-

随着现代液晶电子行业的兴起,清洗液晶电子产品而产生的废水也迅速增加[1]。液晶废水具有成分复杂、COD高及可生化性差的特点。液晶废水中一般都含有大量的烷基葡糖糖苷或烷基磺酸盐、表面活性剂(邻苯二甲酸酯类)和增塑剂(全氟羧酸类或全氟烷基磺酸类)[2-3],其中表面活性剂及增塑剂是强致癌物,对生物有强烈的抑制作用和毒害作用[4]。目前,国内七大水系中均不同程度地检测到表面活性剂及增塑剂,甚至在人体血液中也检测到这种污染物[5]。

高浓度液晶废水可生化性差,因此,物理-化学或物理-生物联合工艺是常用的处理方法。COLADES等[6]研究了电-芬顿降解液晶废水中的主要成分二甲基亚砜,COD去除率仅为79%,产生的中间产物很难去除;高天号等[7]采用芬顿-水解酸化-好氧生物处理组合工艺处理液晶废水,芬顿预处理可将废水COD容积负荷由0.3~0.35 kg·(m3·d)−1提高到0.55 kg·(m3·d)−1,为后期好氧生物降解提供保障;李洪瑞等[8]采用芬顿+水解酸化+好氧+超滤反渗透工艺深度处理高浓度液晶废水时发现,芬顿预处理为后续SBR的稳定运行奠定了基础,最终出水COD低于50 mg·L−1;彭娟华等[9]通过分析芬顿预处理前后钻井废水的紫外-可见吸收光谱峰值的变化,发现芬顿预处理可破坏有机物分子的苯环结构。

由此可见,芬顿预处理可将难生物降解的大分子有机物分解成可生物降解的小分子物质,提高了出水的可生化性。但芬顿反应会产生大量的铁泥危险废弃物,如何实现铁泥的资源化回收也是目前研究的热点。樊帆等[10]采用碱化法回收芬顿铁泥来制备高效磁性聚合硫酸铁;张丽丽等[11]设计了一种铁泥回用的芬顿法污水处理一体化装置,将芬顿产生的铁泥酸化、过滤、紫外双氧水二次氧化、电解,将Fe3+还原为Fe2+,获得再生的Fe2+催化剂,完成铁泥的循环利用。在上述研究中,均需要向铁泥中投加化学试剂来实现铁泥的转化。微波热解是一种新颖的污泥处理工艺,在无需外加试剂的条件下,可直接将铁泥转化为高附加值的氧化铁。为实现液晶废水的高效处理及铁泥的资源化回收,本研究设计了一种芬顿-SBR-微波热解联合工艺,研究了联合工艺的运行条件,并分析了芬顿-SBR联合工艺处理液晶废水的反应机理。

全文HTML

-

双氧水(H2O2,30%)与硫酸亚铁(FeSO4·7H2O)均为分析纯;高浓度液晶废水取自青岛迪爱生精细化学有限公司,水质如下:COD=150 000 mg·L−1,pH=4.61,BOD/COD=0.15,TN=36 mg·L−1,TP=1 mg·L−1;活性污泥取自青岛海泊河污水处理厂,污泥浓度为8 500 mg·L−1,污泥体积指数为80%,使用前进行稀释和曝气驯化。

-

pH计(BOX389,美国HACH公司);COD测定仪(DR2800,美国HACH公司);加热磁力搅拌器(AICE 78-1,北京神泰仪器公司);台式离心机(Sorvall ST8,美国Thermo公司);电子天平(HZY-B,上海华志公司);电热恒温干燥箱(202-0AB,天津泰斯特仪器有限公司);多功能恒温器(MH2800A,天津奥特赛恩斯仪器有限公司);微波炉(M1-L213B,美的);液相色谱-质谱联用仪(2695-Waters ZQ4000,美国Waters公司);气相色谱-质谱联用仪(6890N/5973i,美国Agilent公司)。

-

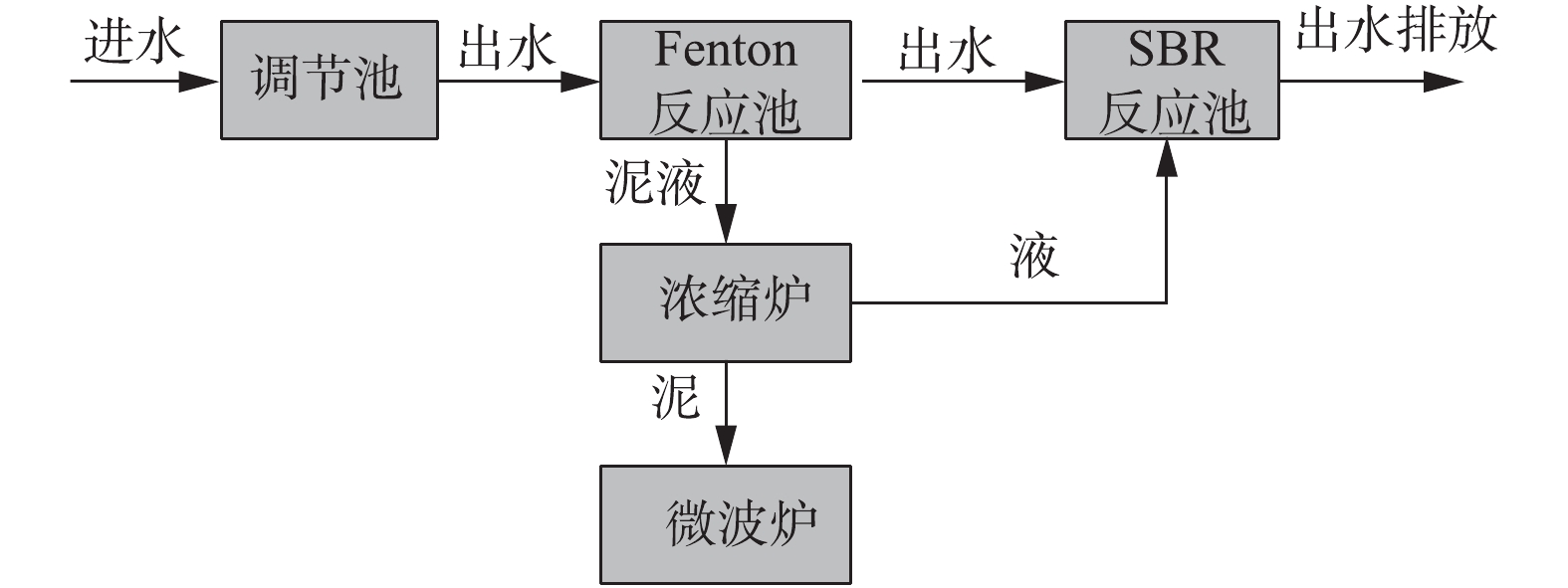

首先将液晶废水pH调至3,然后排入芬顿反应池进行反应。反应结束后,先将溶液pH回调至7,静置1~2 h后进行液泥分离,上层清水液及下层泥液的浓缩液共同排入SBR反应池进行生物好氧降解,浓缩的泥饼直接进入微波炉热解焚烧。在SBR反应池内,保持活性污泥浓度为4 500 mg·L−1,水力停留时间为20 h,实验流程如图1所示。

-

采用COD测定仪测定废水COD;采用液相色谱-质谱和气相色谱-质谱分析废水中的主要物质。液相色谱-质谱分析条件如下:流动相组成为0.1%的乙酸(5%)+甲醇(95%),流速为0.5 mL·min−1,质谱扫描时间为10 min、扫描m/z为100~800;气相色谱-质谱分析条件如下:分离柱为Agilent DB-5Msui,0.25 mm×30 m,0.25 μm,气化室温度为280 ℃,载气为氦气,流速为40 mL·min−1,采用梯度洗脱模式。

1.1. 实验原料

1.2. 实验仪器

1.3. 实验方法

1.4. 分析方法

-

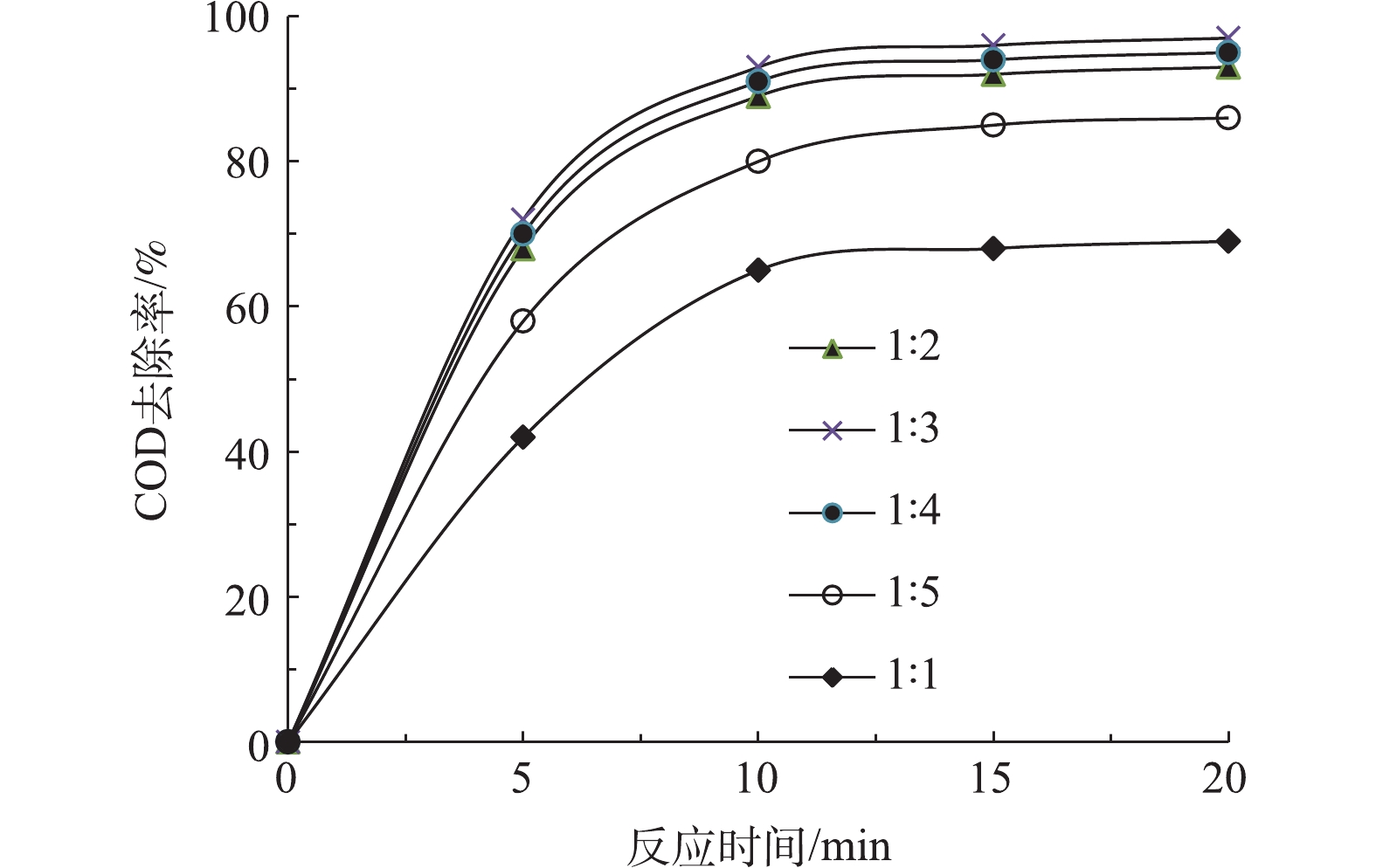

Fe2+∶H2O2对COD去除率的影响如图2所示。可以看出,随Fe2+∶H2O2的增大,COD去除率先增大后减小,最佳比值为1∶3。当Fe2+∶H2O2<1∶3时,随Fe2+浓度的增大,其催化H2O2产生的·OH及HO2·自由基浓度提高,使更多的有机物被氧化降解,所以COD去除率上升,反应过程[12]如式(1)和式(2)所示;但当Fe2+∶H2O2>1∶3时,过量的Fe2+会与有机污染物争夺·OH自由基,从而消耗了·OH自由基的浓度,进而抑制了Fenton反应的氧化降解能力,致使COD去除率下降,反应过程如式(3)所示。

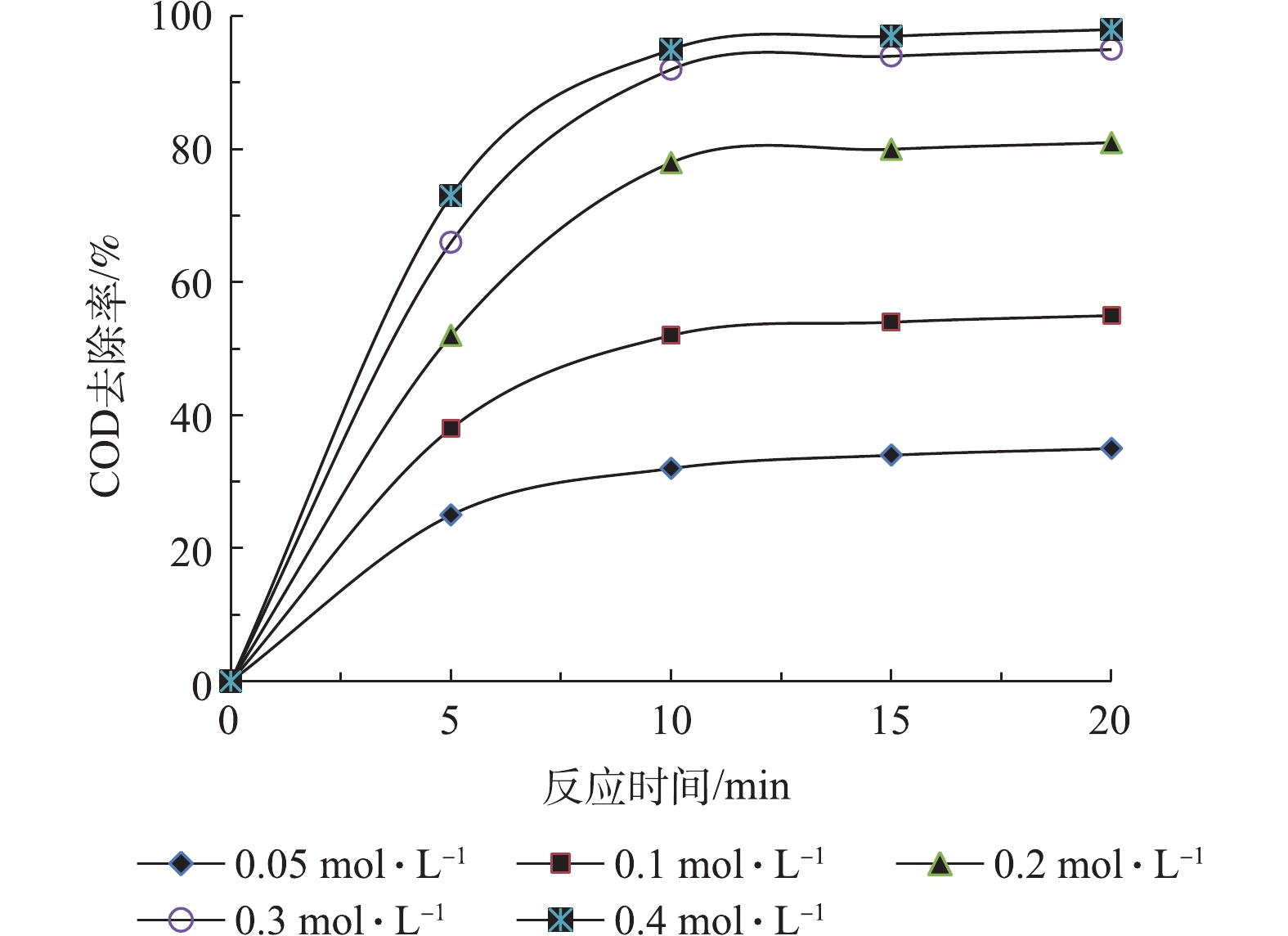

芬顿试剂投加量(Fe2+浓度)对COD去除率的影响如图3所示。可以看出,COD去除率随芬顿试剂的增加而增大。在初始COD不变的情况下,增加芬顿试剂的投加量,可提高·OH及HO2·自由基量等强氧化物质与污染物的碰撞与氧化概率[13],从而提高COD去除率。当Fe2+浓度超过0.3 mol·L−1时,芬顿反应20 min,COD去除率已达到96%,说明液晶废水中的烷基葡萄糖苷已基本被氧化降解,继续提高芬顿试剂投加量不仅不会提高COD去除率,而且还会造成资源浪费。

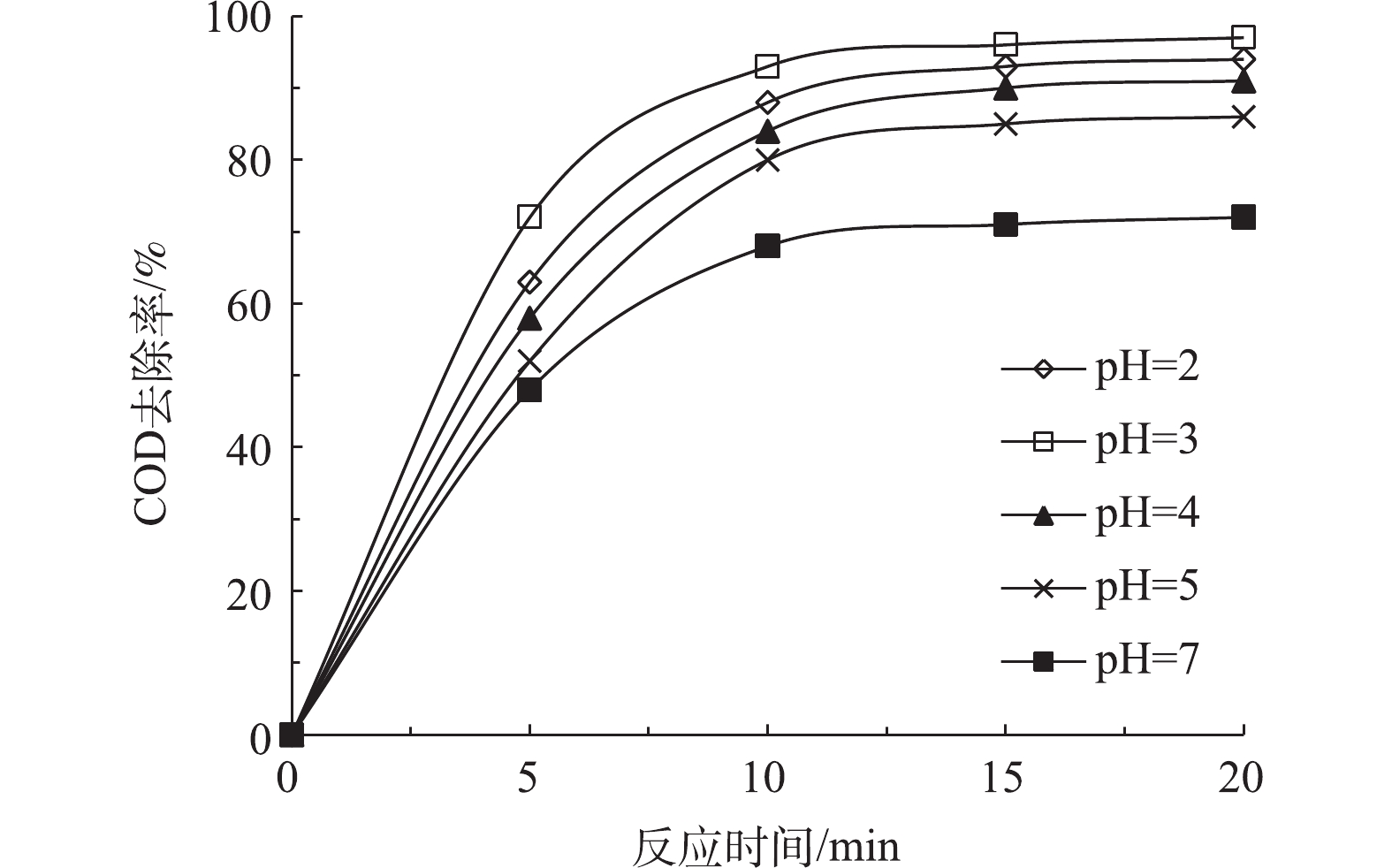

pH对COD去除率的影响如图4所示。可以看出,随pH的增大,COD去除率先增大后减小,最佳pH为3,这与文献报道的芬顿反应最适宜的初始pH在2~4的研究结果[14-15]是一致的。芬顿反应是自由基反应,它包括链引发、传递和终止3个阶段,其中链引发是芬顿反应的关键步骤。Fe2+是同质催化剂,H2O2是氧化剂,只有在酸性条件下,Fe2+催化H2O2产生·OH自由基,链引发反应启动,反应方程如式(1)所示,产生的·OH氧化降解有机污染物,所以酸性条件能提高芬顿氧化效率。当溶液初始pH超过3时,溶液中聚集的OH−不但与Fe2+发生絮凝副反应,而且还会与·OH发生反应,使得体系中·OH的浓度迅速降低,从而减弱了芬顿反应的氧化降解效率。

-

液晶废水进入芬顿反应池,反应20 min,沉淀1 h,出水稀释1.5倍待用。取400 mL稀释后的水置入SBR反应池(泥液5 L),反应20 h,沉淀1 h,排水400 mL,间歇重复8个运行周期,计算芬顿与SBR单元反应前后COD、污泥浓度(MLSS)和污泥体积指数(SVI),各周期进出水及污泥指标参数如表1所示。

由此可知,当芬顿进水COD在150 000 mg·L−1时,出水COD为7 800~8 000 mg·L−1,COD去除率在94.6%以上,说明大分子十二烷基葡萄糖苷基本被氧化降解成小分子物质。在SBR内,经生物好氧降解,出水COD为450~490 mg·L−1,COD去除率在81%以上,说明水中的小分子物质被好氧生物降解为CO2和H2O。经过8个间歇运行周期,出水COD稳定在500 mg·L−1以下,出水满足《污水排入城镇下水道水质标准》(GB/T 31962-2015)中B级标准,可以直接排入市政管网。当SBR单元进水污泥控制在4 500 mg·L−1时,出水污泥从第1个运行周期的3 200 mg·L−1逐渐下降到第3个周期的2 500 mg·L−1,然后随运行周期逐渐回升,到第7个运行周期,出水污泥浓度与进水污泥浓度基本持平。在前3个运行周期,活性污泥中的微生物受到外界负荷的冲击,微生物衰减速率大于生长速率,所以前期污泥浓度明显降低;当污泥经过适应和驯化后,微生物生长速率开始大于衰减速率,出水污泥浓度逐渐上升并与出水污泥浓度基本持平。污泥体积指数随运行周期的延长先降低后升高。此外,污泥形态略有变化,在运行初期,污泥形态逐渐松散,到第4个运行周期,污泥形态基本保持不变,这说明污泥中的微生物菌群及活性已达到相对稳定的状态。HE等[16]采用结晶-芬顿-SBR工艺处理高浓度含硫废水时,也发现了污泥中微生物的衰减与再生长现象。

-

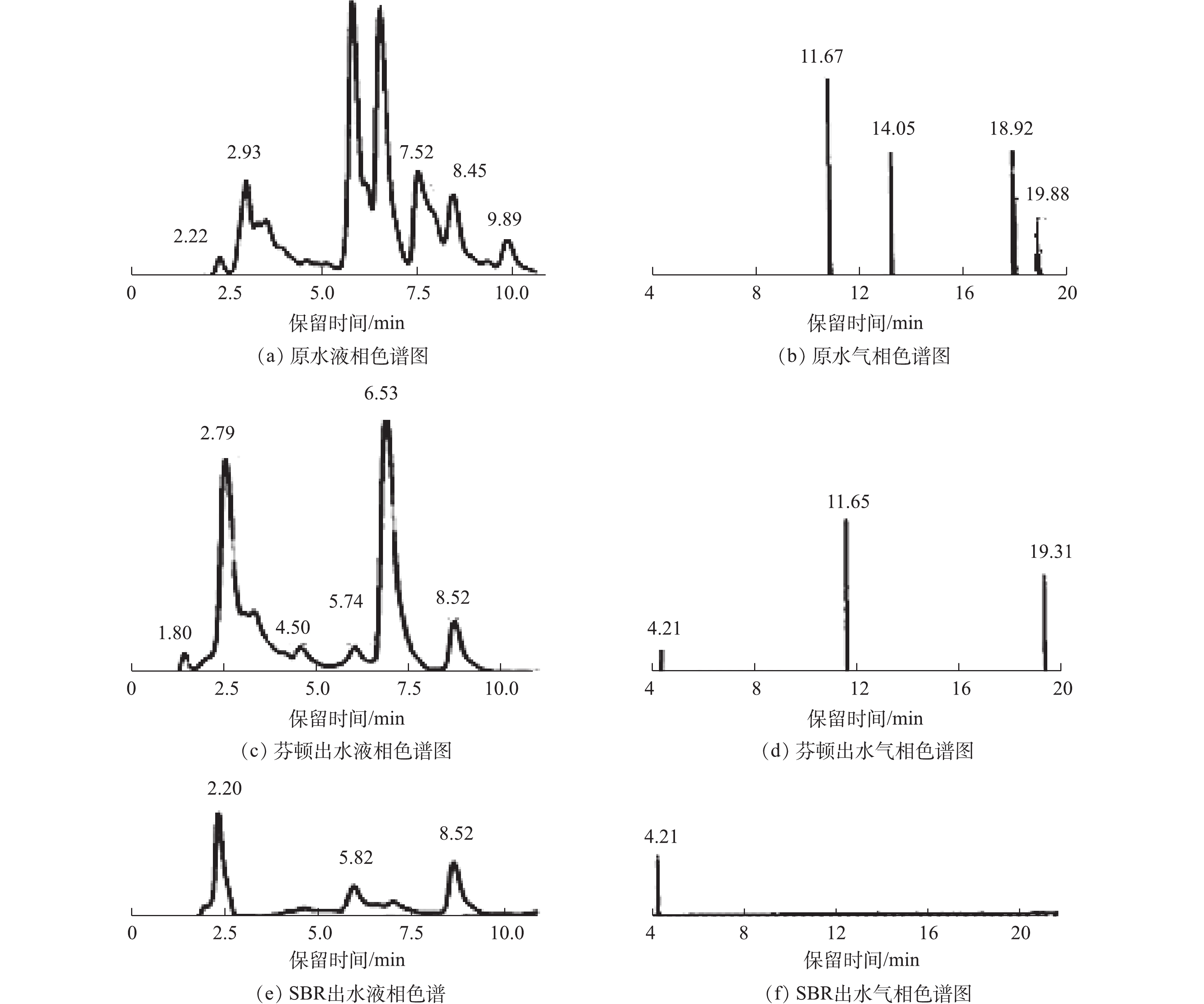

为研究芬顿与SBR工艺产生的主要中间产物及产物变化情况,我们分别采用液相色谱及气相色谱对原水、芬顿出水及SBR出水进行分析,色谱图如图5所示。由图5(a)可以看出,液晶原废水成分较复杂,在液相色谱图中出现了2个主要物质色谱峰,保留时间分别为5.78 min和6.53 min。经推测,保留时间为5.78 min的物质为烷基葡萄糖苷(洗涤剂主要成分);保留时间为6.53 min的物质为全氟辛酸(清洗剂主要成分);此外,在保留时间为2.22、2.98、7.52、8.45和9.89 min处也出现了较明显的物质峰,他们主要是清洗剂中的一些低浓度添加成分。图5(b)为对应的气相色谱图。经分析,原水中含有4种主要的易挥发性有机污染物,出峰时间11.67 min的物质归属于乙醇,出峰时间14.05 min的物质归属于聚乙烯醇(清洗剂中的抗静电剂)。由此可见,液晶废水中含有十几种成分,主要成分为烷基葡萄糖苷、全氟辛酸、聚乙烯醇及乙醇等。因为清洗剂配方保密,很难解析所有成分,所以我们只对主要成分进行了分析。图5(c)和图5(d)分别为液晶废水经Fenton处理后出水液相色谱和气相色谱,与图5(a)液相色谱图对照,原水中的烷基葡萄糖苷被迅速氧化降解;而全氟辛酸含量基本不变,这个现象进一步证实了全氟辛酸很难被芬顿氧化降[17]。与图5(b)原水气相色谱图对照,出峰时间11.67 min的物质信号峰强度明显变弱,而出峰时间14.05 min的物质信号峰几乎全部消失,这说明经芬顿处理后,水中的乙醇与聚乙烯醇基本被完全氧化降解。此外,在图5(d)中,出峰时间4.21 min处出现了1个产物峰,经外标法证实,该产物为CO2。液晶废水经芬顿-SBR联合工艺处理后,出水中主要物质由原先的十几种降解为4种。对照原水及芬顿出水气相色谱图,SBR出水气相色谱(图5(f))中仅有CO2一种产物;对照原水及芬顿出水液相色谱图,SBR出水液相色谱(图5(e))中仅剩3种成分(保留时间分别为8.52、5.82和2.20 min),其他成分均已降解。结合液相色谱和气相色谱图谱,可推测液晶废水先经芬顿氧化降解成产生CO2、有机酸、醇及其他有机产物,然后有机酸及醇等物质再经过SBR好氧生物降解,最后被矿化为CO2和H2O。

-

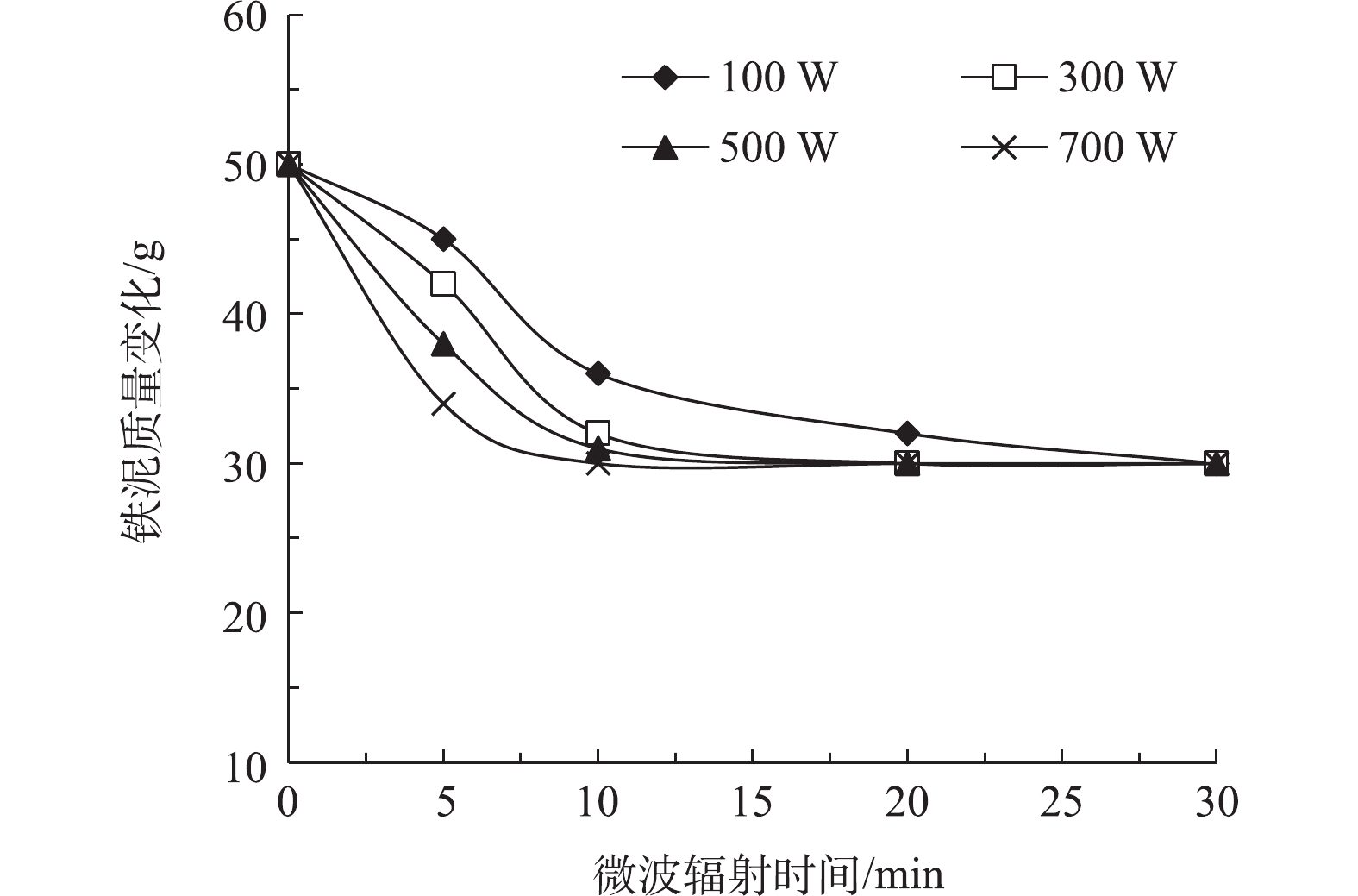

较传统热解,微波热解是一种均匀、快速的热解方式[18]。微波热解功率和时间对热解效率的影响如图6所示。可以看出,随着微波热解功率和时间的增大,铁泥质量越来越低。当微波热解时间超过30 min时,泥渣质量从最初的150 g变为27 g,这说明铁泥中的水分及其他灰分已基本挥发,剩余的残渣为纯度较高的氧化铁副产物。微波热解反应路径为:Fe(OH)2→Fe(OH)3→Fe2O3+H2O。MONDAL等[19]采用微波热解技术成功地制备了氧化铁。此外,微波还具有杀菌消毒的作用,能杀灭铁泥中的一些微生物[20],实现了从危险废弃物到高附加值氧化铁的资源化转化。

2.1. 芬顿反应条件对COD去除率的影响

2.2. 芬顿-SBR运行工艺

2.3. 芬顿-SBR联合降解液晶废水中间产物分析

2.4. 微波热解铁泥

-

1)芬顿预处理可将液晶废水中的大分子污染物氧化降解为小分子有机物,从而提高出水可生化性,为后续SBR的稳定运行提供保障。

2)芬顿出水经SBR工艺后,出水COD低于500 mg·L−1,满足《污水排入城镇下水道水质标准》(GB/T 31962-2015)中B级标准。

3)芬顿反应产生的铁泥经微波热解后可变为附加值较高的氧化铁副产物。

下载:

下载: