方法。利用公式(3)计算从更换底物的时刻起至MFC电压降至峰值电压5%的时刻所收集的电荷量,代入MFC产电性能与不同底物BOD关系的标准曲线,计算样品BOD预测值。

1.1. 实验材料

1.2. 实验装置

1.3. 实验方法

1.4. 分析方法

-

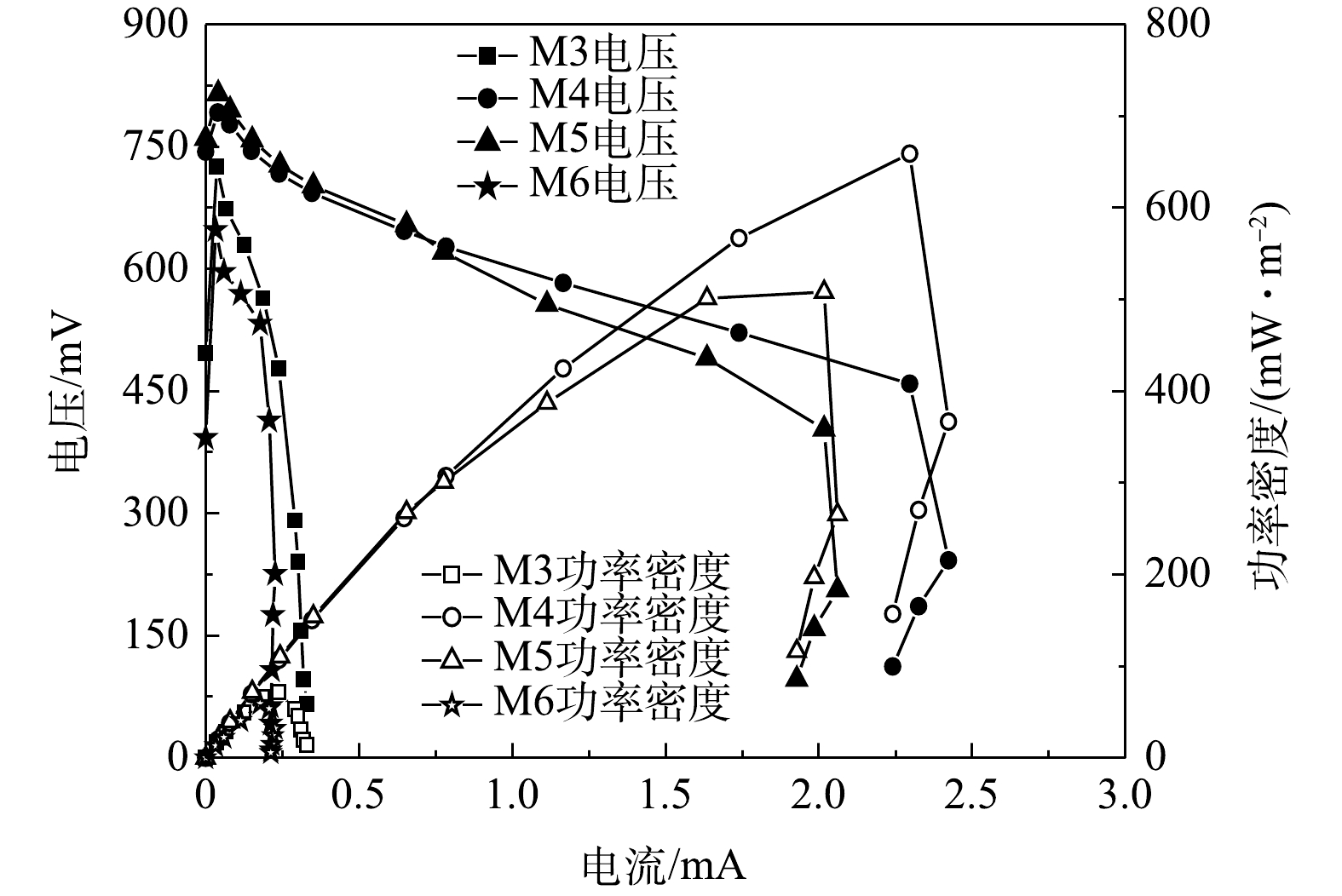

分别对6套稳定运行的反应器进行了极化曲线和功率密度曲线的测定,结果如图2所示。由图2可知,6套反应器的开路电压约为750 mV,波动范围为±5%,这是由于启动期和运行期所采用的阳极底物成分均相同。然而,4套新构型MFC的功率密度明显高于2套旧构型MFC。其中,2套旧构型MFC(M1和M2)的最大功率密度分别为327和465 mW·m−2,略低于KIM等[8]研究得到的最高功率密度514 mW·m−2。而新反应器中功率密度最高为M6(897 mW·m−2),其次为M3(862 mW·m−2)。与M1和M2相比,功率密度提升了100%。且即使是相对功率密度最低的M4也超过了600 mW·m−2。

选取各MFC极化曲线中的线性段,通过斜率分别计算了6套反应器的内阻。结果为:M1电阻458 Ω,M2电阻376 Ω,M3电阻97 Ω,M4电阻185 Ω,M5电阻146 Ω,M6电阻92 Ω,即新构型MFC内阻相比旧构型降低了50%~79%。由此证明,新构型MFC的性能有明显改善。这是由于4套新构型MFC的电极面积更大,有助于产电菌富集[11];电极间距的缩小也有助于降低内阻[12]。同时,4套新构型MFC之间的功率密度和内阻存在差异,可能是由于阳极和阴极电极在人工制备过程中,无法保证其性能完全相同所致。

-

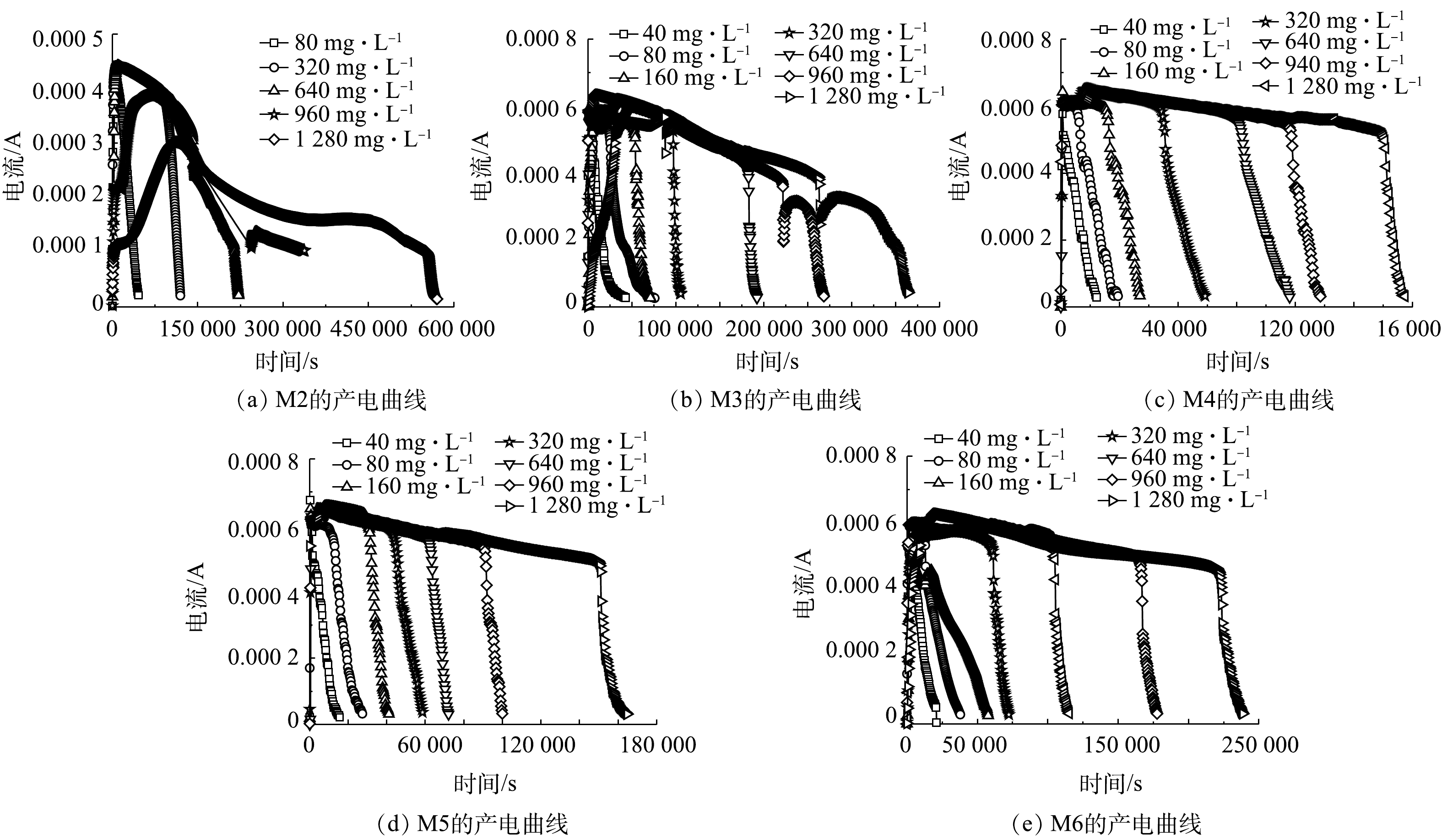

选取M2、M3、M4、M5和M6号反应器进行后续BOD检测性能评价和对比实验。首先以醋酸钠为底物,其反应周期内的产电曲线对比见图3。将更换底物起直到MFC电压降低为峰值的5%所耗费的时间定义为检测时间。对于相同浓度的醋酸钠底物,4套新构型MFC(M3、M4、M5和M6)的检测时间相比M2明显缩短,缩短比例为37%~80%,且这种差异随着底物浓度的提高更加明显。当醋酸钠BOD升至960 mg·L−1以后,M2的最高电压明显下降,且总检测时间长达93.7 h。分析其原因,主要是由于高浓度底物下,阳极室积累了大量质子,传递受阻,导致阳极室酸化严重,从而影响阳极产电菌的活性;继续升高至1 280 mg·L−1时,M2最高电压继续下降,总检测时间长达155 h,已超过传统BOD5的测定时间。检测时间最短为M4,其对于1 280 mg·L−1醋酸钠BOD的检测时间仅为31.27 h,其次为M5和M6,分别需要45 h和66 h。这是由于新构型MFC阳极生物膜的性能更好,且质子迁移距离更短,阻力也更小。

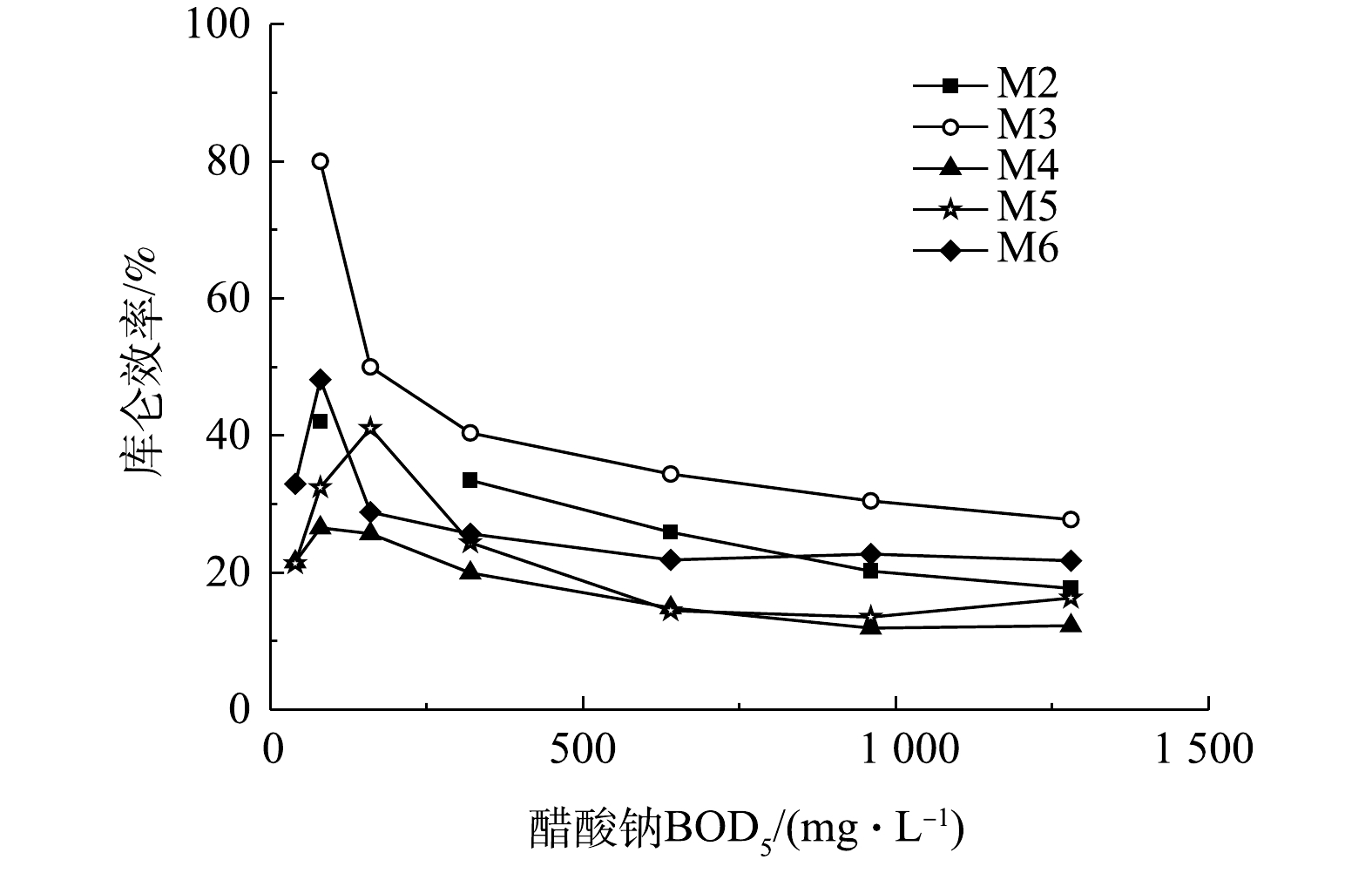

图4表示各反应器收集的电荷量与醋酸钠BOD之间的关系。当醋酸钠BOD为40~1 280 mg·L−1时,4套新构型MFC(M3~M6)的库仑量呈线性变化。本研究中设计的新构型MFC对于高浓度有机废水的BOD检测具有应用可行性。另外,5套反应器的线性可决系数由高到低依次为:M6>M4>M3>M5>M2。说明本研究中对空气阴极MFC构型的优化可有效提升MFC作为BOD快速检测传感器的准确性,且结合检测时间和线性检测限,用于醋酸钠BOD检测时,M6的综合性能相对最佳。

库仑效率是影响MFC型BOD传感器性能的重要指标[13],图5比较了4套新构型MFC的库仑效率。由图5可知,M6在对所有醋酸钠BOD的检测过程中,尤其是醋酸钠BOD5高于160 mg·L−1的条件下,库仑效率相对最稳定,始终保持在25%左右;M4和M5的库仑效率及其稳定性均低于M6;M2和M3的库仑效率均随醋酸钠BOD5的升高持续下降,变化幅度最大的是M3,这与线性可决系数的排序具有相似性。由此推测,影响库仑法检测BOD准确性的主要因素包括反应器内阻及库仑效率的稳定性。因此,后续研究还需采取相应措施,比如通过添加呼吸抑制剂控制溶氧以减少非产电途径的消耗[14],以及进一步通过构型或参数优化减小内阻,提高各反应器库仑效率的稳定性,从而保证BOD检测性能的准确性和重复性。

-

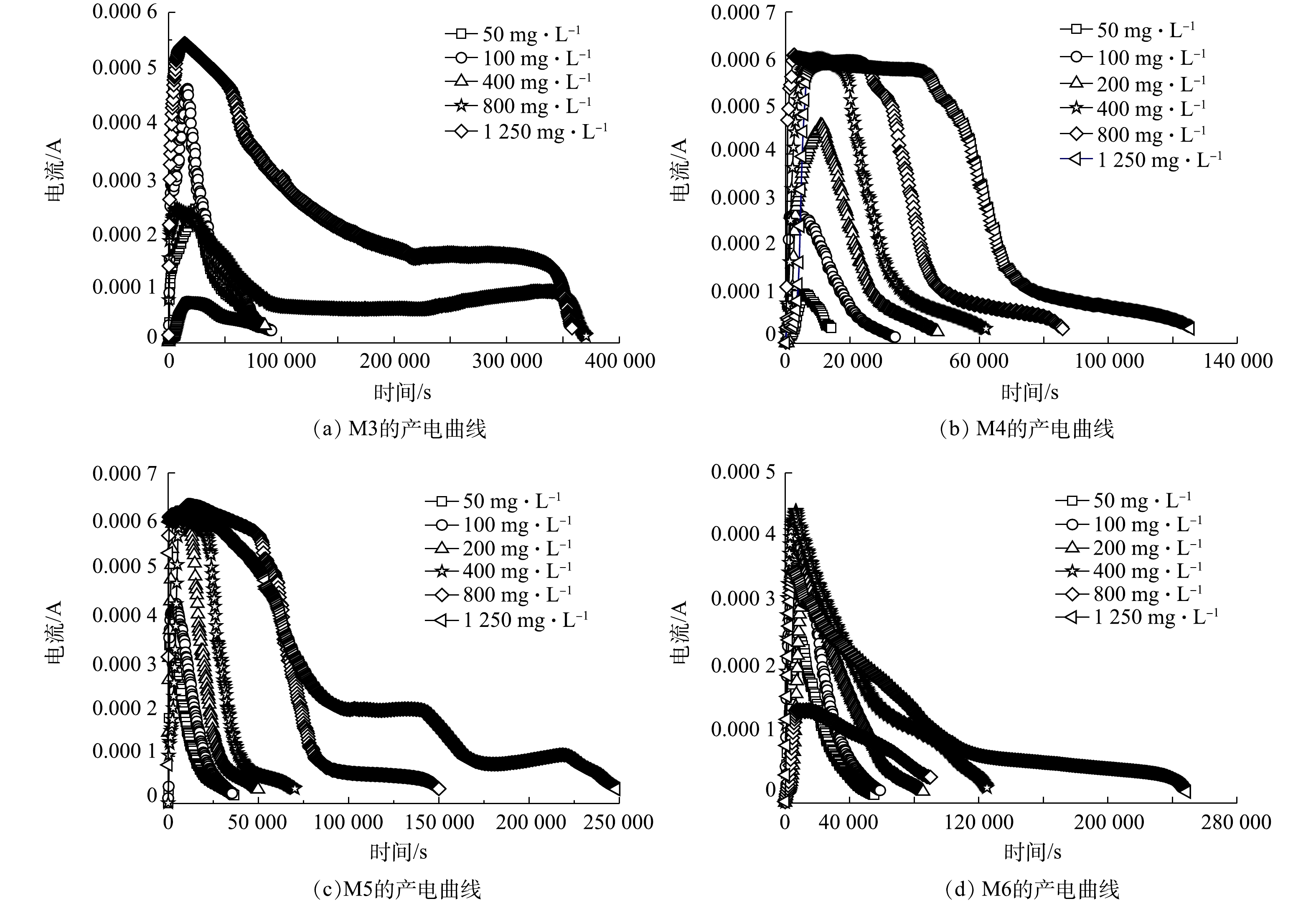

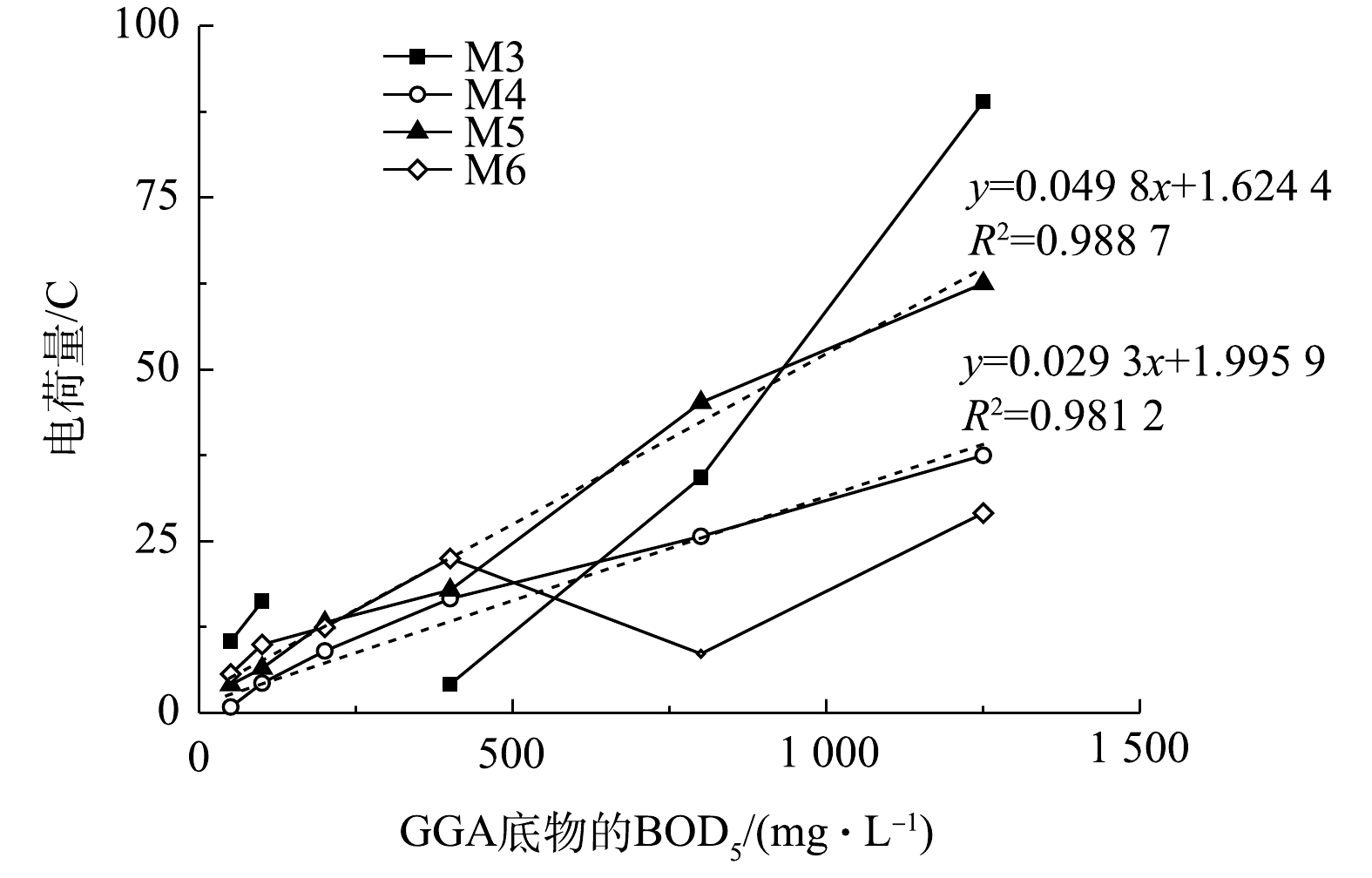

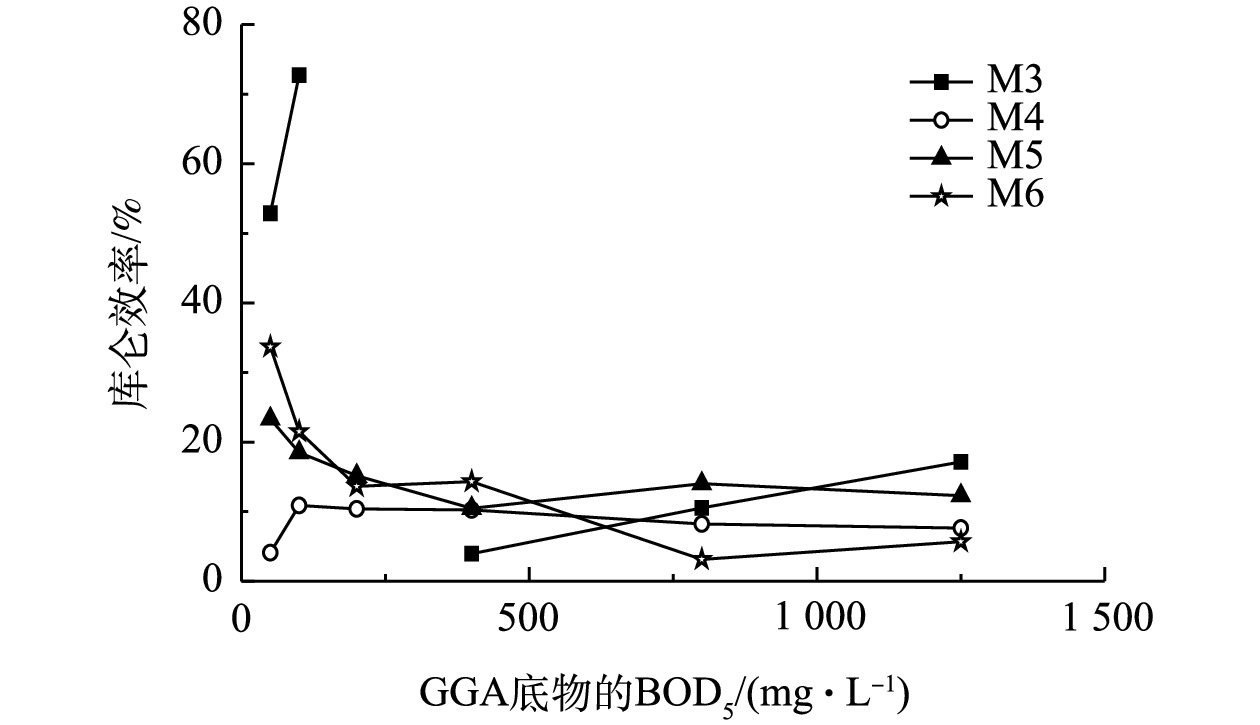

GGA是最常用的BOD检测方法的校准底物[15-17]。为考察新构型MFC对成分较复杂混合底物的适应性,在完成醋酸钠BOD检测实验后,利用4套新构型MFC(M3、M4、M5和M6)进行了GGA底物BOD的检测,结果如图6所示。计算图6中各产电周期内收集的电荷总量,并分析其与GGA底物BOD5的关系,结果如图7所示。上述结果表明, M4和M5的电荷量在50~1 250 mg·L−1BOD5范围内均呈现较好的线性关系,其线性可决系数分别为0.981 2和0.988 7;当GGA的BOD5为1 250 mg·L−1时,M4和M5的检测时间差异较大,分别为33 h和67 h;而M6电荷量仅在GGA的BOD5处于50~400 mg·L−1内时呈线性变化,M3的电荷量分布则不具规律性。

图8呈现了4套新构型MFC在利用不同浓度GGA时库仑效率的变化。对比检测醋酸钠BOD期间的性能数据(见图5)可看出,所有反应器的库仑效率都随着GGA浓度的升高出现明显下降。其中,以M3和M6的变化最为明显。两者的库仑效率最低时不到5%,M5虽也有波动,但相对幅度明显小于M3和M6,且始终高于10%,而M4的库仑效率始终维持在10%以下。由此说明,GGA底物利用期间发生了大量非产电消耗。

为进一步分析造成4套新构型MFC性能差异的原因,再次测定了所有反应器的极化曲线和功率密度曲线(见图9),并选取线性变化段计算内阻。对比图2可发现,M4和M5的功率密度及内阻变化幅度较小,而M3和M6的内阻明显升高。MFC 内阻的影响因素包括反应器构型、电极材料类型与面积、电极距离、离子交换膜、产电底物、微生物、操作条件等[18],各项因素对 MFC内阻的影响具有协同性。结合图8中库仑效率的变化趋势,分析4套新构型MFC检测GGA底物的BOD时性能差异较大的原因,可能是:由于GGA中葡萄糖和谷氨酸都是发酵性底物,相对于醋酸钠,产电菌的利用难度增加,从而导致阳极生物膜中发酵型细菌的比例升高,使非产电反应的损耗也相应增加,最终使得阳极活化内阻增大,整体性能下降。因此,后续还需要对各反应器中的阳极生物膜进行菌群鉴定,并采取相应措施。例如,补充少量接种菌、进一步改进MFC构型,以及采用新型电极材料等措施,以维持产电菌和非产电菌的比例在合适范围。

-

选择相对稳定性较好的M4进行未知浓度底物的BOD检测性能验证。表1为2个不同浓度的醋酸钠样品利用MFC检测的BOD和BOD5的实测值对比。由表1可知,2个高浓度样品的BOD预测值和实测值之间偏差在±5%以内。说明新构型的MFC对于单一成分的高浓度有机物BOD预测准确度较高,后续将采集实际废水样品进一步验证其实际应用性能。

2.1. 启动完成后新旧构型反应器的电化学性能对比

2.2. BOD检测性能评价

2.2.1. MFC产电性能与醋酸钠底物BOD之间的关系

2.2.2. MFC产电性能与GGA底物BOD之间的关系

2.2.3. MFC快速检测BOD的性能验证

-

1)设计了一种新型双室空气阴极MFC,相比传统构型的双室空气阴极MFC,可有效提高功率密度并降低内阻。

2)新型双室空气阴极MFC有望用于快速检测高浓度有机物的BOD,但是其检测性能及平行反应器之间的重复性还有待提升,尤其是在不同底物浓度下其库仑效率存在较大差异。

3)可采取相应措施来维持产电菌和非产电菌的比例在合适的范围,并保持内阻稳定在较低的水平,以进一步改善该构型MFC作为BOD快速检测传感器的性能。

下载:

下载: